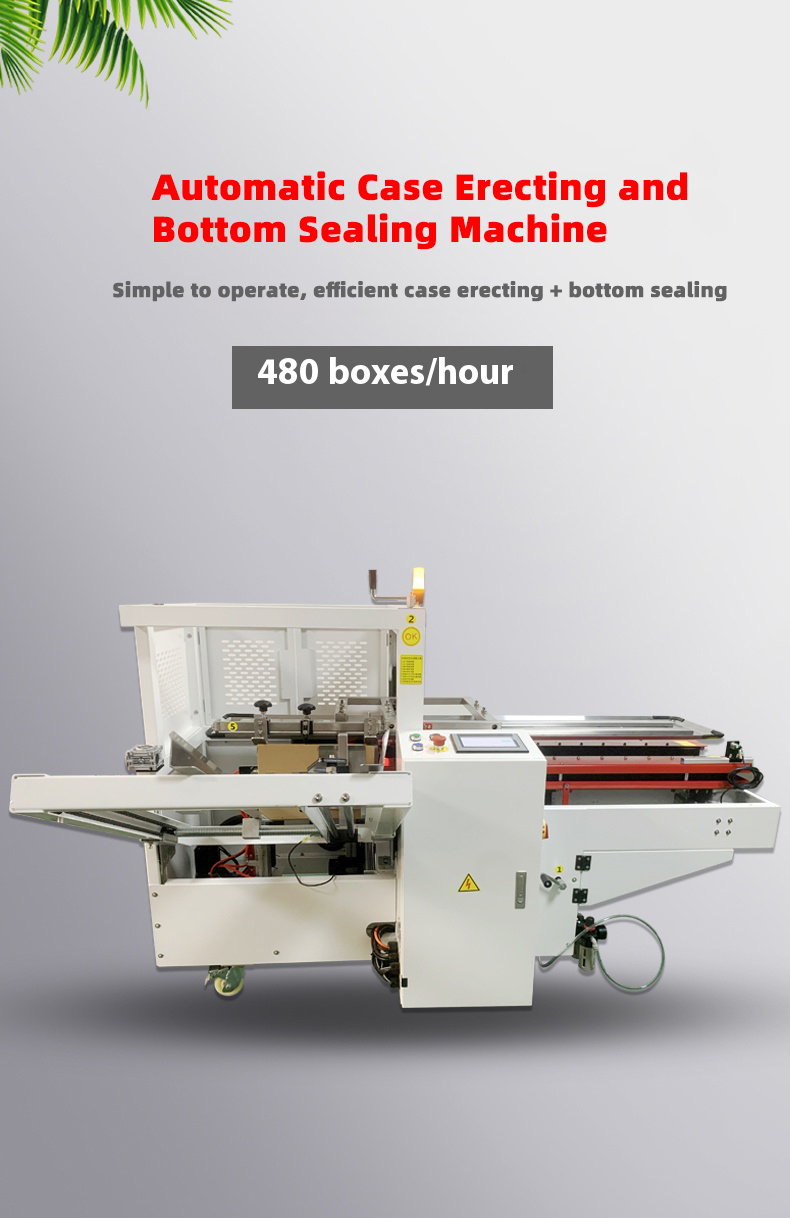

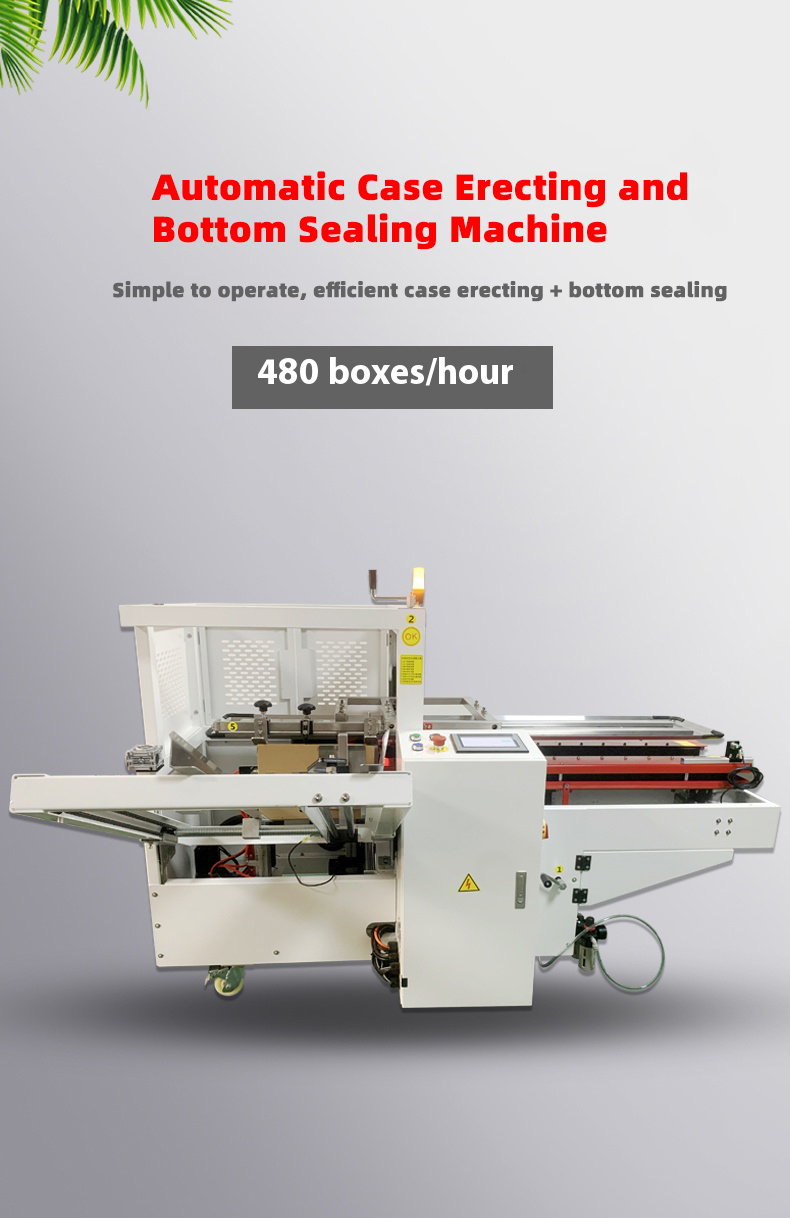

It completes carton suction, erecting, forming, bottom folding and sealing in one go, which can significantly reduce the number of production personnel and labor intensity.

Controlled by PLC + HMI (Human-Machine Interface) display, it features intuitive operation and easy maintenance. It is also equipped with safety devices such as material shortage pre-alarm and automatic shutdown when out of material.

