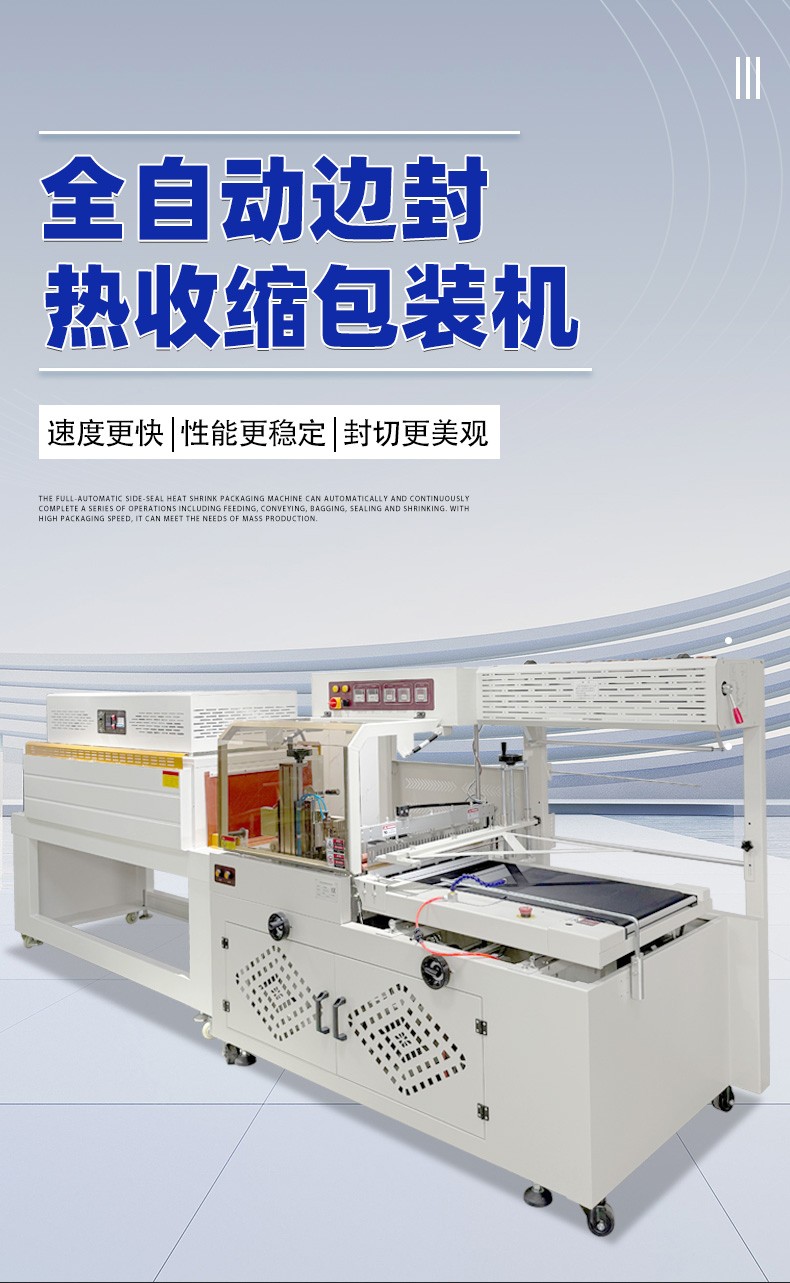

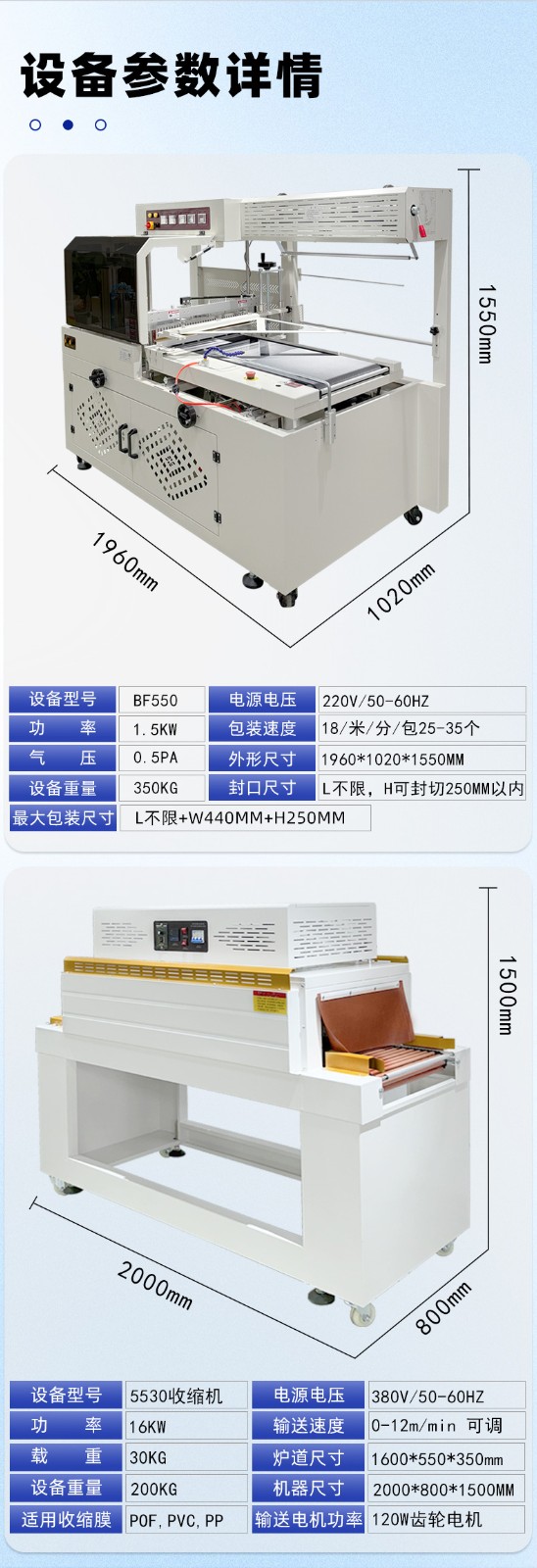

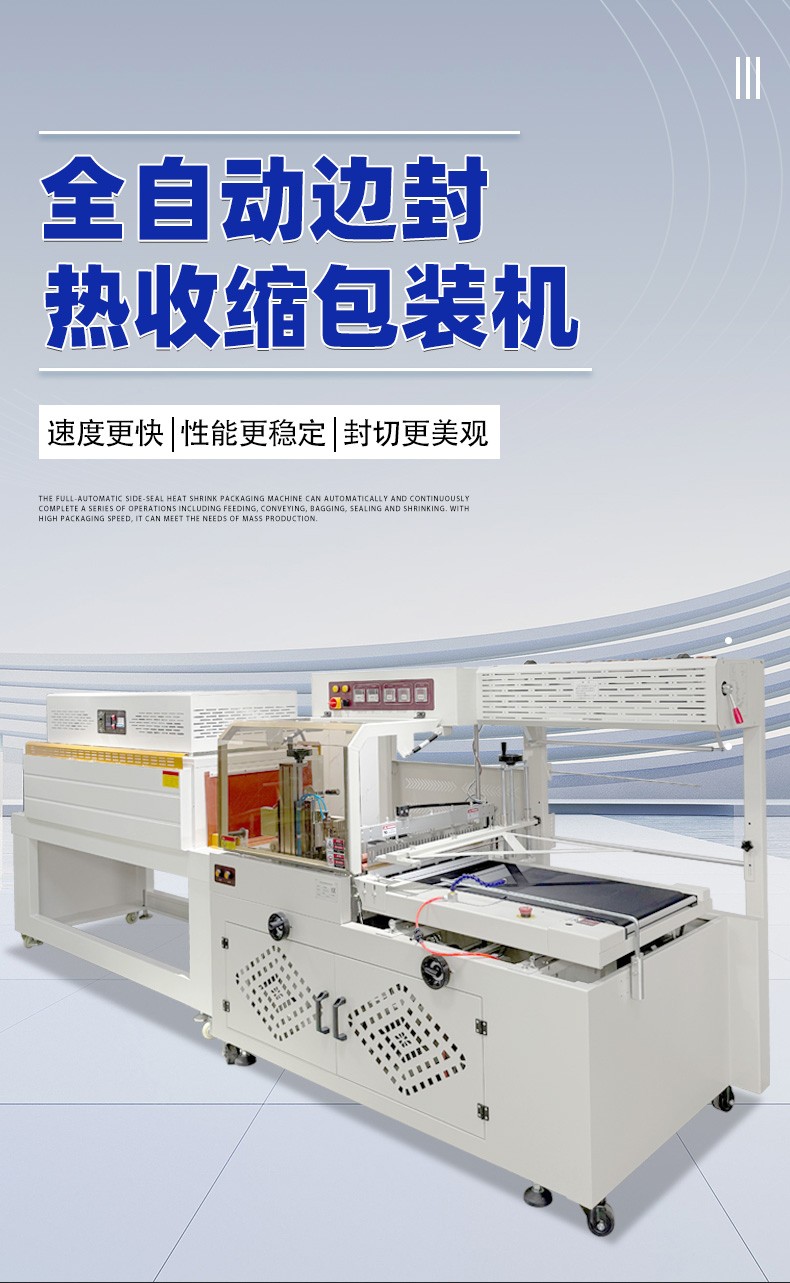

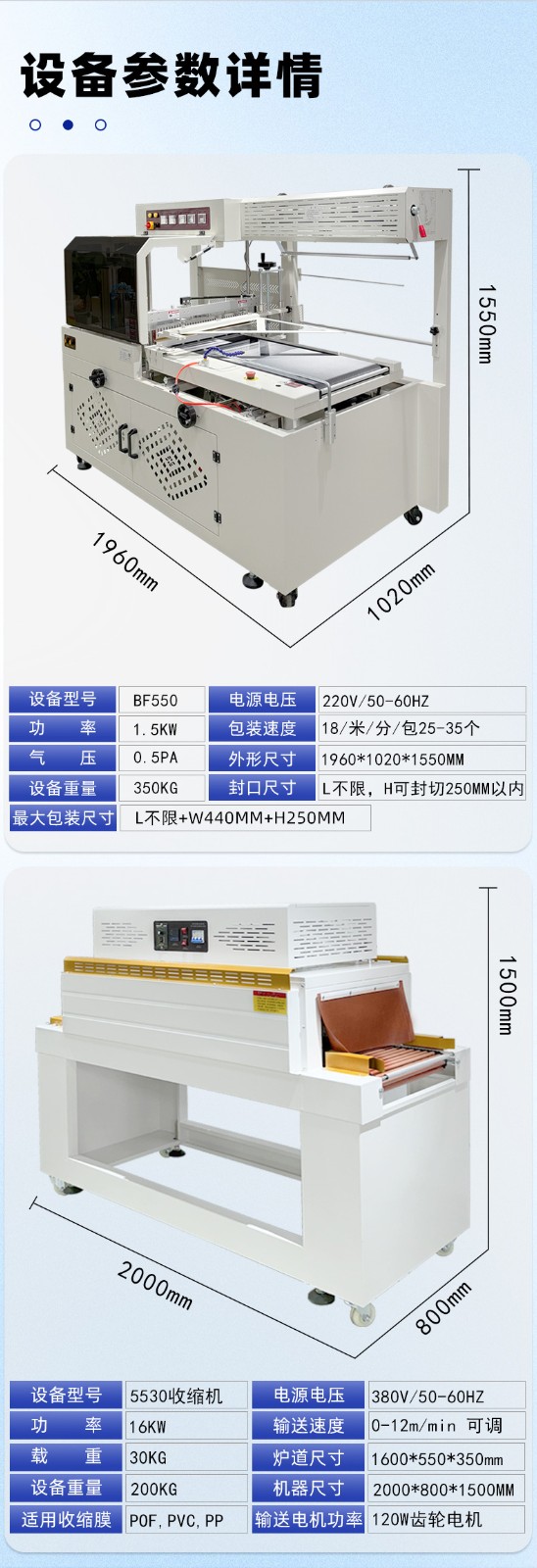

The automatic side sealing heat shrink packaging machine can improve efficiency while ensuring the sealing machine achieves centered and aesthetic packaging by optimizing equipment performance, precisely controlling the sealing and cutting position, and other methods. The details are as follows:

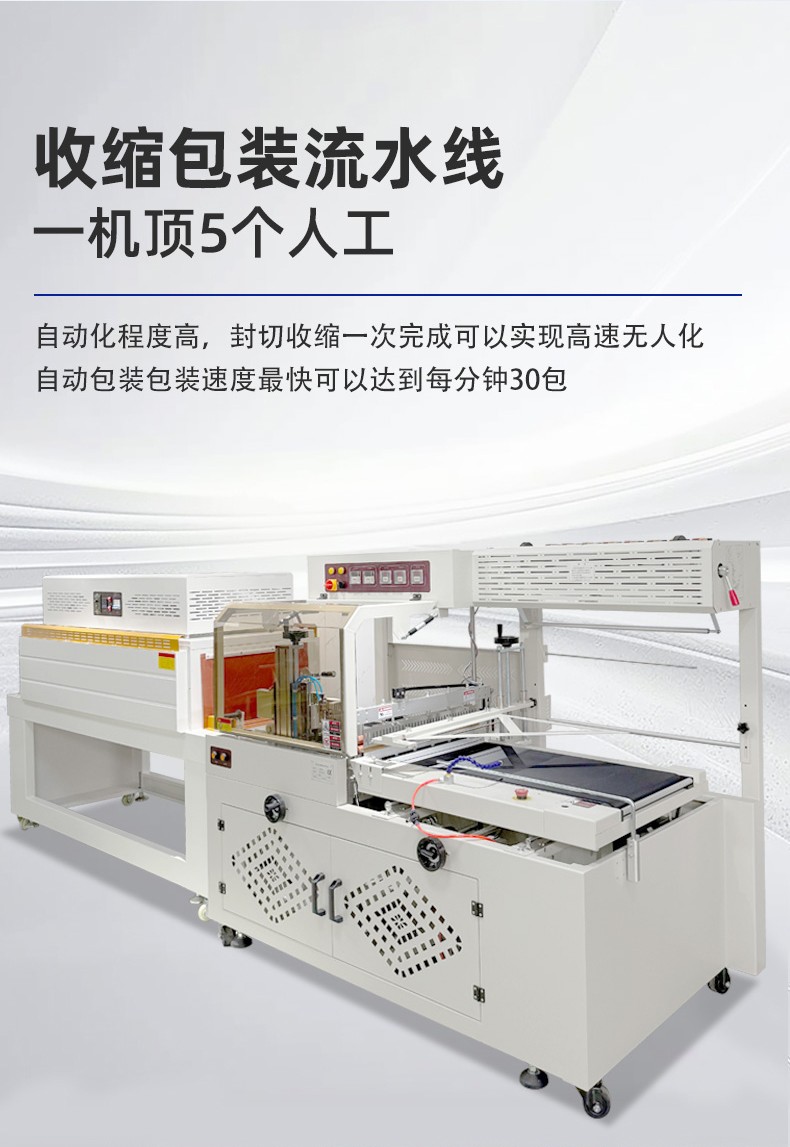

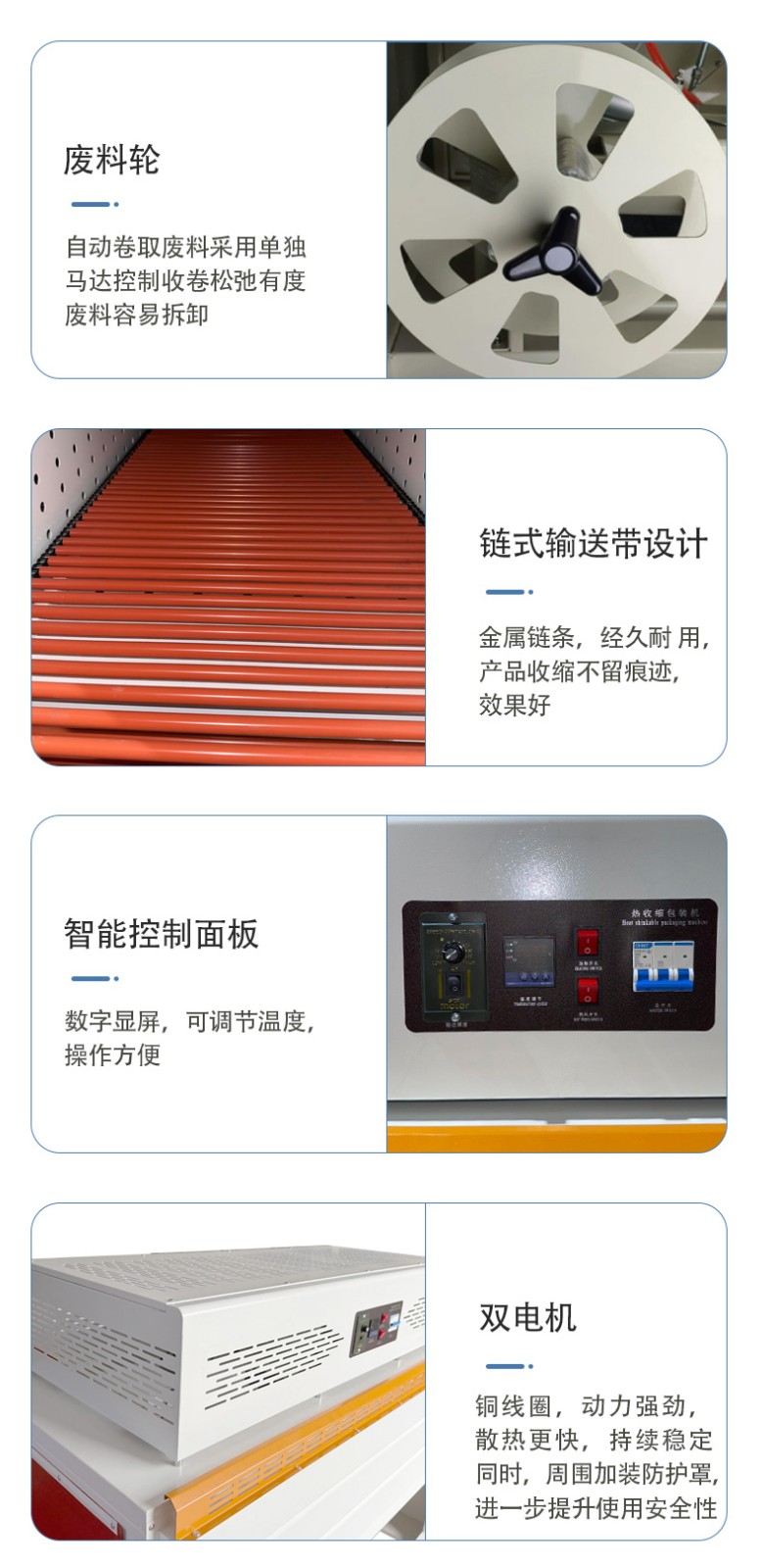

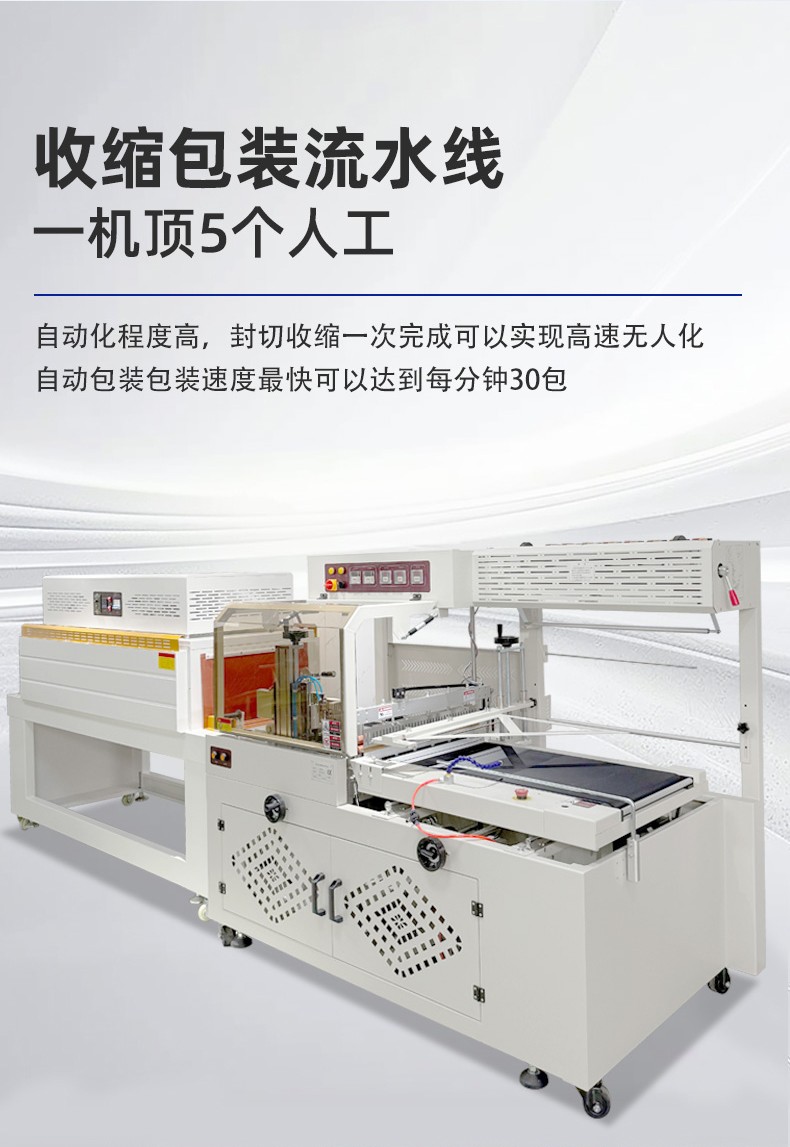

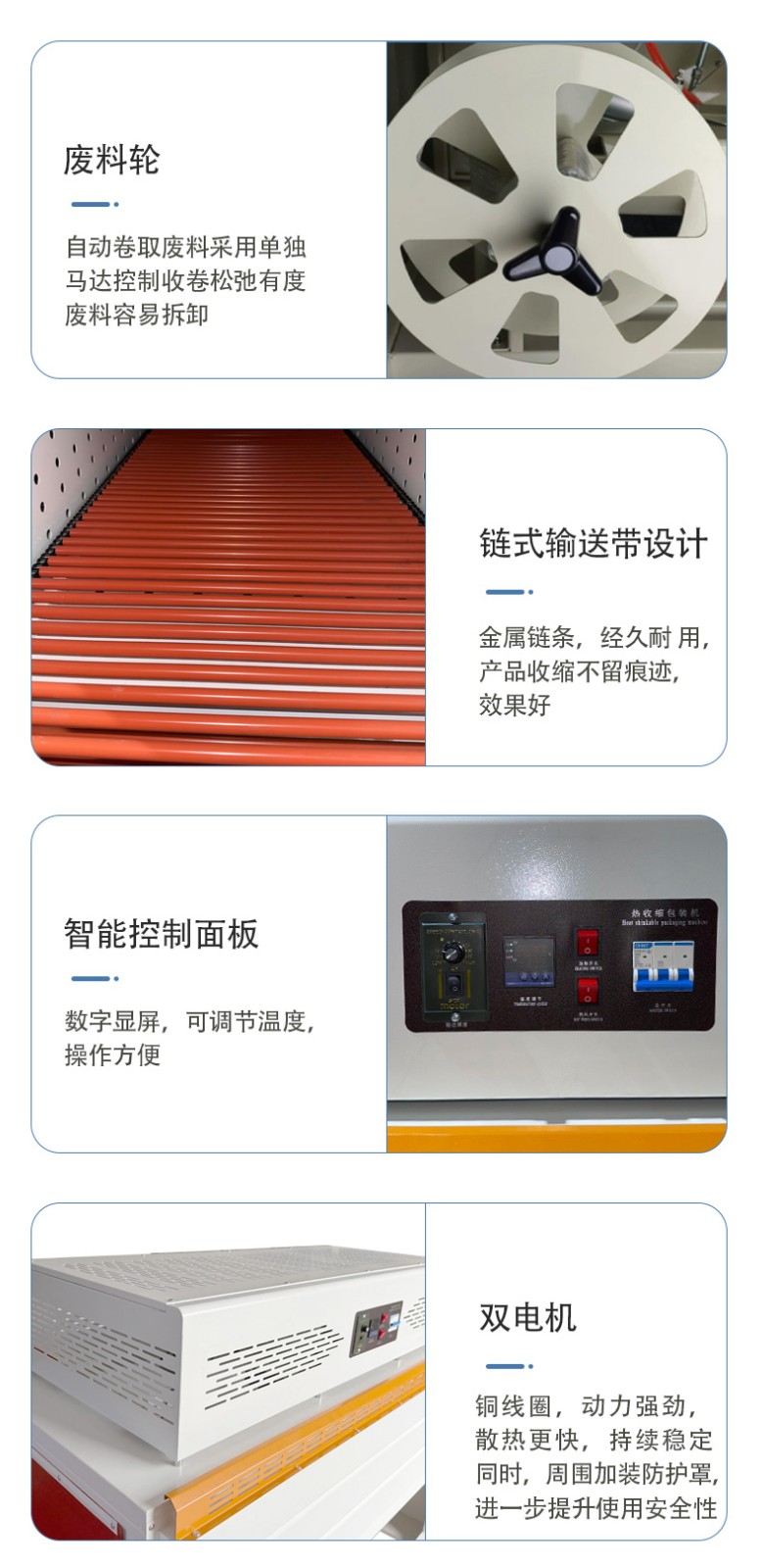

- Fully Automated Process: Adopting an integrated full-process design, it can realize a fully automated assembly line operation from feeding, conveying, bagging to sealing and shrinking, without manual intervention. This reduces labor costs and operation time, and improves overall packaging efficiency.

- Intelligent Control System: Through the combination of PLC (Programmable Logic Controller) and photoelectric detection technology, the equipment can accurately adjust the film length and sealing-cutting position. The addition of a timer further optimizes the action sequence, avoids time waste caused by rhythm disorder, and ensures the efficient and stable progress of the packaging process.

