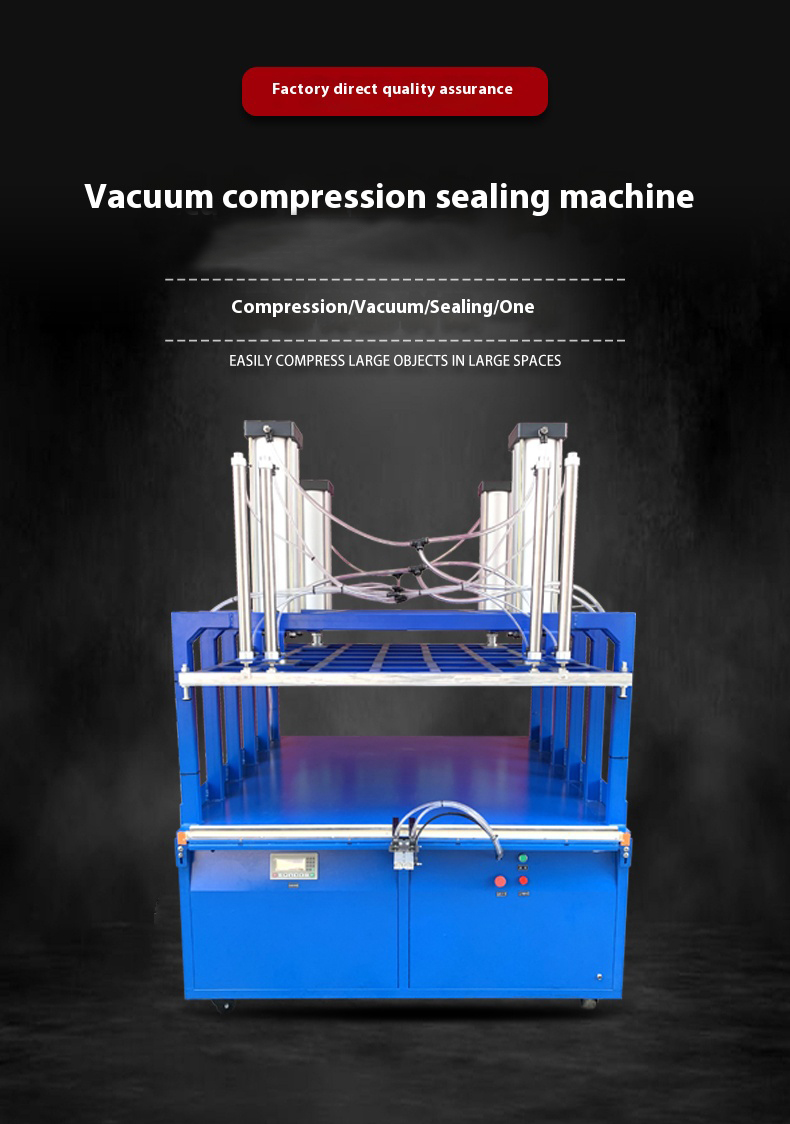

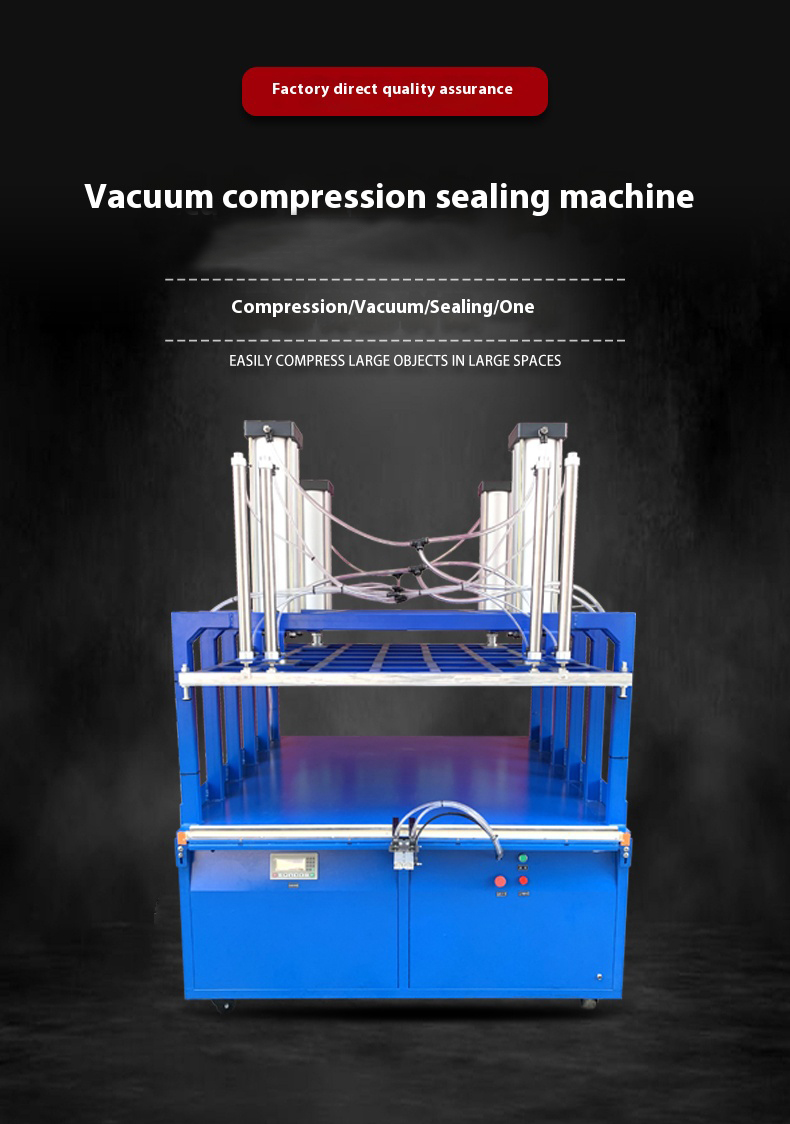

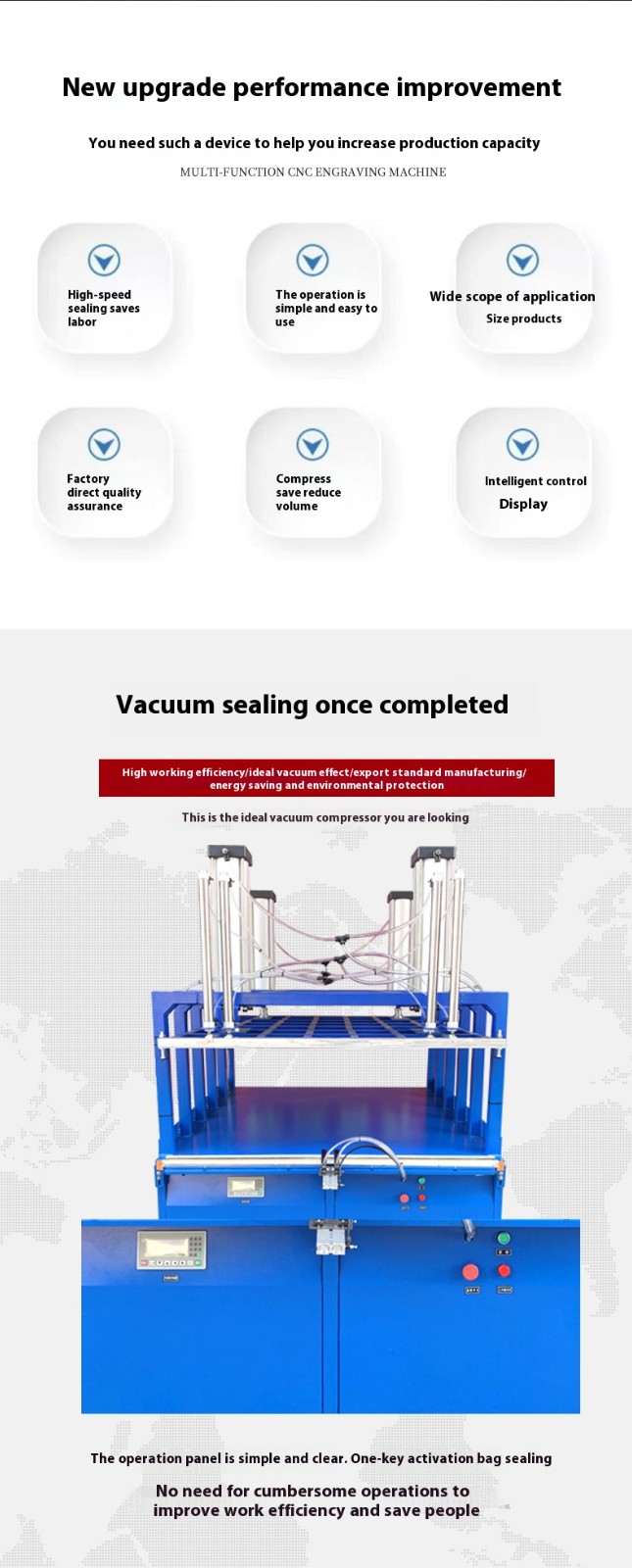

A vacuum compression sealer is a device used for vacuum packaging and sealing items. It can effectively extend the shelf life of items and reduce packaging volume, and is widely used in various industries such as food, home textiles, and electronics.

