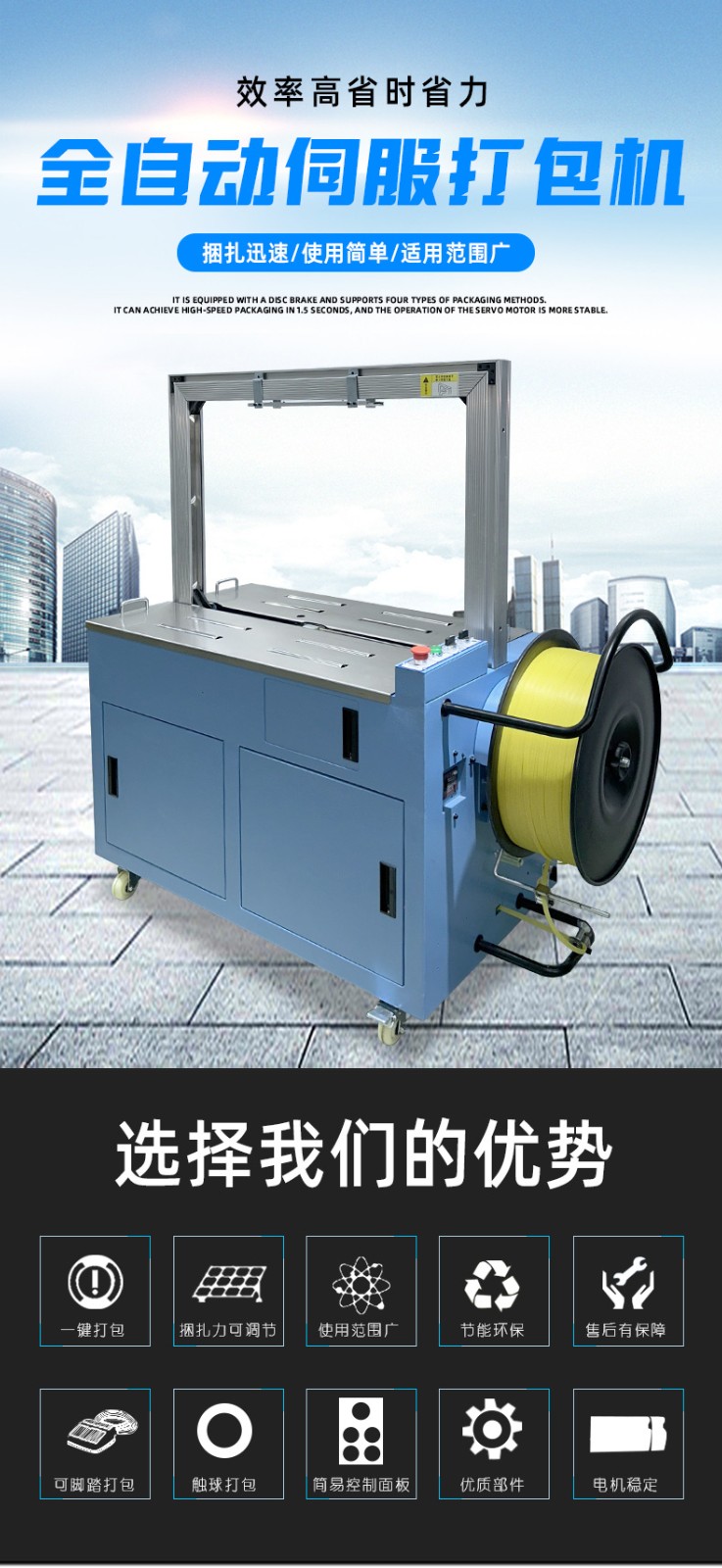

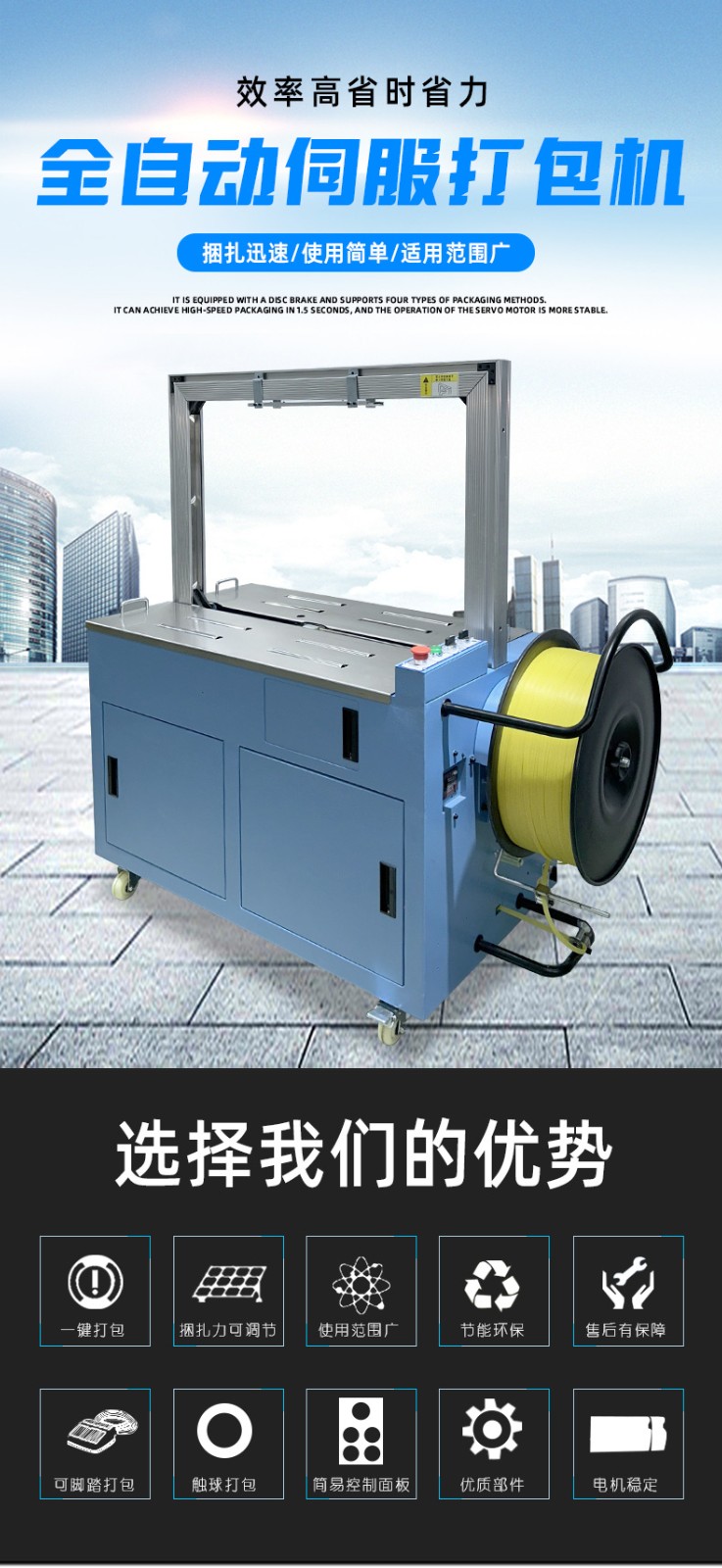

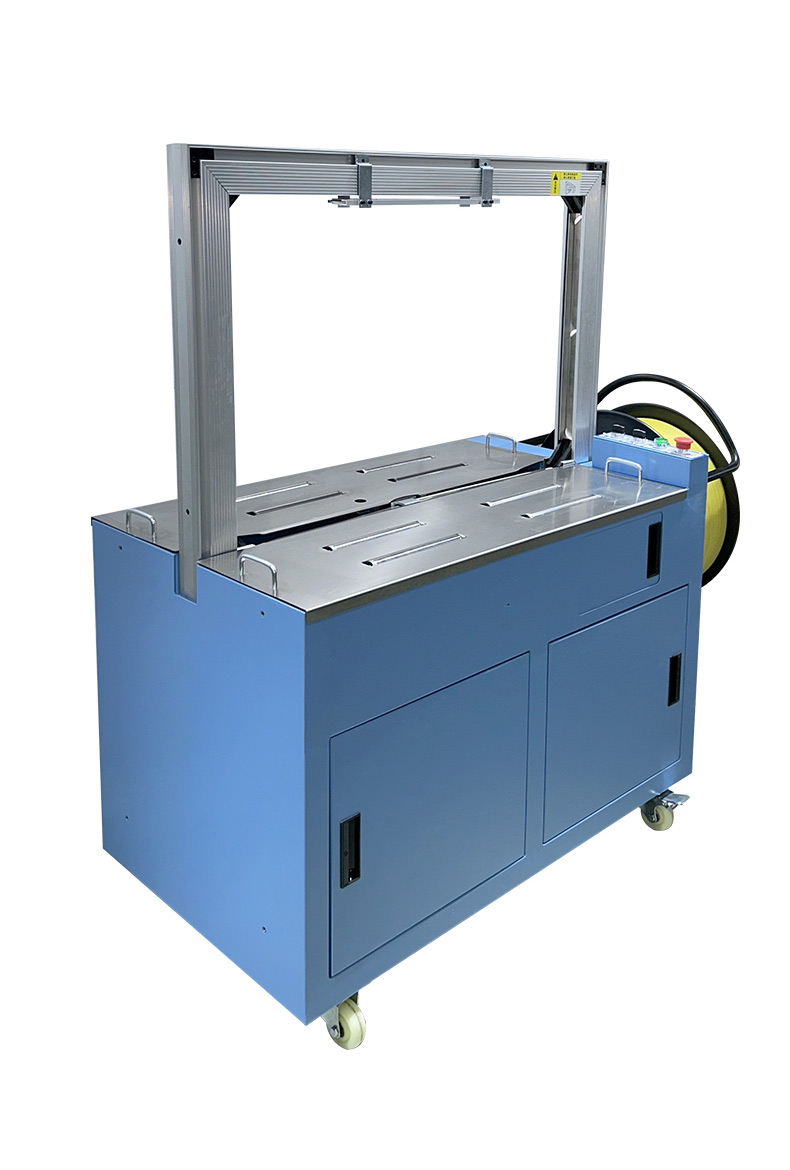

The advantages of automatic servo strapping machines in efficient production and flexible adaptation are the core reasons for their popularity in the modern industrial packaging field, which can be analyzed in detail from the following dimensions:

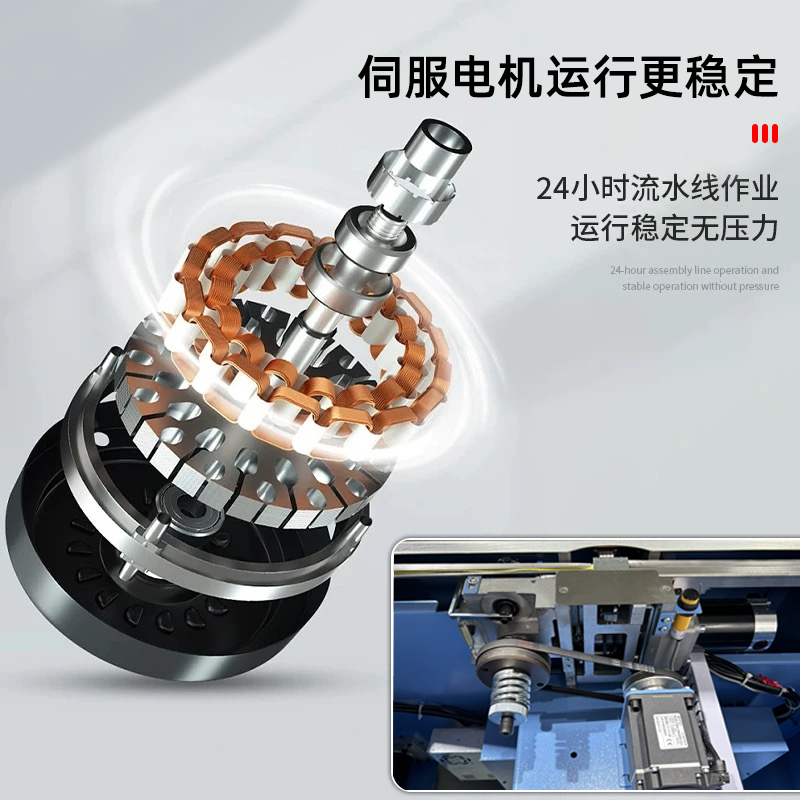

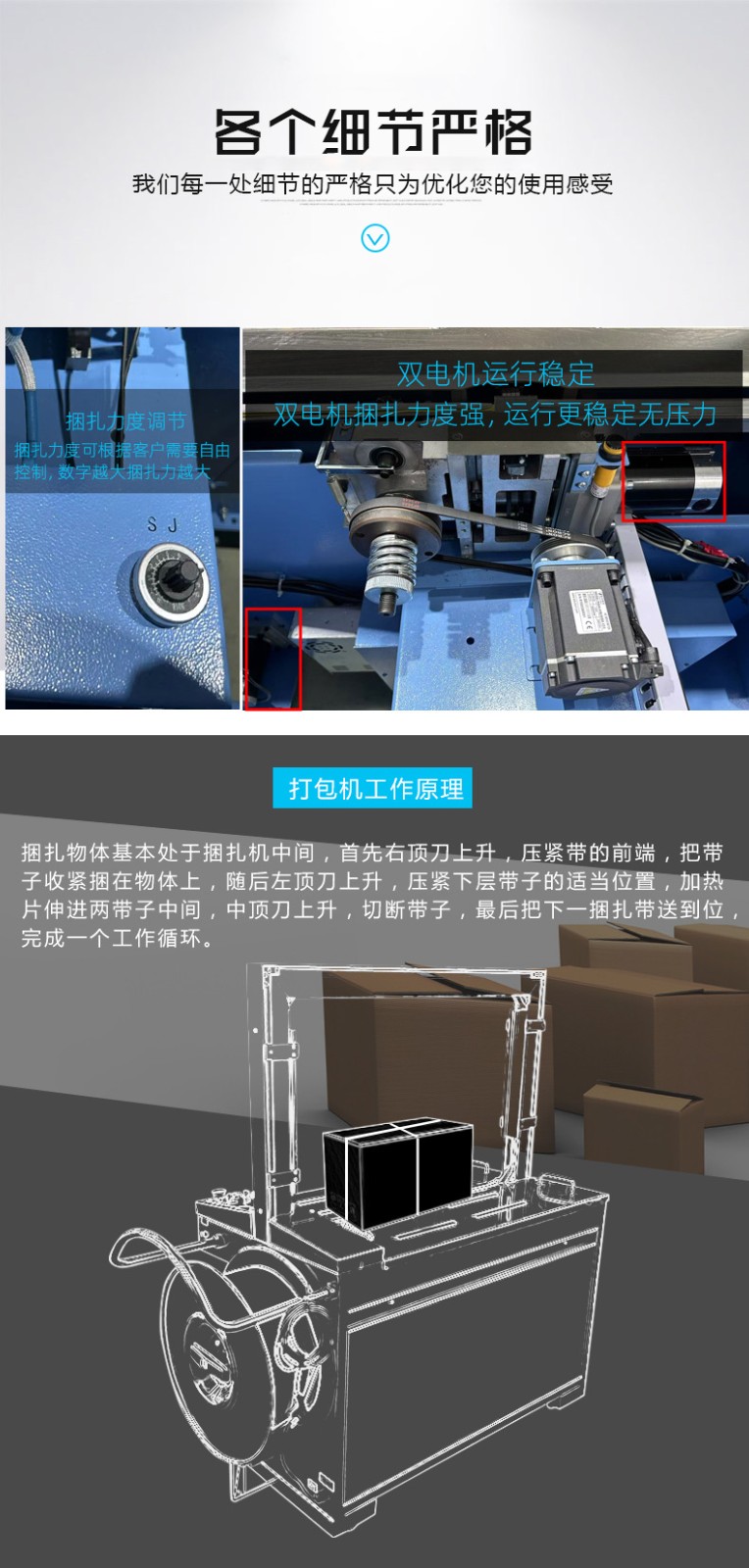

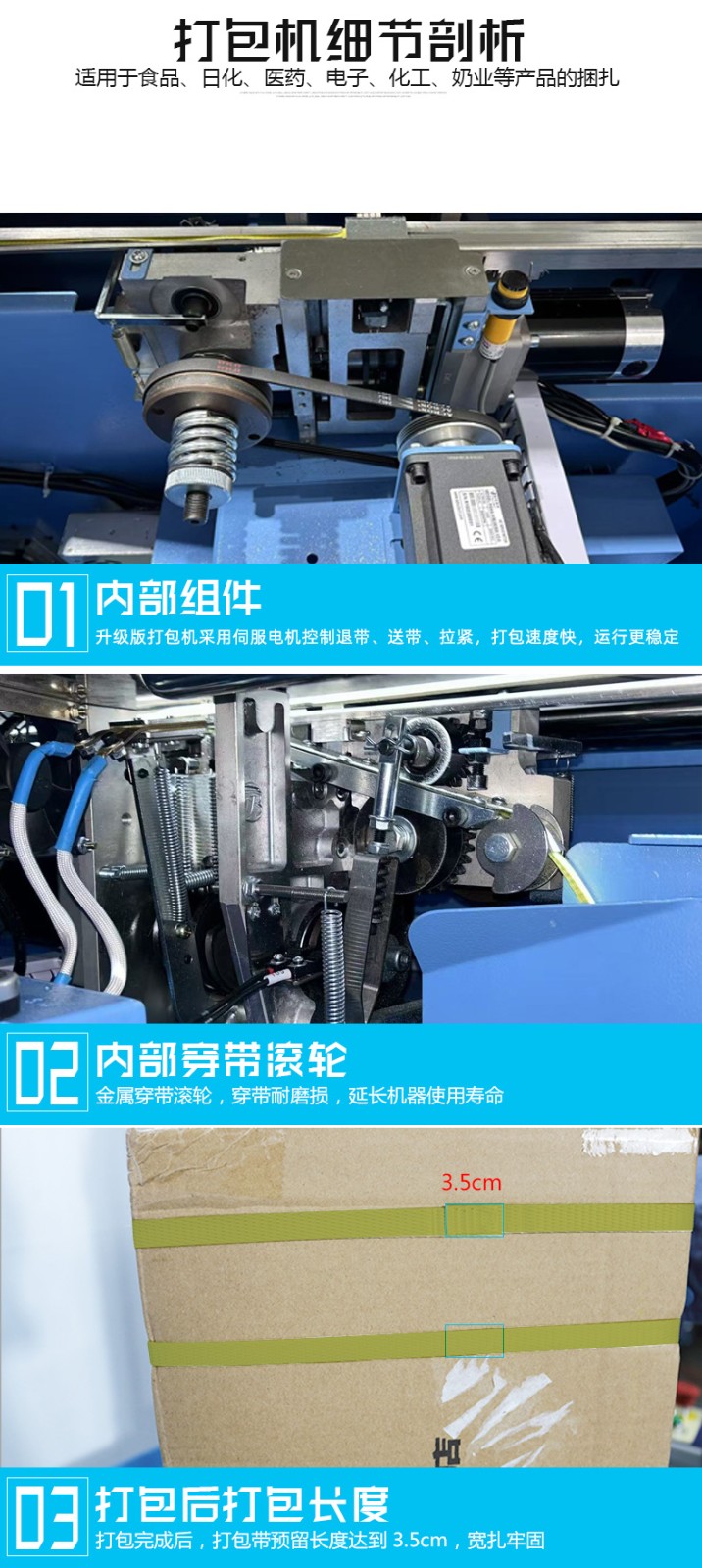

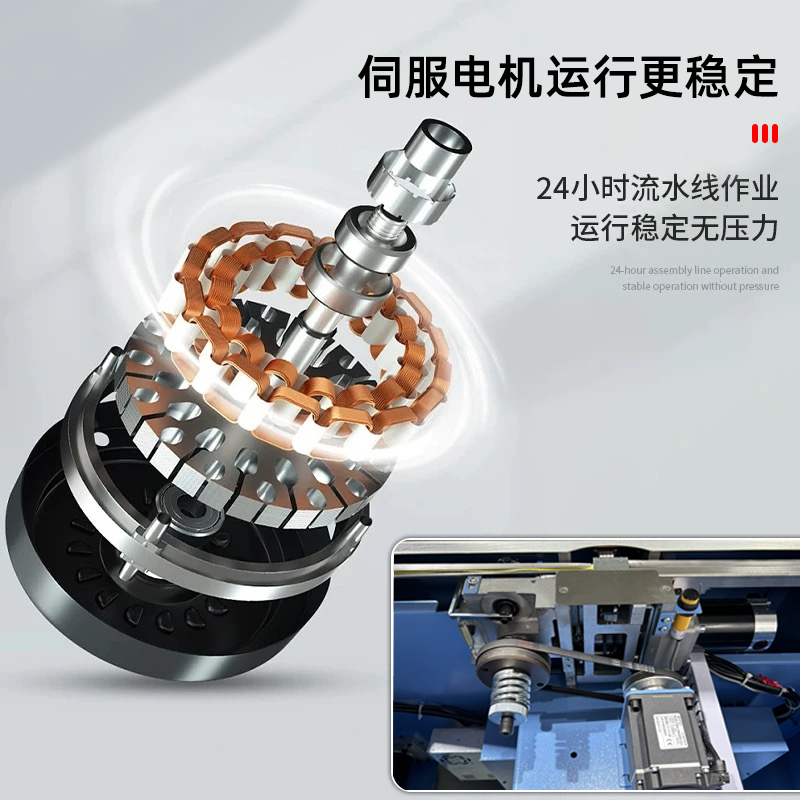

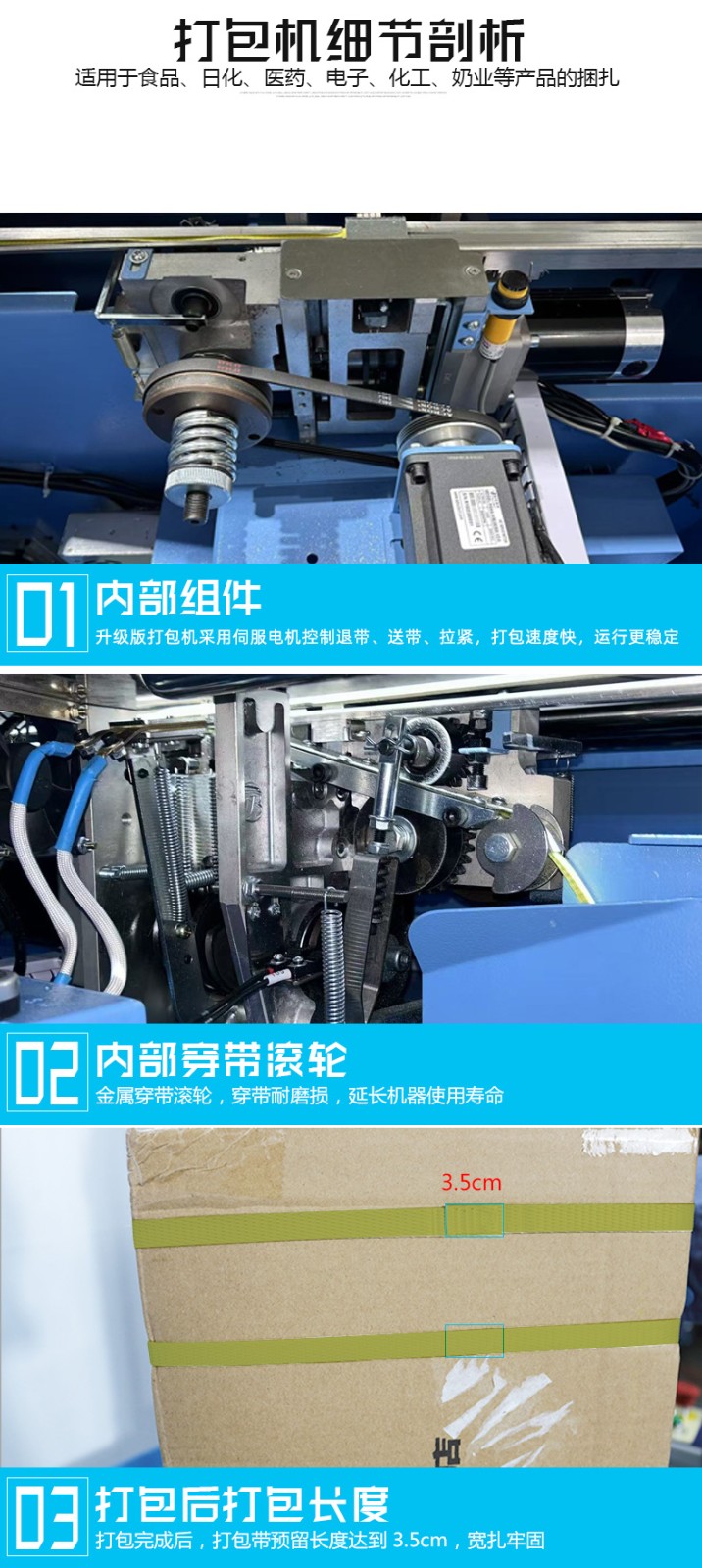

The precise speed regulation and instant start-stop characteristics of servo motors enable the strapping machine to achieve millisecond-level response in processes such as tape feeding, tensioning, welding, and cutting. Compared with traditional pneumatic or mechanical drive equipment, its single-cycle strapping time can be reduced by more than 30% (for example, traditional equipment takes 2-3 seconds per package, while servo models can compress it to 1-1.5 seconds). Combined with the continuous feeding design, it can easily achieve high-speed operation of 20-40 packages per minute, meeting the rhythm requirements of mass production.

The equipment integrates full-process automated modules for automatic feeding, positioning, detection, strapping, and discharging:

- Built-in sensors can identify material positions in real-time, completing alignment without manual intervention;

- The multi-channel design supports parallel processing of multi-specification materials, avoiding single-machine bottlenecks;

- Cooperating with production line linkage (such as docking with upstream filling lines and downstream palletizers), it realizes "unmanned" continuous operations, significantly reducing downtime waiting time.

