Can and box tape wrapping machines typically achieve tape winding through mechanical transmission and tape traction mechanisms. Taking the common rotary table wrapping machine as an example, the can or box is placed on a rotary table that rotates under motor drive. Meanwhile, the tape on the tape rack is pulled out under the action of a tension control device. One end of the tape is first adhered to the surface of the can or box. As the rotary table turns, the tape is evenly wrapped around the side, top, and bottom of the can or box. When the preset number of winding turns or length is reached, the cutting device severs the tape, completing the wrapping and sealing process.

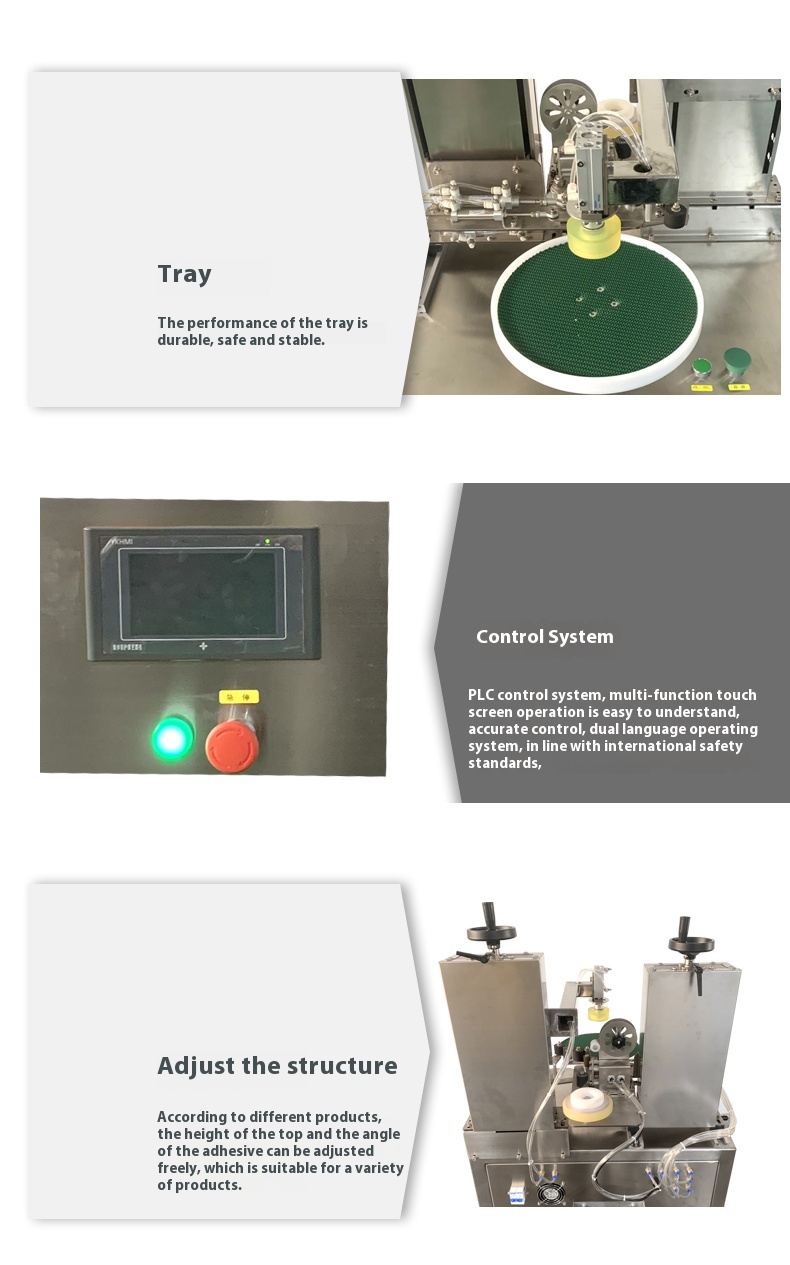

- Conveying Module: Used to transport cans/boxes awaiting wrapping, usually consisting of conveyor belt assemblies, stopping components, and stepping components. It enables precise positioning and conveying of cans/boxes.

