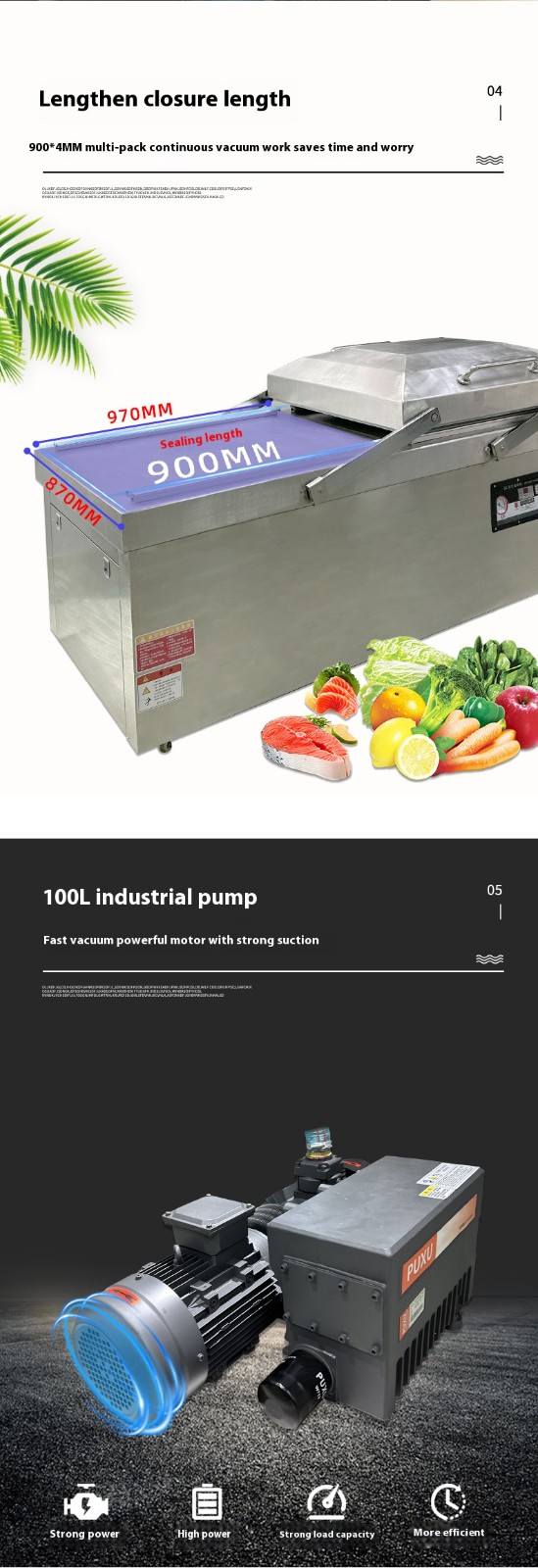

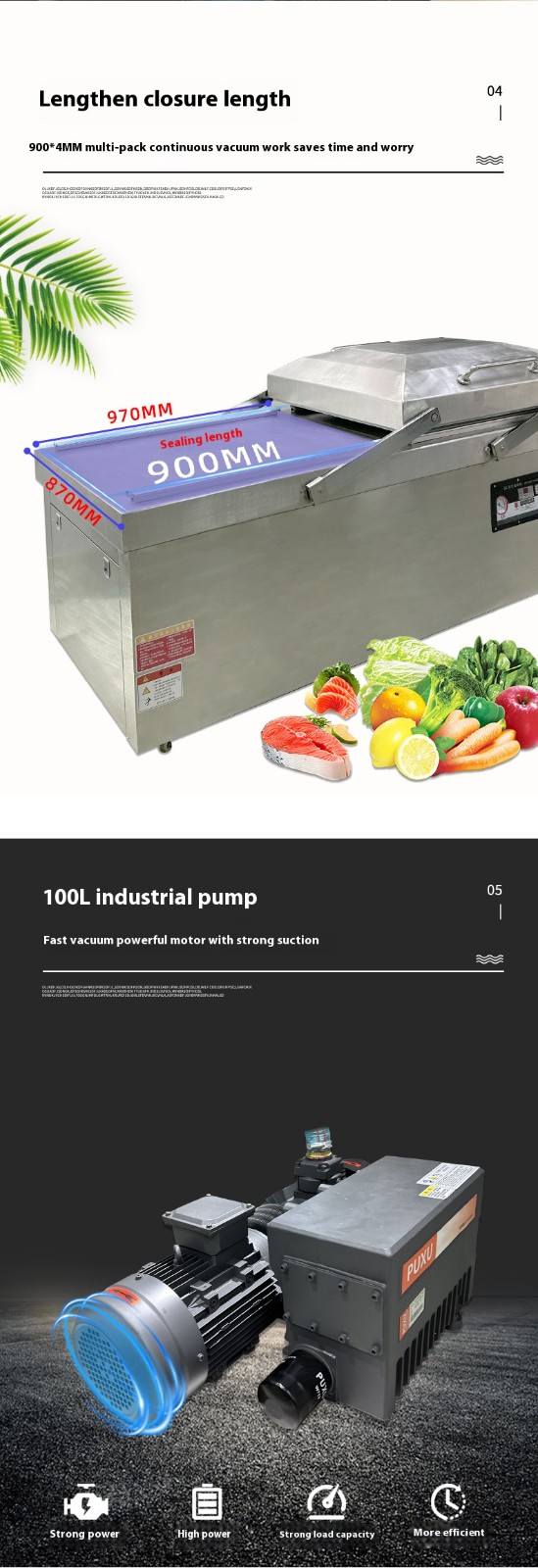

This is the foundation for determining efficiency. The faster the pumping speed of the vacuum pump (unit: m³/h), the shorter the time to reach the target vacuum level, and the subsequent reduction in the single packaging cycle.

The volume of the vacuum chamber must match the product. If the product is much smaller than the vacuum chamber, it will cause space waste and extend the vacuuming time. If the product is too large, frequent adjustments to its placement will also affect efficiency.

