The working efficiency of sleeve-type packaging machines is mainly affected by four core factors: product characteristics, equipment configuration, film parameters, and operation & maintenance. The details are as follows:

The specifications and shape of the product itself directly determine the operation rhythm of the equipment, serving as the fundamental influencing factor:

- Size and Weight: Larger and heavier products (e.g., large packaged beverages with 12 bottles) require longer conveying and positioning time, resulting in lower efficiency (possibly as low as 20-50 packs per minute). Small and lightweight products (e.g., small toothpaste boxes) achieve higher efficiency (up to 80-120 packs per minute).

- Shape Regularity: Regular-shaped products (bottles, cans, square boxes) can operate continuously and stably without additional positioning adjustments. Irregular-shaped products require frequent position calibration, which easily interrupts the process and reduces efficiency.

The design of the equipment's hardware and core systems directly determines the upper limit of efficiency:

- Specifications of Core Components:

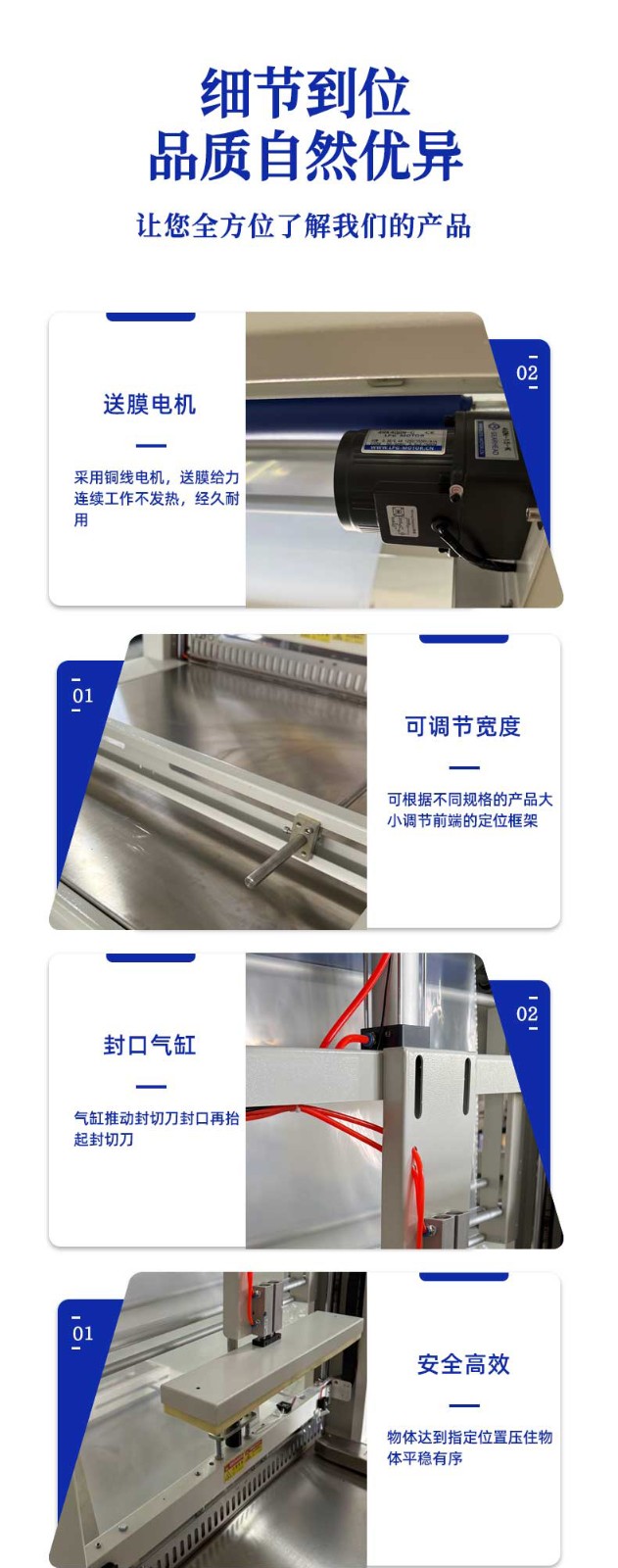

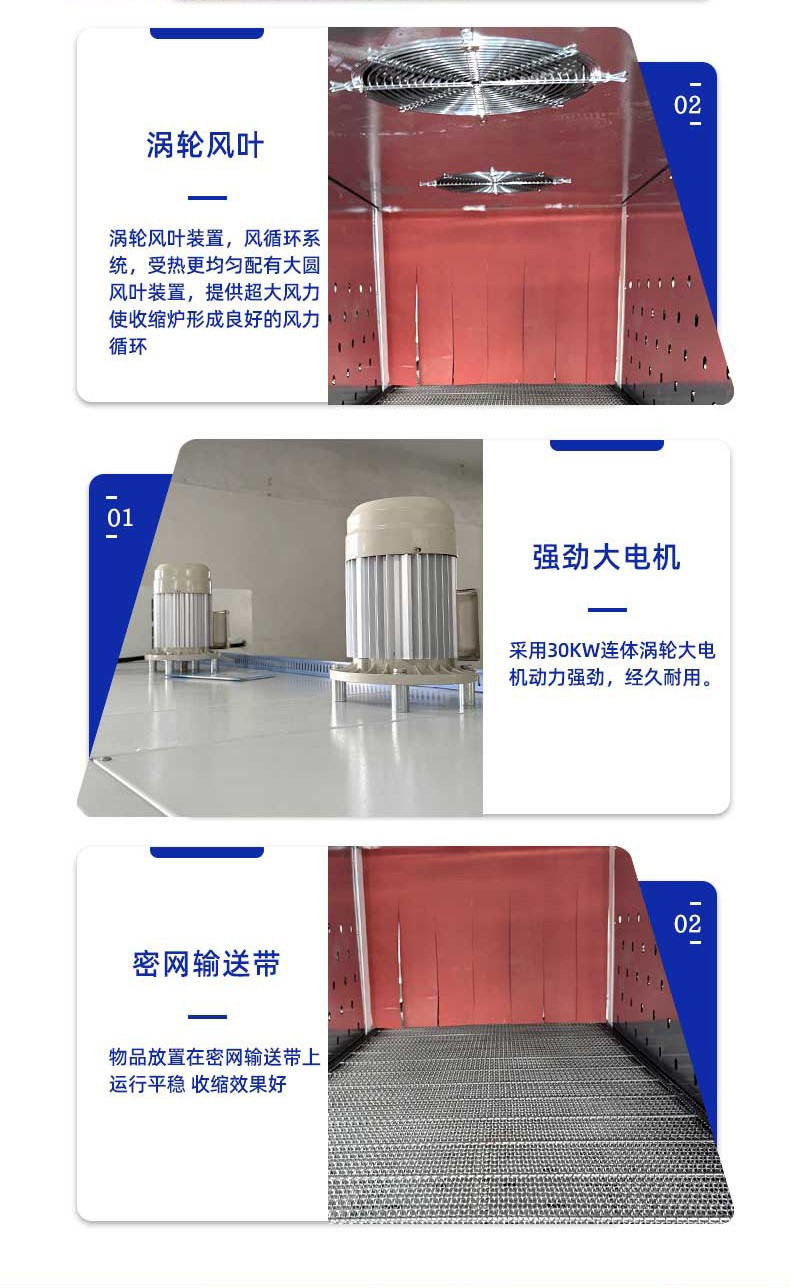

- Conveying System: Models with frequency converters for "stepless speed regulation" can adjust the speed according to the product, enabling more flexible efficiency. Models with fixed conveyor belt width and speed have poor adaptability and are easily restricted.