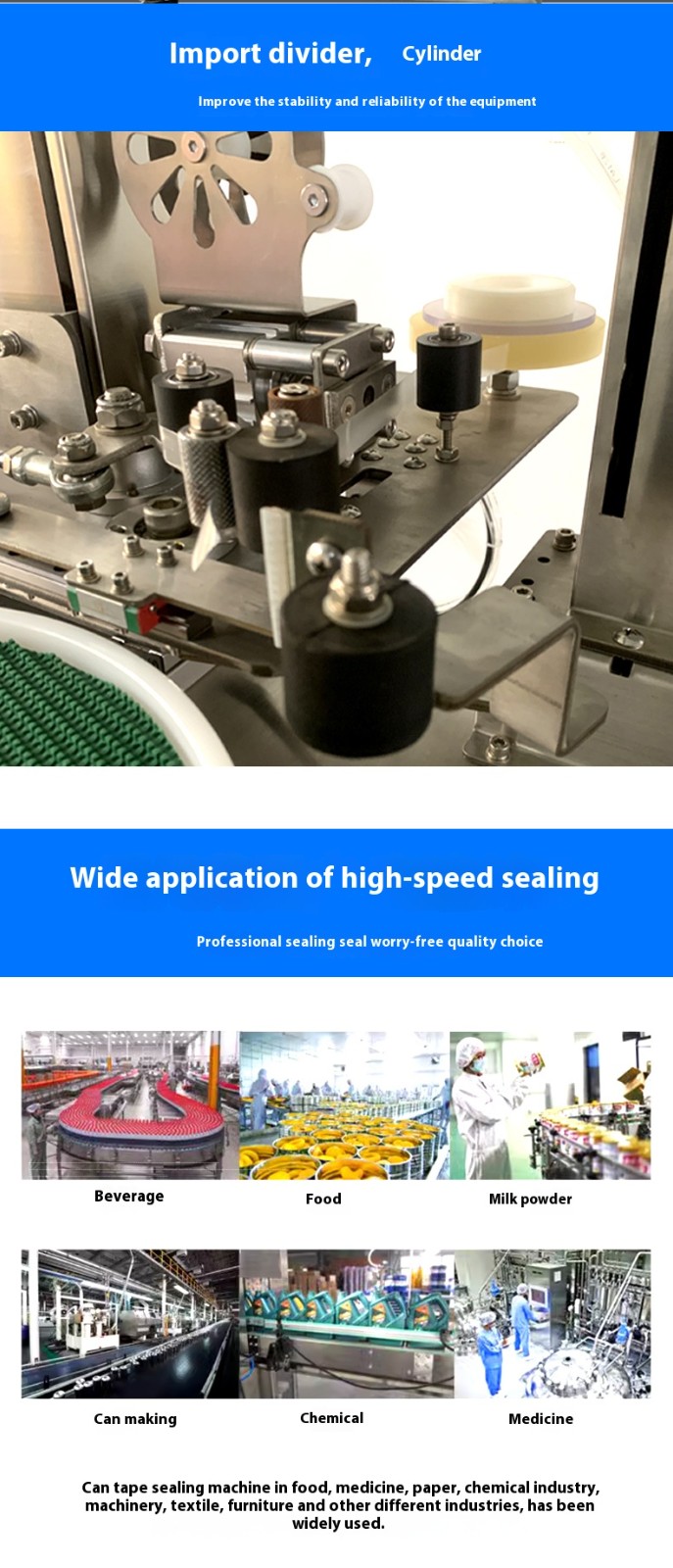

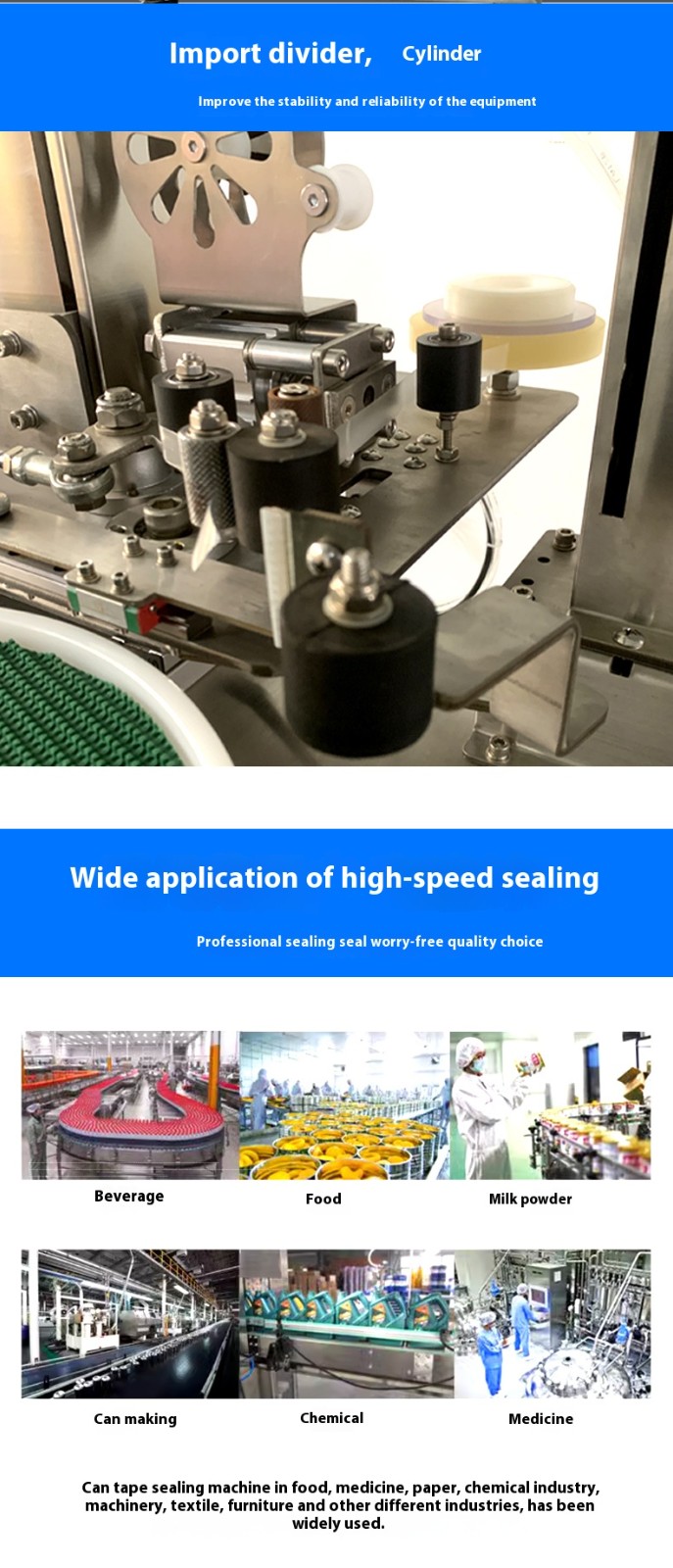

- Tape Application Module: The core part of the wrapping machine, comprising raw material rollers, ejection platforms, and cutting assemblies. It is responsible for tape unwinding, adhesion to cans/boxes, and tape cutting operations.

