In marinated food shops with tempting aromas, fishing port workshops abundant in aquatic products, and food factories mass-producing prepared dishes, packaging products with soup or high moisture content has always been an industry pain point. Traditional vacuum machines are prone to liquid leakage, low efficiency, and poor fresh-keeping performance, which often lead to ingredient waste and frequent customer complaints. The double-chamber grooved vacuum machine is specially designed for such products. With "leak-proof fresh-locking + high-efficiency mass production" as its core, it has become an indispensable packaging tool for the marinated food, aquatic product, and prepared dish industries through structural innovation and technological upgrading. Targeting the special properties of marinated sauce, aquatic product ice glazes, and prepared dish soup, the machine has achieved all-round optimizations in its vacuum system, sealing structure, and operation logic, eliminating packaging risks from the source.

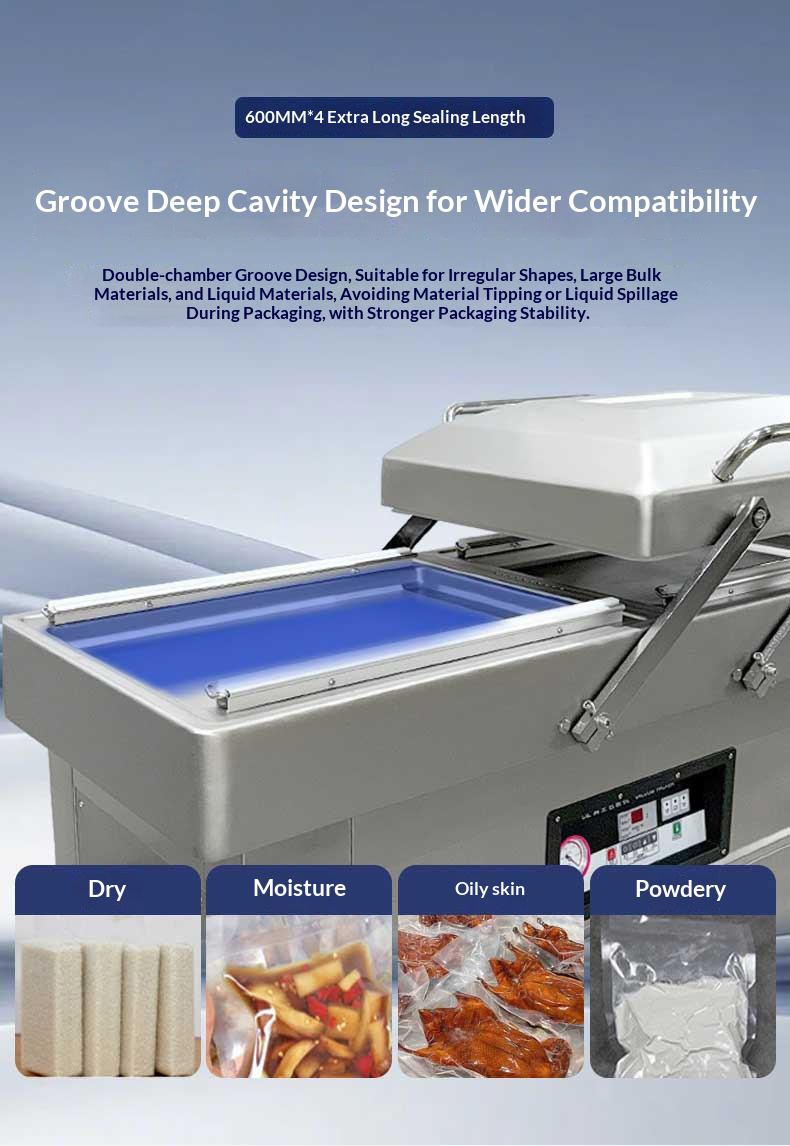

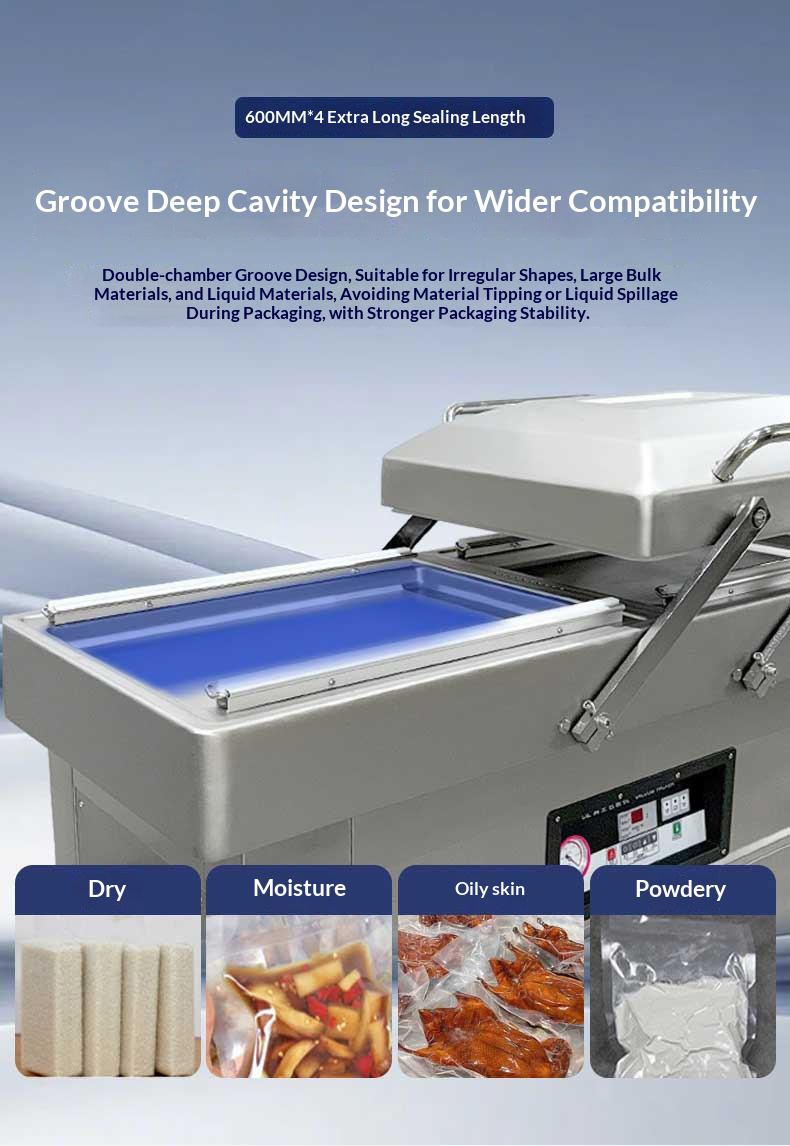

- Deep Groove Structure + Leak-Proof System: Secure Even with Full SoupThe core innovation of the machine lies in the grooved design of the vacuum chamber. The concave depth of the vacuum chamber inner cavity can reach 10–40 cm (customizable). Products such as marinated food platters, whole soup-containing roast chickens, and large portions of prepared dishes can be placed vertically or obliquely. The soup in the bag naturally collects at the bottom of the groove, maintaining a safe distance from the sealing line. Equipped with the "intelligent liquid anti-suction program", the machine adopts a gradient mode of "preliminary micro-pressure exhaust followed by deep vacuum extraction". It slowly expels air from the bag while preventing soup splashing, solving the maintenance problem of "liquid suction into the pump" that plagues traditional equipment during vacuuming.

