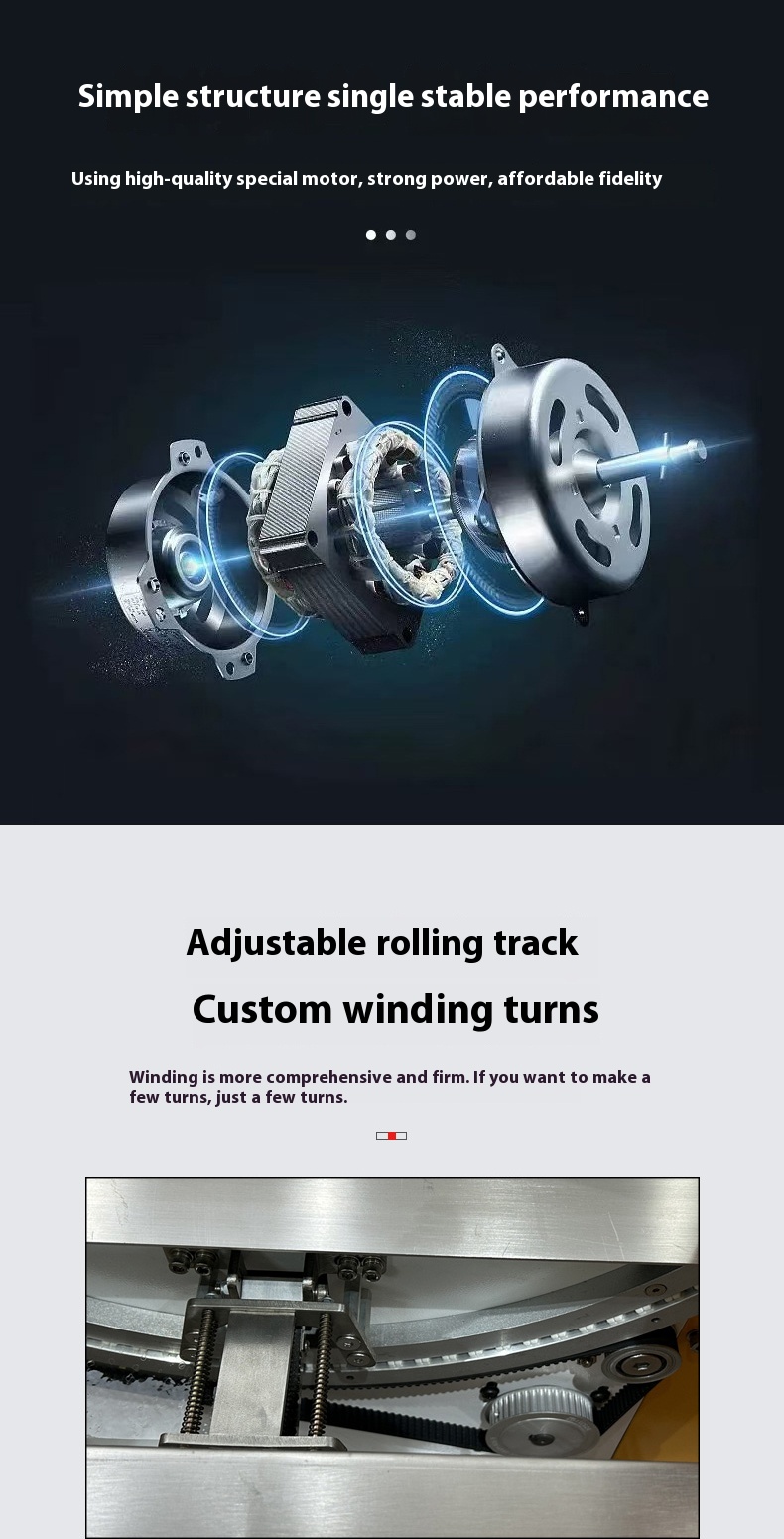

The core power of a winding machine comes from the motor, whose power must simultaneously meet the torque requirement for driving the goods to rotate and the tension control for tape winding.

- Heavy-load Scenarios: When the goods are heavy (e.g., a 2-ton pallet), the motor needs to output greater torque to maintain rotation. If a high winding speed (e.g., more than 15 revolutions per minute) is required simultaneously, it may cause motor overload, or even "jamming" or speed reduction due to insufficient power.

