The Automatic Can & Box Tape Sealing Machine is a commonly used packaging equipment that integrates manual operation with mechanical automation, enabling efficient completion of tape sealing for cans and boxes. Operators first place the product-loaded cans/boxes at the designated position of the equipment, then press the start button. The equipment's pneumatic or mechanical mechanism will automatically clamp the cans/boxes. Subsequently, the tape feeding mechanism pulls out the adhesive tape and wraps it around the mouth of the cans/boxes, and finally, the cutting device cuts the tape to finish the sealing process.

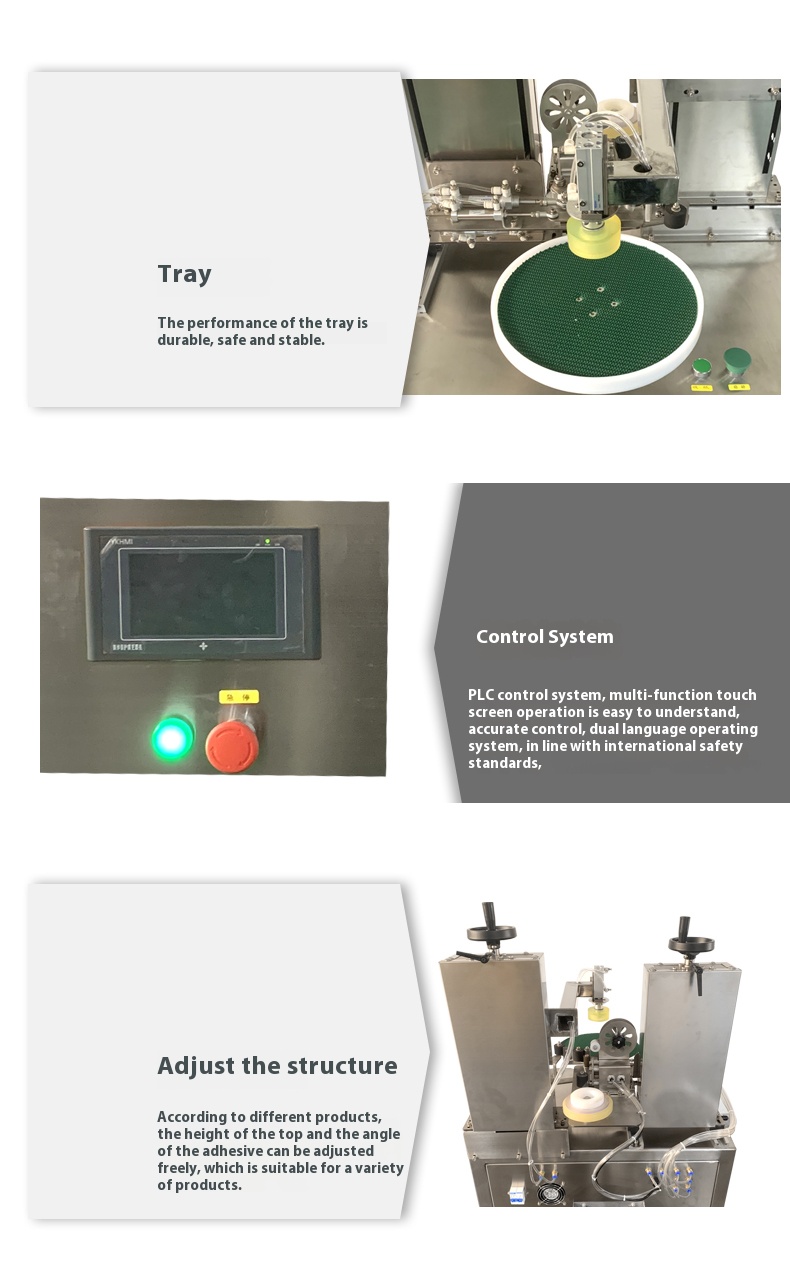

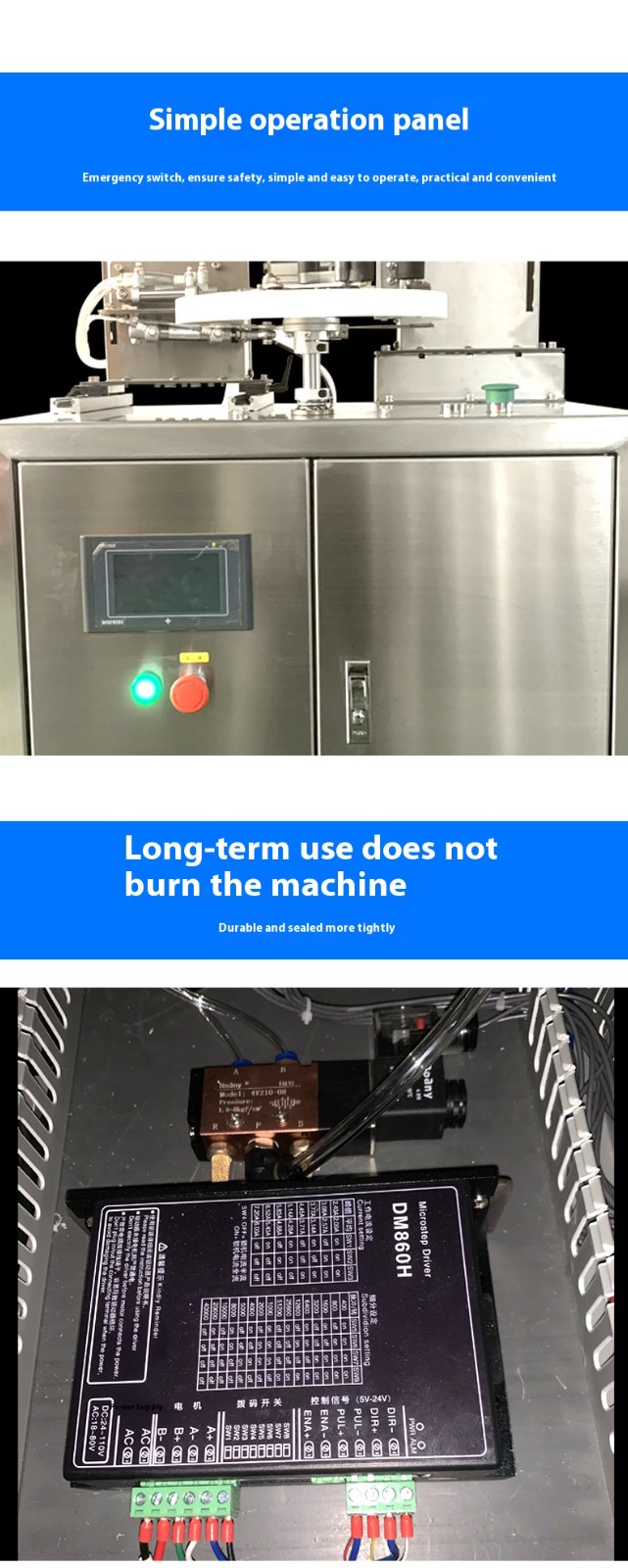

Equipped with an intelligent control system, the machine can be operated by operators after simple training.

Corresponding molds can be replaced according to different sizes and shapes of cans/boxes, featuring multi-purpose functionality.

Ensures the tape adheres flatly and firmly to the mouth of cans/boxes, guaranteeing a reliable sealing effect and effectively extending the product shelf life.

Covers a small floor area, facilitating flexible placement in various production environments. Some models can also be integrated with assembly lines.

Semi-Automatic Can & Box Tape Sealing MachineFor example, the Semi-Automatic Can & Box Tape Sealing Machine from Dongguan Boguan Packaging Industry Co., Ltd. adopts the collaboration of an intelligent control system and pneumatic equipment to complete sealing actions. It requires manual placement of cans/boxes, featuring simple operation, and is suitable for small and medium-sized enterprises (SMEs).