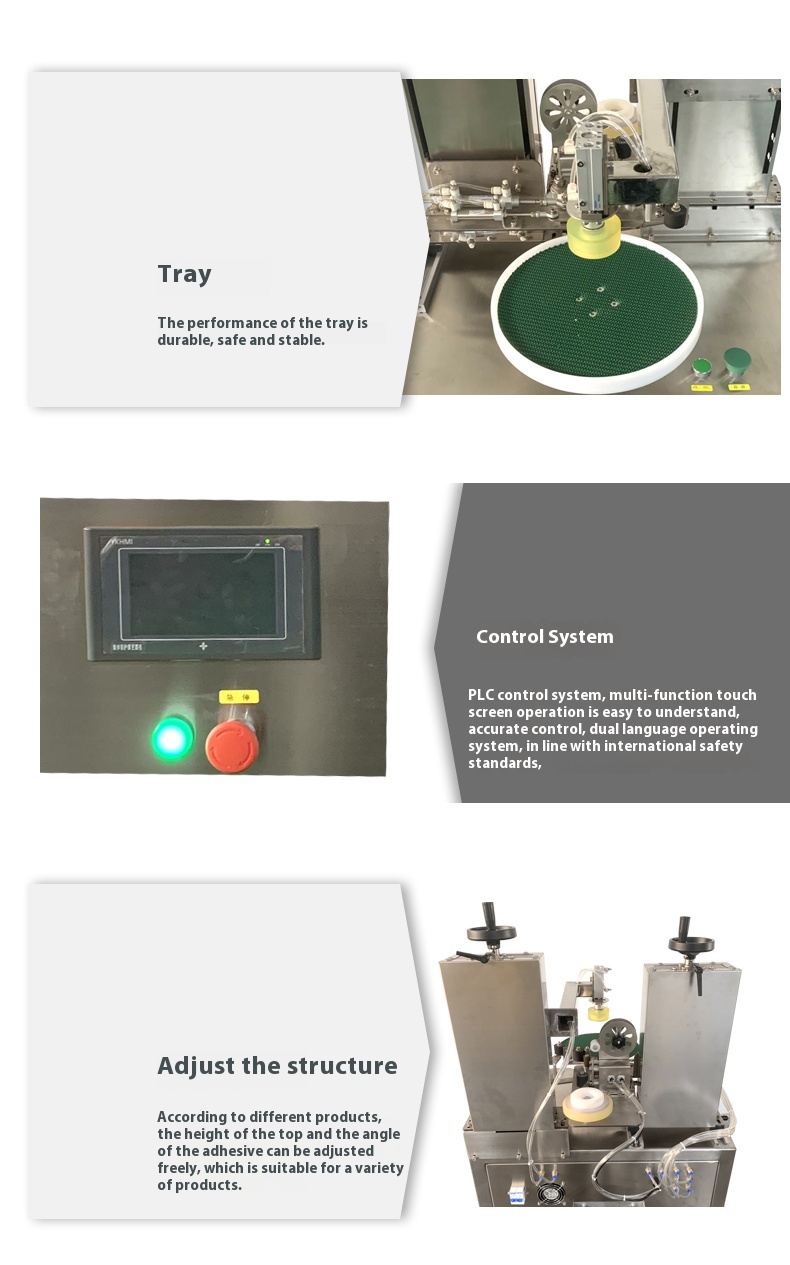

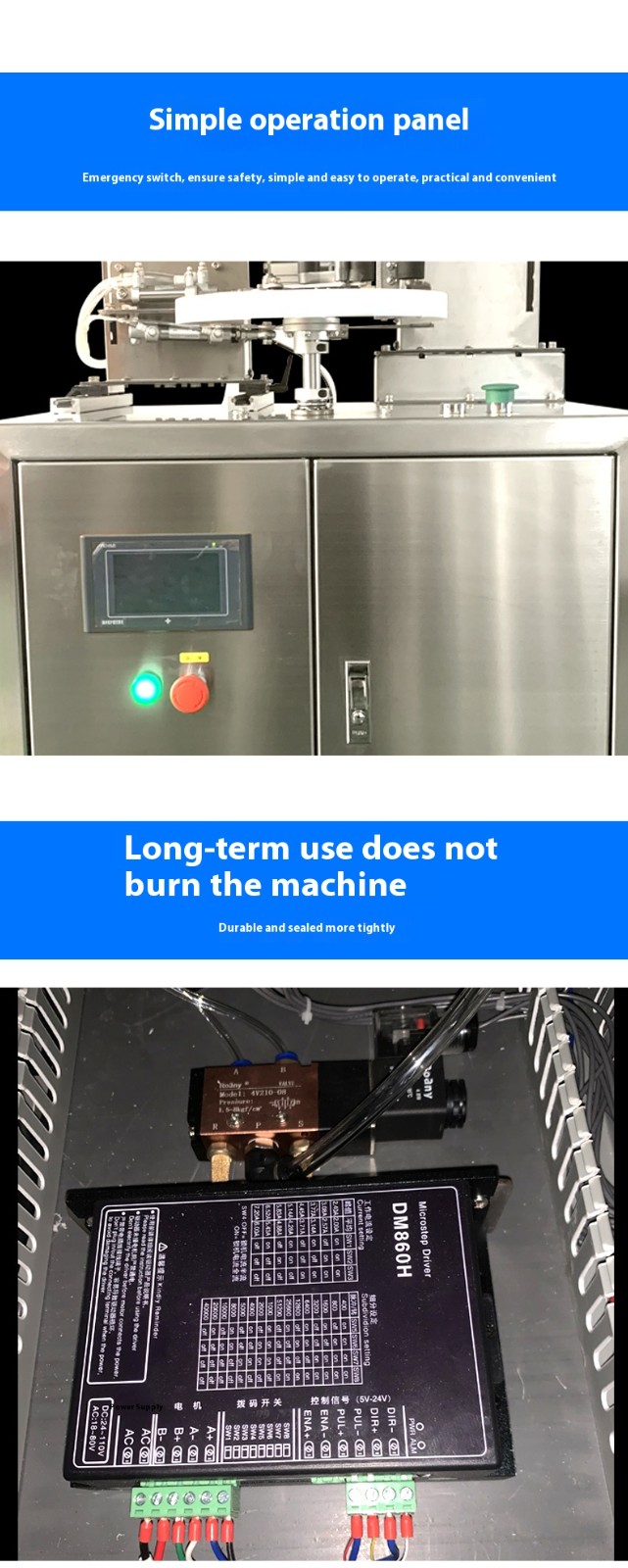

- Control Module: Generally composed of an operation panel and a control system. Operators can set parameters such as winding turns, tape tension, and cutting position via the operation panel, while the control system regulates the operation of all components based on the preset parameters.

- Auxiliary Module: Includes components like pressing devices, which secure cans/boxes during wrapping to prevent shaking, as well as cutting tools such as scribers for trimming excess tape.

- High Efficiency: Automates the entire tape wrapping process, capable of sealing a large number of cans/boxes in a short time, significantly boosting packaging efficiency.

- Excellent Sealing Performance: The tape is wrapped tightly and uniformly, effectively preventing air, moisture, and other contaminants from entering the cans/boxes, thus ensuring product quality and extending shelf life.

- User-Friendly Operation: The machine is equipped with an intuitive operation panel, allowing operators to master the operation after simple training.

- Strong Adaptability: Advanced can and box tape wrapping machines are integrated with adaptive technology, which enables them to handle packaging requirements for cans/boxes of various shapes and sizes.

