The work efficiency of automatic page - separating labeling machines mainly depends on factors such as equipment models, product specifications, label sizes, and production environments. Its core advantages are reflected in high automation, high speed, and high stability. The following is a detailed analysis in English:

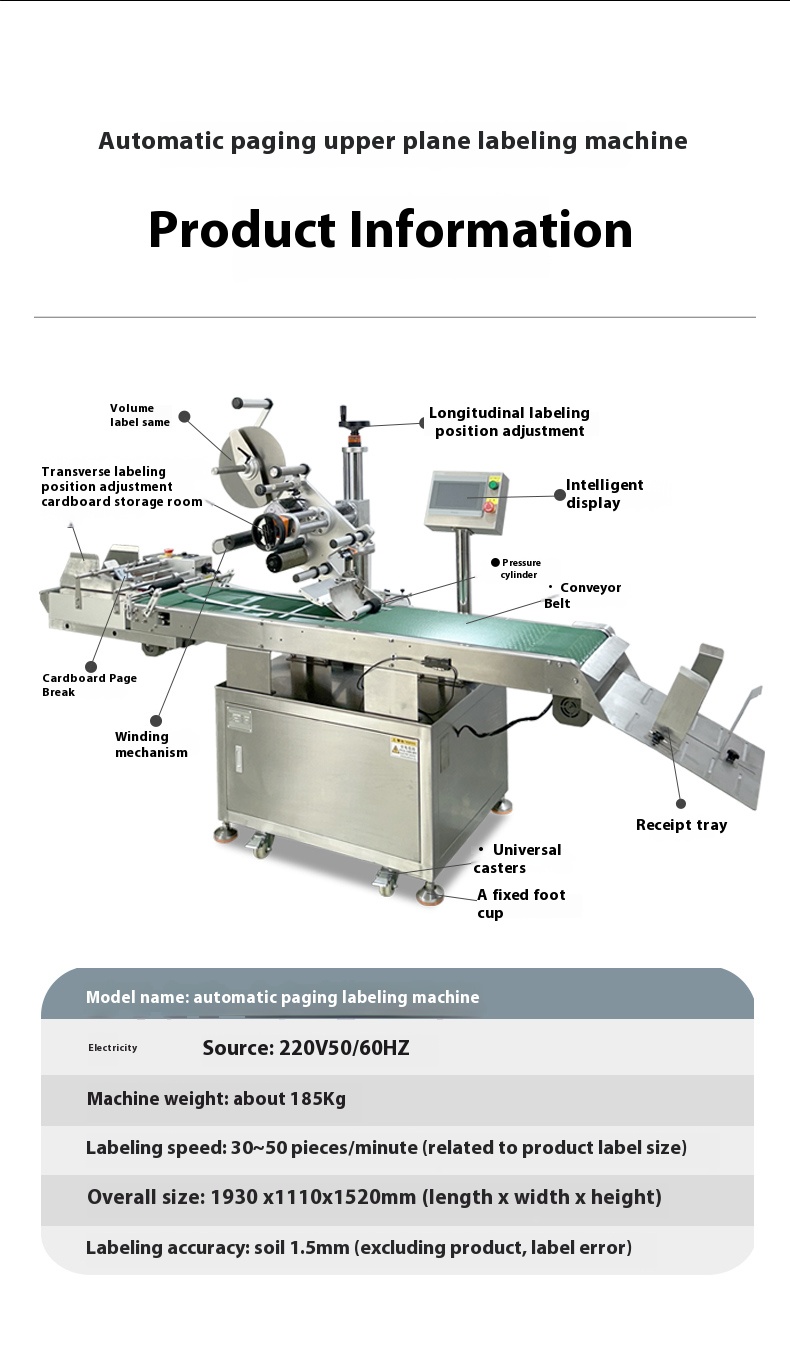

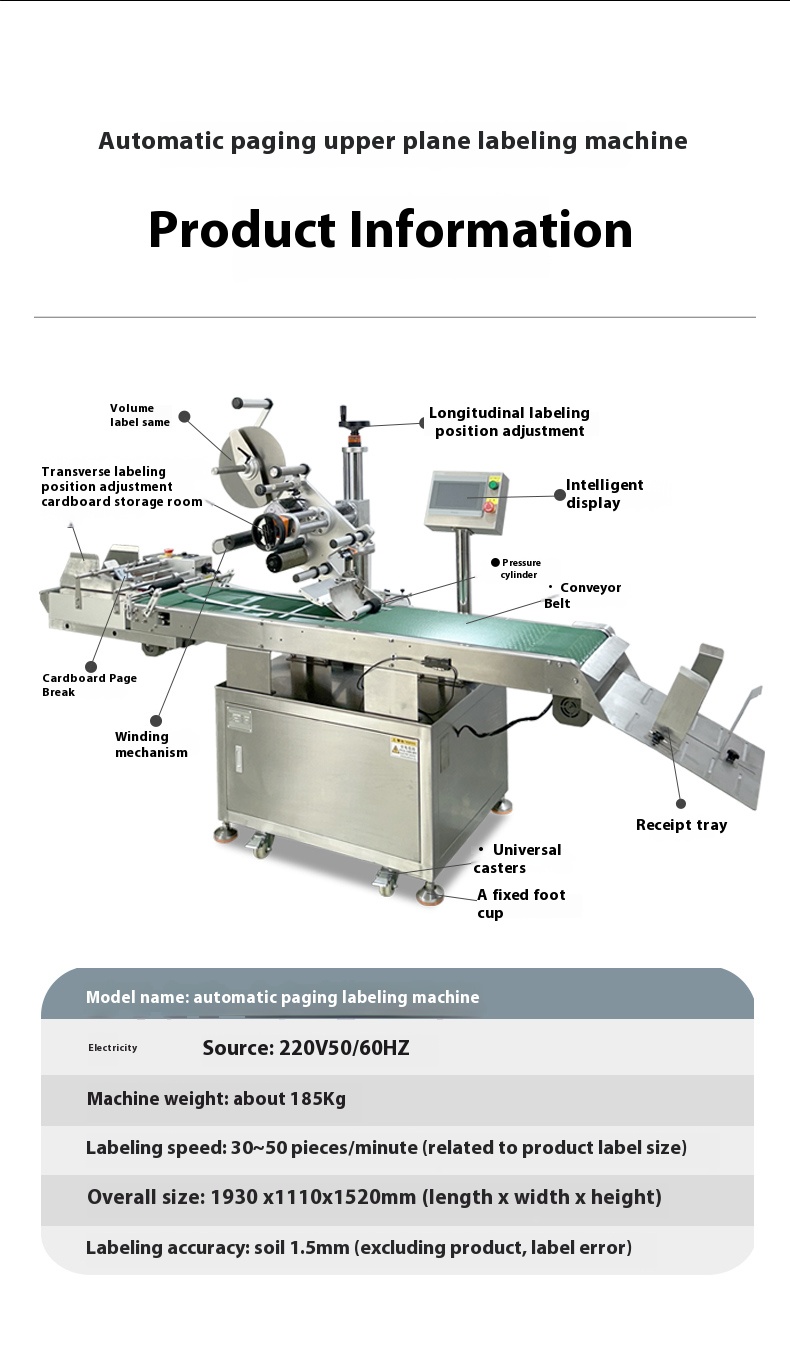

Most standard models of automatic page - separating labeling machines have a labeling speed of 30–150 pieces per minute (specifically depending on product sizes):

- Small - sized products (such as cards and small packaging bags): The speed can reach 80–150 pieces per minute, suitable for large - batch continuous production.

- Large - sized products (such as books and large packaging boxes): The speed is usually 30–80 pieces per minute due to the need for more precise positioning and labeling actions.

