The core advantages of steam shrink machines over traditional electric heating and infrared heat shrink machines are what make them stand out in numerous packaging scenarios. These advantages can be elaborated on specifically from two aspects: characteristic principles and actual packaging effects.

Excellent Thermal ConductivityThe heat capacity of steam is far higher than that of hot air, and its heat transfer efficiency is 10–20 times that of dry air. When steam comes into contact with the shrink film, it can directly and rapidly transfer heat to the film, enabling the molecular chains inside the film to quickly gain energy and move vigorously, thus allowing the film to reach the temperature required for shrinkage in a short time. Moreover, the steam temperature is usually stabilized at 100–120℃, a range that perfectly matches the shrinkage requirements of mainstream heat shrink films such as PE, PVC, and PET. It will neither damage the film due to excessively high temperatures nor cause incomplete shrinkage due to insufficient heat.

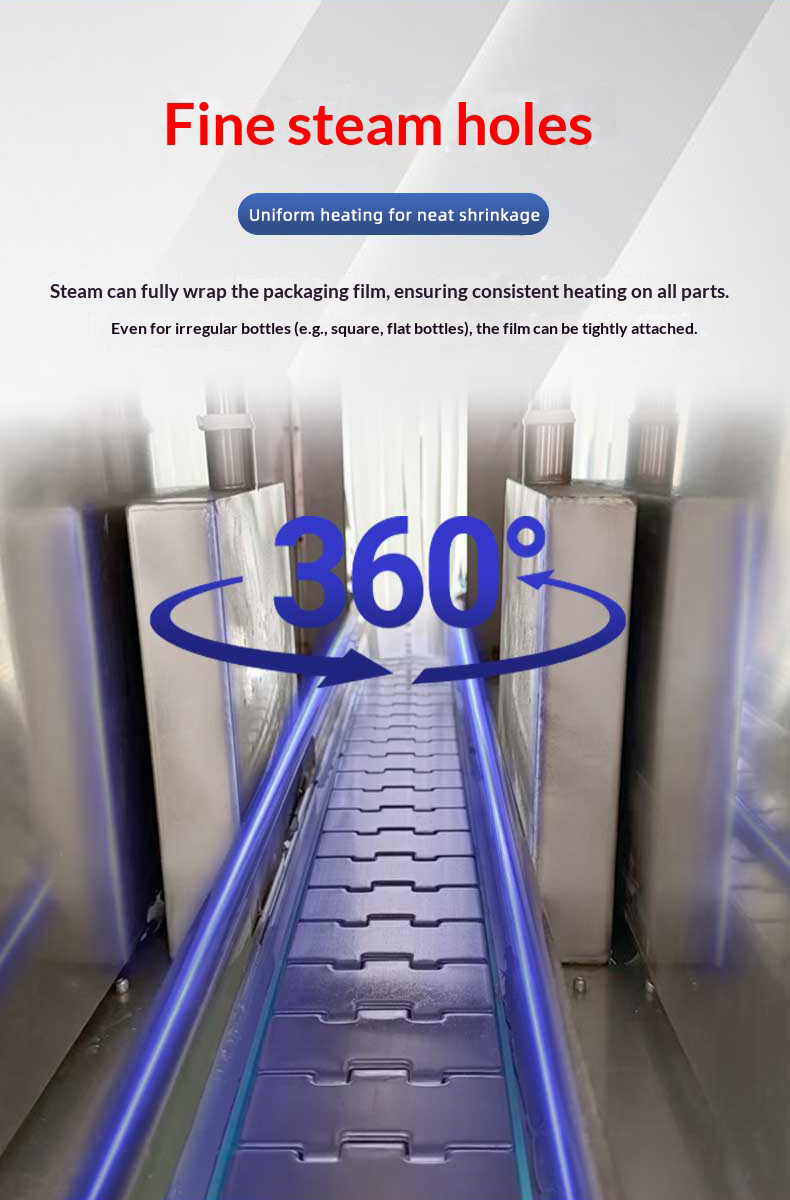

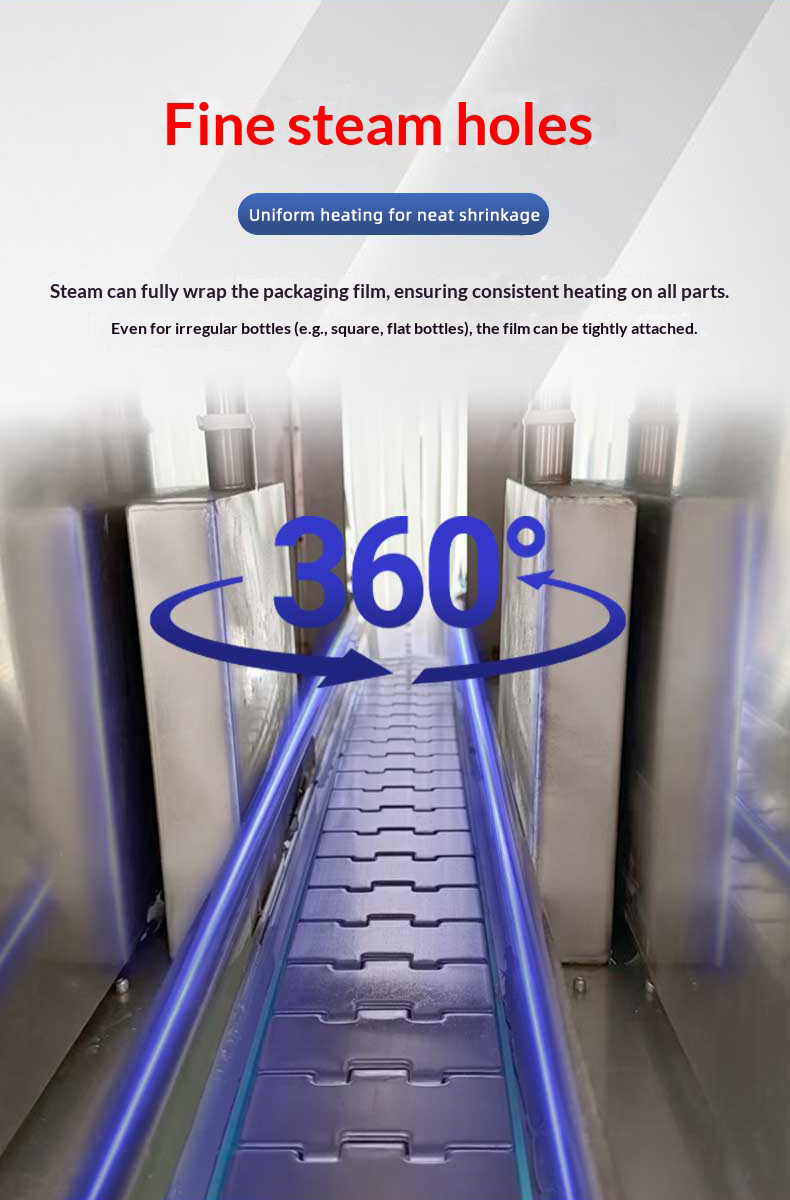

Outstanding DiffusivitySteam can fill the entire shrink chamber in a diffused manner and be evenly distributed through the equipment’s nozzle system. It permeates every corner—not only can it surround regular round and square bottles, but it can also penetrate into the recesses, edges, and other hidden parts of irregularly shaped products. This avoids the problem of blind spots that are difficult to cover with heat in traditional heating methods, laying a solid foundation for uniform shrinkage.

Adaptability to Products of Different Shapes

- For round bottles such as beverage bottles and perfume bottles, steam can surround the bottle bodies without dead angles, allowing the shrink film to shrink uniformly from top to bottom, fit the bottle curves snugly, and remain free of wrinkles.

- For square containers such as cosmetic gift boxes and sauce bottles, steam can evenly penetrate flat surfaces and edges, with the shrink film precisely adhering to the corners to create neat and stiff packaging.