Fully Automatic Can & Box Tape Sealing MachineFor example, the Fully Automatic Can & Box Tape Sealing Machine from Dongguan Zhongbao Intelligent Technology Co., Ltd. can realize a series of automatic actions including can/box conveying, positioning, tape wrapping, and cutting. With high automation and fast sealing efficiency, it is suitable for large-scale production.

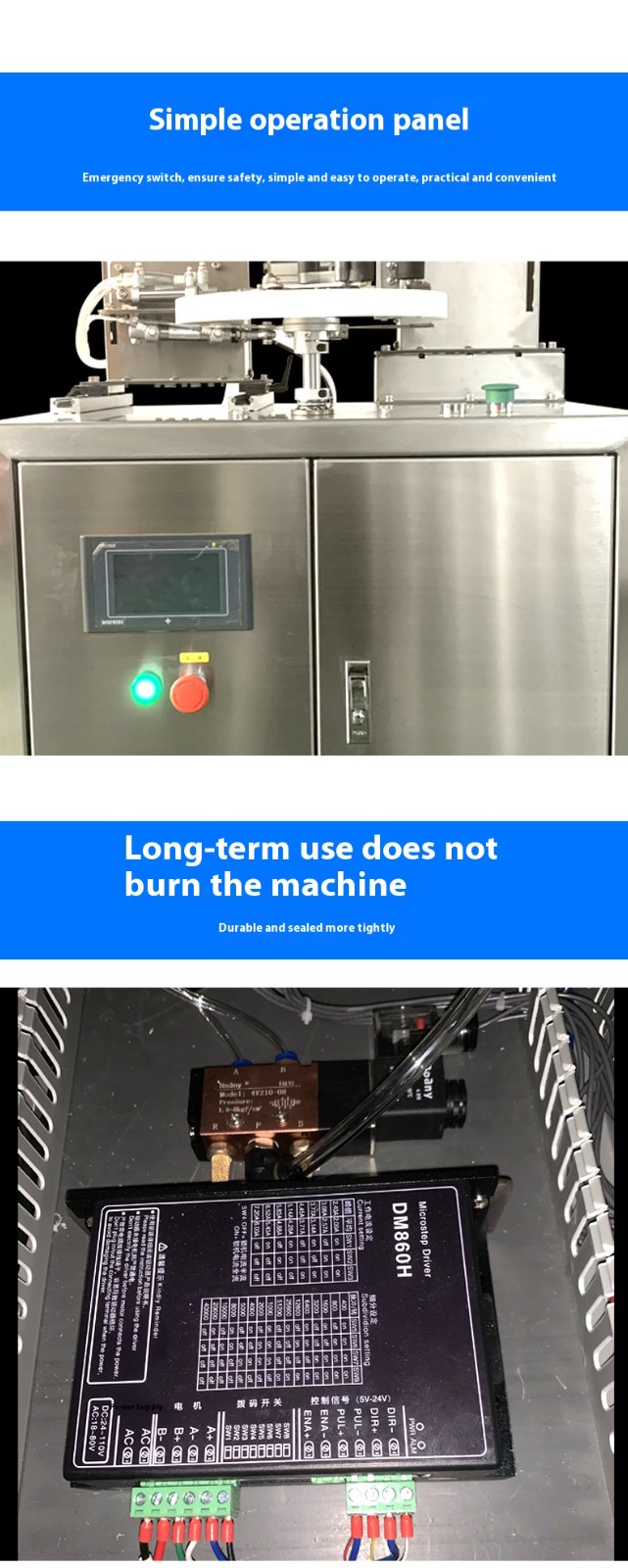

The Can & Box Tape Sealing Machine is applicable to packaging boxes and cans of various materials and shapes, such as iron boxes, tin cans, metal cans, aluminum alloy cans, plastic boxes, and paper boxes. It can be used for sealing chocolate boxes, candy boxes, mooncake boxes, cookie boxes, tea tins, milk powder cans, cosmetic packaging boxes, etc. It ensures the tape wraps smoothly around the can mouth without wrinkles or bubbles, providing excellent sealing performance and effectively extending the product shelf life. Corresponding molds can be replaced or equipment parameters adjusted according to different sizes and shapes of cans/boxes, achieving multi-purpose functionality.

