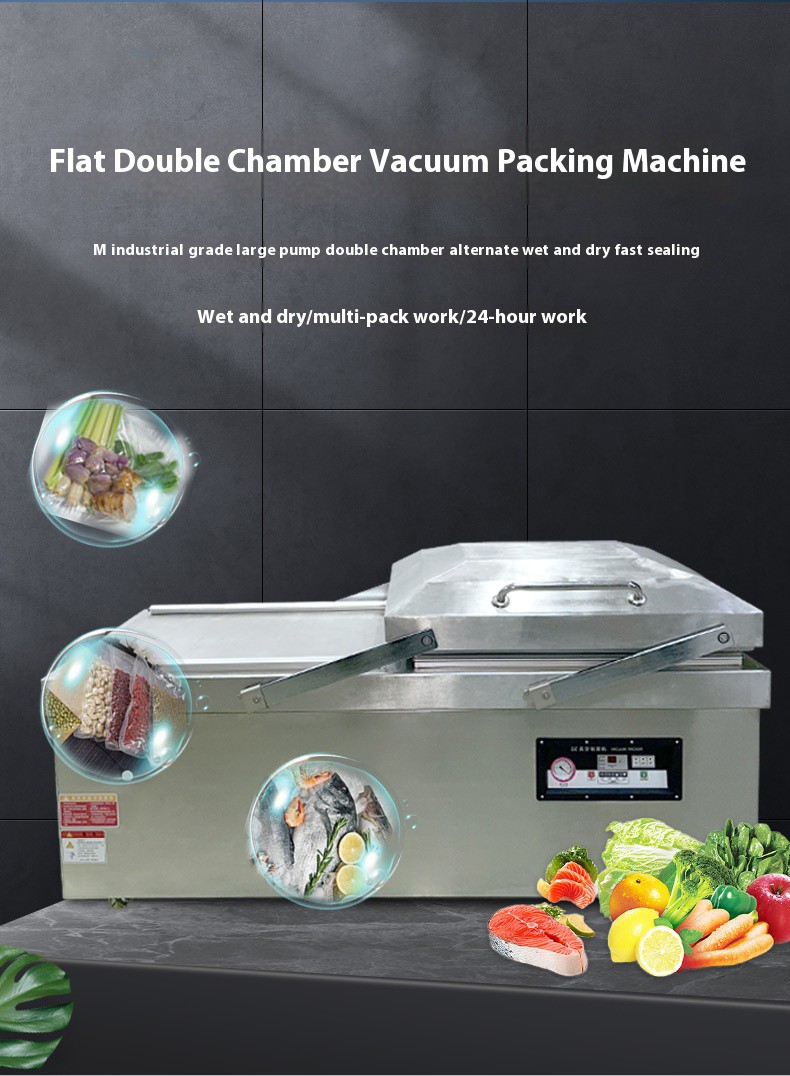

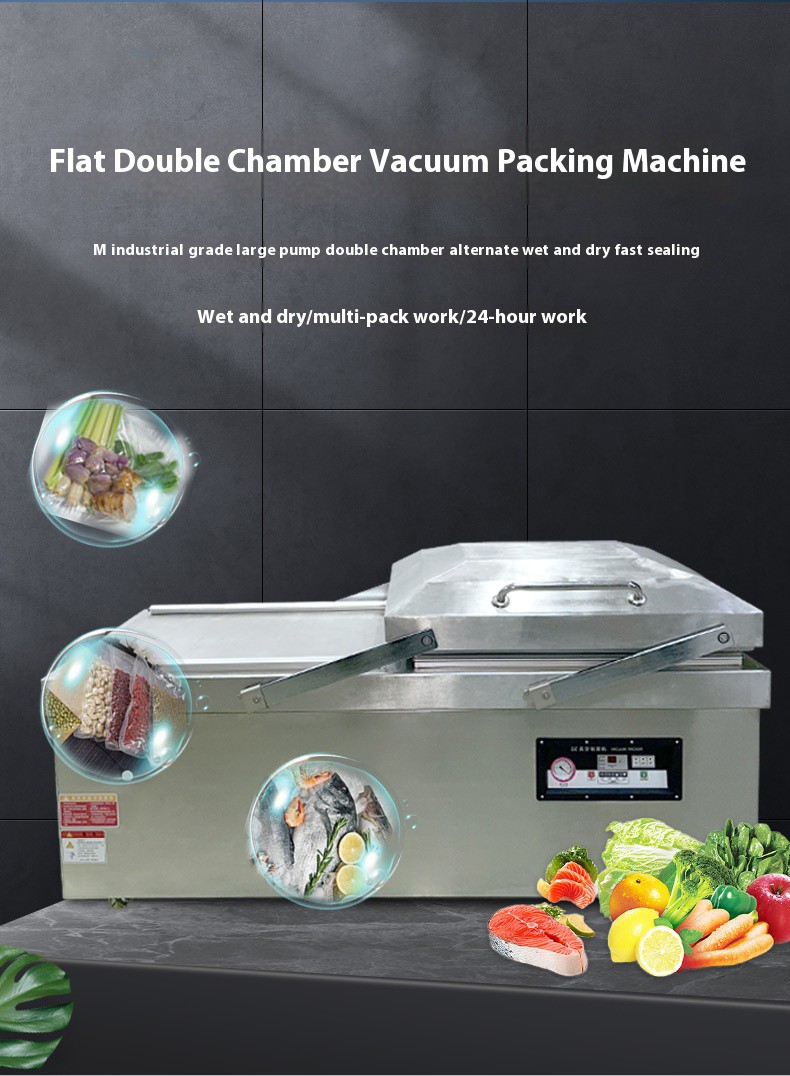

The flat double-chamber vacuum packaging machine demonstrates remarkable advantages in packaging efficiency, application scope, and operational convenience.

Release date:2025-06-17

Here are the detailed advantages of the flat double-chamber vacuum packaging machine, showcasing significant strengths in packaging efficiency, application scope, and operational convenience due to its unique structural design and functional configuration:

- Parallel Operation Mode

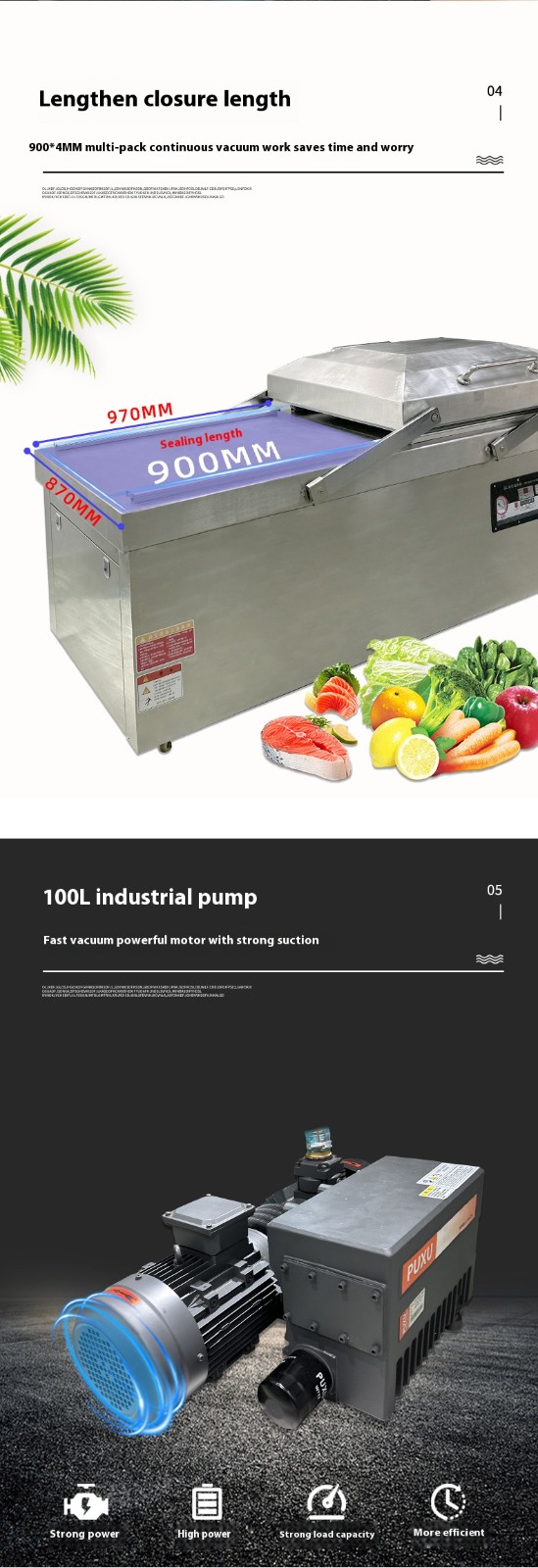

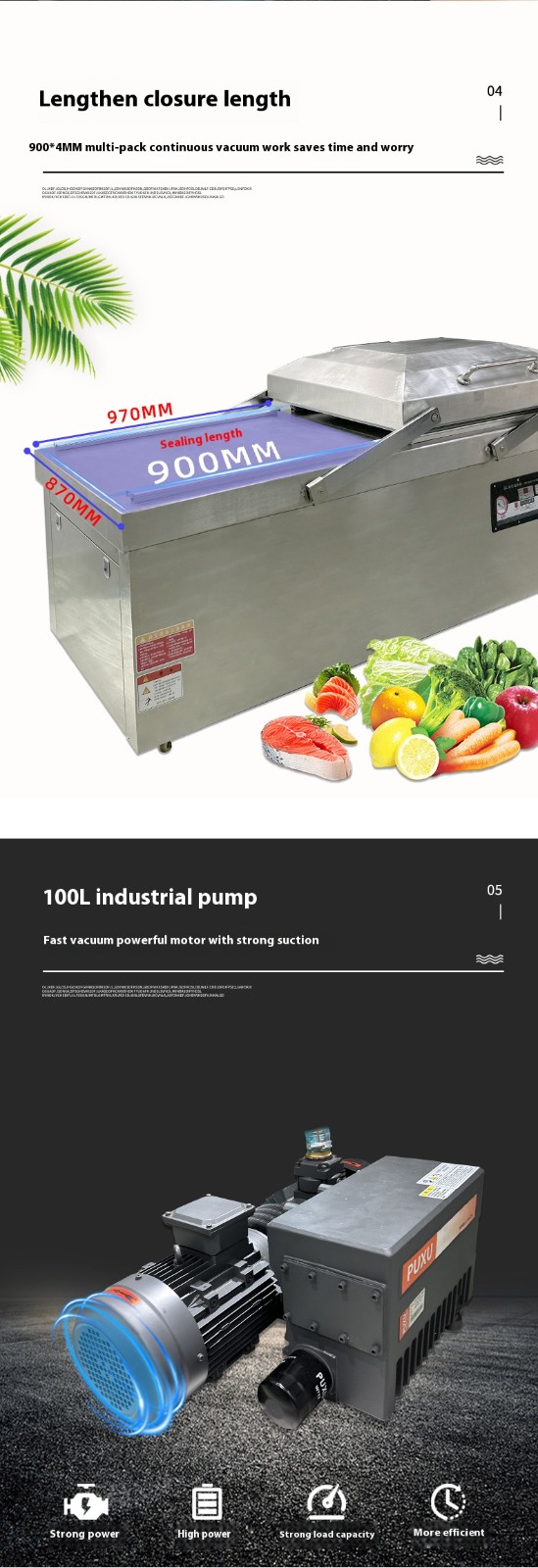

The two vacuum chambers alternately perform vacuum extraction, heat sealing, and material loading. While one chamber is in vacuum extraction or heat sealing, the other can complete loading simultaneously, reducing waiting time. The theoretical capacity is increased by over 50% compared to single-chamber models. - Rapid Vacuum Response

Equipped with a high-power vacuum pump (e.g., 2X-15 type), the pumping rate reaches 15L/s, reducing the chamber vacuum degree to below -0.08MPa within 10-20 seconds, suitable for high-capacity scenarios (e.g., food processing plant assembly lines).