- Light-load Scenarios: Light-weight goods (e.g., below 500kg) have lower torque requirements for the motor, which can more flexibly allocate power to winding speed control to achieve high-speed winding (e.g., more than 20 revolutions per minute).

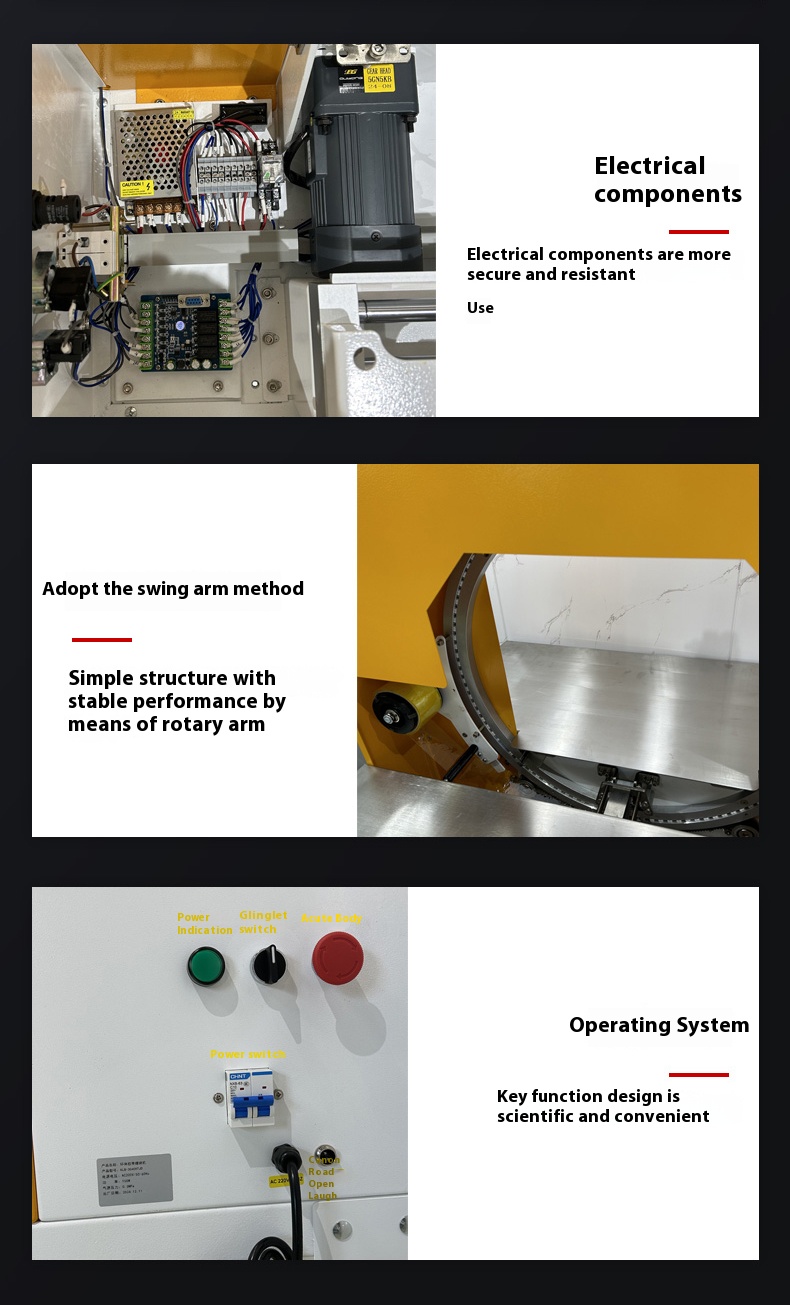

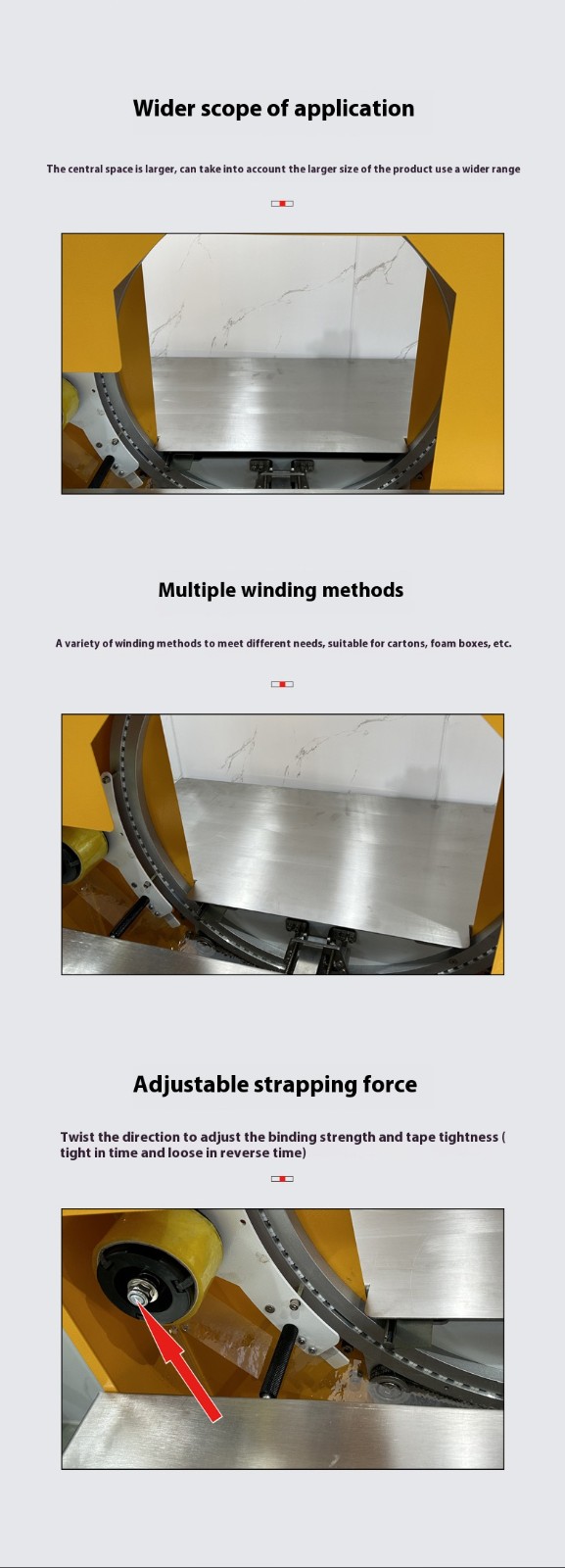

The strength of transmission components such as gears and chains determines the dynamic load that the equipment can withstand.

- High winding speeds increase the inertial impact force on transmission components (e.g., jolts during start/stop). If the equipment's load-bearing capacity is insufficient (e.g., a light-duty frame), it may lead to accelerated wear or even breakage of transmission components.

- Conversely, the reinforced transmission structure of heavy-duty equipment (e.g., cast steel gears) can better adapt to the impact of high-speed operation.

- Physical Limit Constraints: Equipment manuals typically specify the "maximum allowable speed under different load-bearing capacities." For example:

- When the maximum load-bearing capacity of a device is 2000kg, the recommended maximum winding speed is 10 revolutions per minute;

- When the goods weight is reduced to 1000kg, the maximum speed can be increased to 15 revolutions per minute.

- Stability Requirements: High-speed rotation of heavy loads is prone to 晃动 (晃动) due to centrifugal force, which may cause equipment vibration or safety hazards. Therefore, manufacturers restrict the speed of heavy loads through control systems to ensure smooth operation (e.g., equipped with frequency converters for dynamic speed adjustment).

- Increased Dynamic Load: The higher the winding speed, the greater the inertia of the goods during rotation, and the stronger the instantaneous impact force on the equipment's turntable and frame. For example:

- For goods with the same load-bearing capacity of 1000kg, the dynamic load on the turntable when rotating at 20 revolutions per minute may be 30%-50% higher than that at 10 revolutions per minute.

- Impact on Component Life: Long-term high-speed operation accelerates the wear of components such as bearings and motors, indirectly reducing the equipment's actual load-bearing capacity. For example, if light-duty equipment continuously winds heavy loads at maximum speed for a long time, it may cause frame weld cracks or bearing looseness, lowering the safety load-bearing threshold.