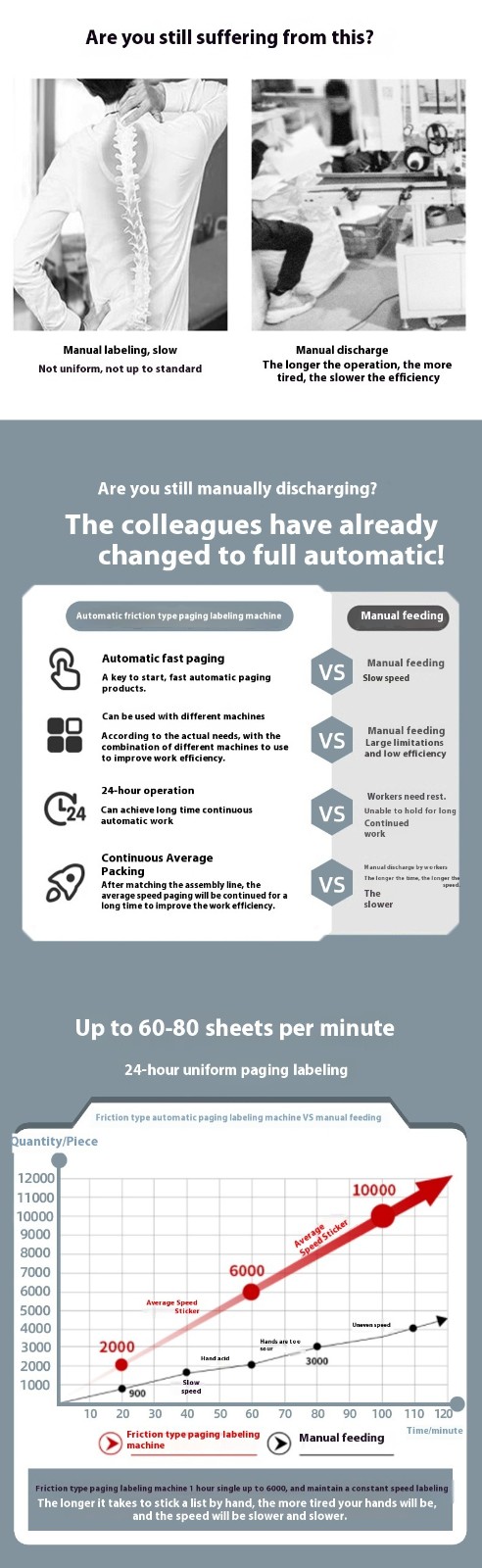

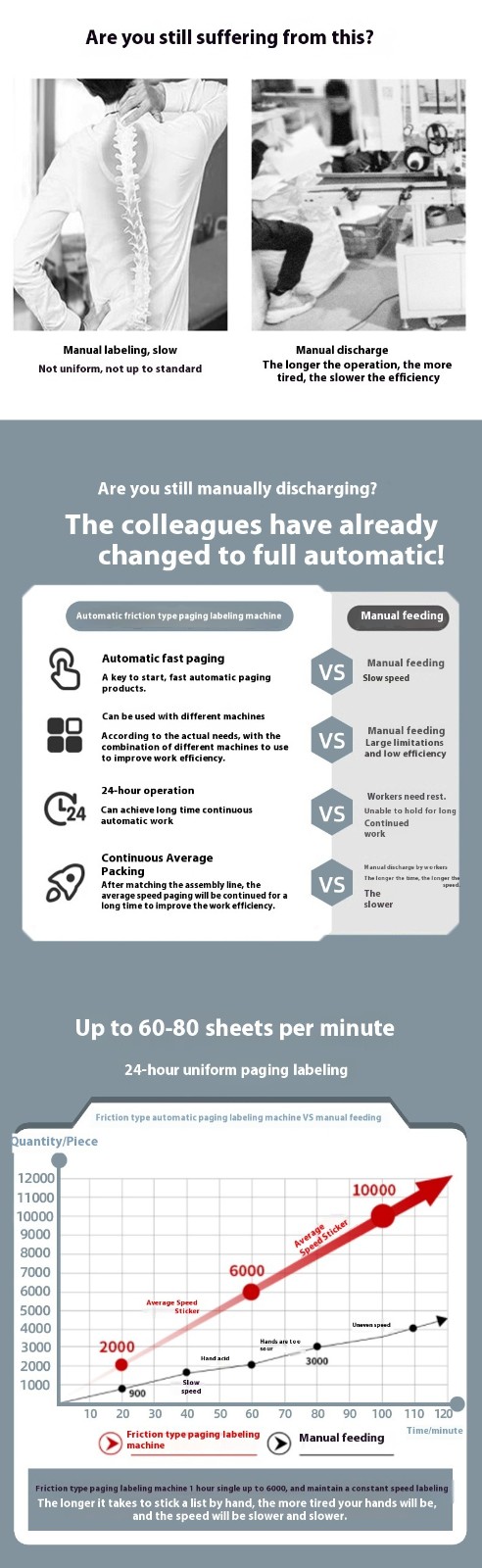

- Manual labeling: The efficiency of a single operator is approximately 10–30 pieces per minute, and it is easily affected by factors such as fatigue and mood, with poor stability.

- Machine labeling: The production capacity under continuous operation can be 3–5 times that of manual labor, and the advantage is more significant during 24 - hour uninterrupted production.

- Product shape: Regular flat surfaces (such as cartons and cards) have the highest labeling efficiency; special - shaped curved surfaces (such as cylindrical bottles) require customized labeling heads, which may reduce the speed.

- Label material and size: Transparent labels and high - precision positioning labels (such as electronic supervision codes) require more precise sensor calibration, which may slightly reduce the speed; large - sized labels (such as those with a length > 200mm) have a slightly lower efficiency due to the long label feeding distance.

