The characteristics and advantages of automatic pallet strapping machines are mainly reflected in multiple dimensions such as efficiency, labor savings, packing quality, adaptability, and operational convenience, as detailed below:

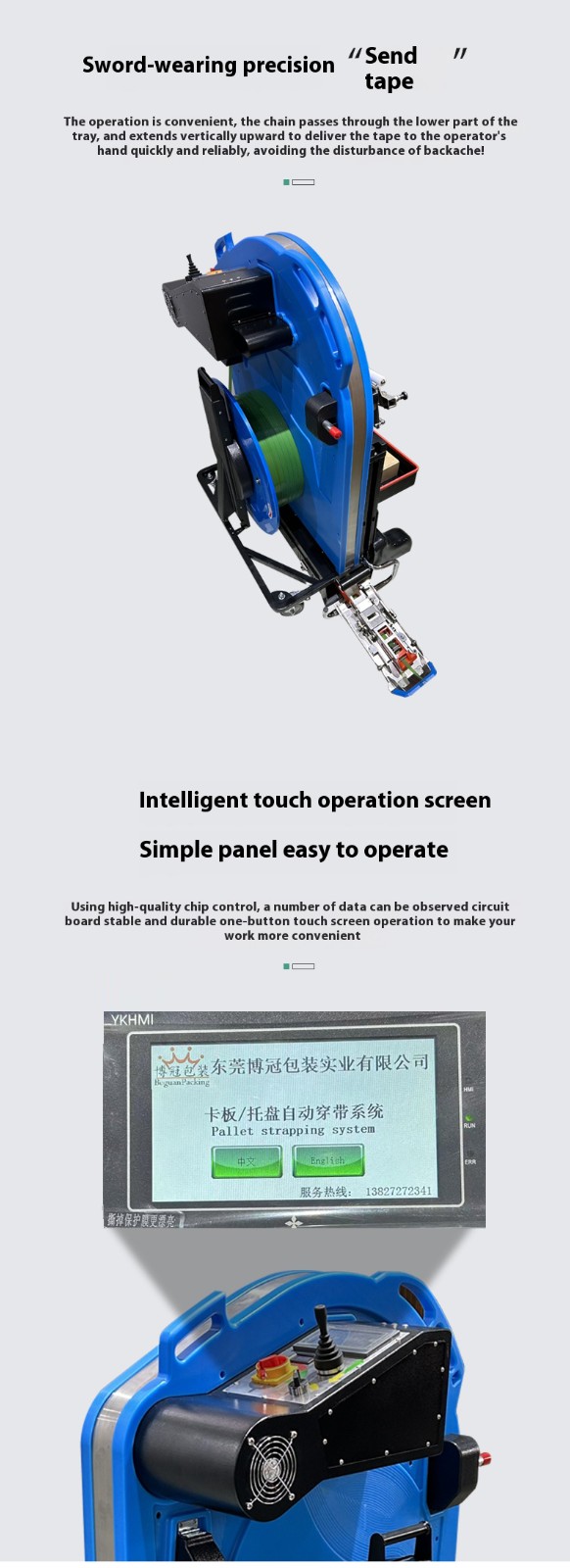

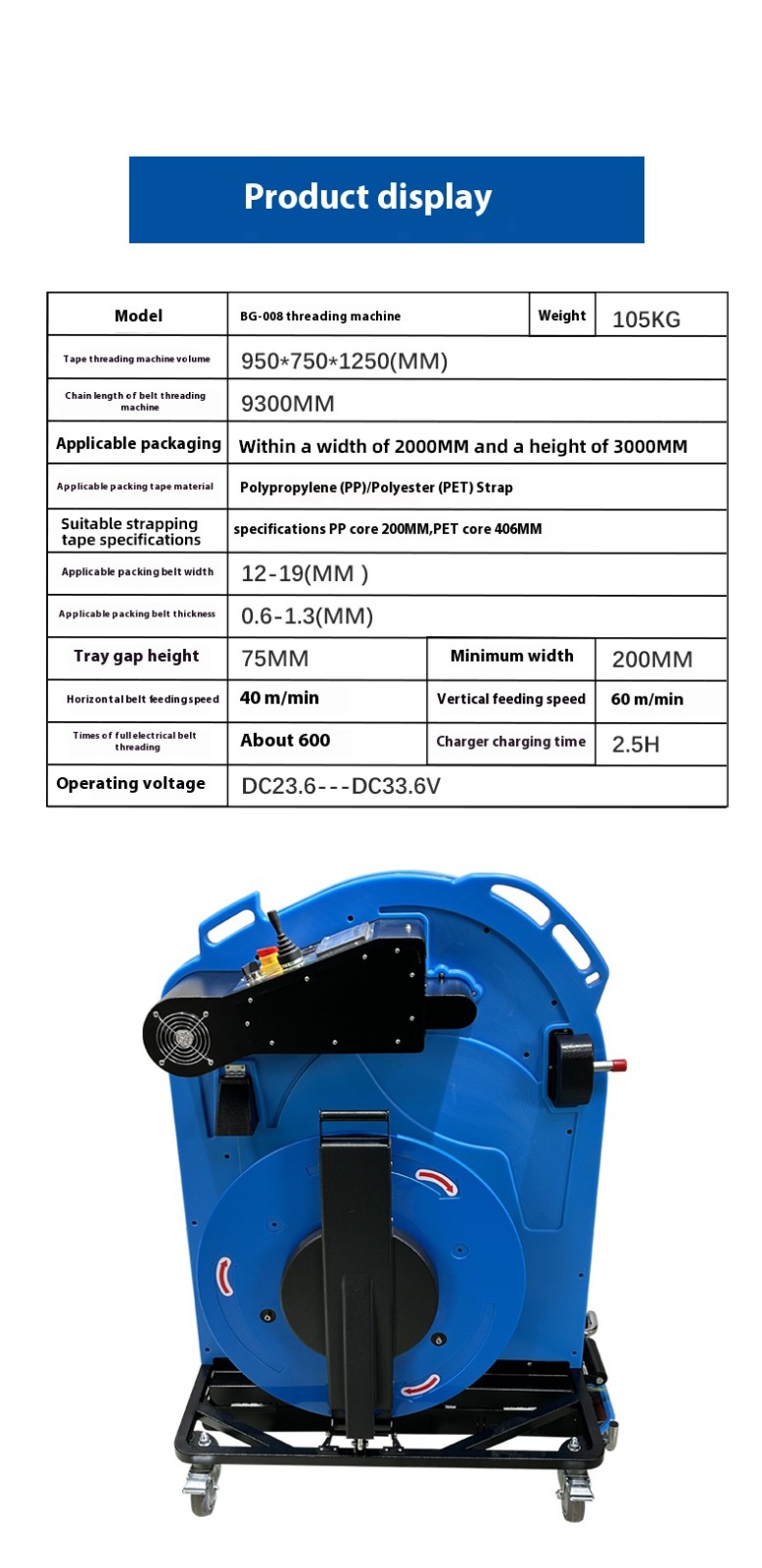

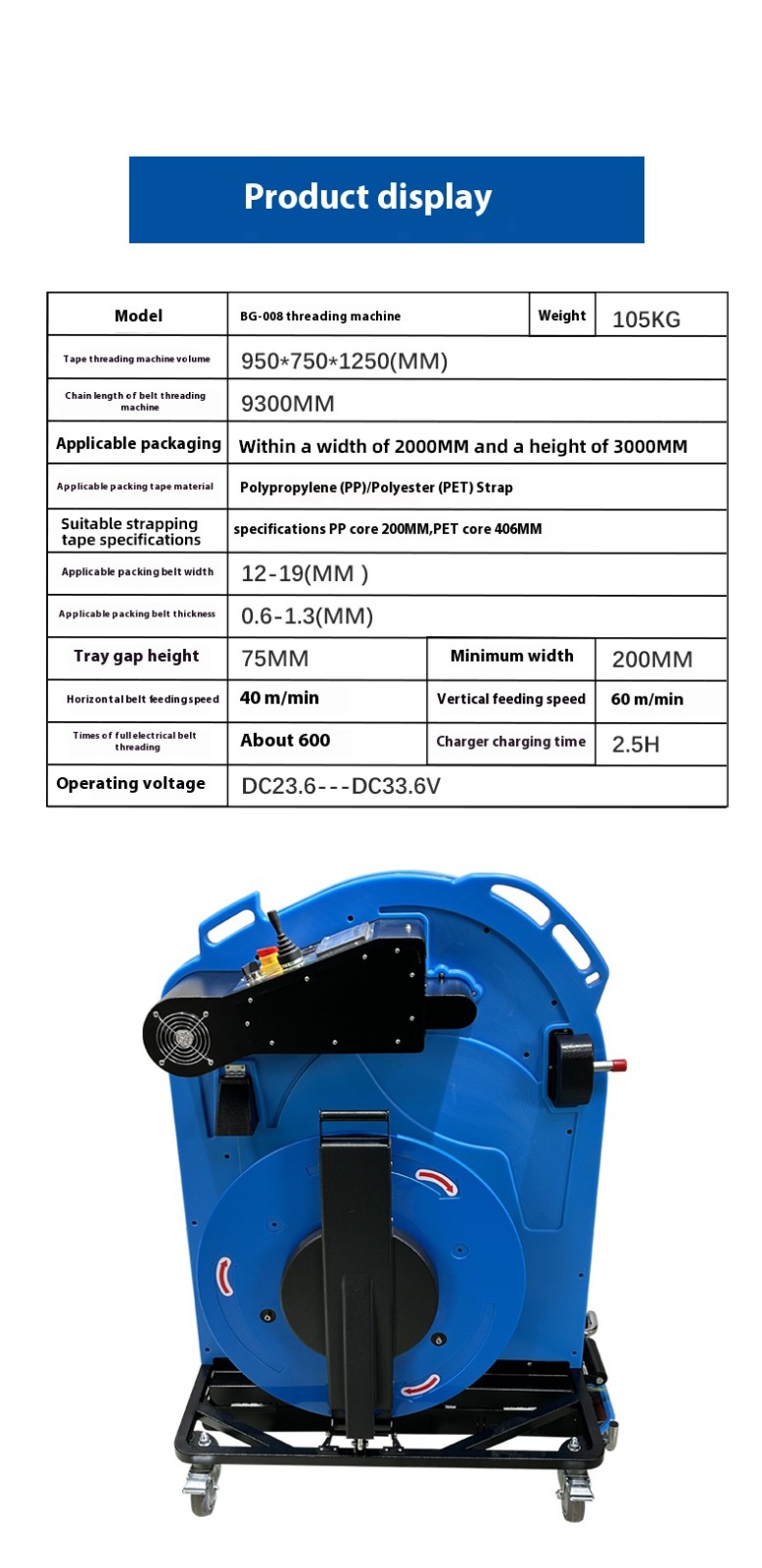

Compared with manual strapping, automatic equipment enables high-speed mechanical operation. For example, the JP727 automatic pallet strapping machine adopts a tank chain drive design, achieving a packing speed of 40-60 meters per minute. This significantly shortens the strapping time for each pallet, making it suitable for batch cargo packing scenarios.