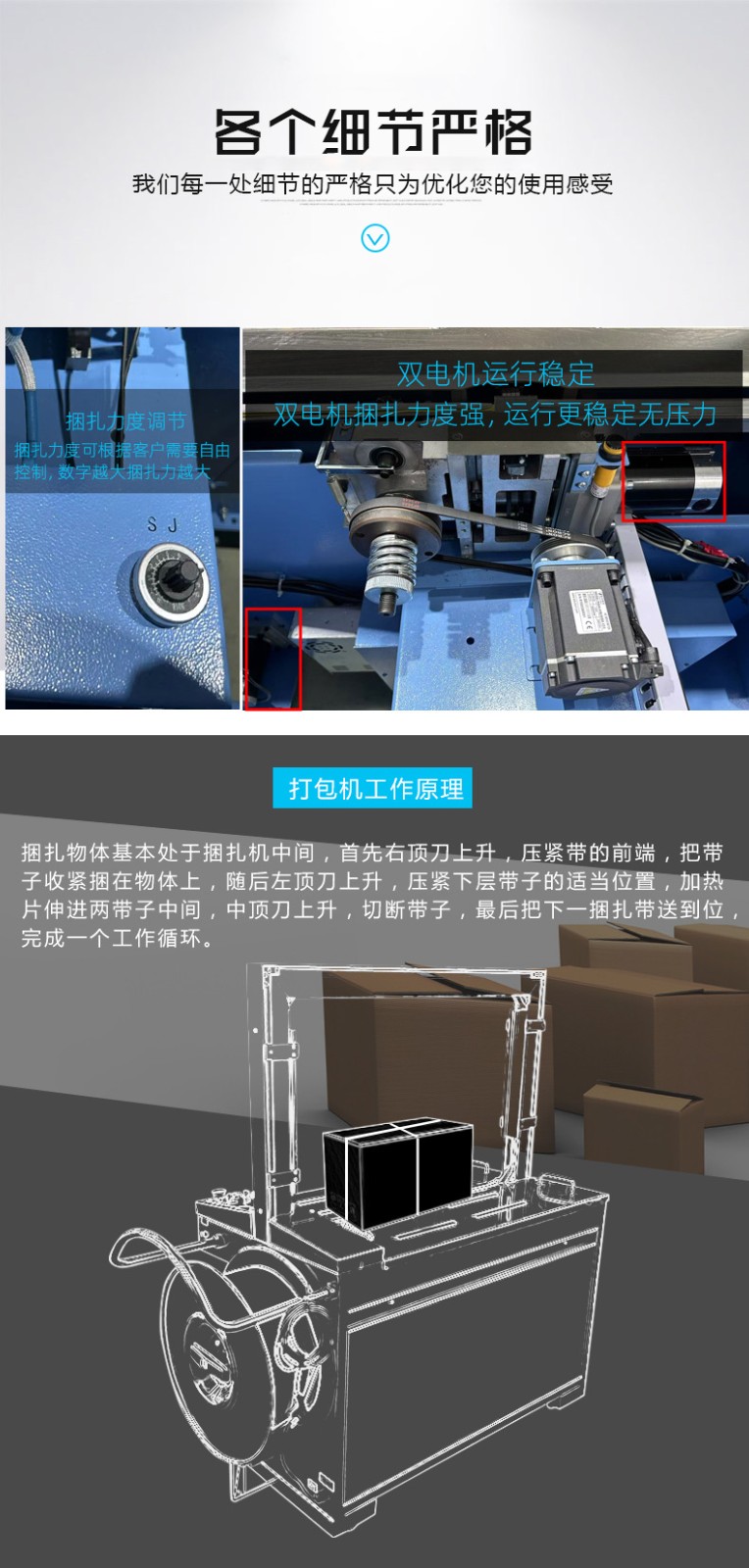

The low failure rate and consistent control of the servo system reduce the rework rate caused by poor packaging. For example, in e-commerce logistics scenarios, traditional equipment may cause goods to scatter due to loose strapping, while servo models, through precise tension control (with an error within ±1N), can ensure package firmness and avoid material breakage caused by excessive stretching, indirectly improving overall production efficiency.