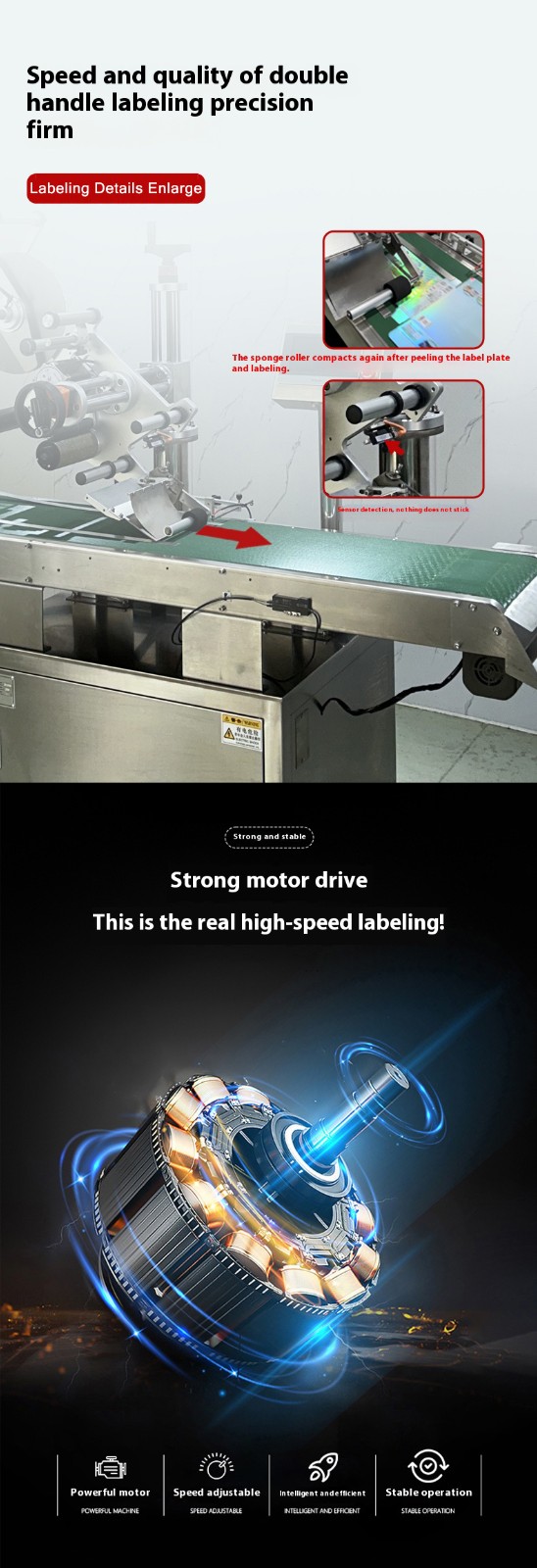

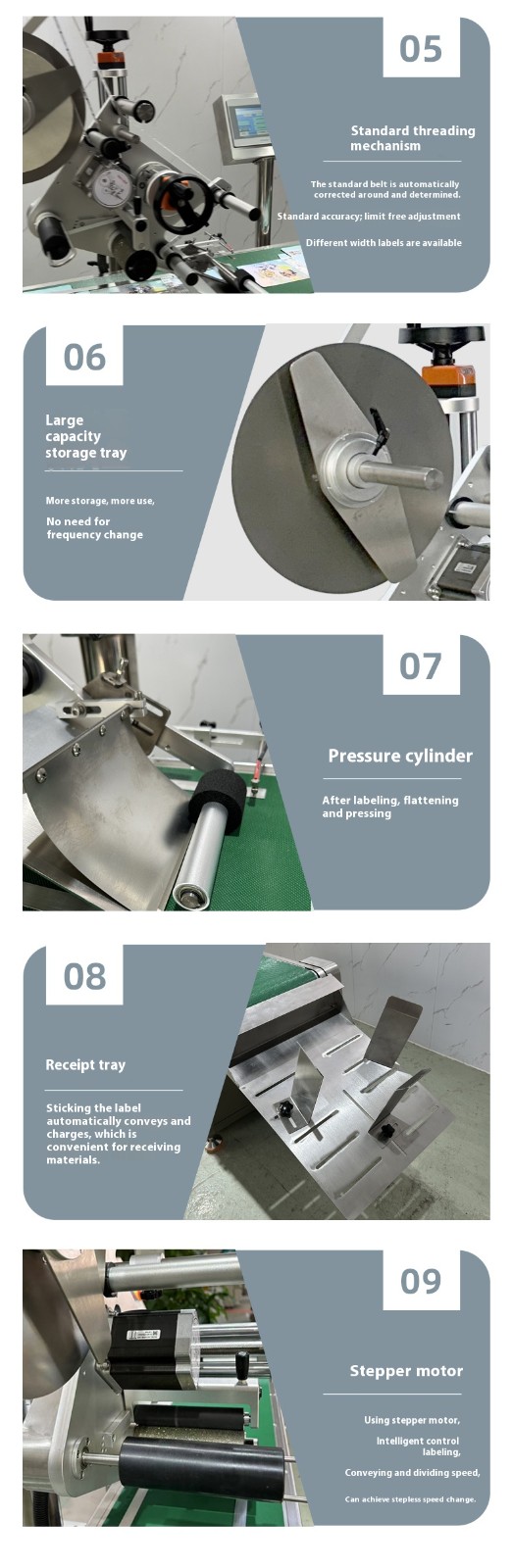

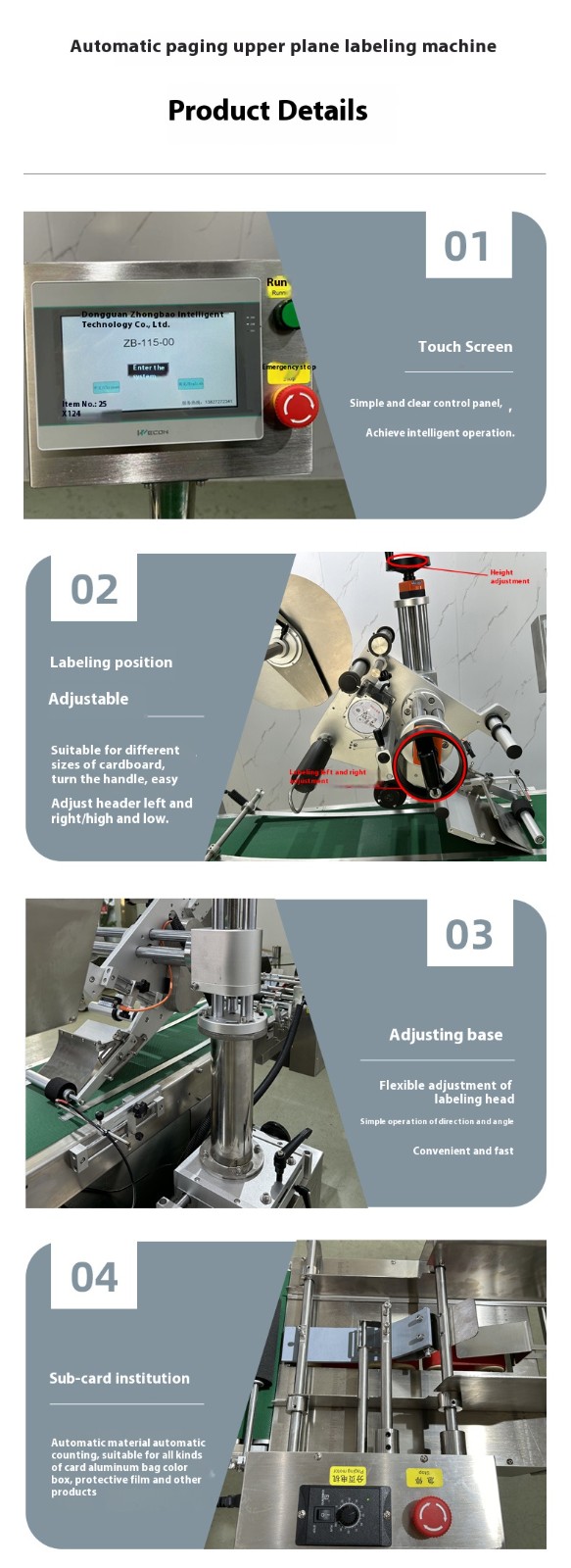