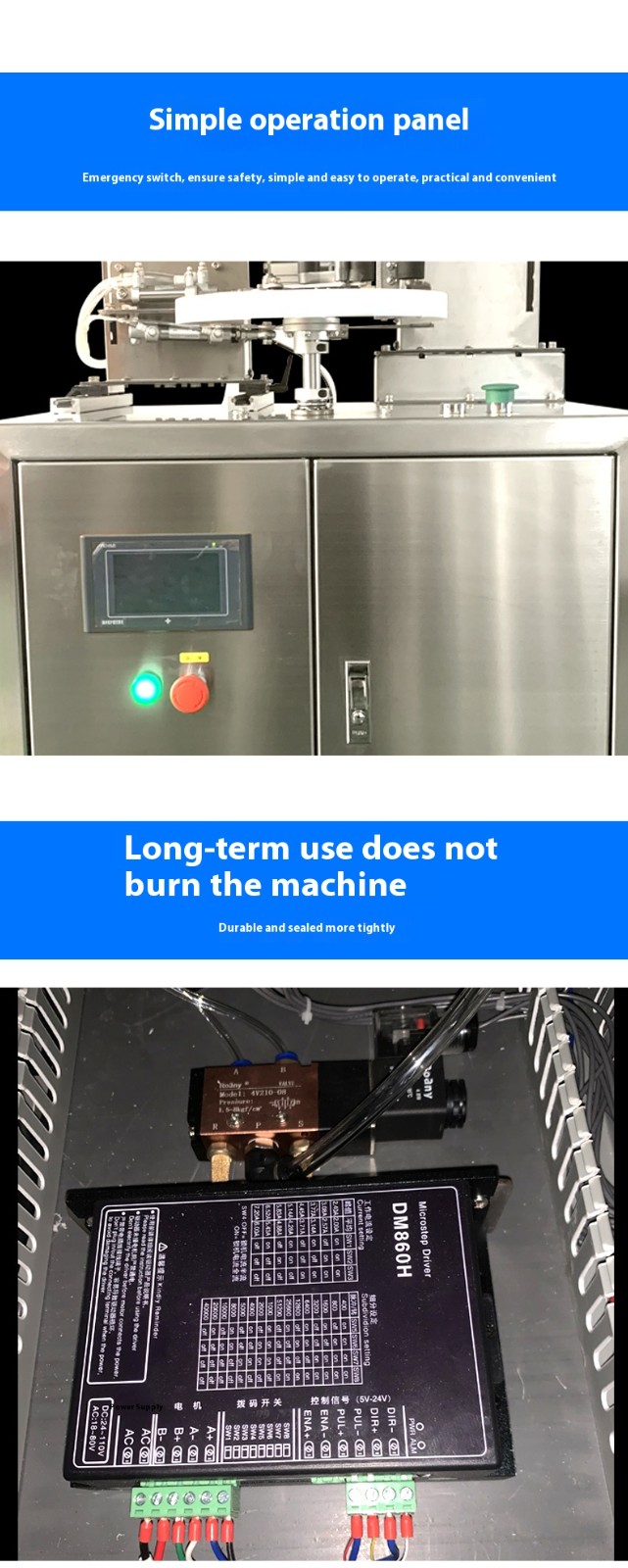

Can and box tape wrapping machines are mainly used in the packaging processes of the food, pharmaceutical, cosmetics, and daily necessities industries. They are ideal for sealing tea tins, cookie boxes, health supplement bottles, cosmetic cases, etc., meeting the dual requirements of product sealing and packaging aesthetics across different sectors.

- Adopts a servo motor drive system with a rotational speed and positioning error of ≤±1mm. The tape wrapping overlap rate is stably maintained at 10%–15%, ensuring gap-free and non-deviated sealing.

- Equipped with an intelligent tension controller that automatically adjusts tension according to tape thickness (0.05–0.2mm), preventing thermal-sensitive and thin tapes from stretching, deforming, or breaking, and ensuring clean, burr-free cuts.

- Boasts high positioning accuracy. For irregularly shaped cans/boxes (triangular, polygonal), anti-offset limit devices are installed, keeping the shaking amplitude of cans/boxes during wrapping ≤±0.5mm.

- Semi-Automatic Model: Processes 10–15 cans/boxes per minute. After manual loading, one-click startup initiates automatic wrapping and cutting throughout the entire process.

- Automatic Model: Integrates with production lines for unmanned operation, achieving a processing speed of 20–30 cans/boxes per minute. It can be connected to upstream filling machines and downstream labeling machines, improving the overall line efficiency by over 80%.

- Supports quick model changeover, with storage for over 10 sets of product parameters. No re-adjustment is required when switching between different can/box specifications, and the changeover time is ≤2 minutes.

- Size Compatibility: Accommodates cans/boxes with a diameter/side length of 50–300mm and height of 30–200mm, covering most can/box specifications used in the food, pharmaceutical, and cosmetics industries.

- Material Compatibility: For soft cans/boxes made of paper or plastic, a flexible pressing device with adjustable pressure (0.1–0.5MPa) is provided to prevent crushing and deformation. For metal cans, a high-strength pressing mode can be activated to ensure tighter wrapping.

- Tape Compatibility: Compatible with various tape types, including BOPP sealing tape, thermal-sensitive tape, and anti-counterfeiting tape. The applicable tape width ranges from 15mm to 50mm.

- Core components (motor, cutter, conveyor belt) adopt a standardized design. The machine can operate continuously for ≥800 hours without failure, with a failure rate as low as 0.5%.

- Wear parts (cutter, roller) have a long service life. The cutter can perform ≥100,000 consecutive cuts, and the rollers feature high wear resistance, resulting in low replacement costs and easy maintenance.

- Offers outstanding energy-saving performance, reducing energy consumption by 15% compared to traditional models. Dual voltage options (220V/380V) are available to adapt to different factory power configurations.

- Cost Reduction & Efficiency Improvement: Cuts labor costs by over 60%.The automatic model can replace 3–5 manual workers, eliminating repetitive tasks such as manual loading, sealing, and sorting. The semi-automatic model features low operational thresholds, allowing new operators to be on duty after just one day of training, significantly reducing labor and management costs.

- Multi-Purpose Functionality: Adapts to multi-variety production needs.No mold replacement is required—switching between different can/box specifications only needs adjustments to the rotary table diameter and tape rack height. This satisfies the production requirements of small-batch, multi-variety orders and overcomes the limitation of "one machine for one purpose" associated with traditional equipment.

- Sealing & Protection: Extends product shelf life.The tight, gap-free wrapping effectively isolates air, moisture, and dust. For products with high sealing requirements such as food and pharmaceuticals, it can extend shelf life by 3–6 months. Additionally, it supports tamper-evident wrapping design to enhance product anti-counterfeiting capabilities.