- Flat Chamber Design

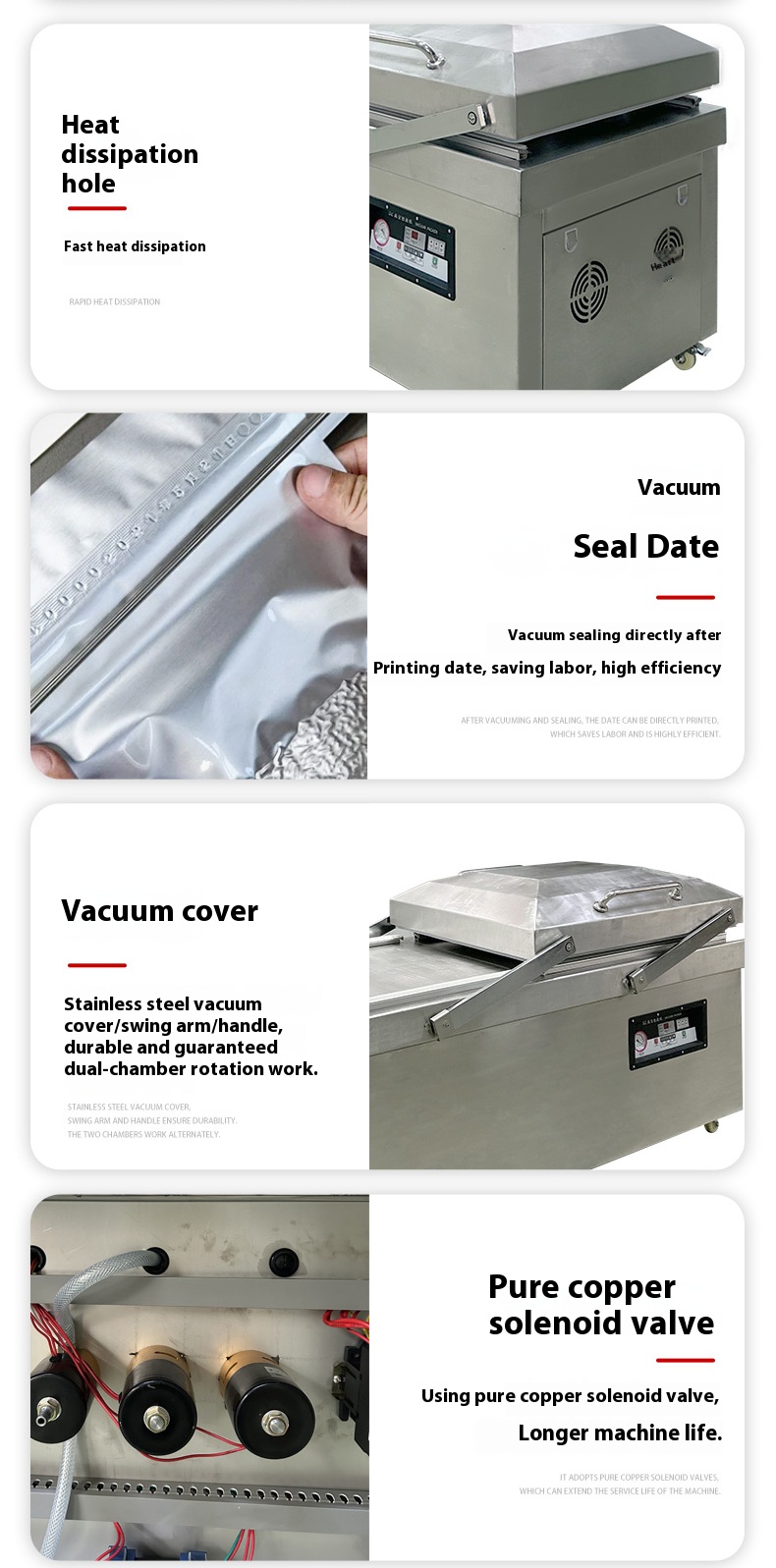

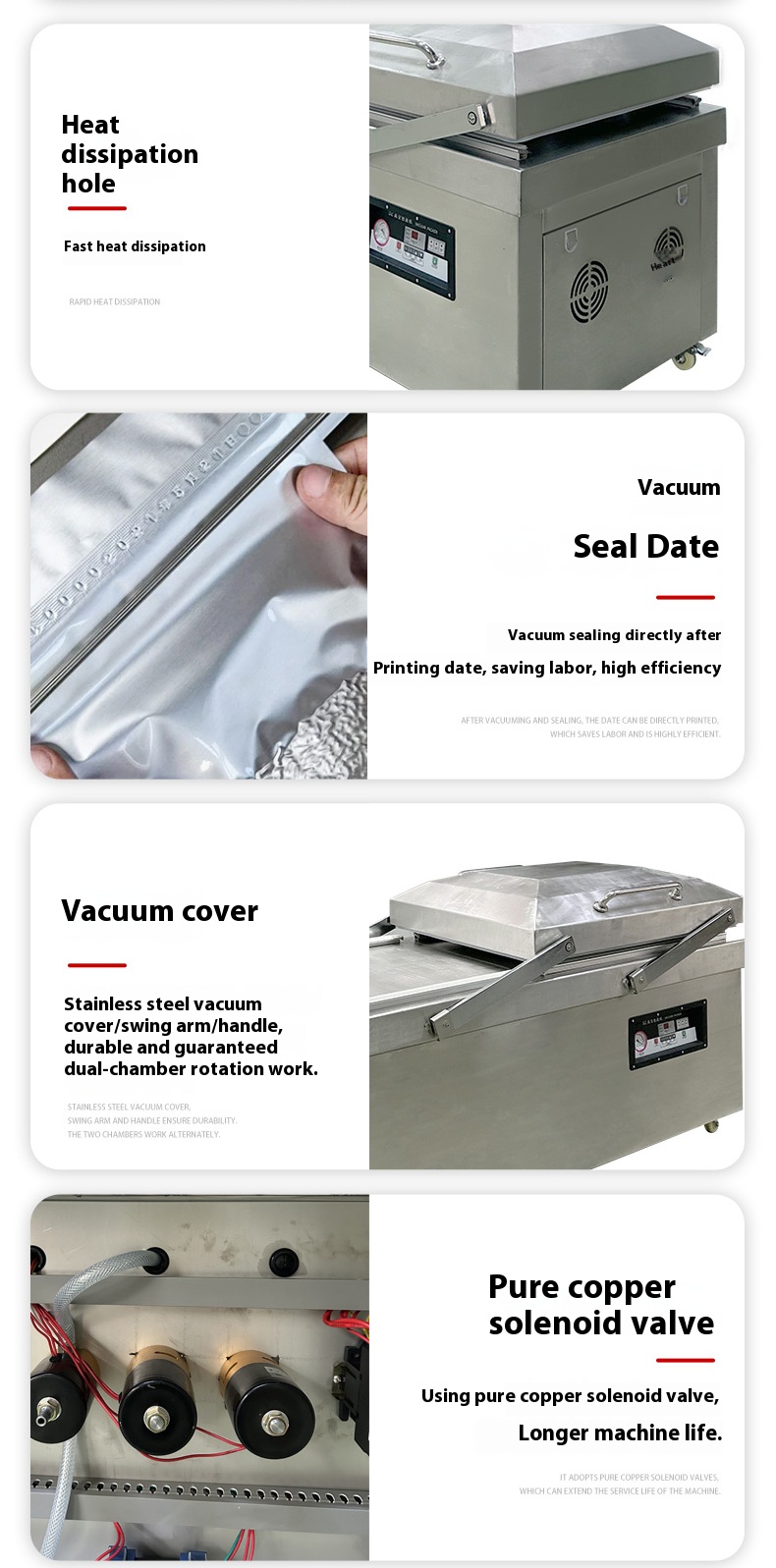

The bottom of the vacuum chamber is flat with no grooves or gaps, allowing direct wiping of grease, debris, etc. It complies with food industry hygiene standards (e.g., FDA, HACCP), and the cleaning efficiency is 30% higher than traditional concave-convex chambers. - High-Strength Sealing System

Adopting high-density V-shaped silicone sealing strips (hardness 60±5 Shore A) combined with metal pressure strips at the chamber edges, it can withstand over 100,000 opening/closing abrasions, with an air leakage rate below 0.1Pa·L/s, maintaining sealing performance for long-term use. - Labor-Saving Operation Device

The vacuum cover is equipped with a suspended hinge or spring-assisted structure, enabling operators to close the cover with one hand. Labor intensity is reduced by 40% compared to traditional models, suitable for prolonged continuous operation.