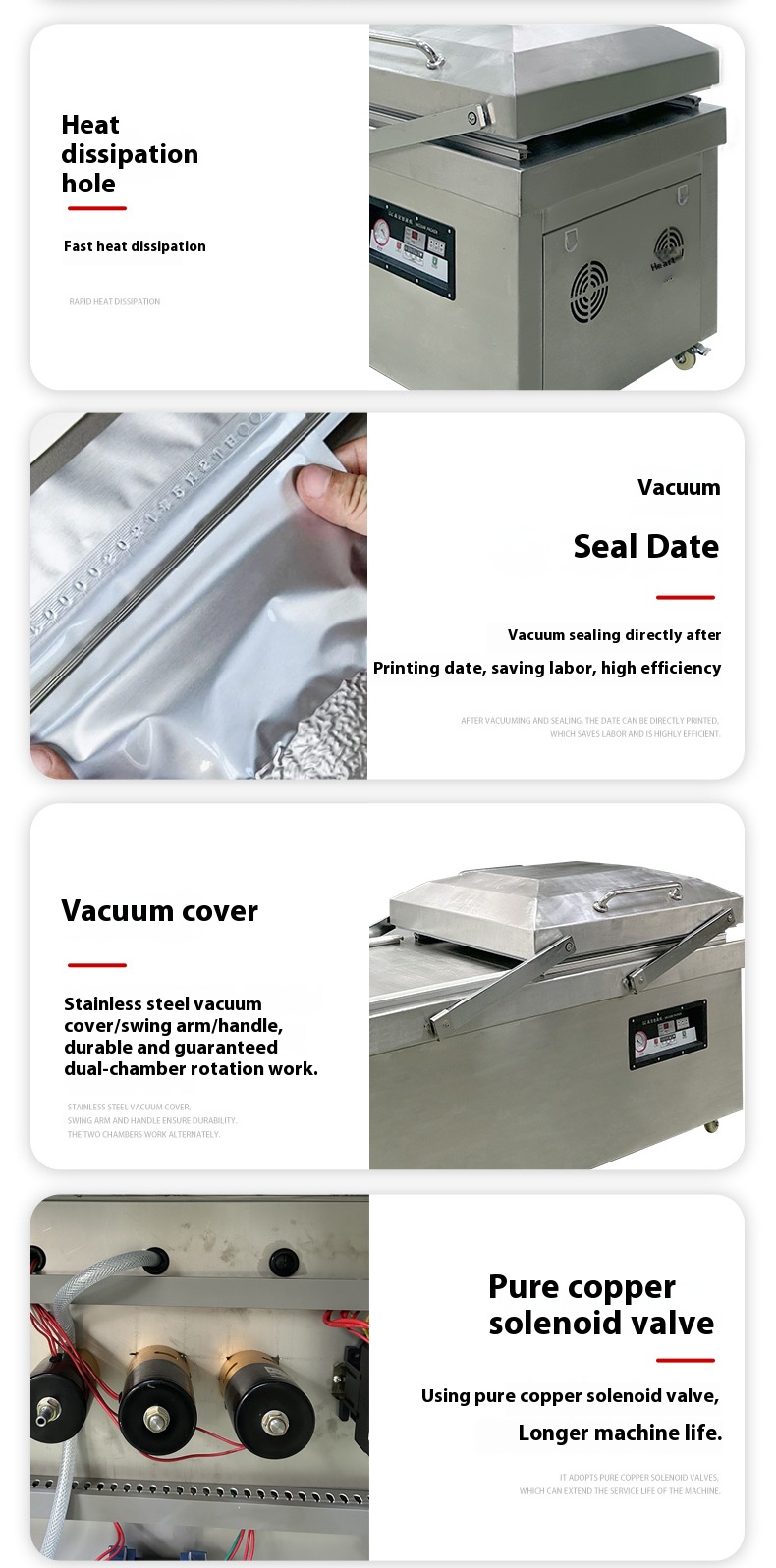

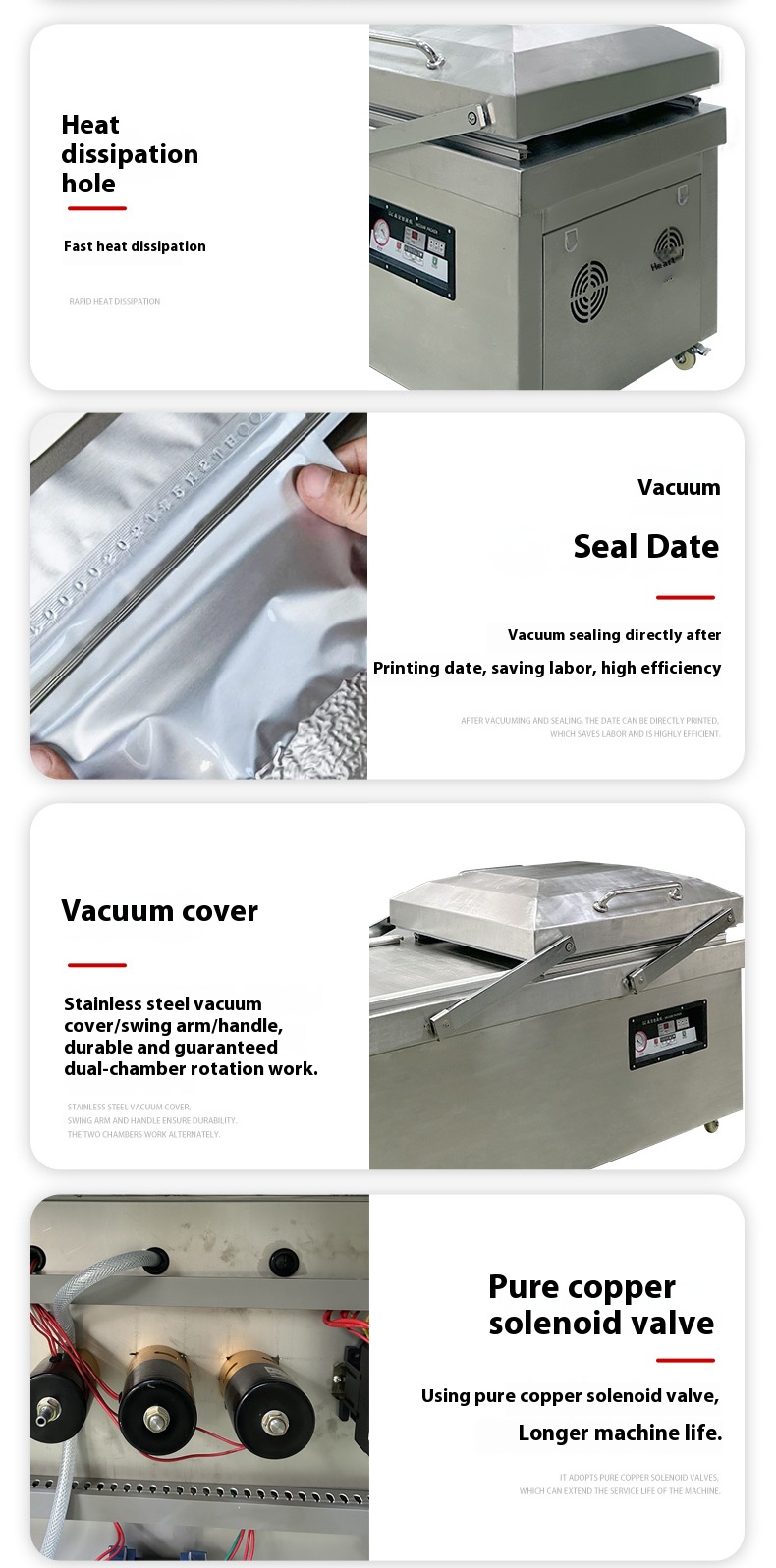

Insufficient heating power or unreasonable seal width will lead to prolonged sealing time. In even worse cases, it may result in insecure seals that require rework, directly reducing overall efficiency.

- Operator Proficiency: The speed at which operators place products, smooth bag openings, and remove finished products directly affects the alternating efficiency of the two vacuum chambers. Inexperienced operators may increase "idle waiting" time.

- Loading and Unloading Coordination: Without supporting automated feeding equipment, manual loading and unloading will become an efficiency bottleneck. The ideal scenario is that while one vacuum chamber is in operation, the other has already completed loading to achieve seamless connection.

- Rationality of Parameter Settings: Overly conservative settings for parameters such as vacuum level, sealing time, and cooling time (e.g., excessive vacuuming, overly long cooling) will add unnecessary process time.