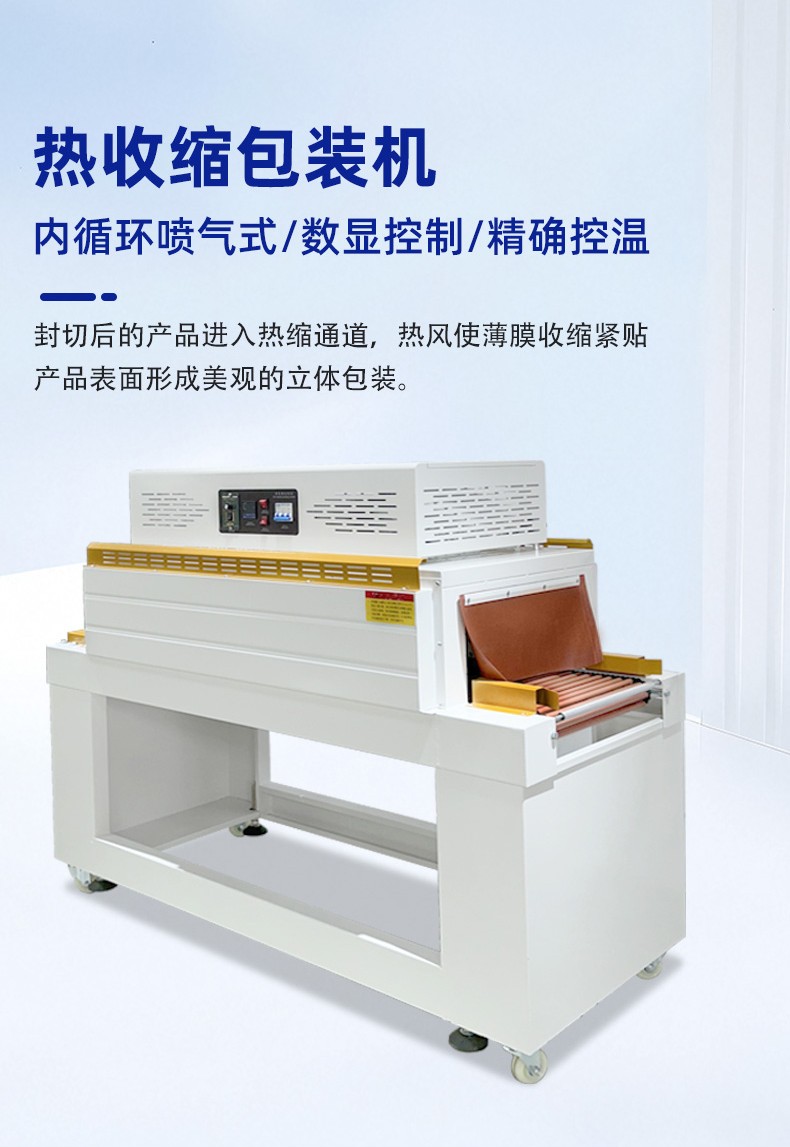

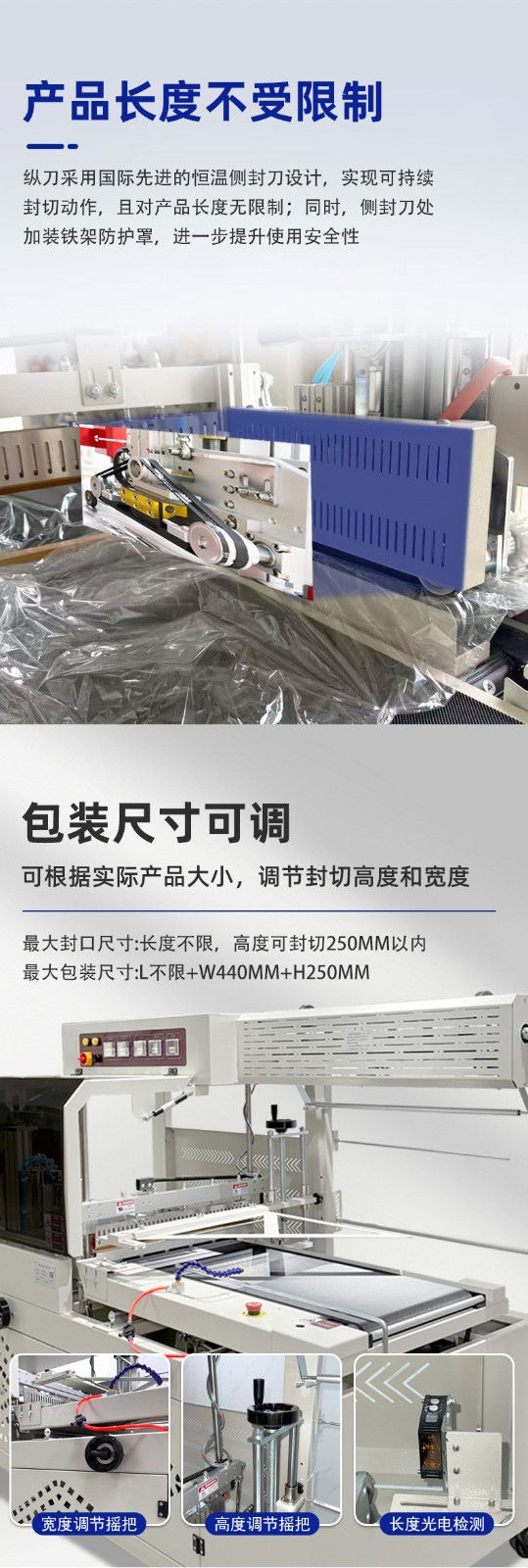

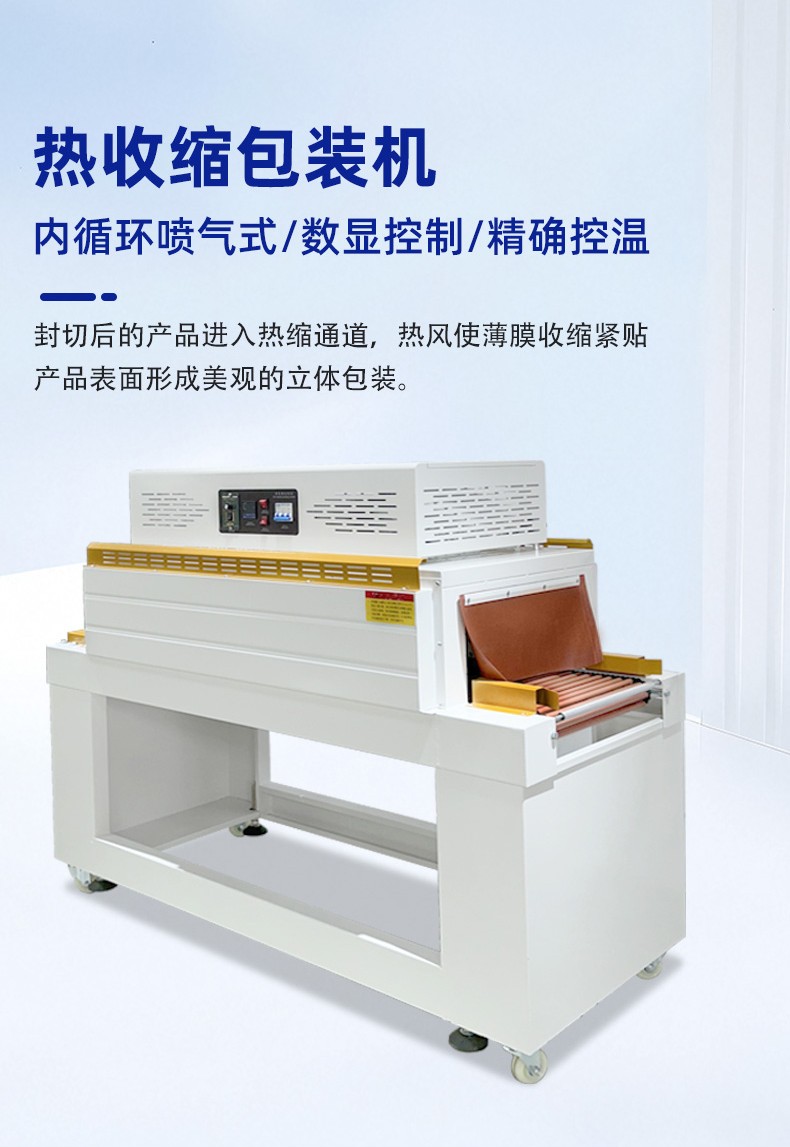

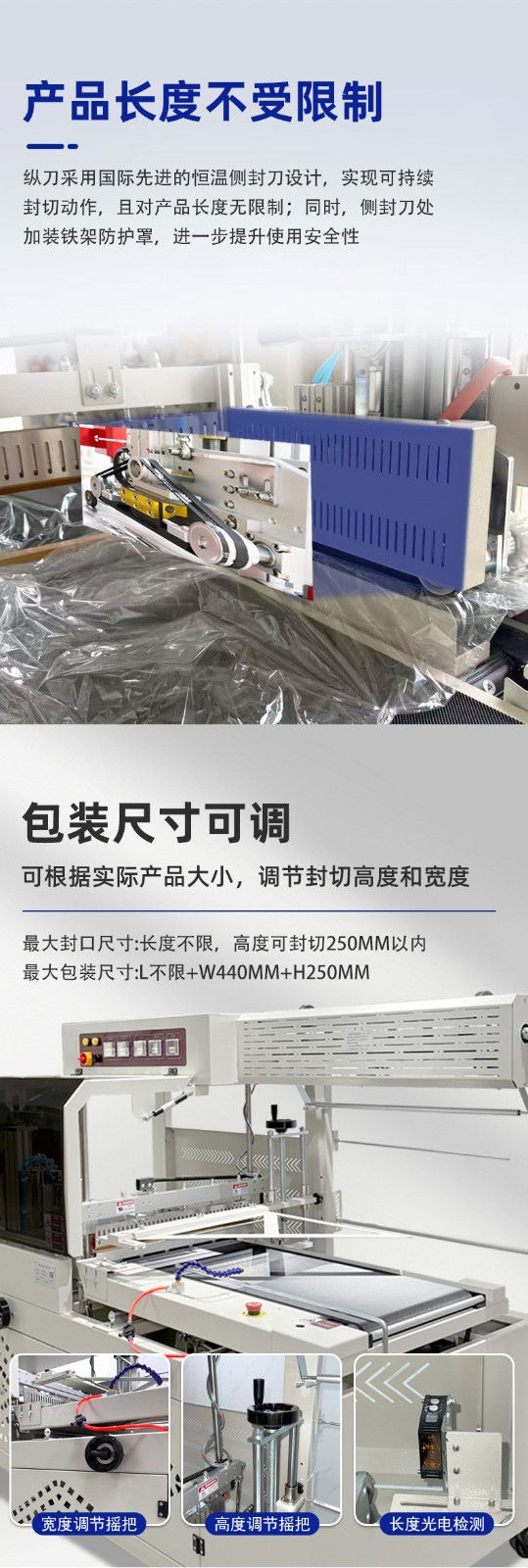

- High-Speed Operating Components: For example, the vertical seal of the high-speed side sealing machine uses a constant-temperature knife for continuous and uninterrupted sealing and cutting, while the horizontal seal adopts a constant-temperature knife design with lifting-type sealing and cutting. Cooperated with the front-end feeding system with adjustable speed and the rear-end storage workbench, the overall operation of the machine can truly achieve high-speed operation.

- Quick Adjustment Mechanism: When the product size changes within the allowable range of the equipment, simple adjustment mechanisms such as the handwheel on the equipment itself can be used without replacing any components. This reduces product changeover time and improves the adaptability and production efficiency of the equipment.