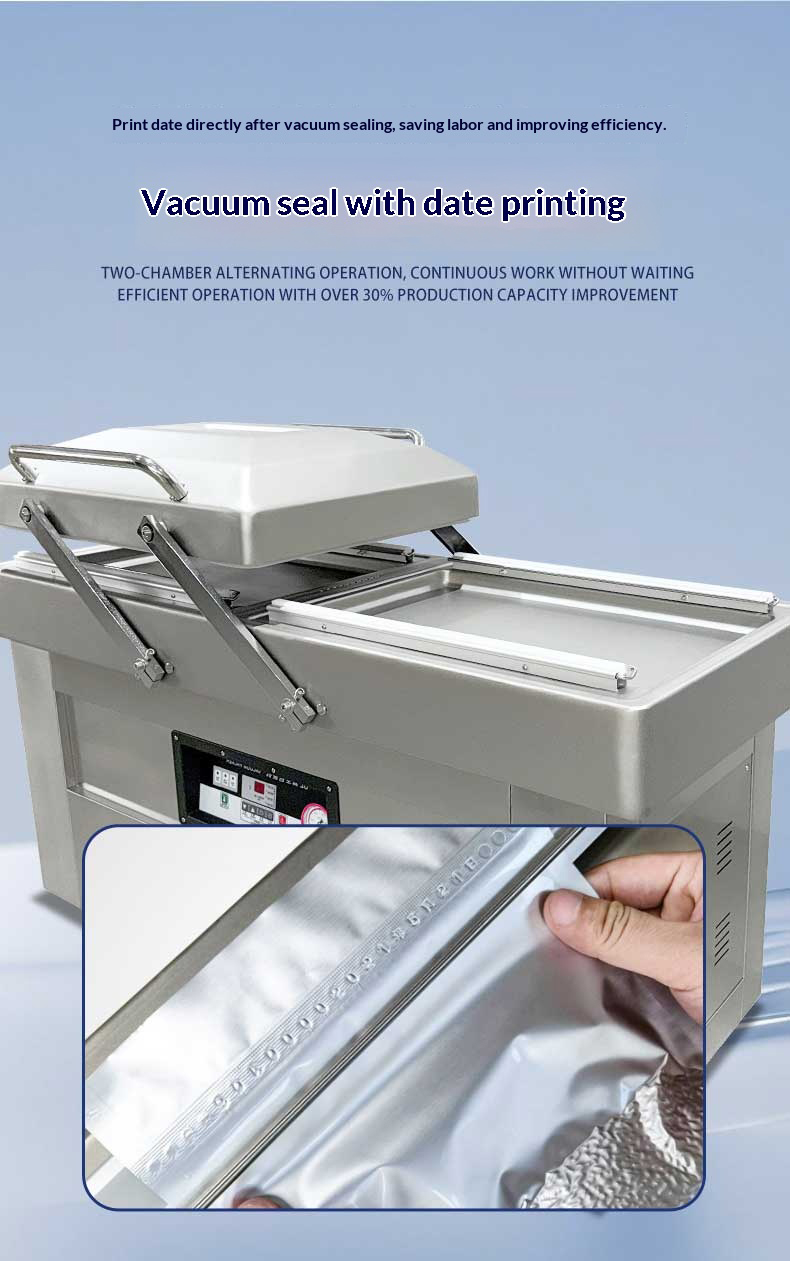

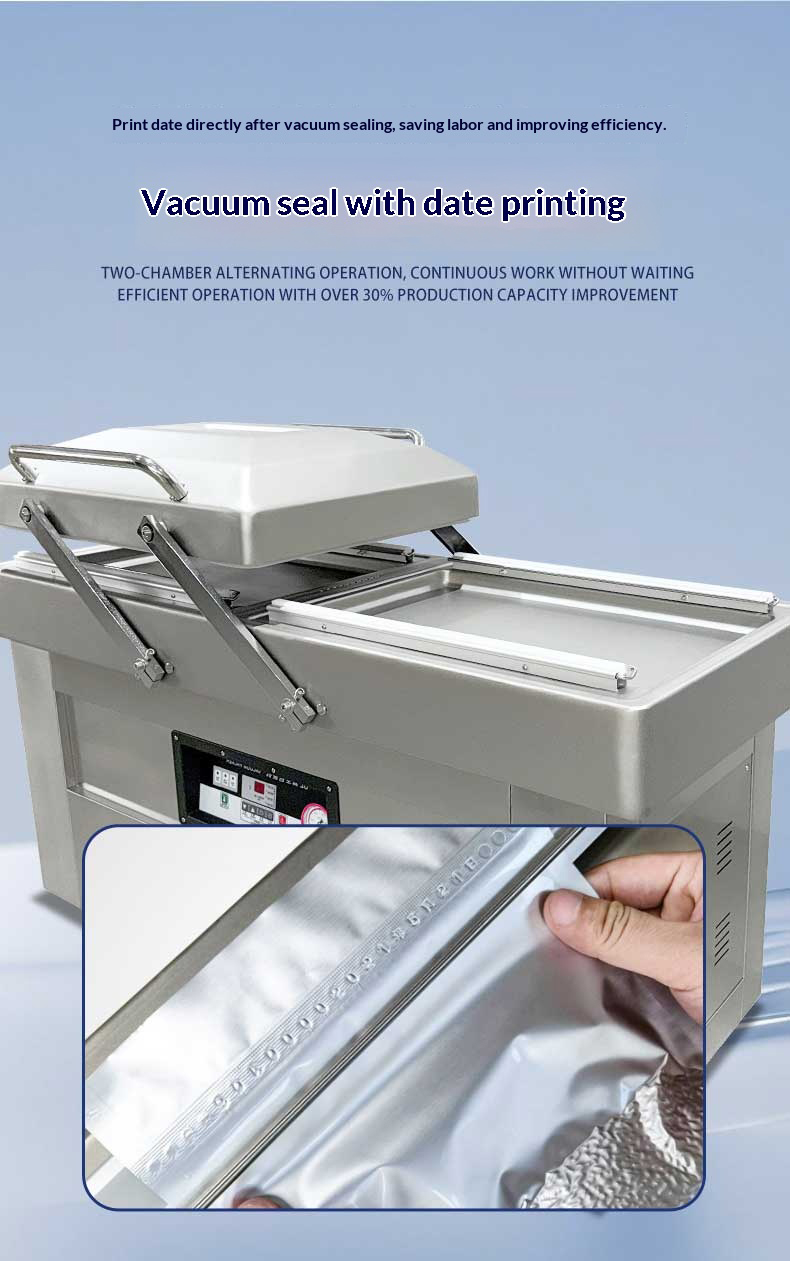

For the sealing process, it is also fitted with 10mm widened sealing strips and imported high-temperature-resistant bakelite boards, forming a high-density heat-sealed joint that boosts sealing strength by 40%. Field tests show that packaged soup-containing pickled chicken feet remain completely leak-proof even when dropped from a height of 1.5 meters, thoroughly eliminating negative reviews caused by liquid leakage during transportation. Some models are equipped with a double-sealing strip design, which can complete multi-bag packaging in one go, further enhancing batch processing capabilities.