- Easy Operation: Semi-automatic models are simple to operate, while fully automatic models are equipped with an automated operation interface. Operators can master the operation after simple training.

- High Efficiency: The sealing speed is generally 10-30 units per minute, and fully automatic models offer faster speeds, meeting the needs of different production scales.

As a packaging equipment balancing flexibility and practicality, the Automatic Can & Box Tape Sealing Machine has become the mainstream choice in food, chemical, cosmetics, and other industries, thanks to its adaptability to small and medium production capacities, easy operation, and stable sealing performance.

Sealing Speed: Adapted to Small & Medium Production Needs

- Standard Speed: 10-30 units/minute (adjustable according to can/box size and tape type)

- Actual Capacity: Based on 8 working hours per day, the daily capacity of a single device can reach 4,800-14,400 units (deducting material replacement and adjustment time, the actual capacity is about 70%-80% of the theoretical value)

- Speed Advantage: Compared with manual sealing (3-5 units/minute), the efficiency is improved by 2-6 times. No need to wait for the entire line to operate; small-batch orders can be quickly launched, reducing production waste.

Adjustment Efficiency: Quick Adaptation to Multi-Specification Products

- Size Adjustment: For can diameters of Φ40-350mm and sealing heights of 50-220mm, manual/pneumatic adjustment only takes 3-5 minutes without professional technicians.

- Mold Change Efficiency: Equipped with a quick mold change device, replacing adaptive molds for different specifications of cans/boxes only takes 10-15 minutes, meeting the needs of multi-category production.

- Tape Replacement: Open tape installation design allows roll change in ≤2 minutes, reducing downtime.

