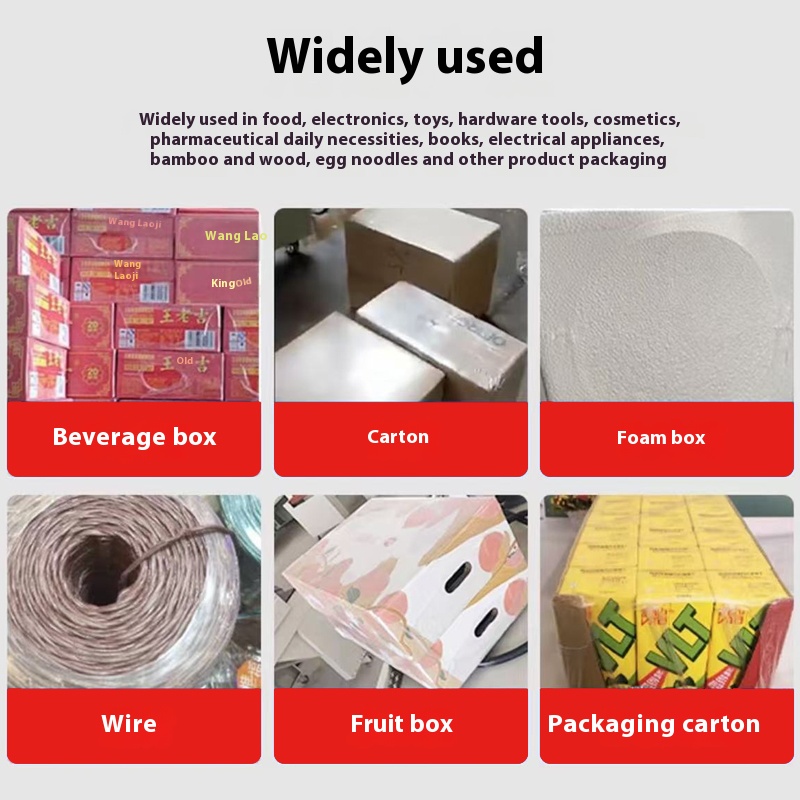

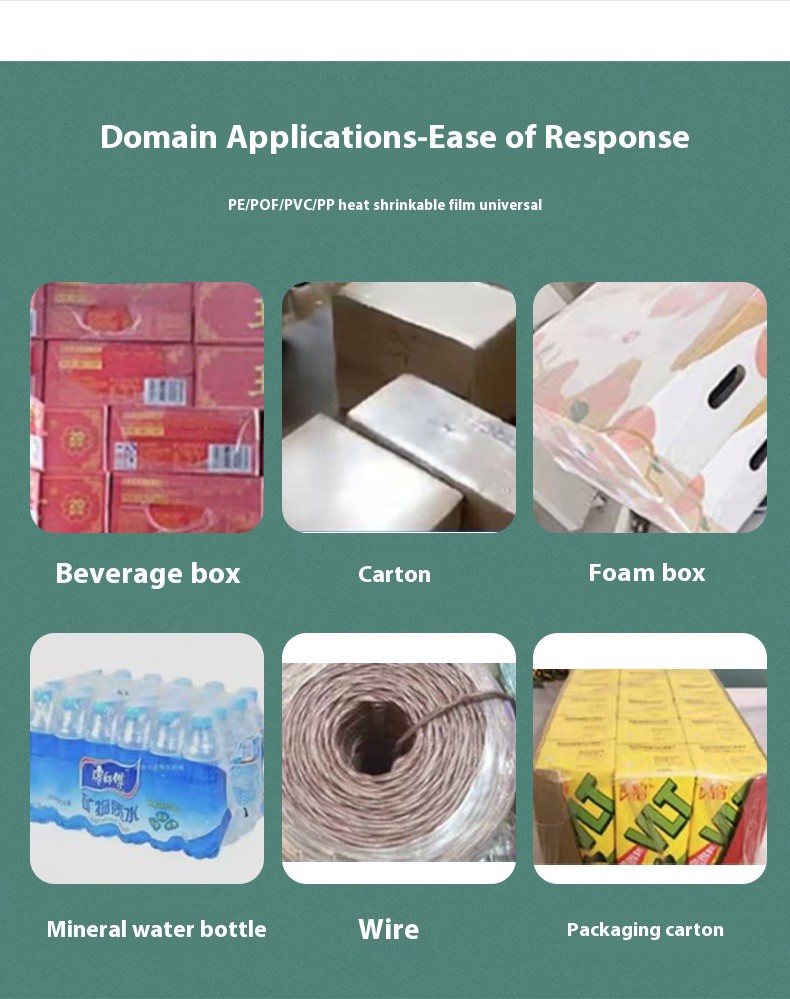

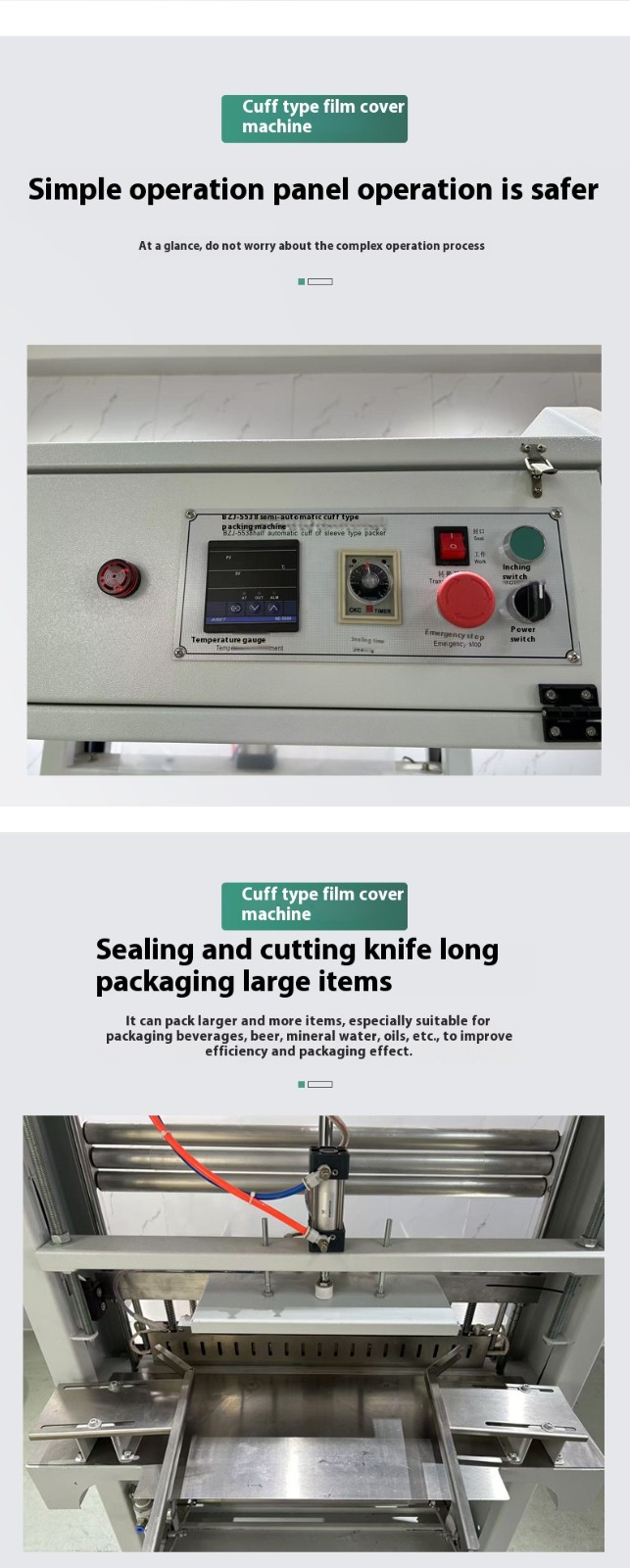

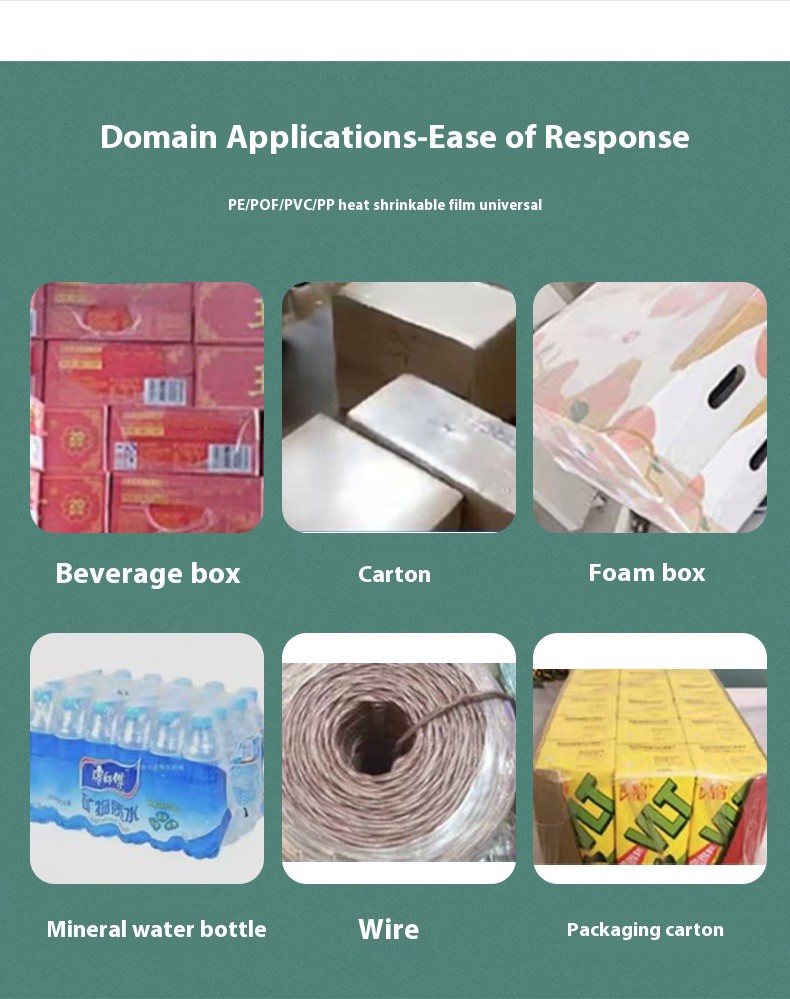

On one hand, its strong packaging adaptability is reflected in its compatibility with different product forms and sizes. Without complex mold adjustments or programming settings, it can quickly adapt to a variety of products—from small and medium-sized bottles (such as 500ml beverage bottles and cosmetic jars) to small cartons and irregularly shaped parts boxes—through manual assistance in placing products (e.g., arranging bottles, boxes, bags, and other items of different shapes on the conveyor track) combined with manual or semi-automatic adjustment of film tension and sealing/cutting positions. This "flexible switching" feature is particularly important for enterprises with small output but a large variety of products (such as small food processing plants, local specialty workshops, and small-batch electronic parts factories)—there is no need to configure special equipment for each product, thus reducing the risk of equipment idleness.