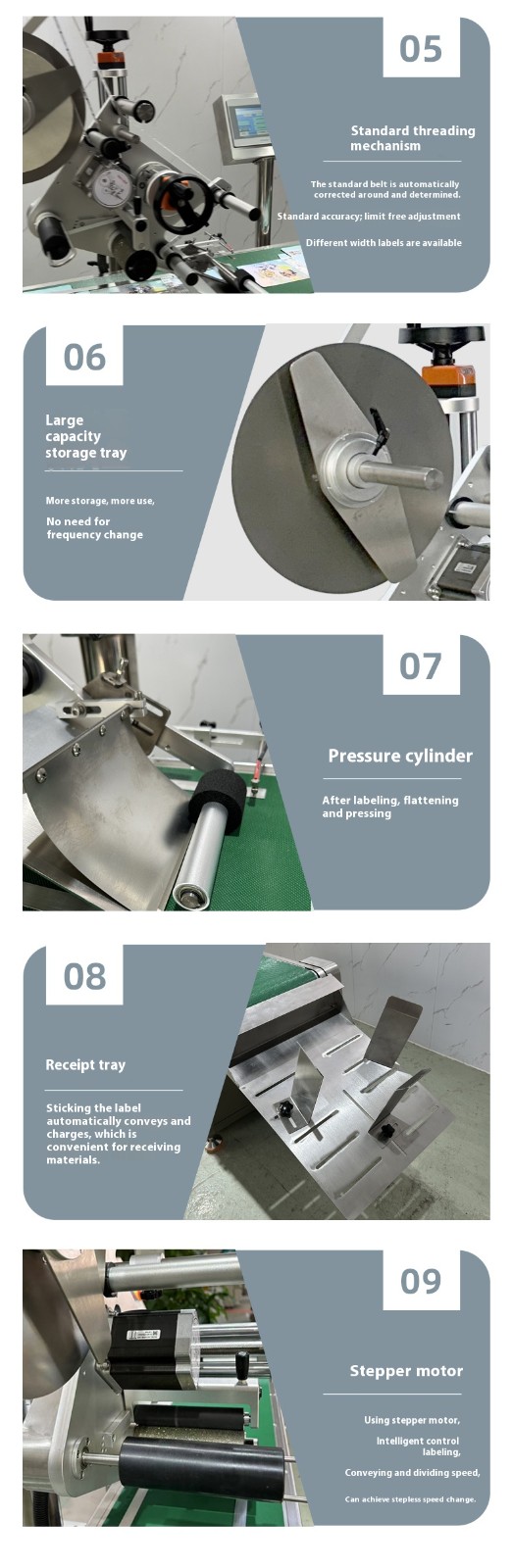

- Page - separating mechanism: An efficient pneumatic or mechanical page - separating device can ensure continuous and stable separation of products, avoiding paper jams or stacking, which directly affects the overall speed.