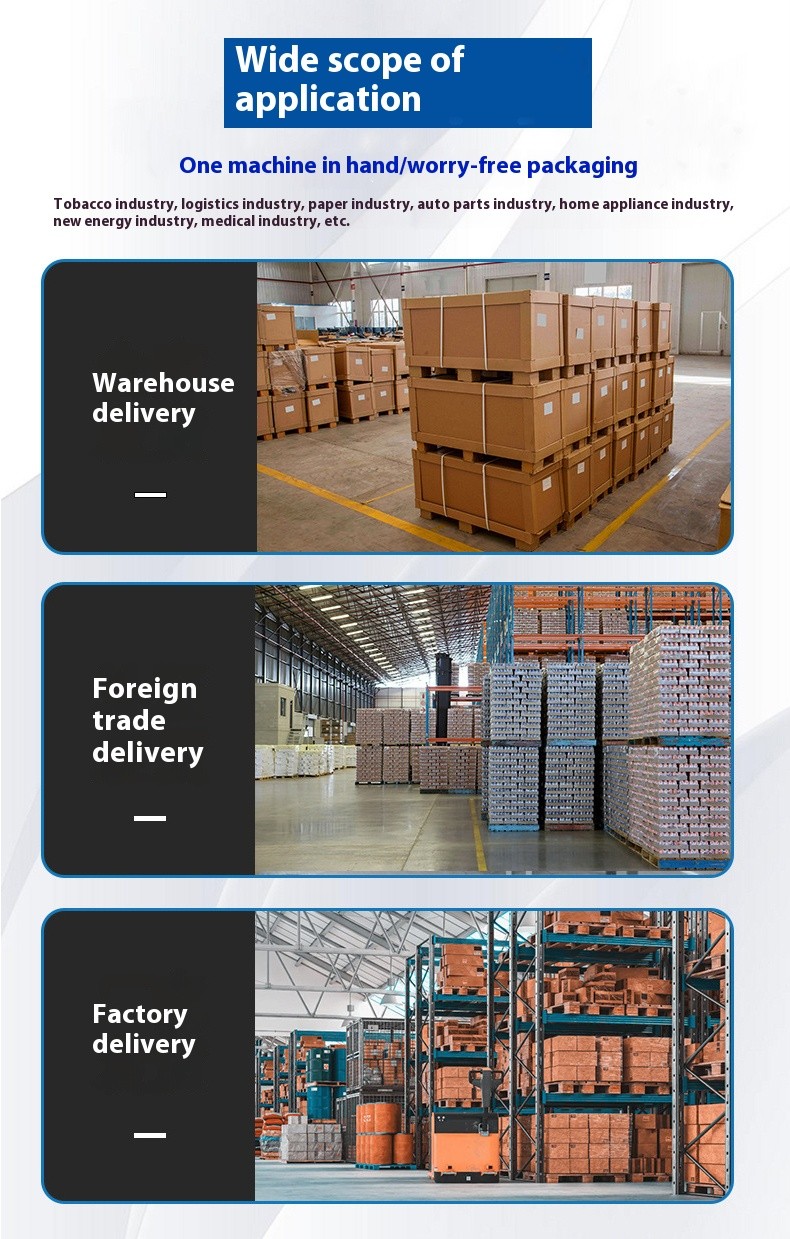

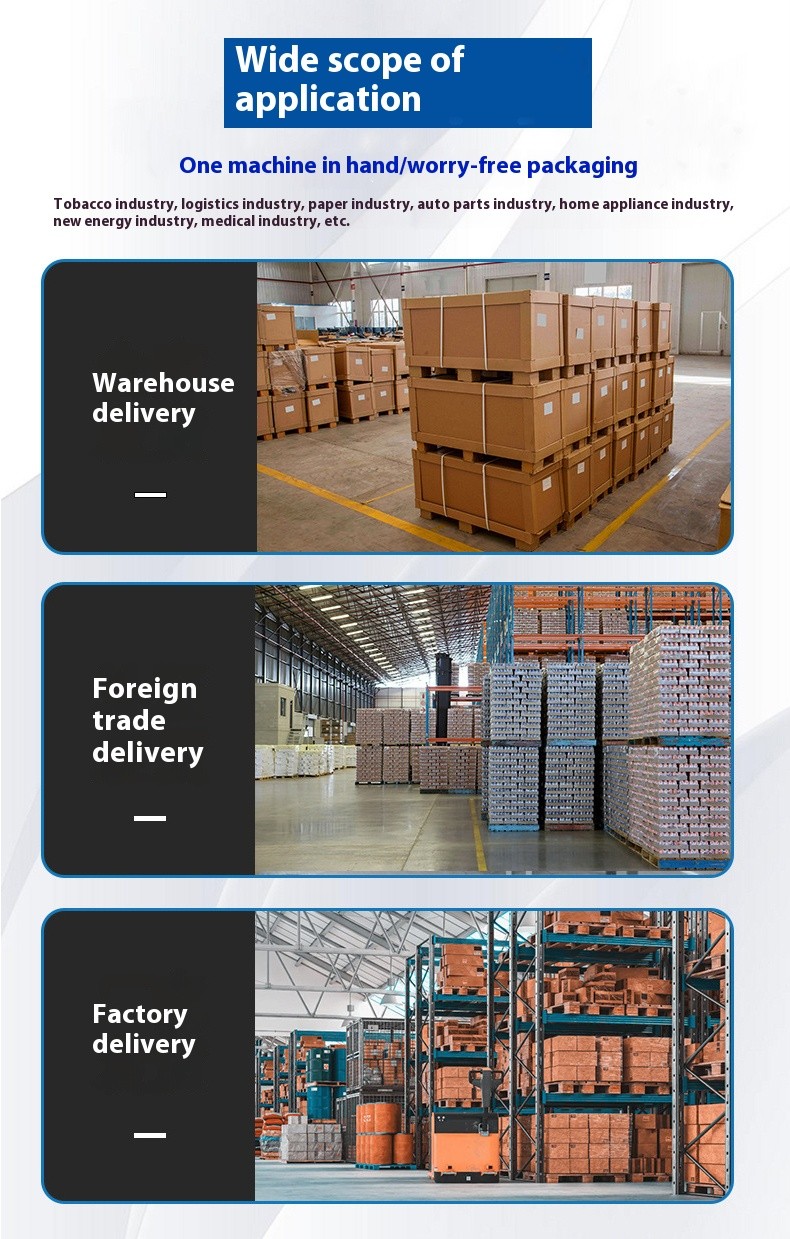

The equipment can operate continuously for 24 hours without being affected by manual fatigue, especially suitable for high-frequency packing demands in logistics, warehousing, manufacturing, and other industries, effectively improving the overall production rhythm.