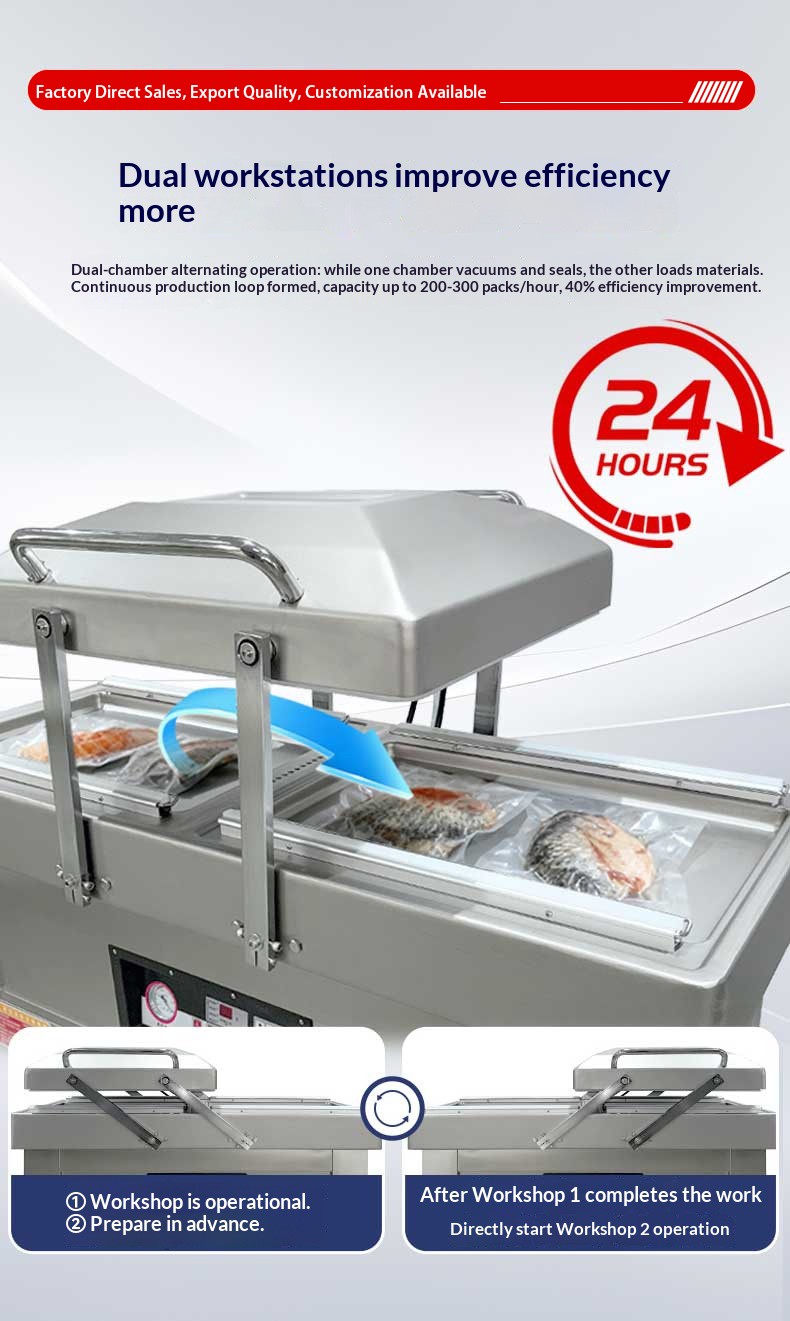

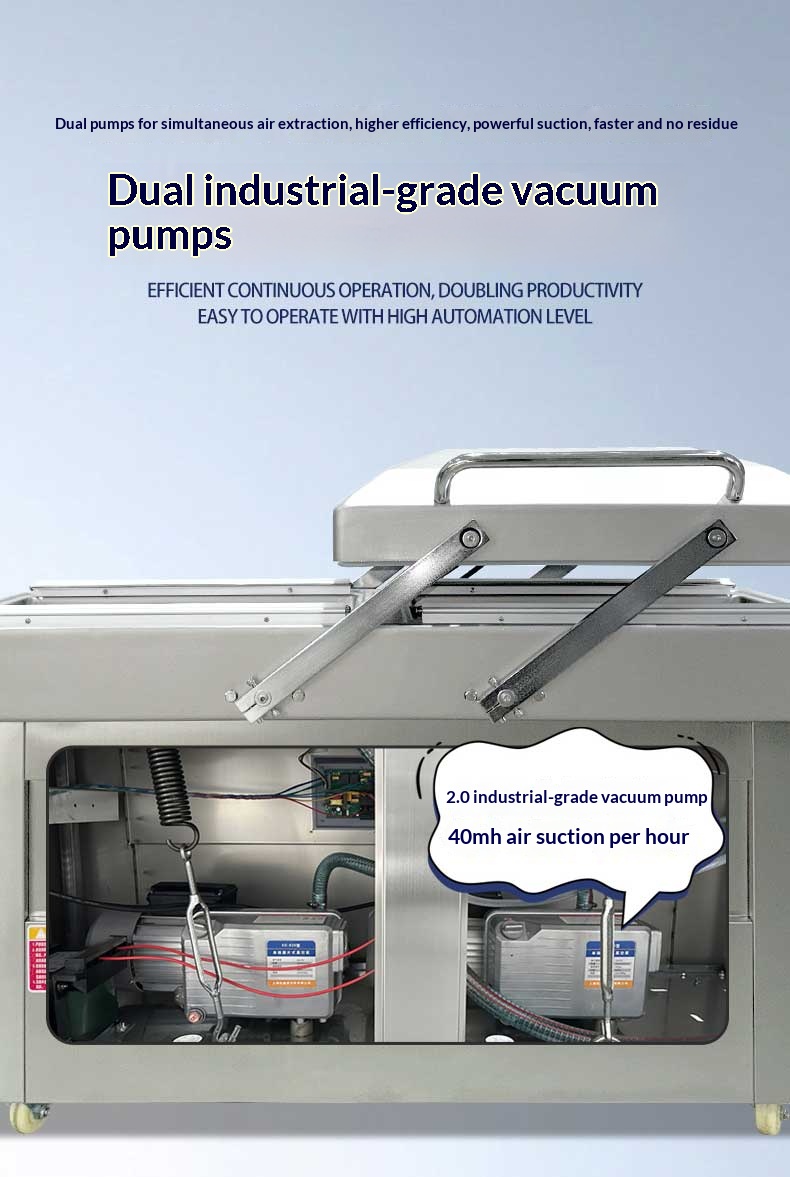

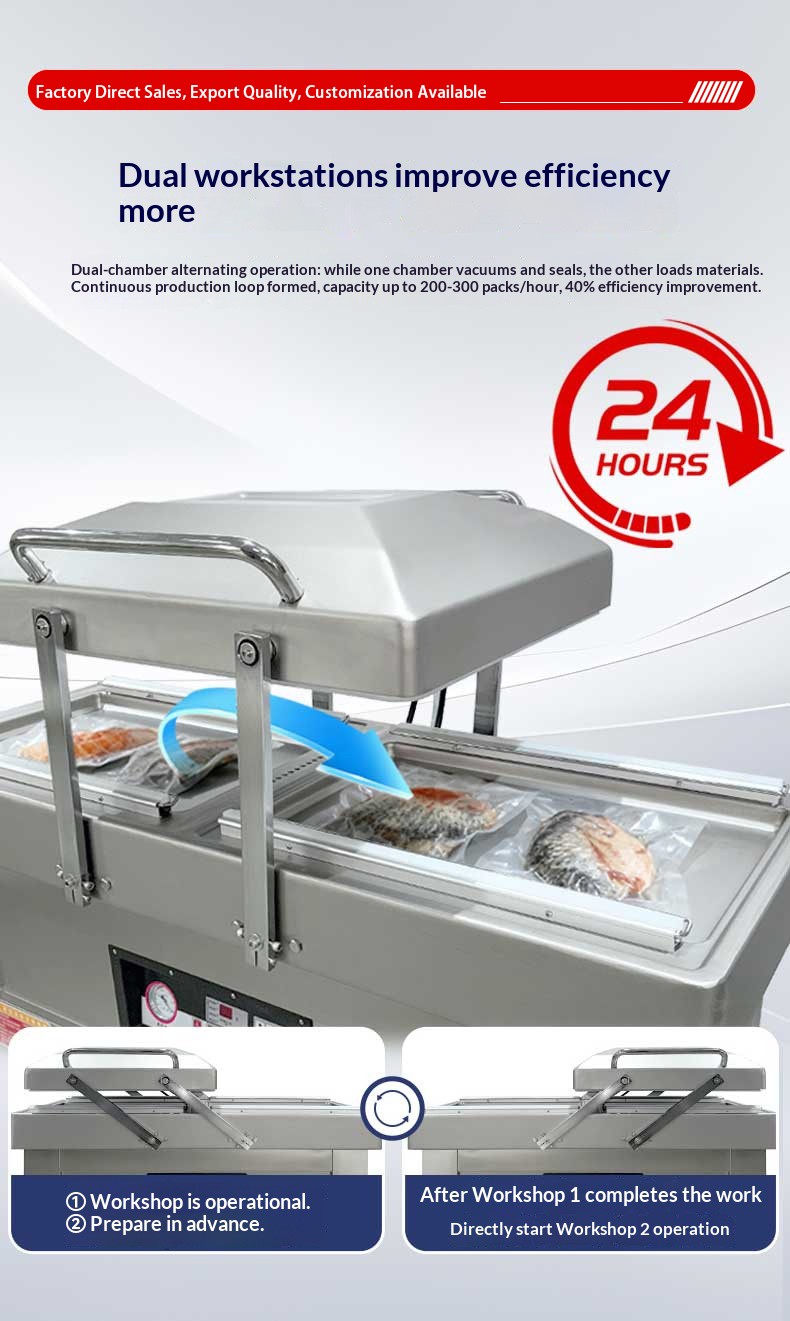

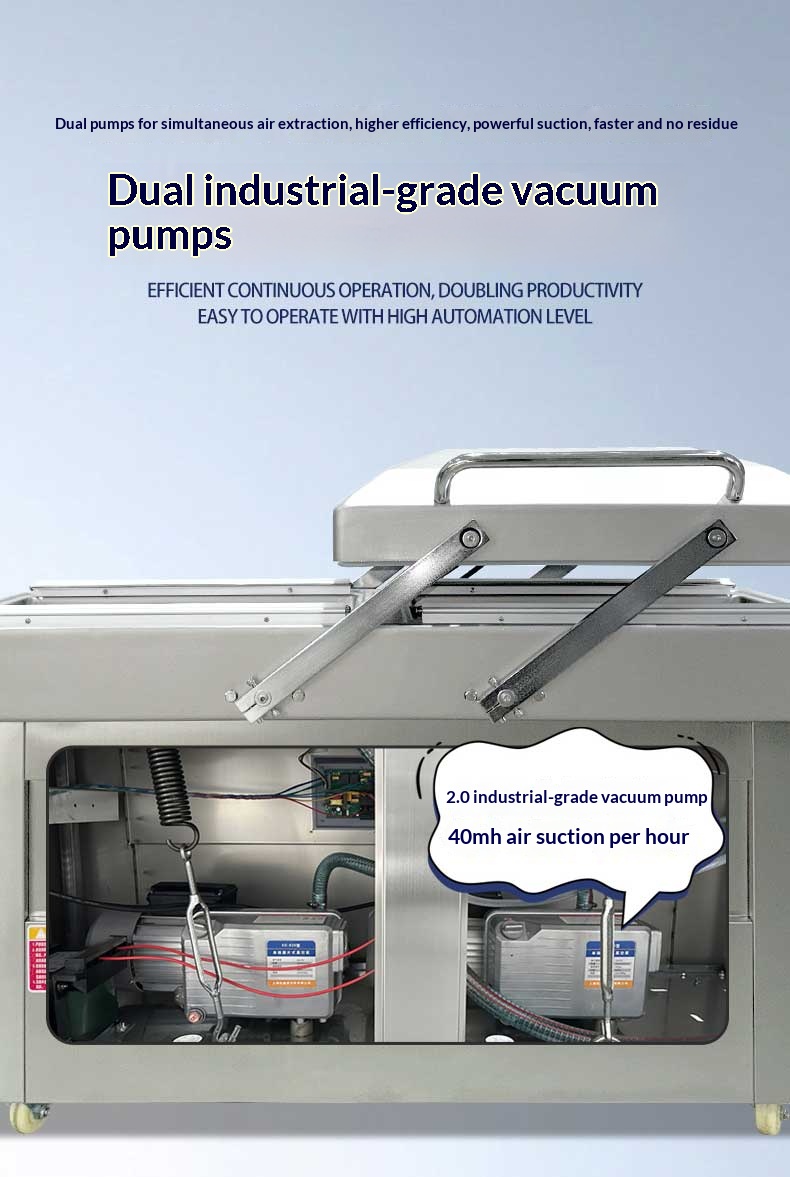

- Dual-Chamber Alternating Operation: Over 60% Higher Efficiency Than Single-Chamber MachinesThe dual-chamber structure is the core of the machine’s efficiency. The two vacuum chambers operate alternately under the control of a microcomputer program. While the left vacuum chamber completes the entire process of vacuuming, sealing, and cooling, the right vacuum chamber is already loaded with materials and on standby, truly realizing "non-stop continuous operation". Paired with high-power vacuum pumps from well-known Shanghai brands, the dual independent pumps deliver an air extraction rate of 2×20m³/h, whereas single-chamber machines can only handle a maximum of 160 packaging cycles per hour.

Operationally, it features a fully intelligent control panel that allows presetting of 10 groups of commonly used parameters such as vacuuming time, vacuum level, and sealing temperature. Novice operators can get started with just one button press.