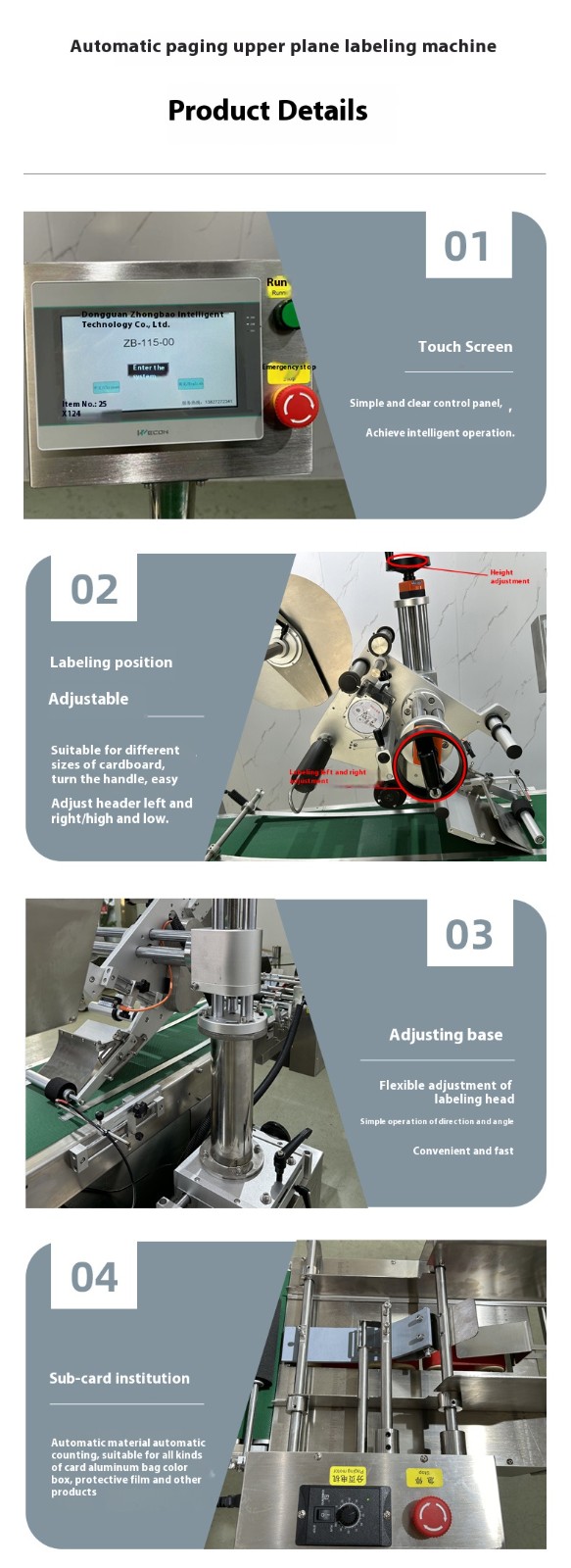

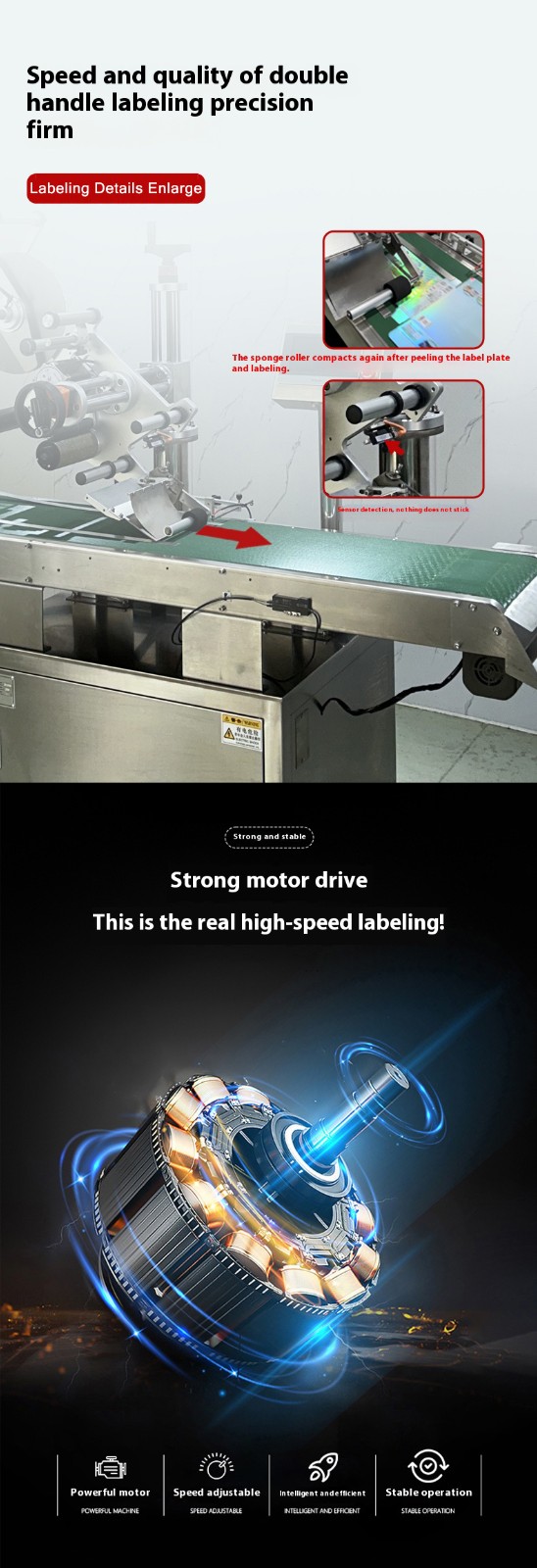

- Control system: Imported servo motors + PLC control systems have fast response speeds (millisecond - level) and small positioning errors, which can reduce downtime and rework caused by empty labels or misaligned labeling.

- Optional functions: Equipped with automatic feeding and receiving lines or multi - station labeling devices (such as labeling both the front and back sides simultaneously), the comprehensive efficiency can be further improved.

- Initial debugging: When changing product specifications, parameters such as page - separating spacing and label positions need to be adjusted. Skilled operators can complete the switching within 10–30 minutes, while novices may take longer.

- Maintenance status: Regular lubrication of transmission components and cleaning of sensors (to avoid dust interference with detection) can reduce fault downtime and ensure an equipment utilization rate of >95%.

In the large - scale production of industries such as food and daily chemicals, the equipment can operate continuously for 8–12 hours, with a daily production capacity of 100,000–200,000 pieces, far exceeding manual efficiency.

By presetting multiple groups of parameters (such as labeling positions and label lengths for different products), production tasks can be switched with one click. This is suitable for scenarios such as customized packaging for e - commerce and small - batch pharmaceutical orders, reducing model - changing losses.

In scenarios such as labeling electronic components (requiring ±1mm precision) and labeling drug supervision codes (requiring synchronous code scanning and verification), the machine can use a visual inspection system for real - time error correction, avoiding rework caused by manual missing or mislabeling and indirectly improving efficiency.