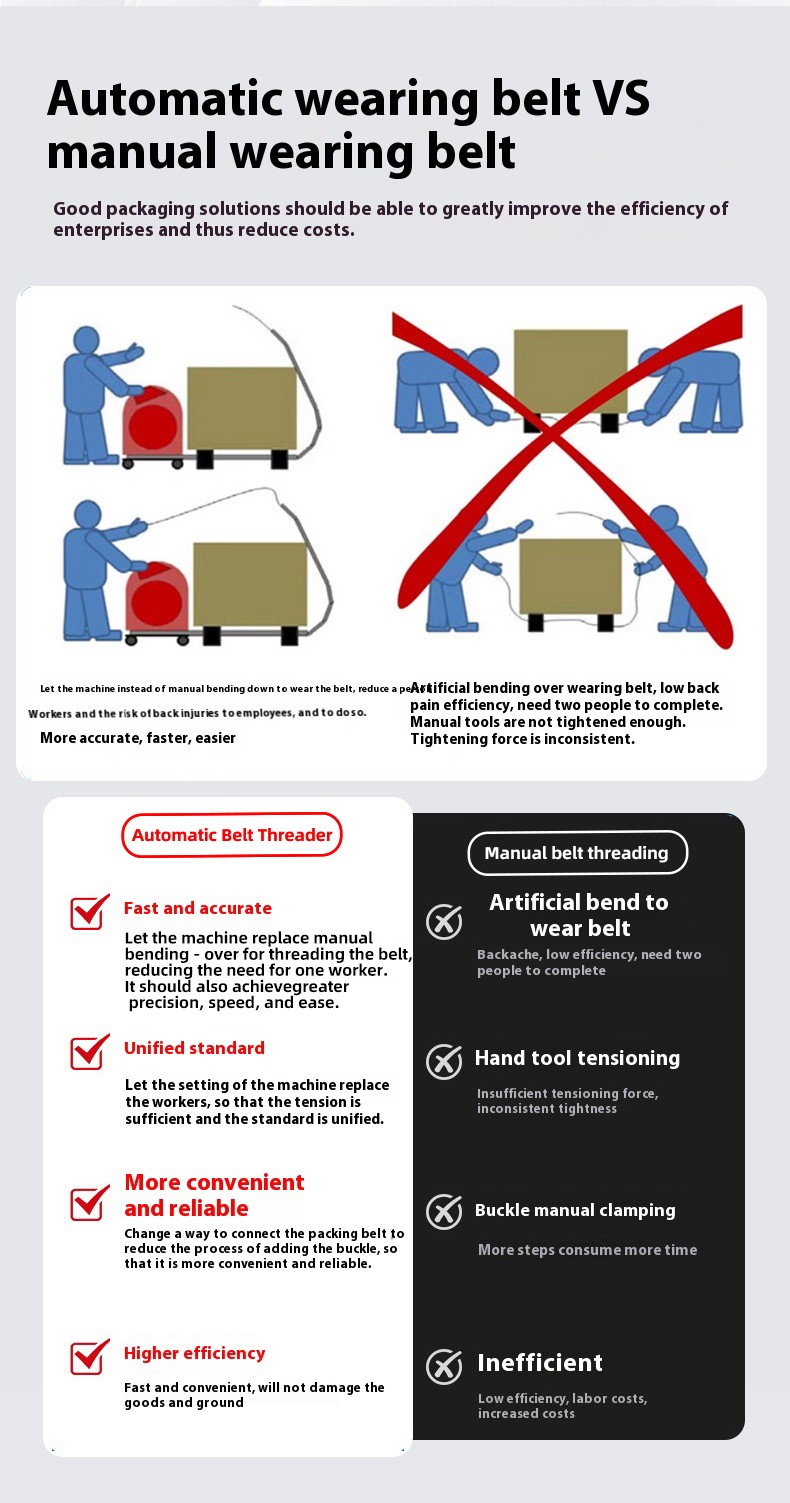

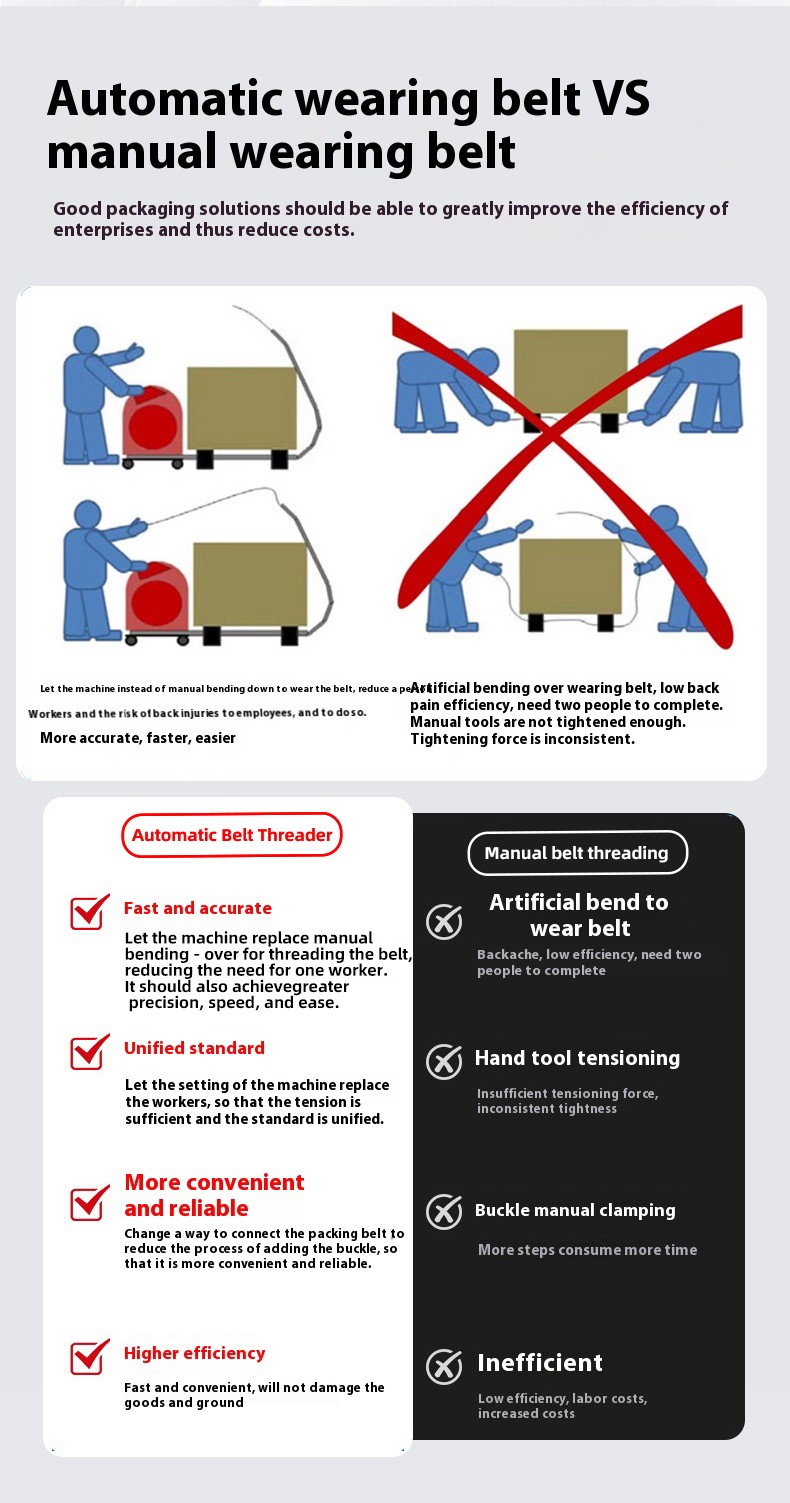

Eliminates the need for operators to repeatedly bend over or crouch for strapping, avoiding lumbar and shoulder strain caused by long-term repetitive movements, and reducing the risk of occupational diseases.

Operators only need to place the pallet and start the equipment. The strapping process is automatically completed by the machine, reducing manual intervention and saving labor costs.

Through mechanical structures and program settings, the equipment accurately controls the tension force of the strapping belt, avoiding issues like loose packaging due to uneven force in manual operation or cargo damage from excessive tension. Meanwhile, the fixed strapping position ensures consistent packing quality for each pallet.

Standardized packing enhances the impact resistance and anti-shaking ability of goods during transportation and handling, reducing the risk of cargo scattering or damage—especially suitable for the packaging needs of precision products such as electronics and automotive parts.

- Adapts to pallets of different sizes (e.g., standard specifications like 1200mm×1000mm, 1100mm×1100mm), and some models support customized adjustments for special pallet specifications.

- Compatible with various strapping belt materials and sizes. For instance, the JP727 model supports PP and PET strapping belts, with a width of 12-19mm and thickness of 0.6-1.2mm, meeting the packaging material requirements of different industries such as food & beverage and chemicals.