- Food-Grade Materials + High Power: Adapted for Long-Term Operation in Harsh Working ConditionsBoth the machine body and vacuum chambers are made of stainless steel. The vacuum chamber steel plates are acid and alkali resistant as well as corrosion-proof, so they won’t easily rust or deform even with long-term contact with marinated oil and aquatic product brine. Meanwhile, the machine supports 24-hour continuous operation, and can stably handle high-intensity scenarios such as early-morning sorting peaks in aquatic product processing factories and night-shift mass production in prepared dish plants.

The machine is equipped with heavy-duty universal wheels (with locking function). Despite its sturdy and robust build, it is easy to move, enabling flexible adjustments of its position according to production layouts, and is suitable for various scenarios including deli counters and factory assembly lines.

Beyond its basic performance, the machine offers unique advantages in fresh-keeping, cost reduction, and compliance, tailored to the industry needs of marinated food, aquatic products, and prepared dishes, making it a core tool for enterprises to cut costs and enhance efficiency.

- Ultimate Fresh-Locking: Extend Shelf Life & Preserve Original Ingredient FlavorsPowered by high-power vacuum pumps, it achieves an industry-leading vacuum level with residual oxygen content in the bag below 0.8%, which effectively inhibits the reproduction of aerobic microorganisms and the oxidation of ingredients. Data shows that the shelf life of marinated food packaged this way extends from 3–5 days at room temperature to 15–30 days; the umami loss of frozen aquatic products after thawing is reduced by 70%; and the taste difference between reheated prepared dishes and freshly made ones is less than 10%. Some models can be optionally equipped with a gas flushing function. After vacuuming, inert gases such as nitrogen are filled into the bag. This not only prevents marinated food from being crushed and aquatic products from losing their shape, but also further extends the shelf life to 180 days, helping businesses expand sales channels such as e-commerce and cold chain logistics.