- Even for flat containers such as wine flasks and flat hand sanitizer bottles, steam can adapt to their special contours, ensuring the shrink film fits perfectly and highlighting the product shape.

Avoidance of Packaging DefectsTraditional electric heating tube heating tends to cause local overheating, leading to uneven shrinkage, wrinkling, and tearing of the film. In contrast, the uniform heating of steam can completely eliminate these defects. For example, in bottle label packaging, it ensures the labels adhere tightly without bubbles or warping; in gift box packaging, it enables the shrink film to cover the surface smoothly, delivering a sleek and tight finish that greatly enhances the aesthetics and premium feel of the product packaging.

- Steam Generation DeviceIt includes heating elements, a water tank, and a pressure control system, capable of efficiently generating stable steam. Some models support automatic water replenishment.

- Shrink TunnelEquipped with steam injection holes or nozzles inside, its length and width are adjustable according to product dimensions to ensure uniform steam coverage.

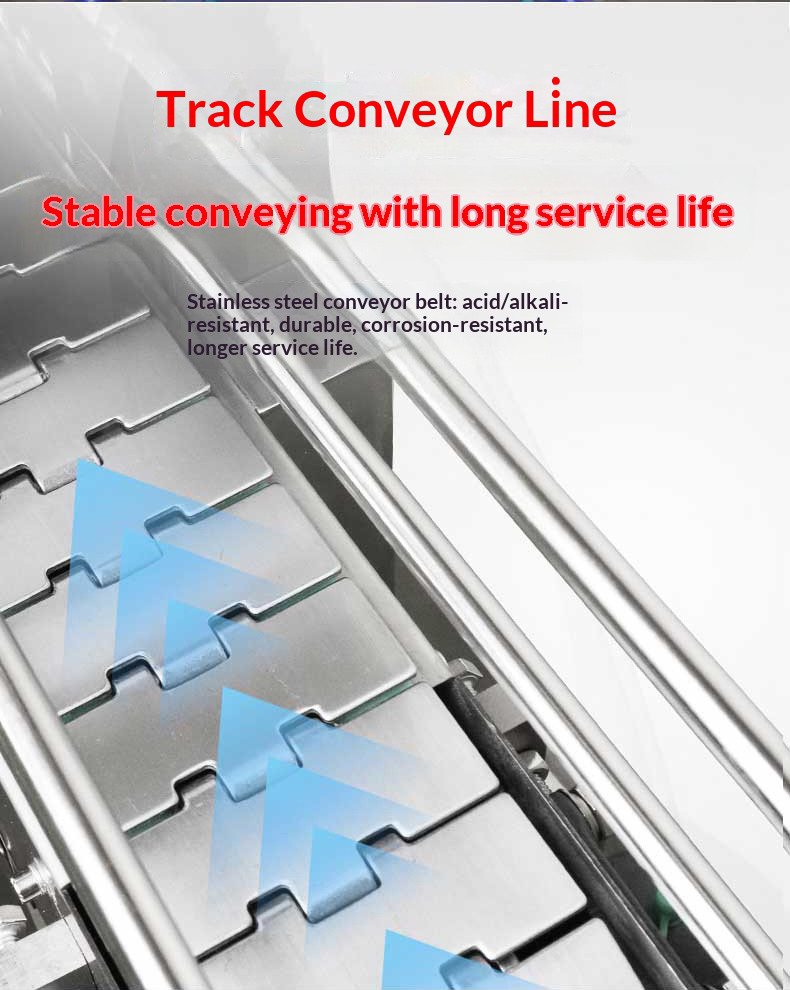

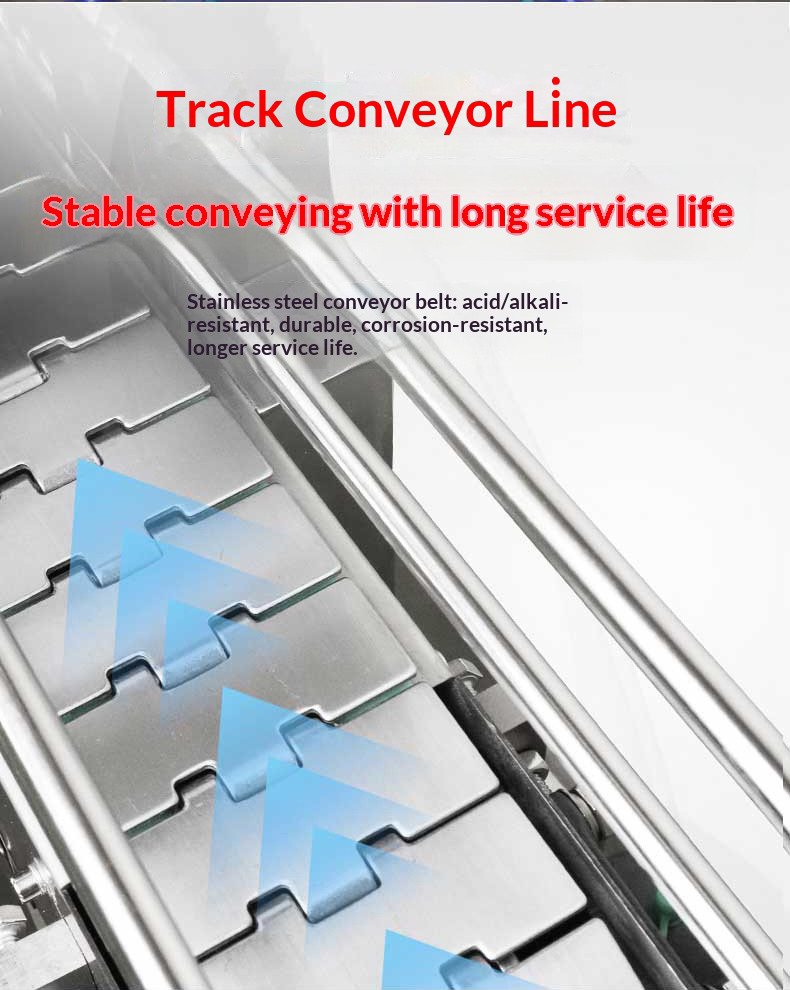

- Transmission SystemProducts are conveyed via mesh belts, chain plates, or rollers, with variable frequency speed adjustment typically ranging from 0.5–10m/min to meet different production capacity requirements.

- Control SystemIntegrated with a touch screen, it allows setting of key parameters such as steam temperature, pressure, and conveyor speed, and supports automatic start/stop and fault alarm functions.

