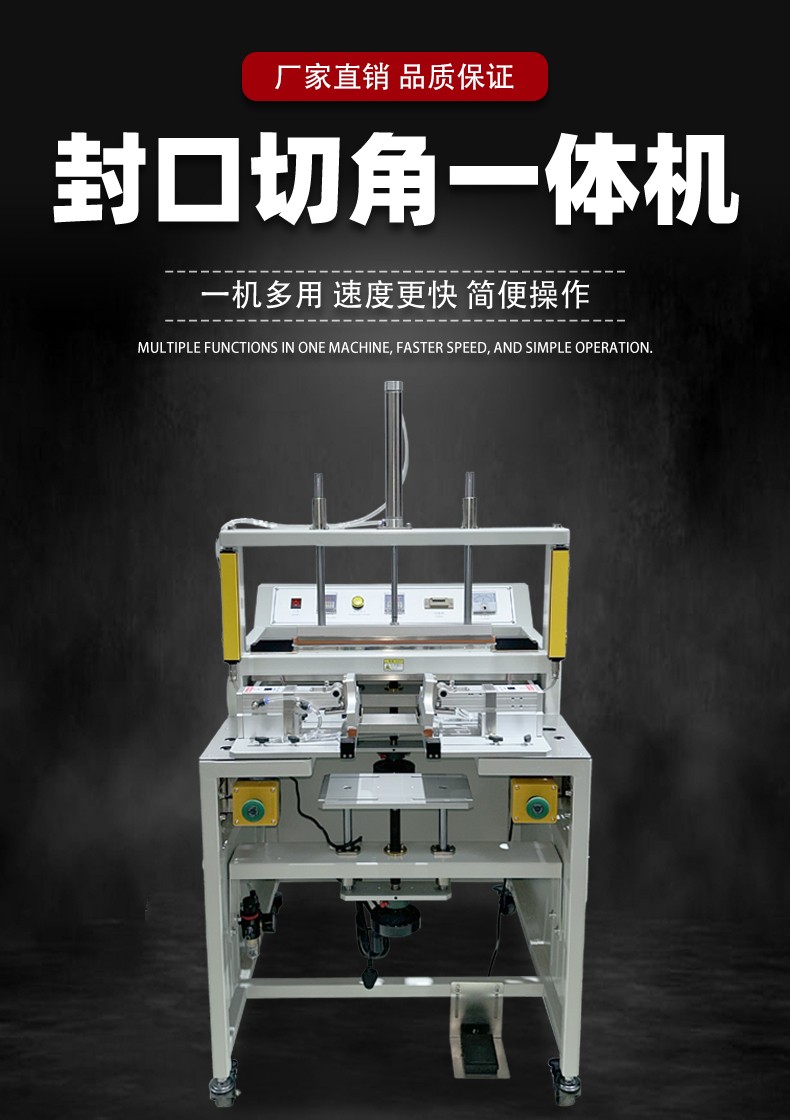

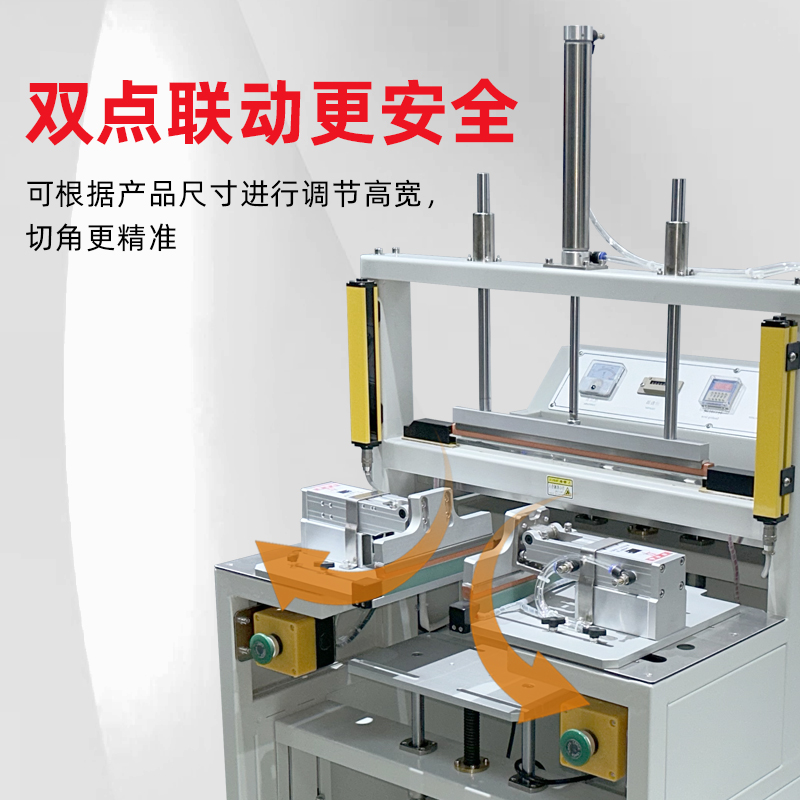

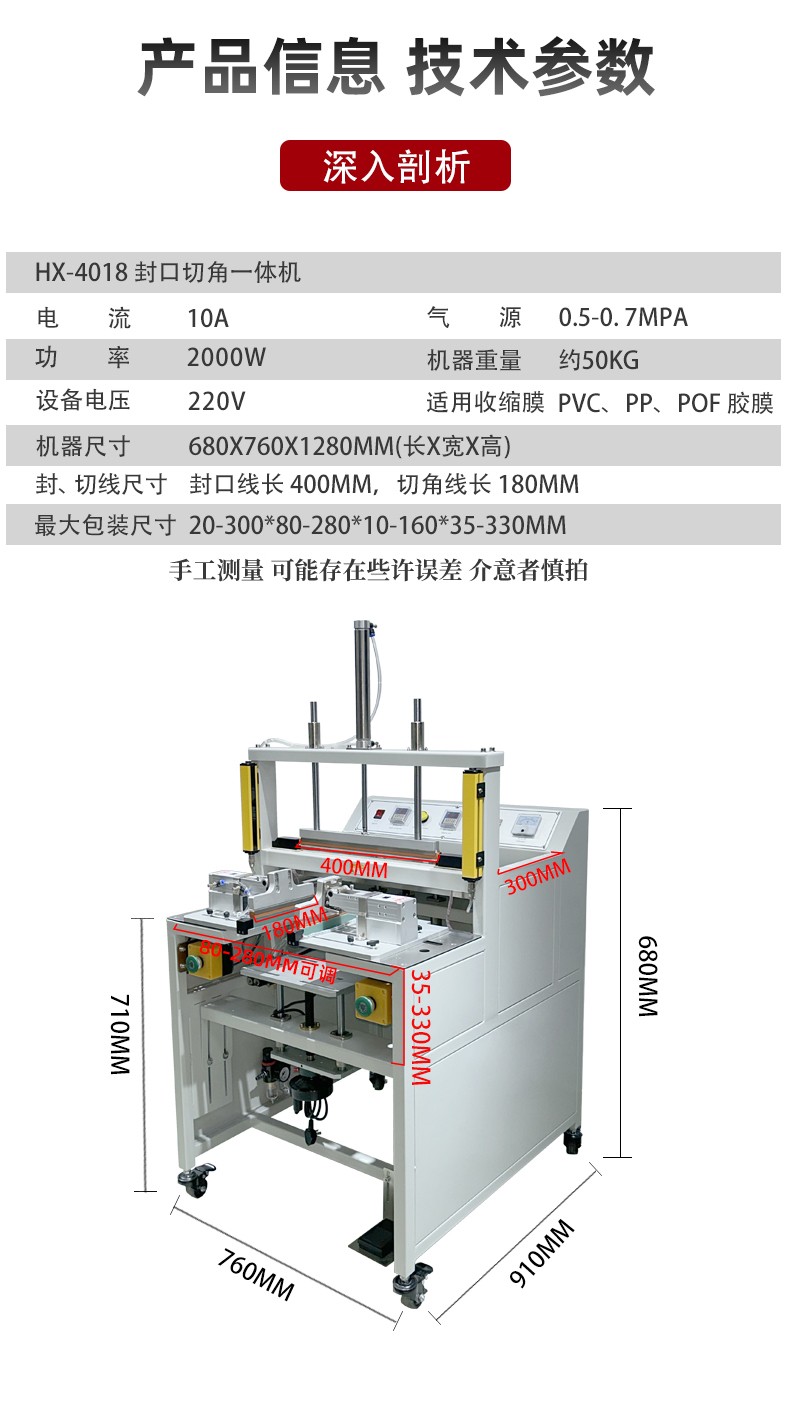

The equipment integrates full-process automated functions such as conveying, positioning, corner cutting, and sealing, eliminating the need for manual intervention in intermediate links. For example, after products automatically enter the workstation via the conveyor belt, the visual system quickly positions them, and the control system synchronously coordinates the activation of cutting and sealing components. The entire process is seamlessly connected, reducing pauses and waiting times caused by manual operations, and fundamentally improving the processing speed of individual products.

Production capacity performance per unit time:

Equipment of different models varies in production capacity due to differences in design specifications and applicable scenarios. Taking common high-speed models (such as the Zhicheng automatic corner-cutting and film-wrapping machine) as an example, in high-speed mode, they can handle more than 60 products per minute; while standard models for small and medium-sized enterprises typically have a production capacity of 30-50 pieces per minute. This efficiency is far higher than that of manual packaging (manual operations usually handle only 5-10 pieces per minute, with poor quality stability).

Adapting to mass production needs:

The equipment supports long-term continuous operation and can achieve uninterrupted packaging of bulk products in coordination with the feeding rhythm of the production line. For instance, in the assembly line of a food processing plant, the equipment can seamlessly connect with the front-end food forming machine and the back-end boxing machine, easily reaching a daily production capacity of tens of thousands of pieces, which meets the efficiency requirements of large-scale production.

Outstanding efficiency stability:

Compared with manual operations, which are prone to being affected by fatigue and skill differences, the equipment can maintain stable processing efficiency through precise parameter control (such as corner cutting speed and sealing time). It avoids efficiency fluctuations caused by human factors and ensures the reliable execution of production plans