Made of high-strength, wear-resistant materials (e.g., stainless steel trolley chains, anti-corrosion coatings), it can operate stably in industrial environments with moisture, dust, etc., reducing equipment failure rates.

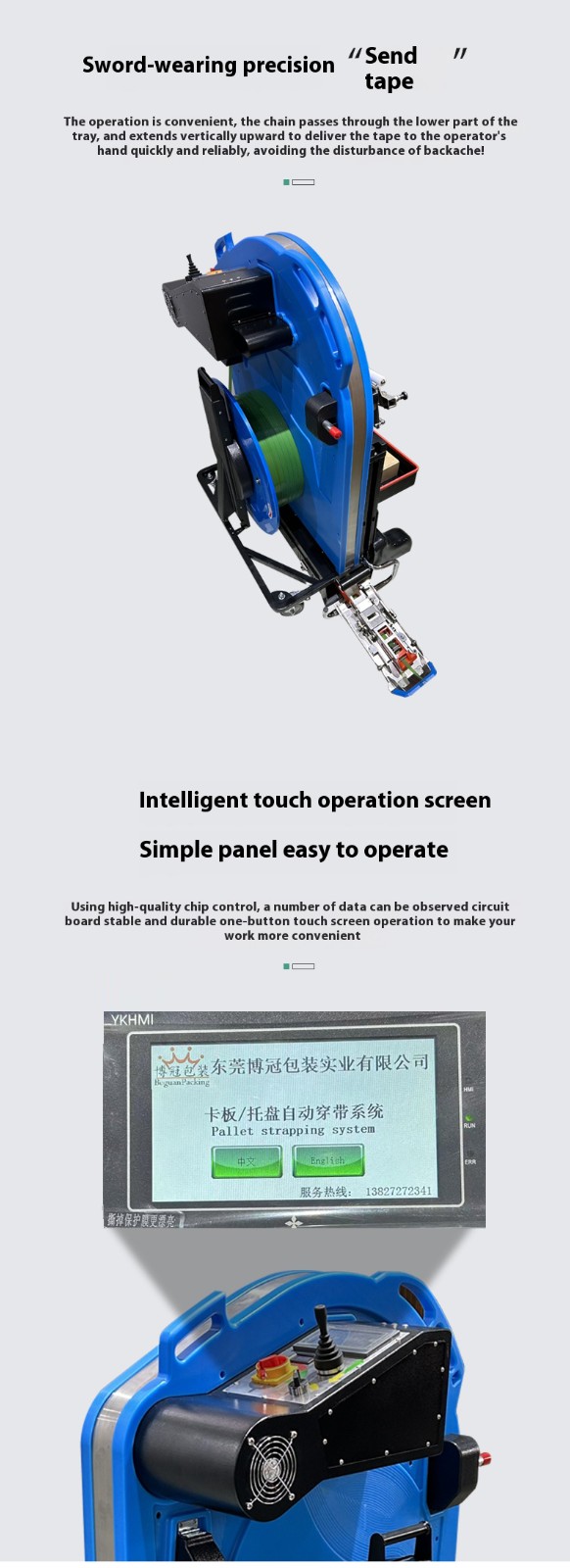

Equipped with a touchscreen or button-type control panel, supporting one-key activation and parameter presetting (e.g., strapping speed, belt length). Ordinary employees can master the operation after simple training.

Sensors monitor the trolley chain position, strapping belt 余量 (remaining quantity), etc., in real time. In case of abnormalities like belt jamming or shortage, it automatically alarms and stops, reducing manual inspection pressure and improving equipment operation safety.

Precisely controls the usage length of strapping belts, avoiding material waste caused by measurement errors in manual operation, and reducing packing costs in the long run.

Features a modular design, allowing convenient replacement of vulnerable parts (e.g., chains, sensors). Routine maintenance is simple, and regular maintenance can extend the equipment service life.