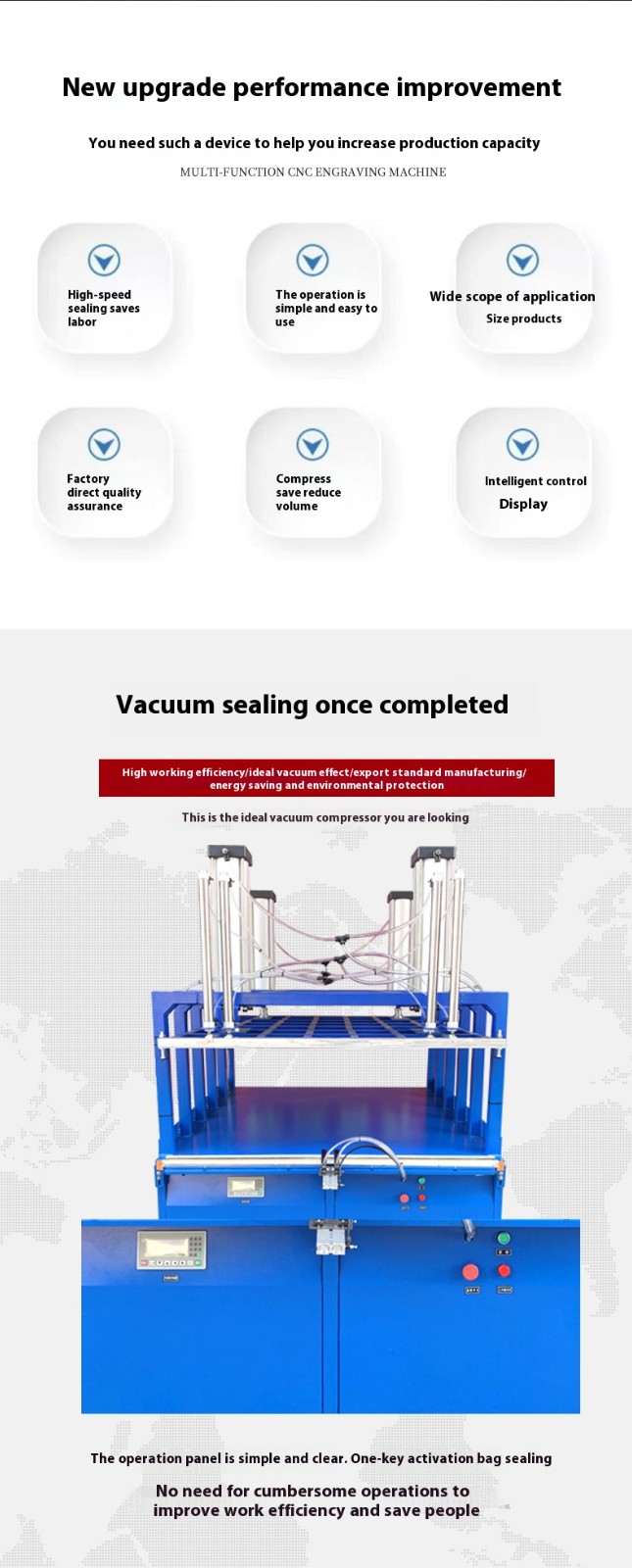

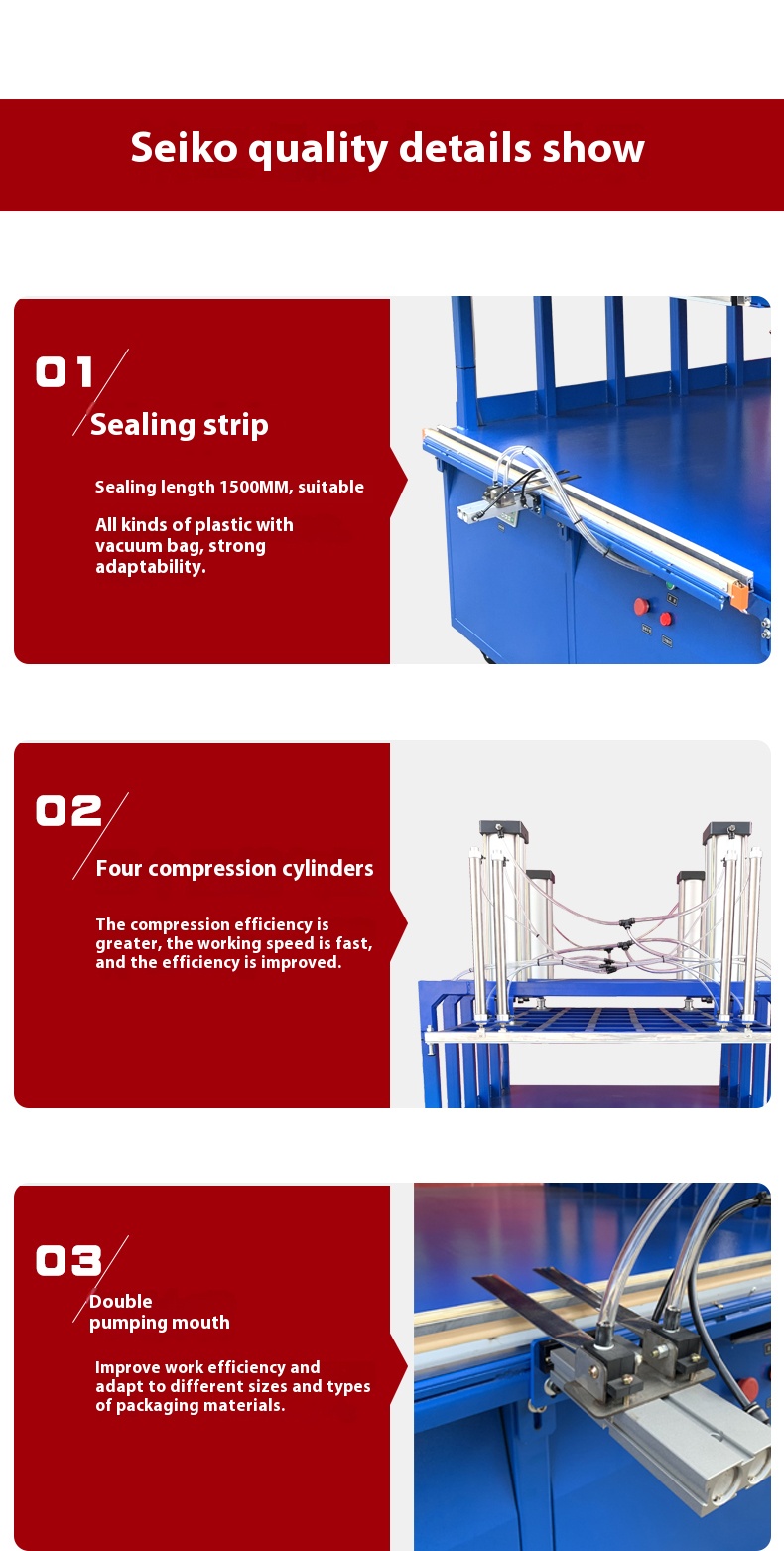

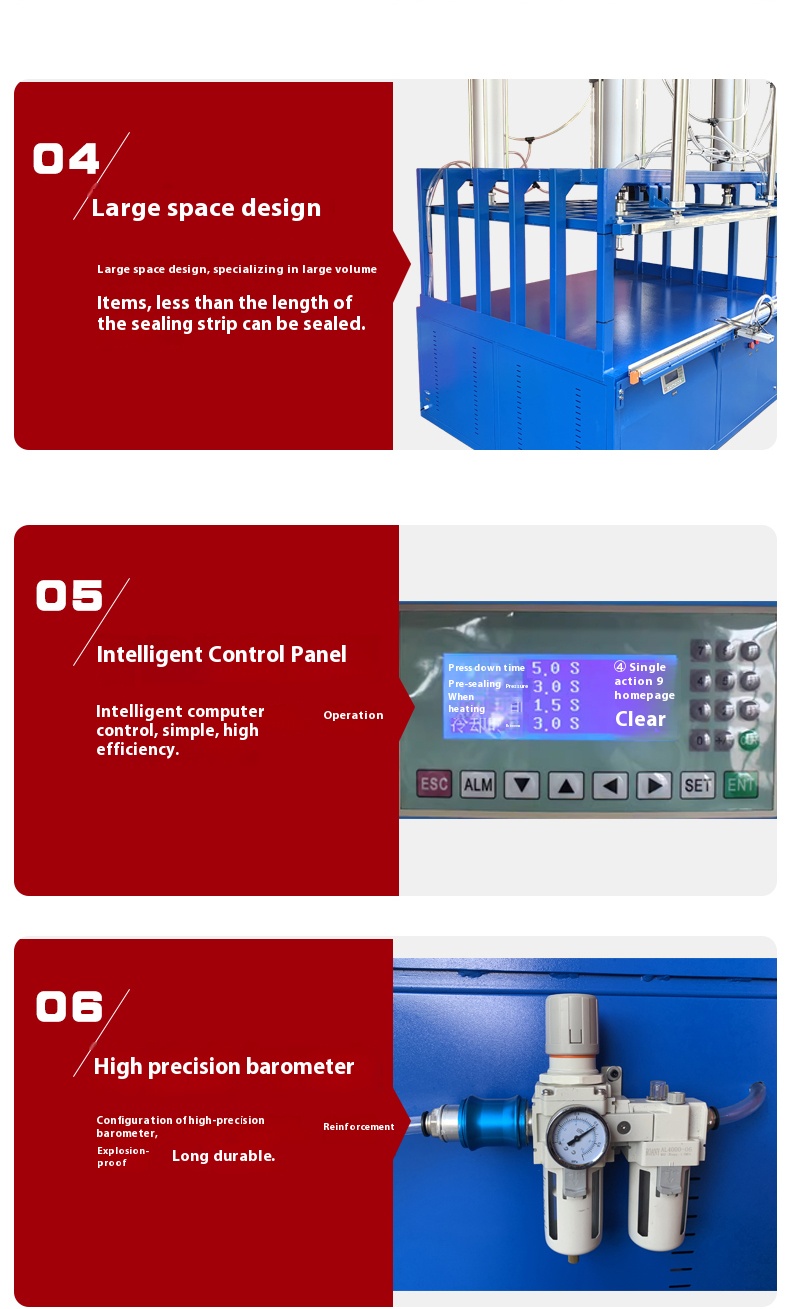

Operating procedures vary slightly among different models of vacuum compression sealers, but the general steps are as follows: First, place the items to be packaged into a packaging bag and tidy up the bag opening. Then, put the bag opening into the sealing groove of the sealer; for external suction models, pull out the air suction nozzle and fit it over the packaging bag. Next, press the vacuum button to start air suction; once the required vacuum level is reached, the air suction nozzle will retract (this is automatically completed by some models). Finally, press the relevant button again to perform the sealing operation, and after cooling, the packaged item can be taken out.

- Isolate oxygen to inhibit microbial activity. Most bacteria and molds rely on oxygen for growth, and a vacuum environment can significantly slow down their reproduction rate to prevent items from spoiling.

- Reduce oxidation reactions. Oxygen can cause food to oxidize, discolor, and lose nutrients, and also cause metal parts to rust. Vacuum packaging can effectively block this process.

- Prevent cross-contamination. The sealed state can isolate external dust, insects, rodents, and odors, maintaining the original quality of the items.

- Expel air to compress bulky items. For home textile products such as down jackets and quilts, or bulky materials like plush toys and sponges, the volume can be reduced by 50%-80% after the internal air is pumped out.