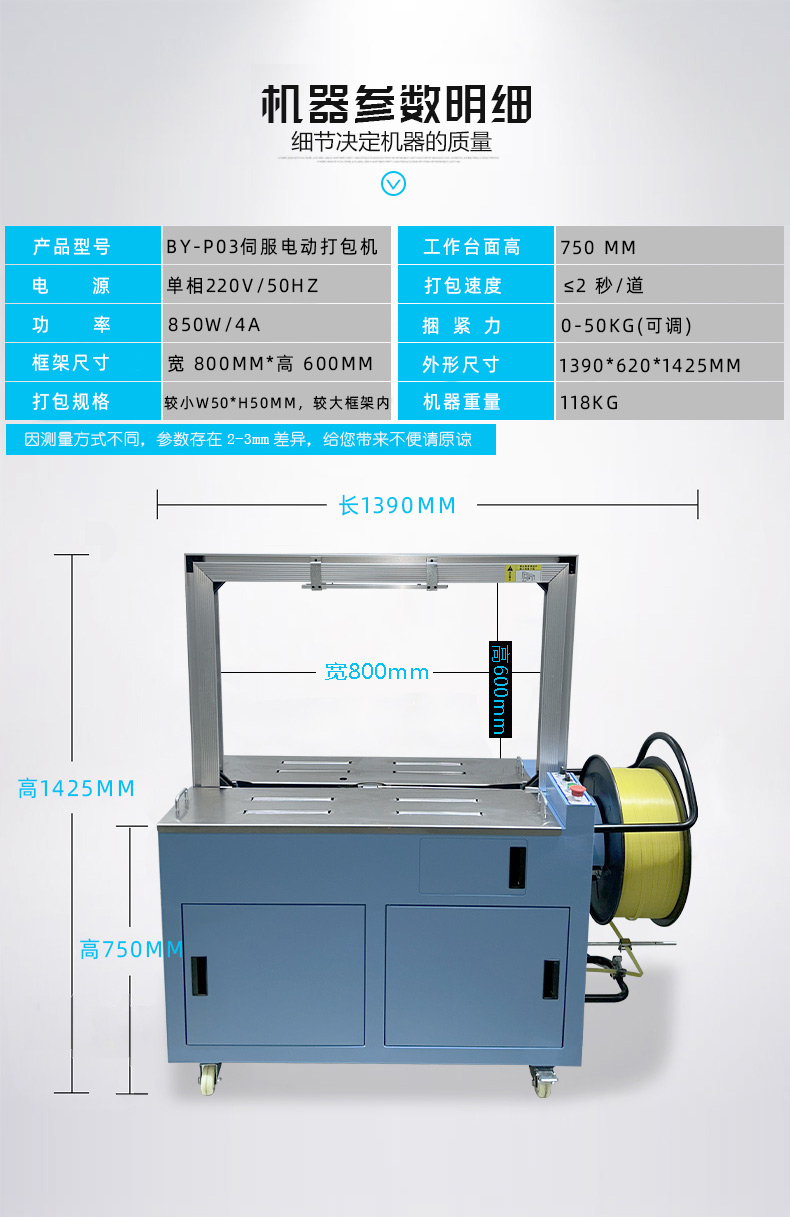

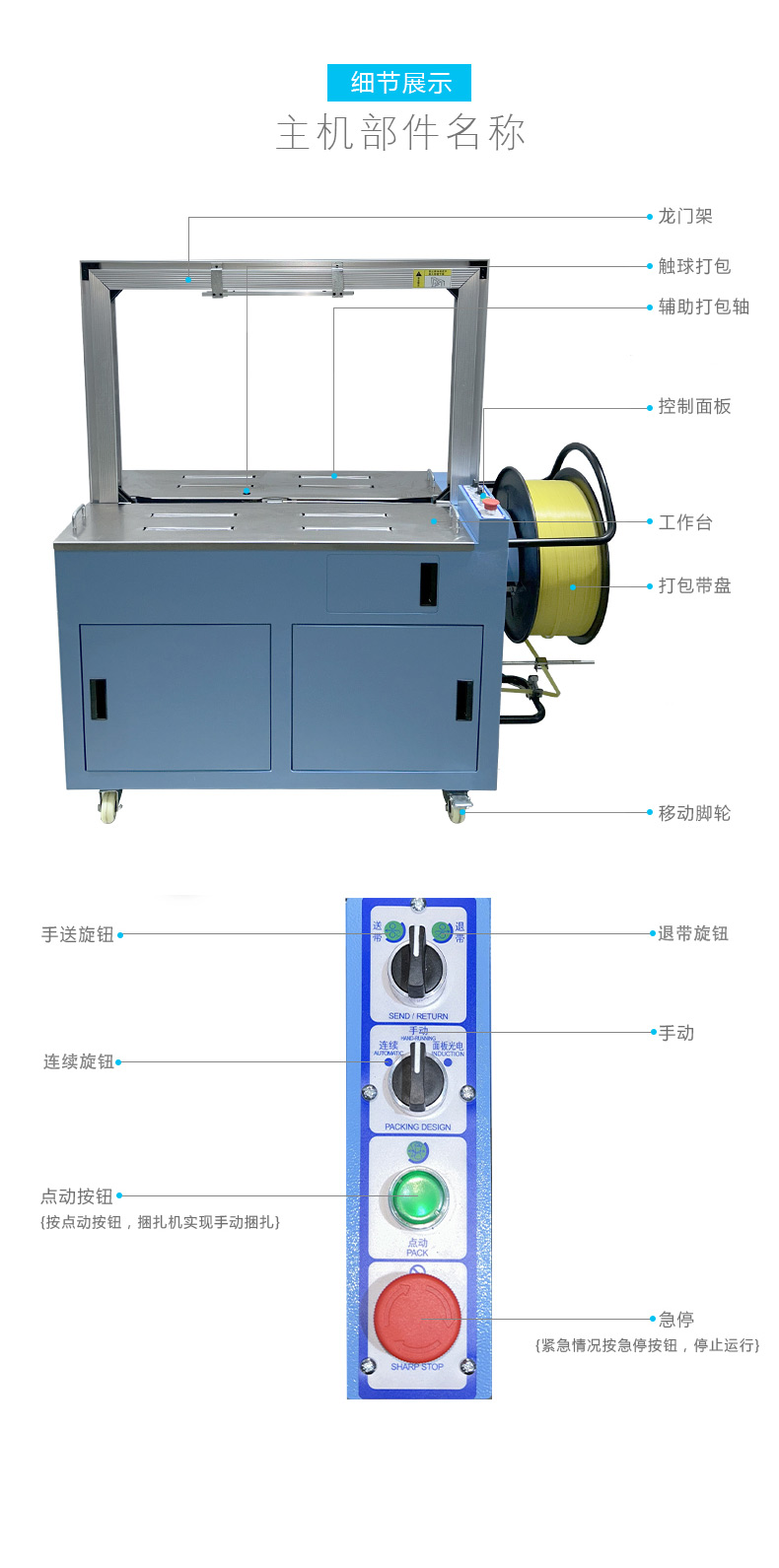

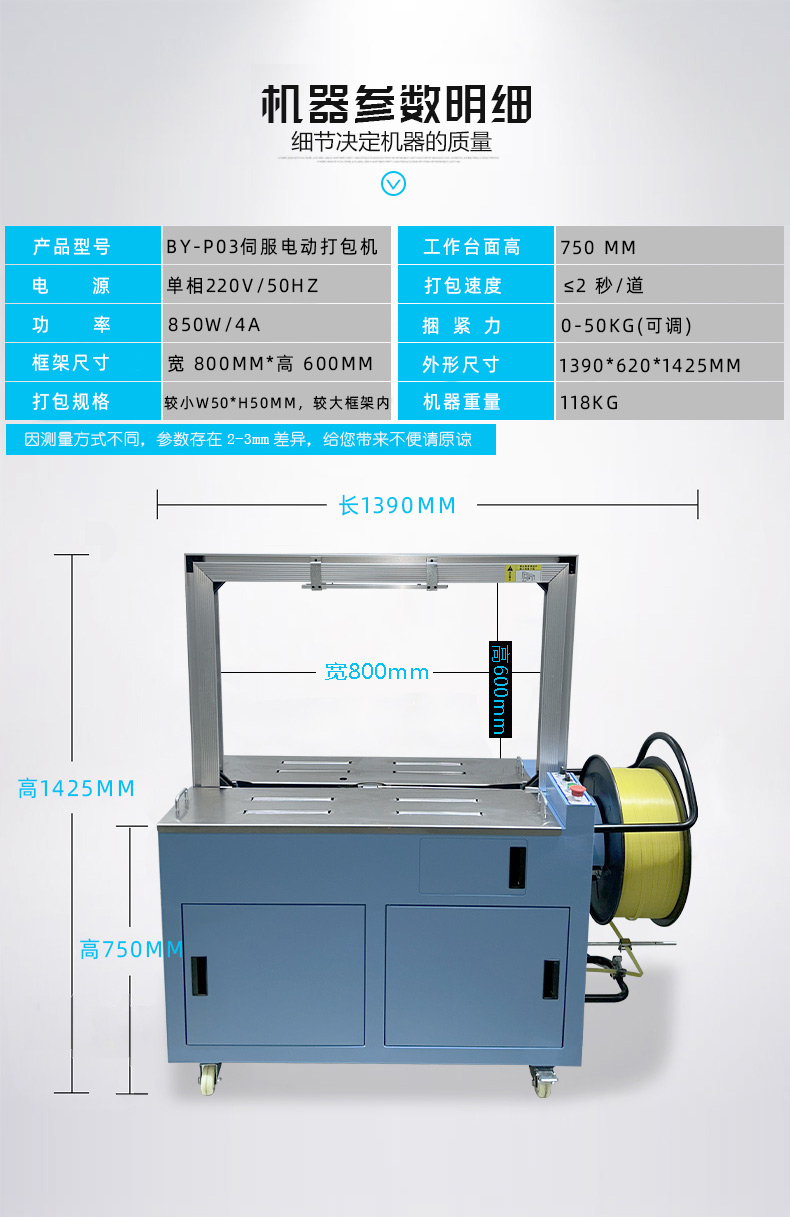

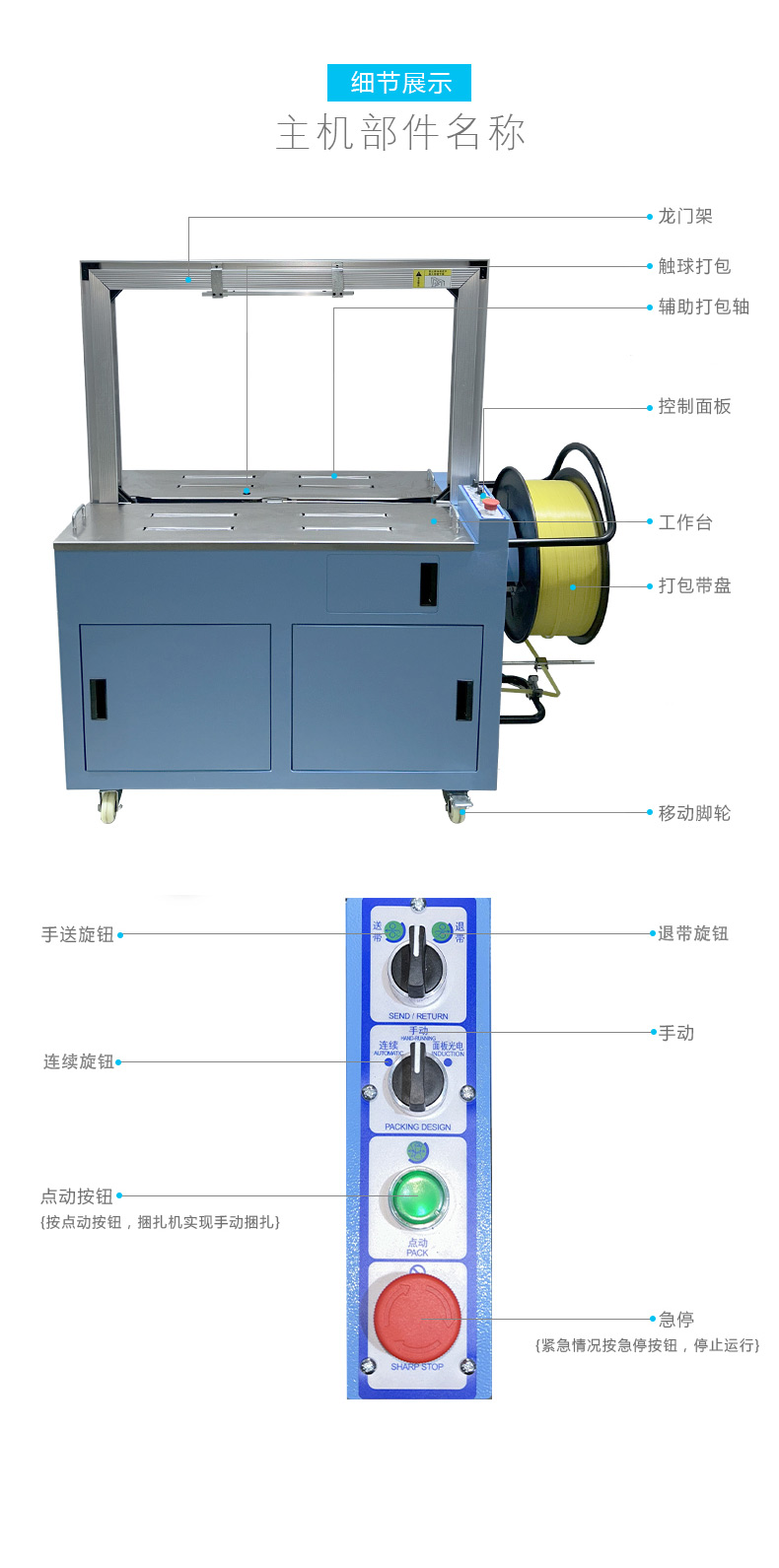

Relevant strapping parameters can be quickly set through the human-machine interface (HMI), including:

- Strap tension (adjustable from 5-500N, suitable for materials of different hardness such as cartons, plastic parts, and metal parts);

- Strapping positions (multiple strapping points can be preset, such as "cross-shaped" and "grid-shaped" strapping for cartons);

- Tape speed and welding time (adapted to straps of different materials, such as PP straps and PET straps).

When changing products, parameter switching takes only 3-5 minutes without complex mechanical adjustments, making it particularly suitable for flexible production modes with multiple varieties and small batches.