Operating Efficiency: Stable, Reliable, and Low Failure Rate

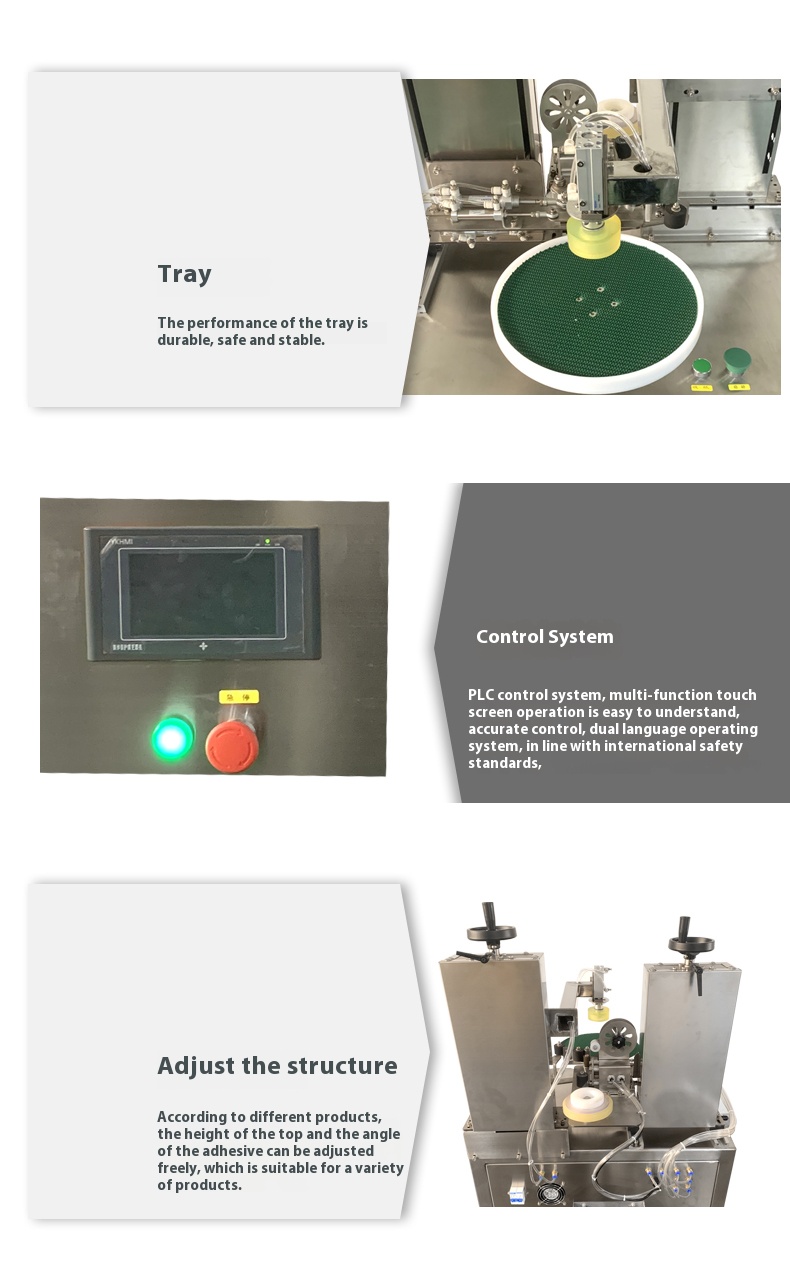

- Equipment Utilization: Core components are made of industrial-grade materials, with a continuous operation failure rate of ≤1% and an annual effective working time of over 3,000 hours.

- Maintenance Cost: Daily maintenance only requires basic operations such as cleaning and lubrication, with monthly maintenance time ≤2 hours and a maintenance cost as low as 0.5% of the total equipment price per year.

Low Operation Threshold and Controllable Labor Costs

- Ultra-Simple Operation: Only 1 operator is needed to complete the 3-step process of "placing the can - starting the machine - taking the can". No professional skill training is required; new operators can get started in 1 hour.

- Labor Optimization: Compared with fully automatic equipment that requires special personnel for monitoring, semi-automatic models can be managed by one employee for 2-3 machines, reducing labor input.

- High Fault Tolerance: Equipped with safety devices such as emergency stop and anti-misoperation functions, the machine has a low operation error rate, reducing product loss caused by human errors.

Strong Adaptability to Meet Multi-Scenario Production

- Can/Box Compatibility: Supports various materials including iron boxes, tin cans, plastic cans, and paper boxes. Round, square, and special-shaped cans/boxes are all adaptable (by replacing corresponding molds).

- Industry Coverage: Widely used in food (mooncake boxes, tea tins, candy boxes), chemical (small reagent cans, paint cans), cosmetics (face cream jars, essential oil boxes), pharmaceutical (Chinese herbal medicine cans, health product boxes) and other industries. Especially suitable for enterprises with multi-category and small-batch production.

- Flexible Placement: Compact design with a floor area of ≤1㎡, can be flexibly placed in workshops, warehouses, or beside assembly lines without large-scale modification of the production environment.

Stable Sealing Quality to Ensure Product Safety

- Sealing Effect: Adopts a pneumatic pressure wheel design, ensuring uniform tape wrapping and adjustable tension. No wrinkles or bubbles, effectively preventing moisture, oxidation, and leakage, and extending product shelf life.

- High Consistency: Mechanical automation executes the sealing process, avoiding problems such as uneven force and tape deviation in manual sealing. The qualified rate of product sealing is ≥99.5%.

- Tape Compatibility: Supports various tape materials such as BOPP, cloth-based, and kraft paper. The width can be adjusted according to needs (usually 20-50mm), meeting the packaging and protection needs of different products.

Strong Stability and Low Operation & Maintenance Costs

- Durable Material: The machine body is made of stainless steel, featuring rust and wear resistance, with a service life of 8-10 years.