- Optimize storage space. Compressed packaging is more neat, allowing efficient use of spaces such as wardrobes, suitcases, and storage rooms, which is especially suitable for home storage and travel carrying.

- Lower transportation costs. Reduced volume means more goods can be loaded in a single shipment, indirectly reducing logistics costs and damage caused by extrusion during transportation.

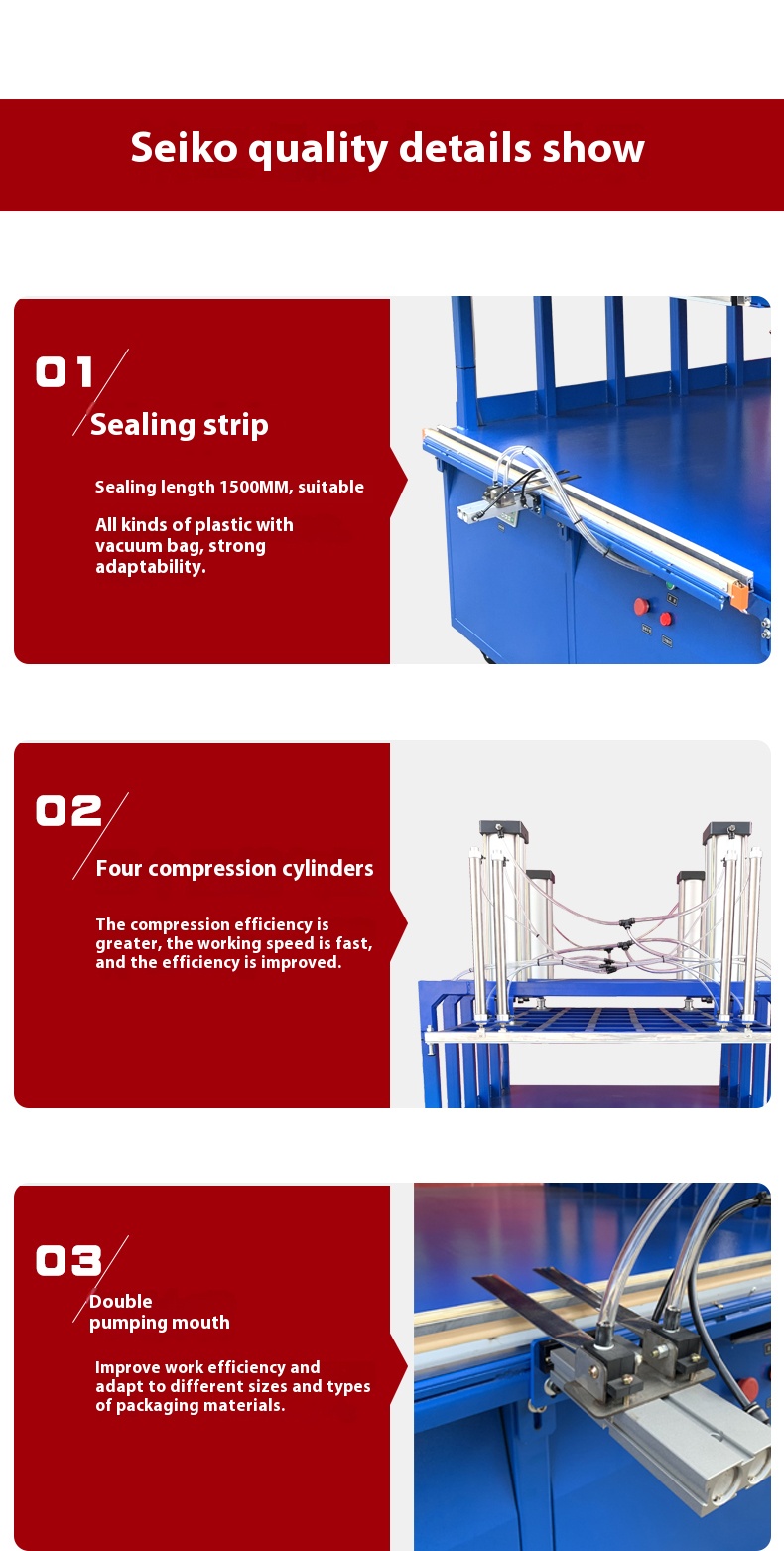

- Sealing Size: Choose an appropriate sealing length and width based on the size of the commonly used packaging bags to ensure it meets packaging needs.