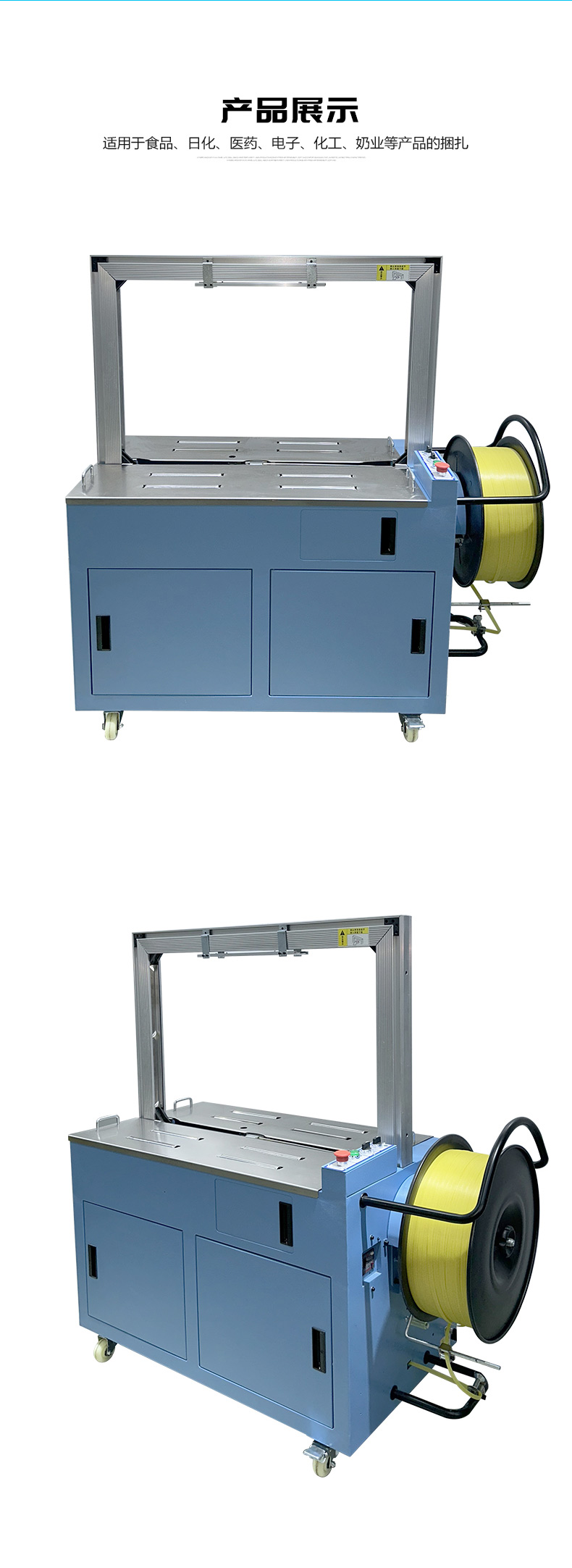

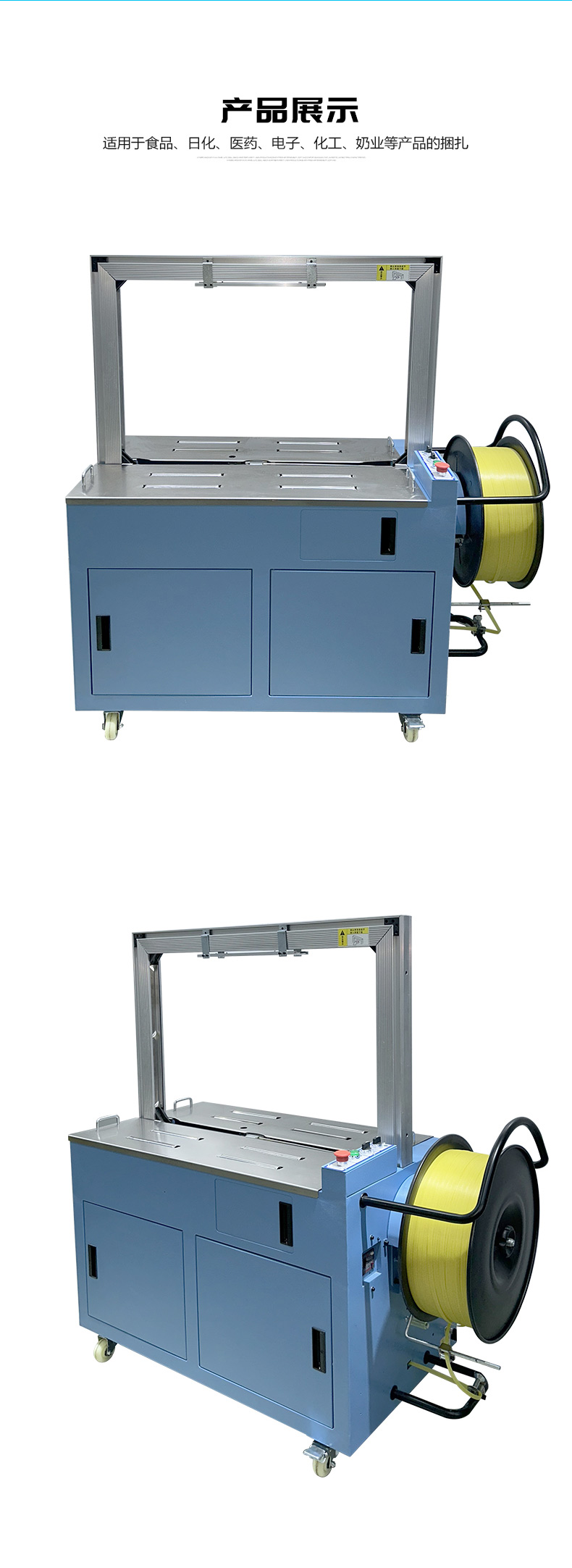

The equipment can be equipped with different functional modules according to needs:

- Adding a side strapping mechanism to realize side strapping of vertical materials (such as pipes and plates);

- Integrating an automatic tape threading device to adapt to extra-long or irregularly shaped materials (such as furniture and large equipment);

- Matching conveyor belts of different widths (adjustable from 500-1500mm) to meet packaging needs from small electronic products to large household appliances.

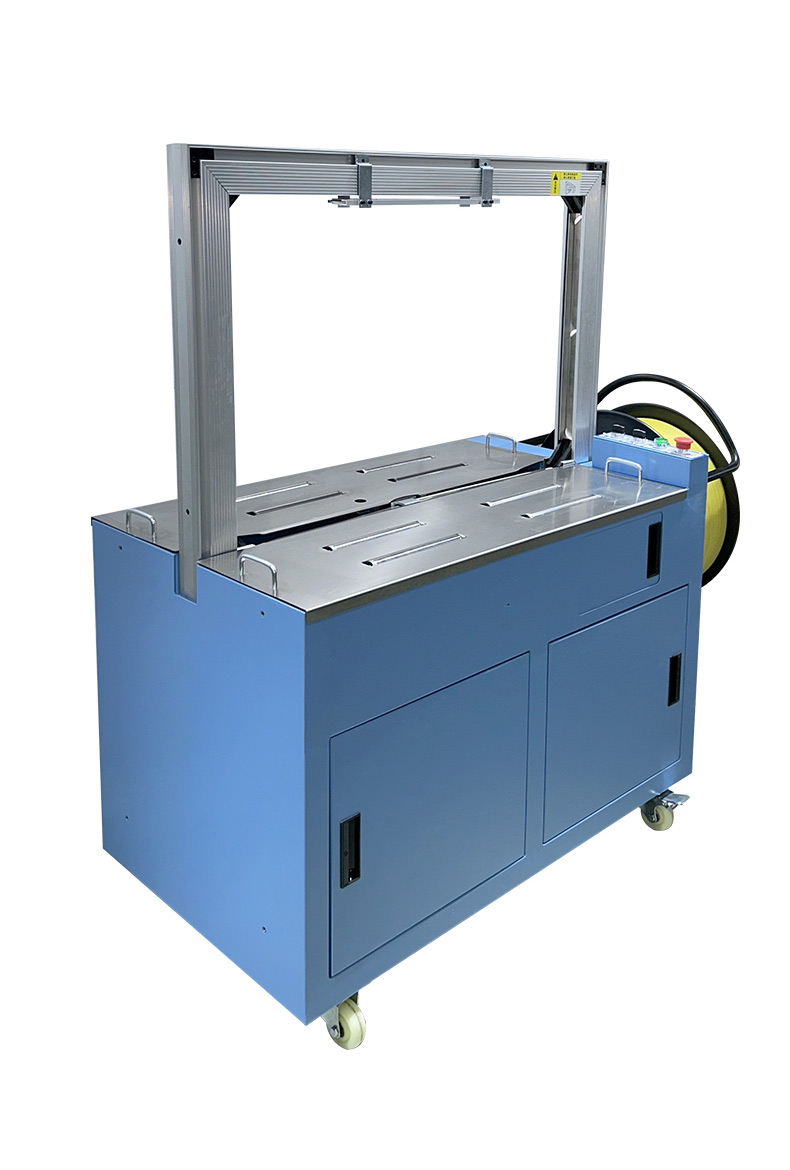

With a dust and water resistance rating of IP54, it can adapt to complex environments such as food processing workshops (humid) and building material warehouses (dusty);

It is compatible with various strap materials (PP, PET, steel straps, etc.) and widths (6-25mm), and can even handle reticulated and woven packaging materials through special designs.