- Adjustable Microcomputer Parameters

The PLC control system allows independent setting of vacuum time (5-30s), heat-sealing temperature (120-200℃), and sealing time (1-5s), adapting to packaging bags of different materials such as PE, PA, aluminum foil, etc., and even handling composite films with a thickness of up to 0.3mm. - Multi-Mode Operation Function

Supports "vacuum mode" and "vacuum + inflation mode" (e.g., filling with N₂/CO₂ mixed gas), meeting differentiated needs such as food preservation (e.g., anti-oxidation for braised foods) and electronic product moisture protection (e.g., anti-mildew for PCB boards).

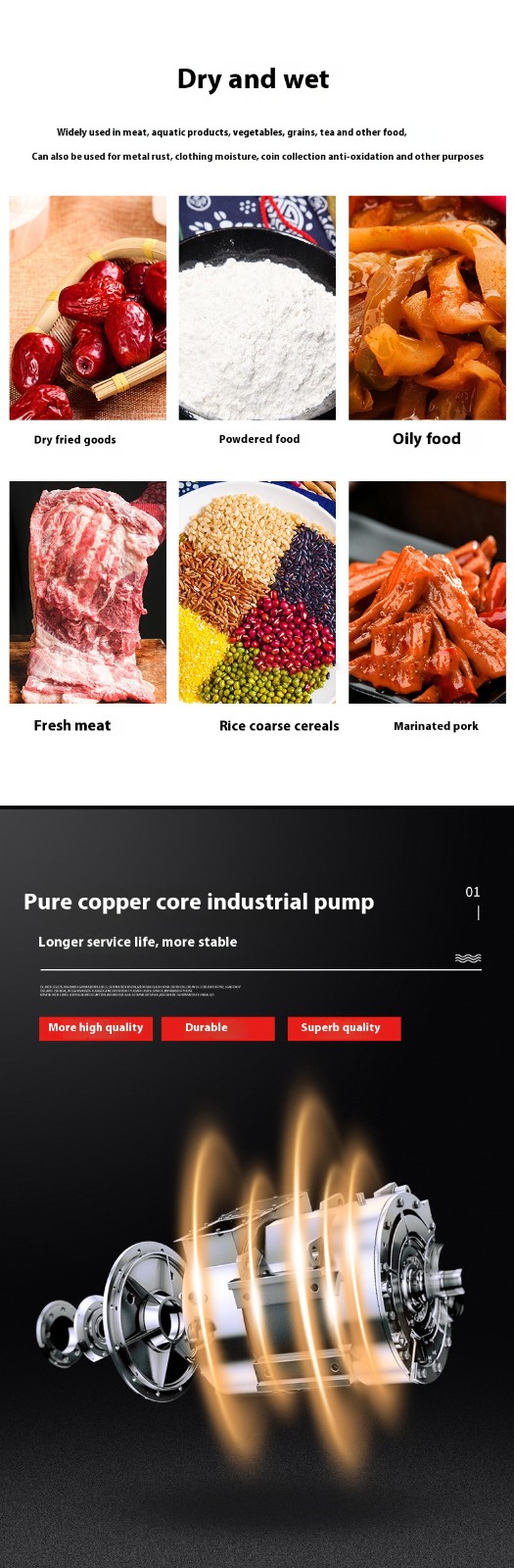

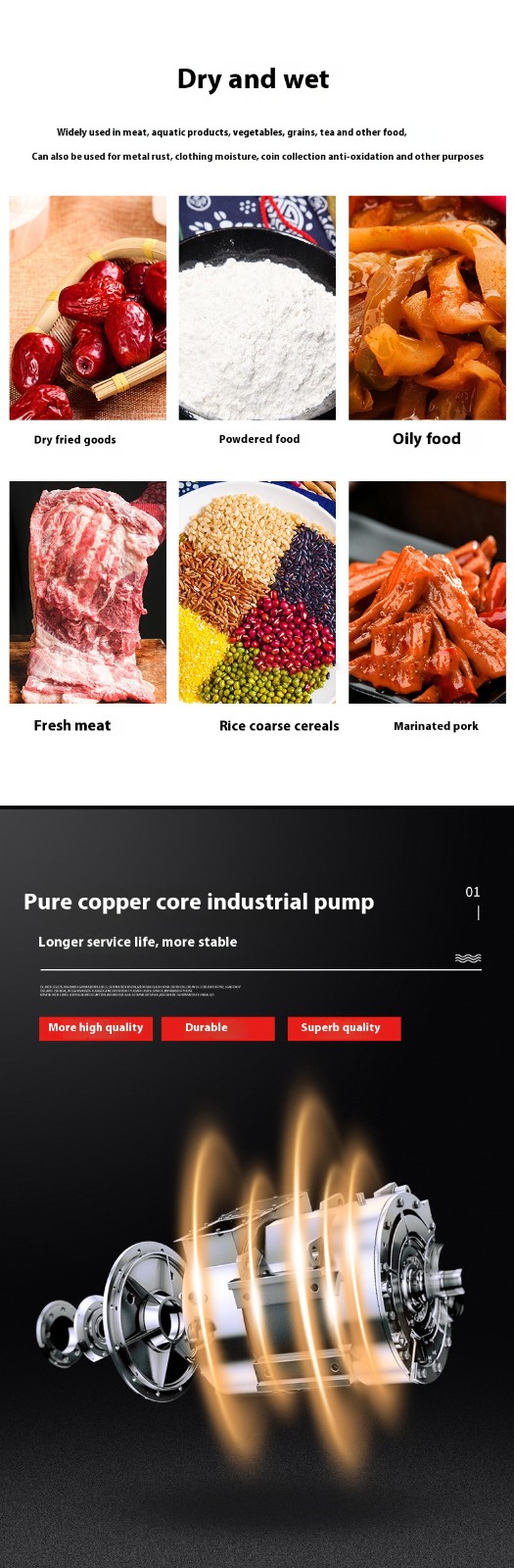

- Food Industry

Suitable for meats (e.g., beef jerky, marinated duck), fruits/vegetables (e.g., vacuum-preserved strawberries), dried goods (e.g., wolfberries, tea), etc. The low-oxygen environment inhibits microbial reproduction, extending the shelf life by 3-5 times (compared to ordinary packaging). - Industrial Field

Can package precision instruments (e.g., sensors) and metal parts (e.g., bearings). The vacuum environment isolates moisture and oxygen, preventing parts from rusting or circuits from oxidizing, especially suitable for export marine packaging. - Pharmaceutical & Daily Chemicals

Meets the sterile packaging requirements for medicines (e.g., traditional Chinese medicine decoction pieces) and cosmetics (e.g., paste masks). When used with a sterile workshop, it can achieve ISO 100 cleanliness standards.

- Convenient Handling Capacity

Four heavy-duty casters (each load-bearing ≥100kg) with brake locking are installed at the bottom, allowing easy movement of the equipment to different production lines, adapting to workshop layout adjustments. - Multiple Safety Protections

Equipped with overload protection (motor overheating shutdown), leakage protection (automatic power-off for ground faults), and heat-sealing anti-scald design (heat-insulating silicone wrapped around the sealing strip), reducing operational risks.

- Energy Consumption Optimization

Using an energy-saving vacuum pump (power 1.5-2.0kW), it saves 15% more electricity than traditional models. Calculated by 8 hours of daily operation, annual power consumption can be reduced by approximately 5,000 kWh. - Low Maintenance Cost

Vulnerable parts (e.g., sealing strips, vacuum pump oil) are easy to replace. The cost of a single sealing strip is about 50-100 yuan, with a replacement cycle of 1-2 years, and the overall maintenance cost is 20% lower than similar equipment.