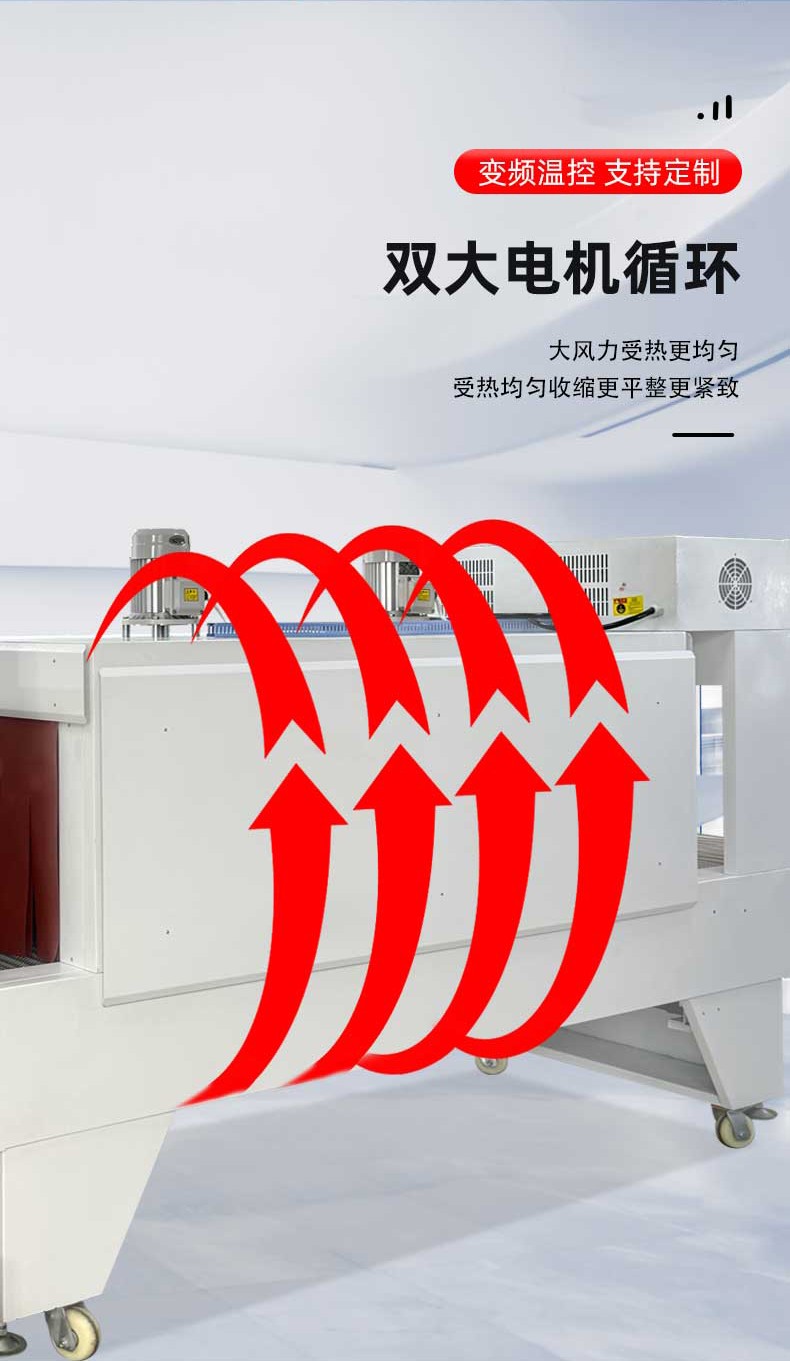

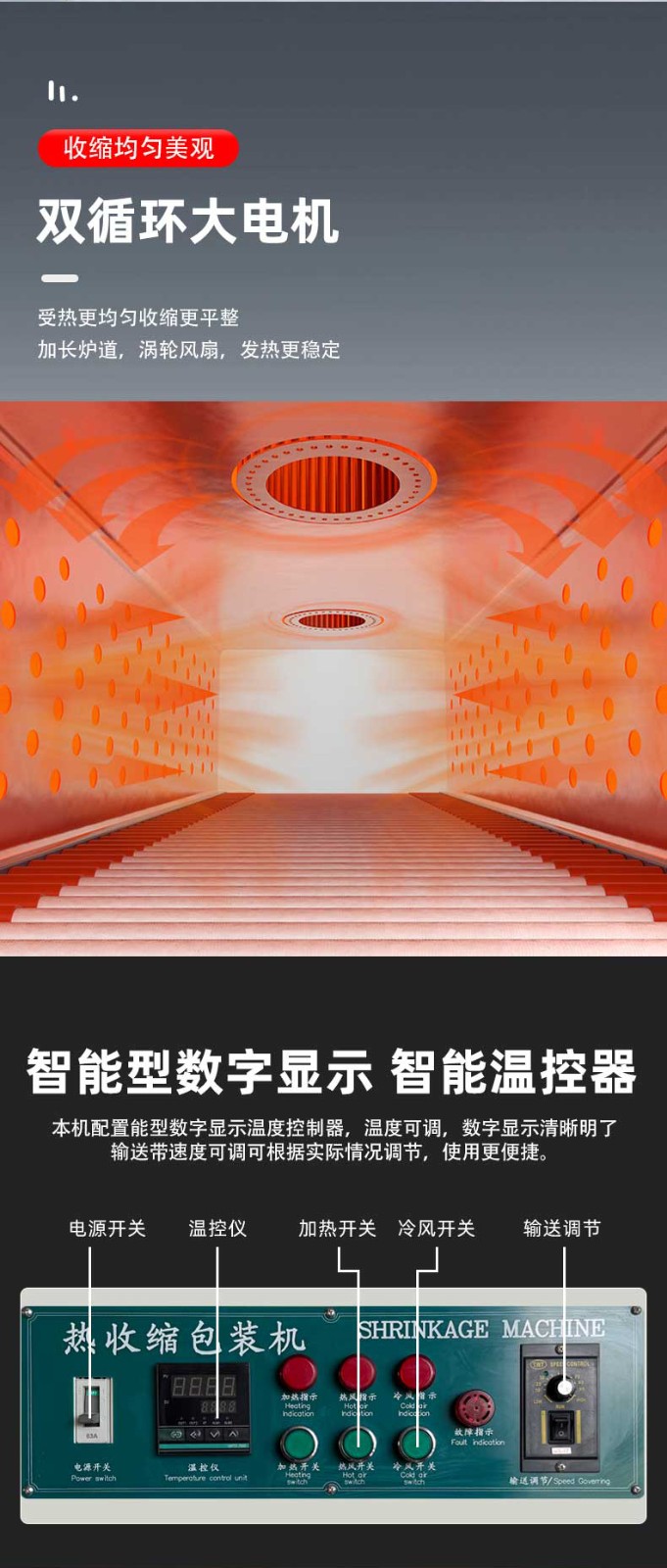

- Heat Shrinkage Oven: Models with spiral air ducts feature more uniform hot air circulation, shortening the shrinkage time by over 20%, reducing the product's residence time in the oven, and improving overall efficiency. Ovens with ordinary straight air ducts have lower shrinkage efficiency.