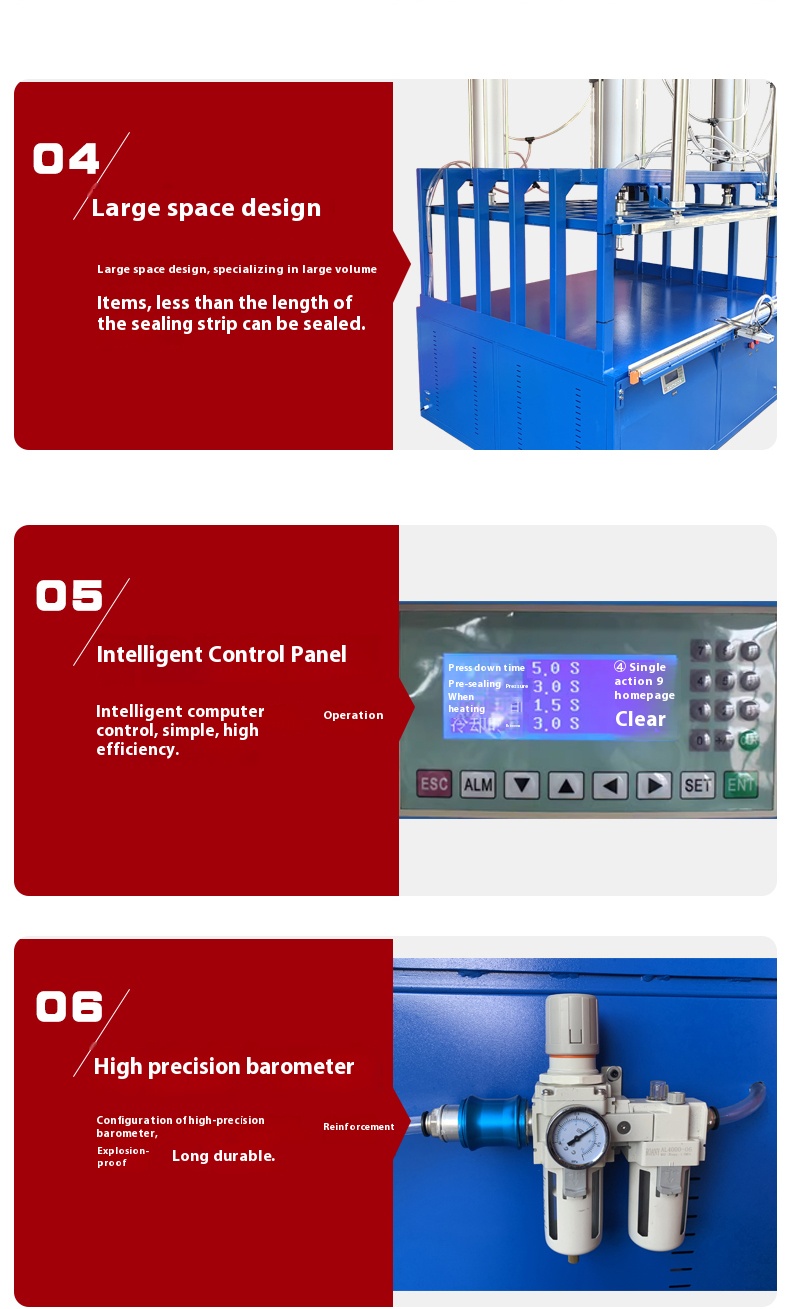

- Vacuum Level: The higher the vacuum level, the better the item preservation effect. For items that require long-term storage or have high vacuum requirements, select a model with a vacuum level of up to -80kPa or lower.

- Sealing Method: Common methods include heat sealing and cold sealing. Heat sealing is widely used, while cold sealing is suitable for some temperature-sensitive packaging materials. The selection should be based on the characteristics of the packaging materials.

- Automation Level: Models with high automation level are equipped with a conveying system, which can realize continuous packaging, improve production efficiency, and are suitable for enterprises with mass production.