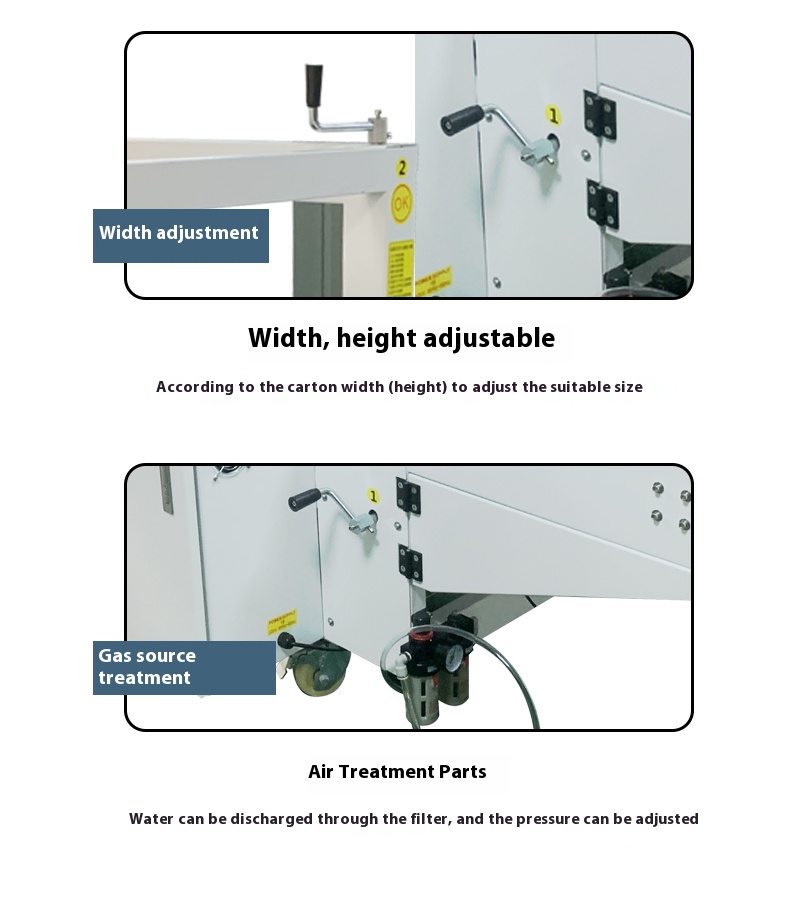

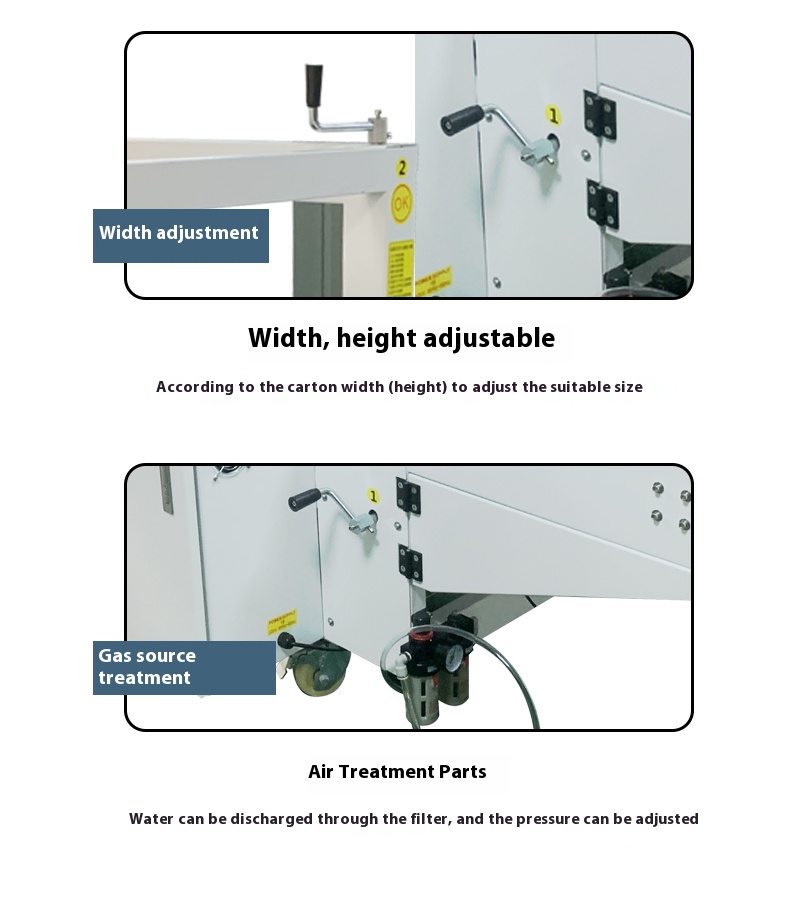

It has a wide range of applicable cartons, and adjustment for cartons of different sizes is simple and fast. Manual adjustment generally only takes 1-2 minutes when changing carton specifications.

With professional and precision design, the whole machine adopts a cam continuous system, ensuring accurate and stable operation. The machine parts are precise and durable, running without vibration, and featuring stable operation and long service life.

Breaking through the traditional tape applicator design, it ensures tight carton sealing and excellent tape flattening effect with zero tape skipping. The length of the tape fold at both ends of the carton can be customized.

The equipment is classified into low-speed, medium-speed and high-speed models according to the degree of automation. The low-speed model can erect 8-12 cartons per minute, the medium-speed model can reach 12-25 cartons per minute, and the high-speed model can even achieve a carton erecting and bottom sealing efficiency of 30-60 cartons per minute. Compared with manual carton erecting (only 1-3 cartons per minute), the efficiency is increased by 5-20 times, which can quickly meet the high-speed operation needs of automated production lines and avoid slowing down the overall production rhythm due to the carton erecting process.

The equipment has strong adaptability to cartons of different specifications. Manual adjustment only takes 1-2 minutes to complete when changing carton sizes, without complicated disassembly or reassembly procedures. This feature is especially suitable for multi-category and small-batch production scenarios, which can greatly reduce downtime losses caused by specification switching and ensure the continuity of the production line.

The equipment realizes full-process automatic control through PLC + touch screen, and can complete the integrated operation of carton suction, erecting, forming, bottom folding and sealing without manual intervention in individual processes. At the same time, it is equipped with material shortage pre-alarm, automatic shutdown when out of material and other devices to avoid idling waste, effectively improve the effective operation rate of the equipment and reduce the ineffective working hours of manual attendance.

Manual carton erecting and bottom sealing is not only inefficient, but also requires repetitive actions such as bending over, folding covers and sealing cartons, which is labor-intensive and prone to fatigue damage. One automatic carton erector and bottom sealer can replace 3-5 workers, which can significantly reduce the labor costs of enterprises in the long run; at the same time, it completely frees workers' hands, enabling them to shift from repetitive physical labor to more value-added positions.

The equipment adopts a professional and precision cam continuous system, running without vibration. Combined with the optimized tape applicator design, the tape is attached smoothly and firmly during carton sealing, without problems such as tape skipping, missing sealing and irregular folding angles. The length of the sealing tape fold at both ends of the carton can also be customized according to needs, ensuring the consistency of all packaged finished products and improving the overall appearance and standardization level of product delivery.