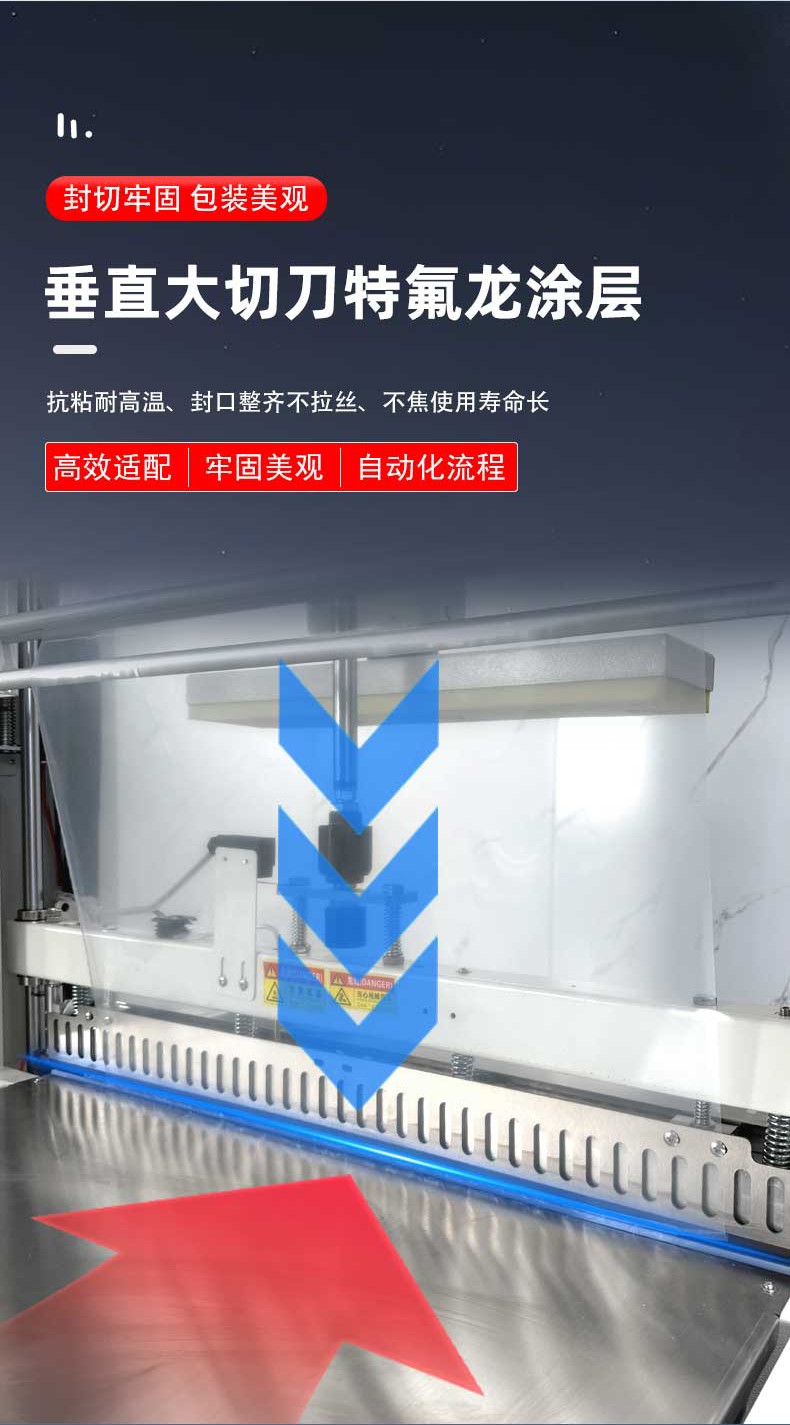

- Sealing and Cutting Device: Models equipped with a PLC control system can adjust the sealing and cutting temperature, pressure, and time in real time, eliminating the need for shutdowns when adapting to different films. Models requiring manual adjustment of sealing and cutting parameters need frequent shutdowns, causing significant efficiency loss.

- Automation Integration: "Full-process automated" models with automatic feeding, automatic material distribution, and automatic finished product stacking functions can operate continuously for 24 hours without manual intervention. Models with only basic packaging functions and requiring manual assistance for feeding/material distribution have efficiency limited by the rhythm of manual work.

The properties of the heat-shrinkable film affect the time consumption of the sealing, cutting, and shrinkage processes:

- Film Material and Thickness:

- Material: POF film has a low shrinkage temperature and fast shrinkage speed, suitable for high-efficiency production. PE film requires a higher shrinkage temperature and longer heating time, which prolongs the product's residence time in the heat shrinkage oven and reduces efficiency.

- Thickness: Thin films (e.g., 0.02-0.05mm) heat and shrink quickly with short time consumption. Thick films (e.g., above 0.08mm) require longer heating time, which easily slows down the process.

- Film Flatness and Adaptability: When the film is wrinkle-free and has uniform tension, film feeding and sealing-cutting can be completed in one go. Films that are prone to wrinkling or have a width mismatched with the product (requiring cutting and adjustment) increase the frequency of shutdowns for calibration, affecting efficiency.