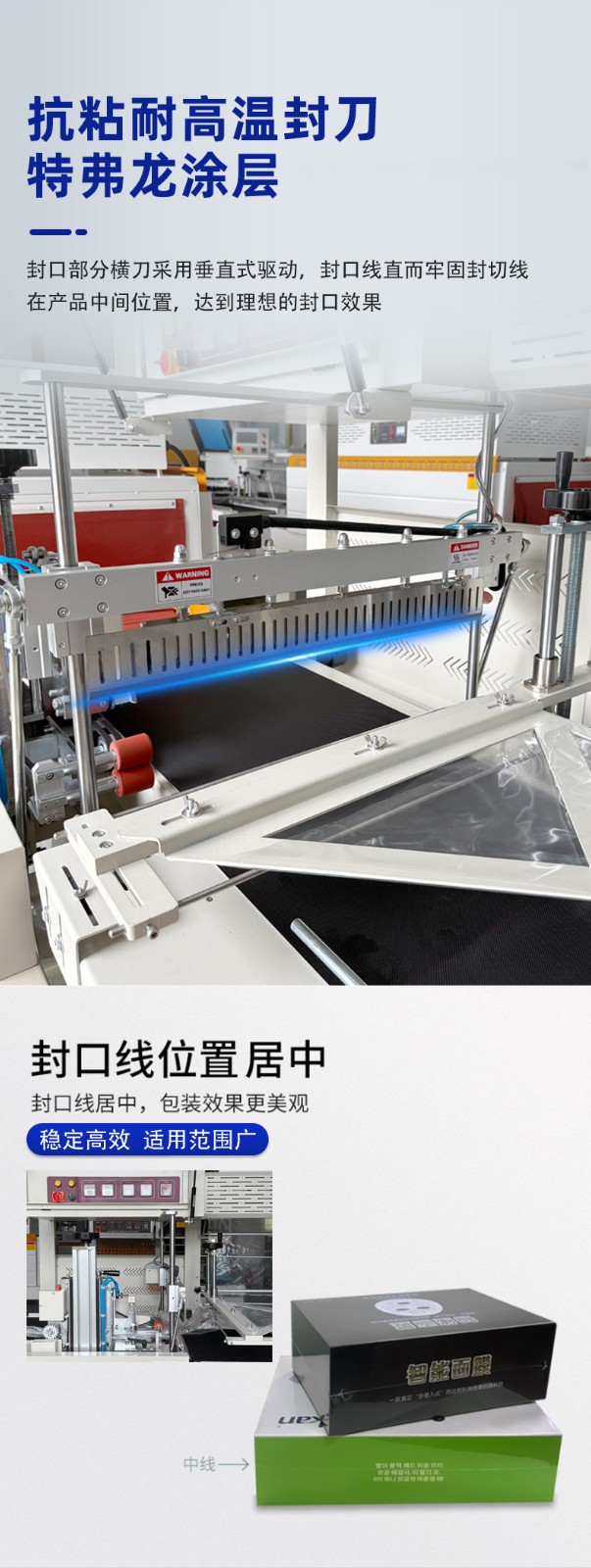

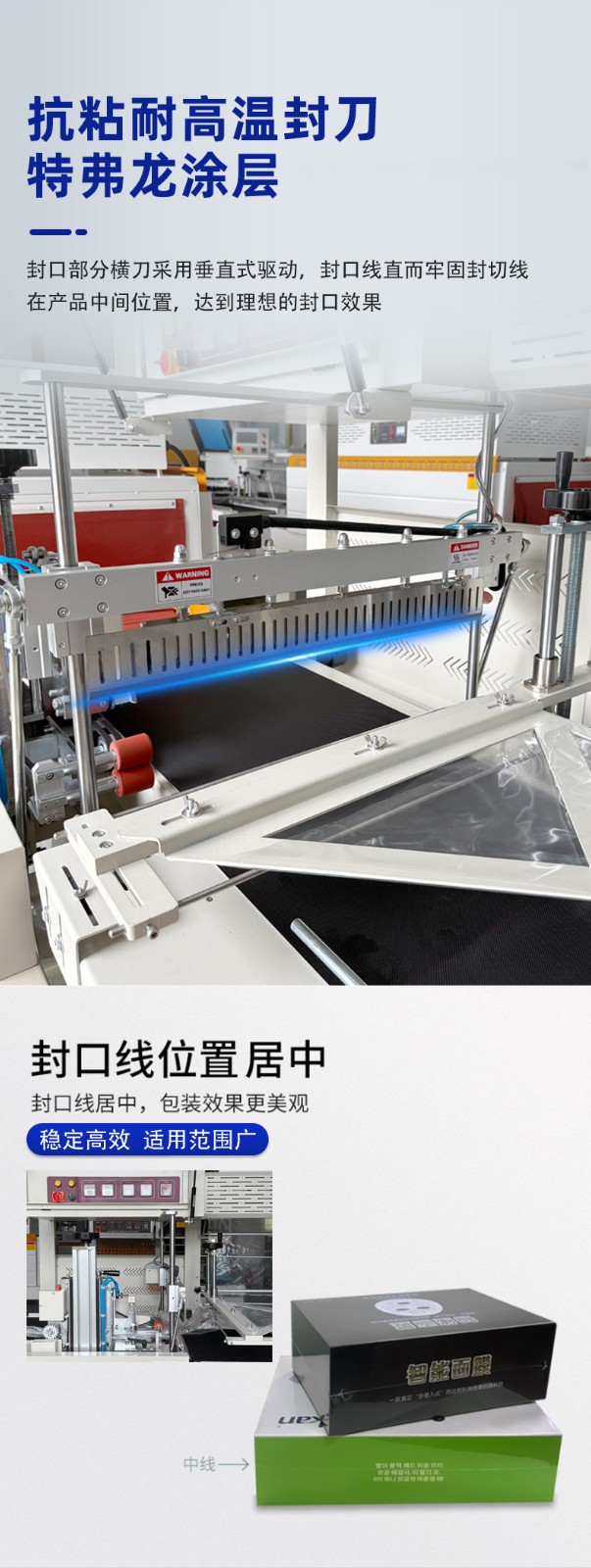

- Vertically Driven Sealing-Cutting Knife Holder: The sealing-cutting knife holder is controlled by vertical drive, such as a four-column vertical system drive. It can solve the problems of wrinkles and the sealing line not being in the middle of the product that occur in traditional L-type sealing machines, enabling the sealing line to be accurately located in the middle of the product and ensuring the aesthetics and firmness of the seal.

- Precision Detection Photoelectric Sensor: Equipped with imported detection photoelectric sensors, including one set each for horizontal and vertical detection, which is convenient for switching and selection. It can accurately detect the position and size of the product, and can easily complete the sealing and packaging operation even for thin and small packages, ensuring the accuracy of the sealing-cutting position and thus realizing centered sealing.

- High-Quality Sealing-Cutting Knife Material: The sealing-cutting knife is made of imported special materials, and its surface is coated with American Teflon high-temperature resistant material. This ensures that the seal is not broken, the sealing line is strong, and there is no cracking, coking or smoking, making the sealing line firm and aesthetic.

- Film Upper and Lower Synchronization Mechanism: The designed film upper and lower synchronization mechanism can correct the film deviation problem, ensure that the film maintains the correct position during the conveying process, so that the sealing line can be located in the middle of the product, and the sealing quality is stable and aesthetic.