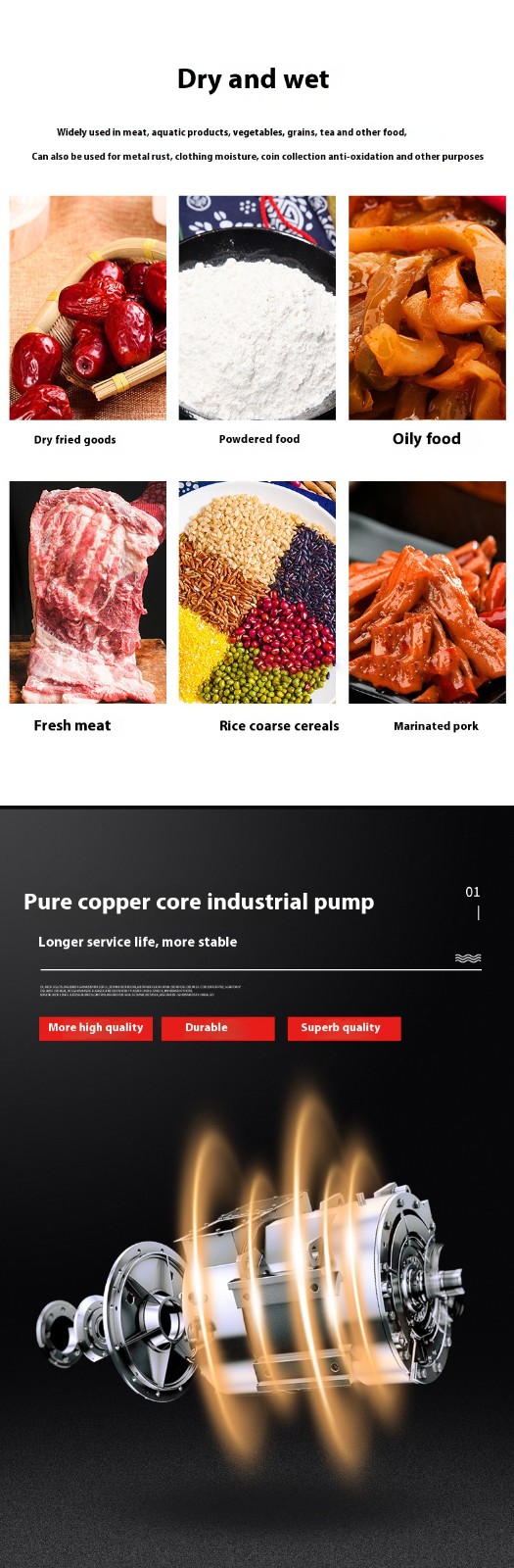

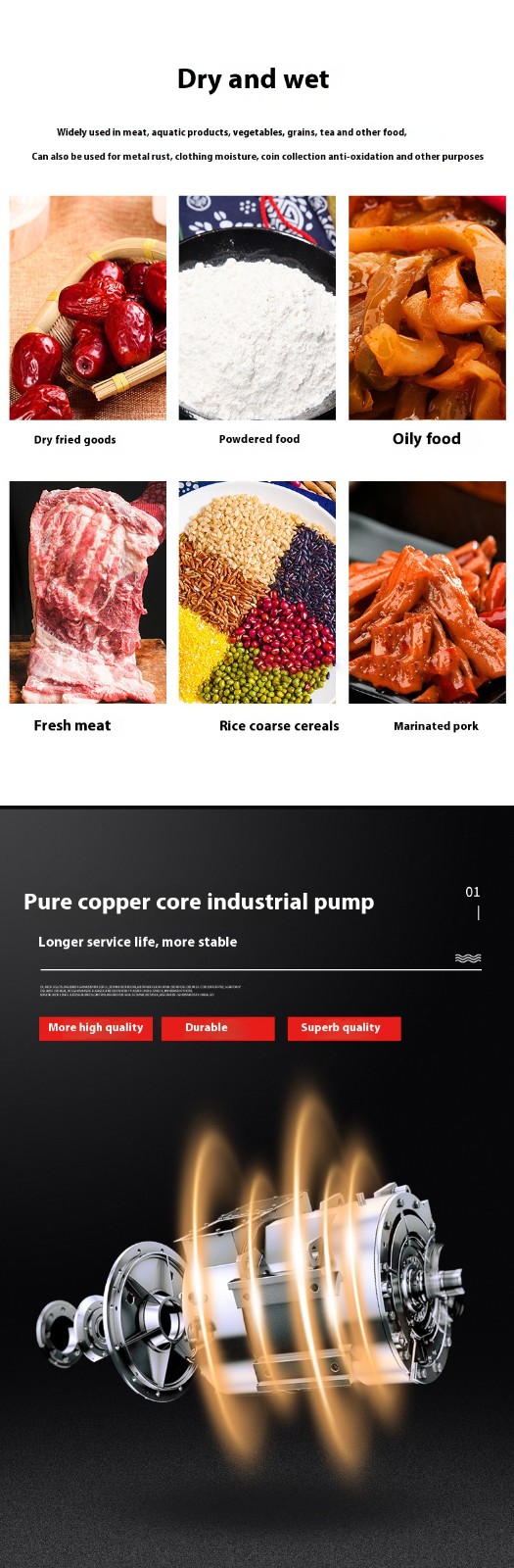

- Material Form: When packaging liquid or powder materials, the operation speed must be slowed down and leak-proof functions (such as inclined vacuum chambers) activated. Otherwise, it is easy to contaminate the equipment or cause packaging failure, indirectly reducing efficiency.

- Packaging Bag Specifications: Using packaging bags of uniform size and suitable material can reduce the time spent adjusting the equipment. If the sizes of packaging bags are inconsistent, frequent fine-tuning of the vacuum chamber or sealing position is required, leading to a significant drop in efficiency.