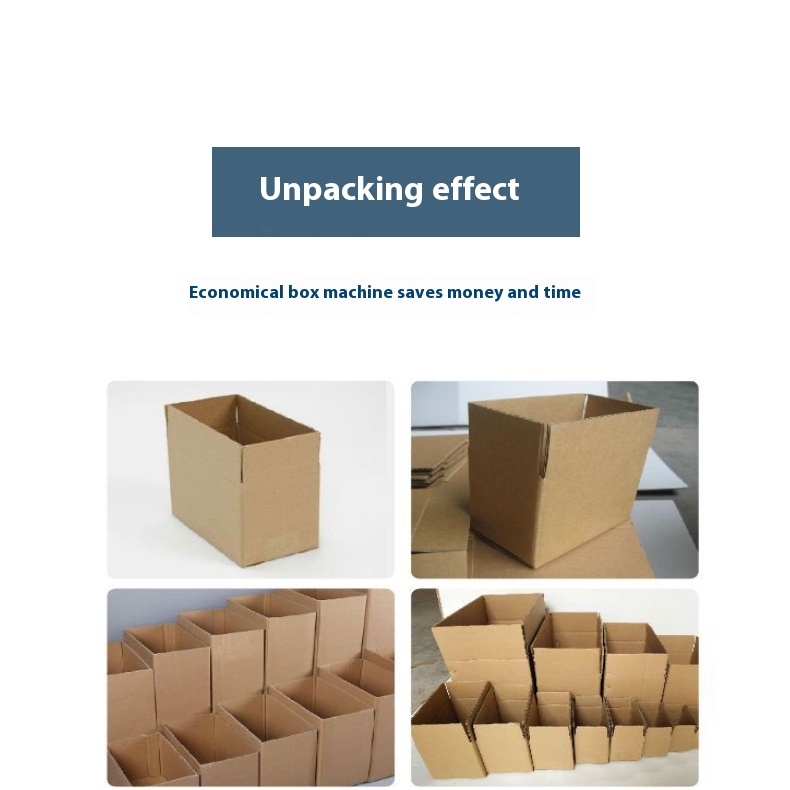

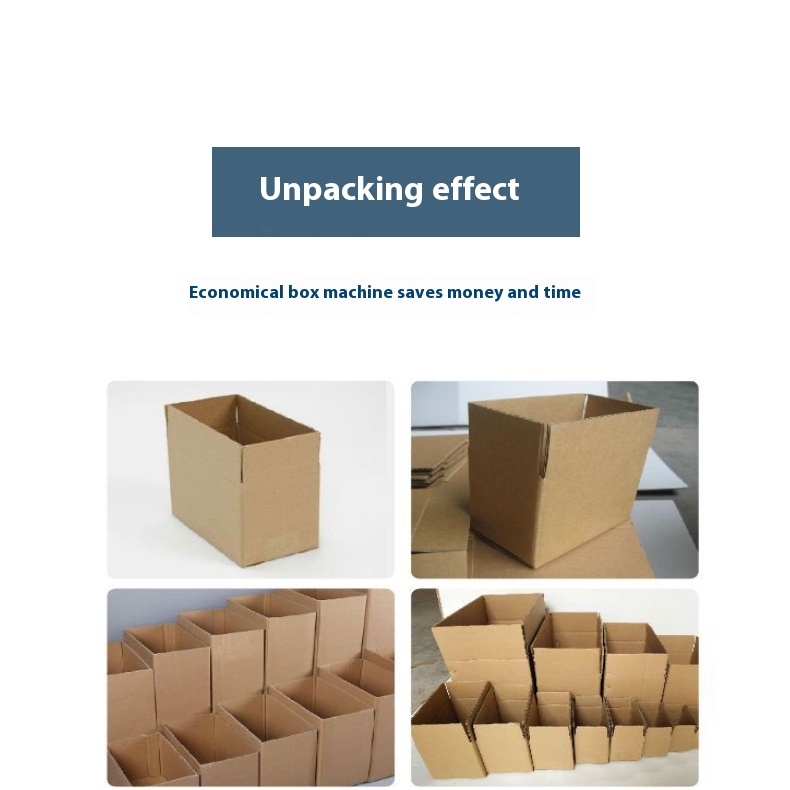

The equipment has a wide range of applicable carton sizes (length 150-550mm, width 150-400mm, height 100-400mm), which can meet the packaging needs of multiple industries such as food, pharmaceuticals, dairy products, beverages, daily chemicals, electronics and tobacco. At the same time, it can seamlessly connect with subsequent automated equipment such as cartoning, case sealing and palletizing to build a complete automated packaging line, helping enterprises achieve large-scale production.

The whole machine is designed with precision, and the machine parts are stable and durable with low failure rate during long-term operation. The operation interface is intuitive and easy to understand, and maintenance does not require professional technicians, only simple cleaning and component inspection need to be carried out regularly. Compared with the uncertainty of manual operation, the stability of the equipment can also reduce the rework rate caused by unqualified packaging, further reducing the comprehensive production cost.