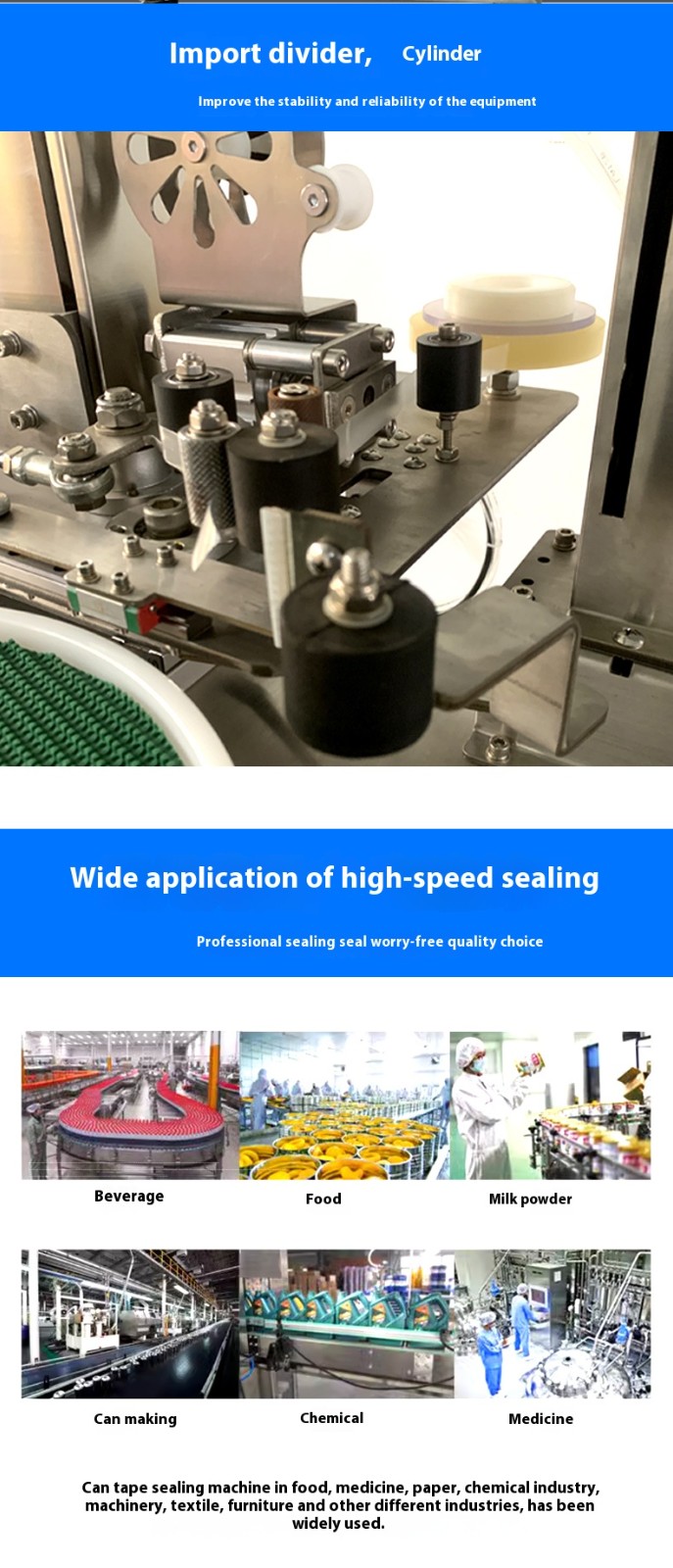

- Core Components: Key components such as motors and cylinders are selected from well-known brands, with low failure rates and easy procurement of spare parts.

The Automatic Can & Box Tape Sealing Machine is particularly suitable for scenarios such as small and medium production capacity enterprises, multi-category production, limited space, and controlled budgets. It not only solves the problems of low efficiency and poor quality in manual sealing but also avoids the high investment and high maintenance pressure of fully automatic equipment. It is the optimal solution balancing "efficiency, cost, and flexibility", laying the foundation for enterprises to achieve large-scale production.