- Steam Recovery and PurificationSome high-end models are equipped with condensed water recovery devices and steam filtration systems to reduce energy consumption and environmental pollution.

- Superior Heat Shrink EffectThanks to steam’s excellent thermal conductivity and diffusivity, the heat shrink film is heated evenly. The packaged products after shrinkage feature flat, smooth, and tight surfaces without local uneven shrinkage.

- High-Efficiency ShrinkageSteam can rapidly transfer heat to the film, enabling it to complete shrinkage in a short time. This greatly improves production efficiency and meets the needs of large-scale production.

- Precision PackagingKey parameters of the steam shrink machine, such as steam temperature, pressure, and conveyor belt speed, can be precisely controlled to ensure that the shrinkage effect of each packaging batch meets the expected standards.

- Environmental Protection and Energy SavingIf waste heat steam from factories is used as the heat source, energy conservation and emission reduction can be achieved. Furthermore, steam itself is relatively eco-friendly and does not generate electromagnetic radiation during use.

Take the Model 1135 Small-Sized Steam Shrink Machine from Dongguan Boguan Packaging Industry Co., Ltd. as an example. Its specifications are as follows:

- Power: 12kW

- Voltage: 380V

- Steam Pressure: 0.08MPa

- Overall Dimensions: 1700mm×900mm×1250mm

- Conveyor Belt Width: 110mm

Dongguan Boguan Packaging Industry Co., Ltd. Model 1135 Steam Shrink Machine is equipped with a powerful steam generation system and a precise control system, which can accurately adjust steam temperature, pressure, and injection duration.