On the other hand, the core logic behind its suitability for small-output enterprises lies in the "balance between cost and efficiency." The purchase cost of semi-automatic models is usually only 30%-50% of that of fully automatic models. Moreover, they have a small footprint (most models occupy 1-2㎡), have low requirements for production sites, and are suitable for the layout of small workshops. At the same time, although their production efficiency (typically 5-30 packs per minute) is lower than that of fully automatic models, it is sufficient to meet the daily needs of small-output enterprises (such as a daily output of several hundred to several thousand pieces), avoiding resource waste caused by "low-load operation of large equipment."

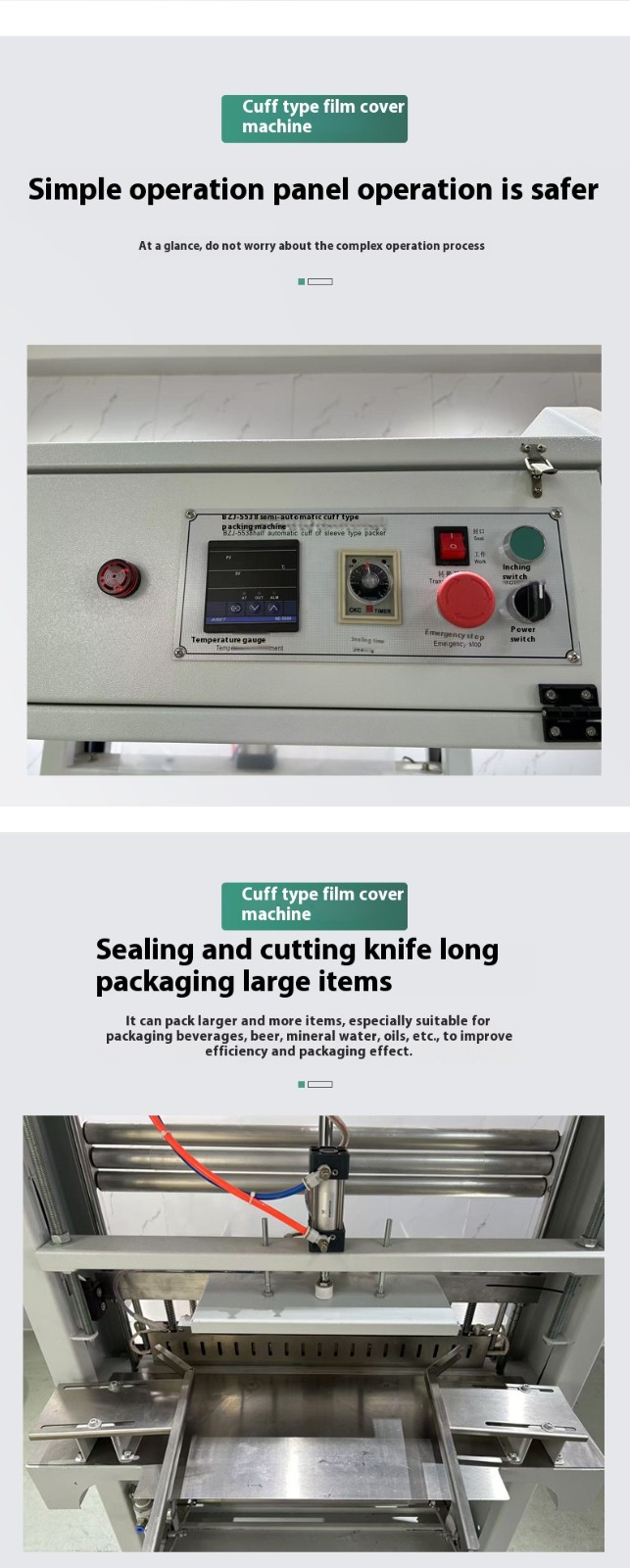

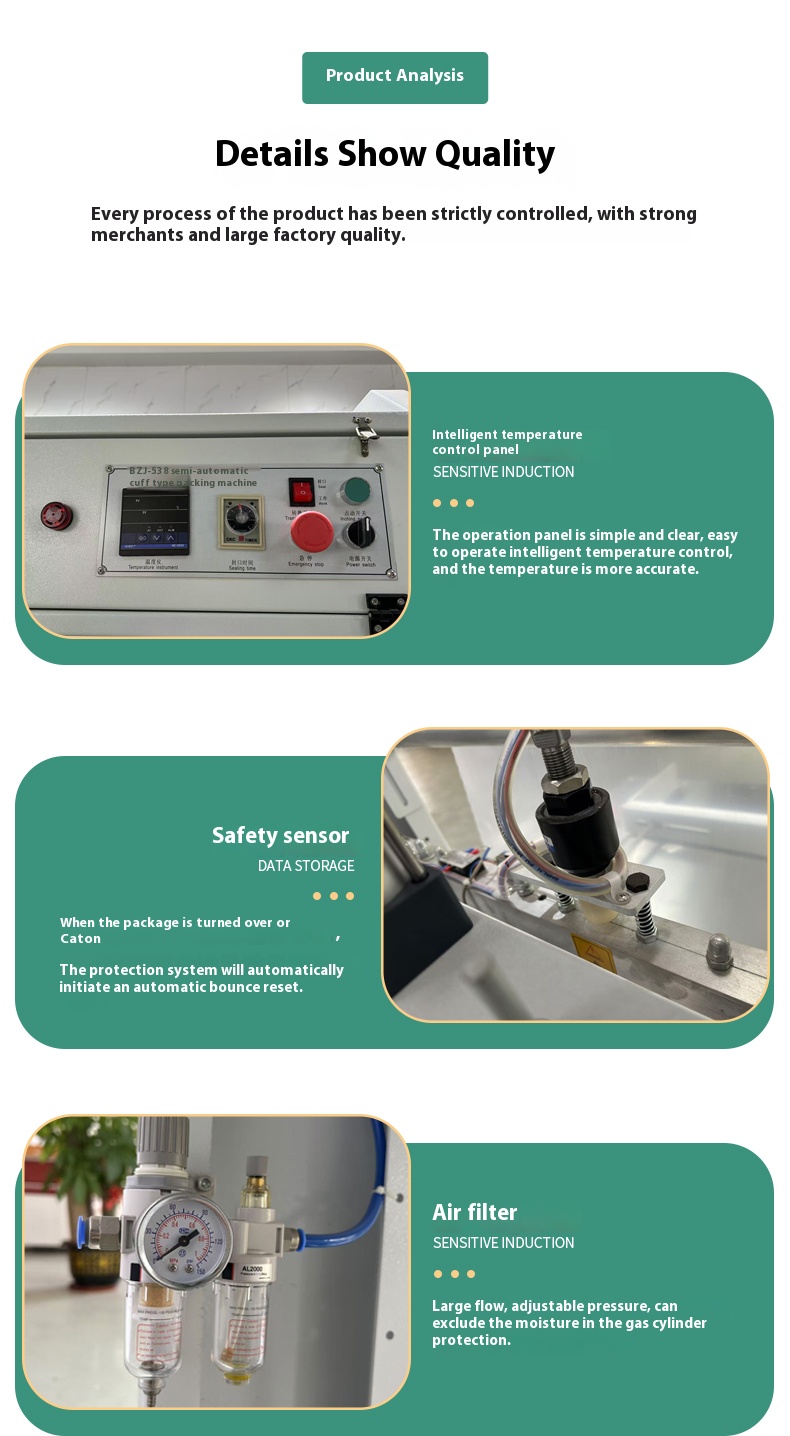

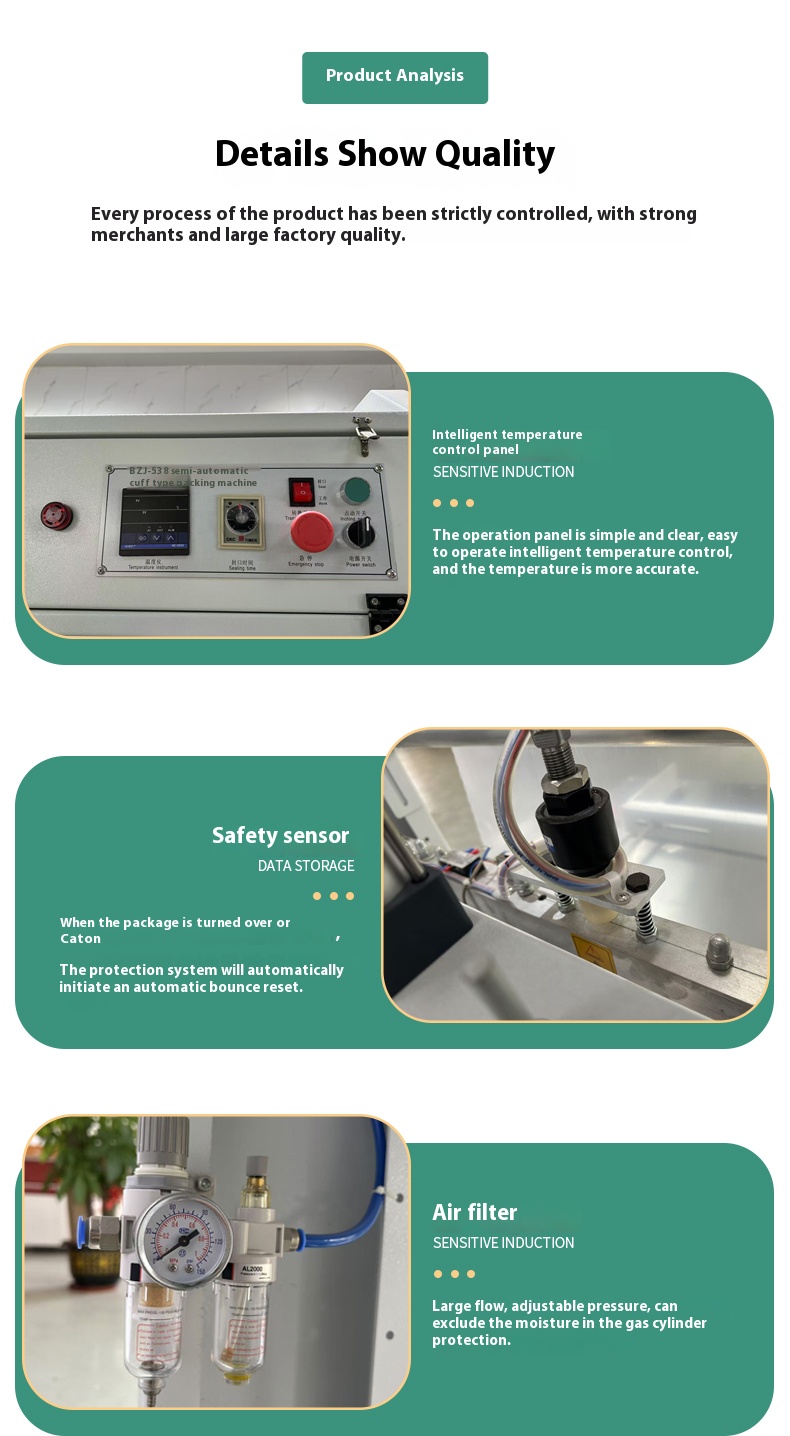

In addition, semi-automatic models have a low operational threshold. Ordinary employees can get started after simple training (such as learning how to adjust the film, start the sealing/cutting and heat shrinking processes), and there is no need for professional technicians for maintenance, which further reduces labor and management costs for small factories. For small-volume enterprises with fast product updates and unstable batch sizes, such characteristics of "low cost, easy operation, and strong compatibility" can better cope with the production needs of multiple varieties and small batches, balancing packaging effect and economy