Compared with traditional strapping machines (such as pneumatic strapping machines, mechanical transmission strapping machines, etc.), the fully automatic servo electric strapping machine has significant advantages in terms of technical performance, efficiency, adaptability, etc. The details are as follows:

Traditional strapping machines:

They mostly rely on pneumatics (cylinder-driven) or mechanical transmission (gears, cams, etc.). The power output stability is poor, and the adjustment of parameters such as strapping force and strap feeding length is rough, which easily leads to problems such as "excessive tightness damaging products" or "excessive looseness resulting in insecure strapping". For example, the force of a pneumatic strapping machine is affected by the fluctuation of air source pressure, and the difference in strapping tightness of products in the same batch can reach more than ±10%.

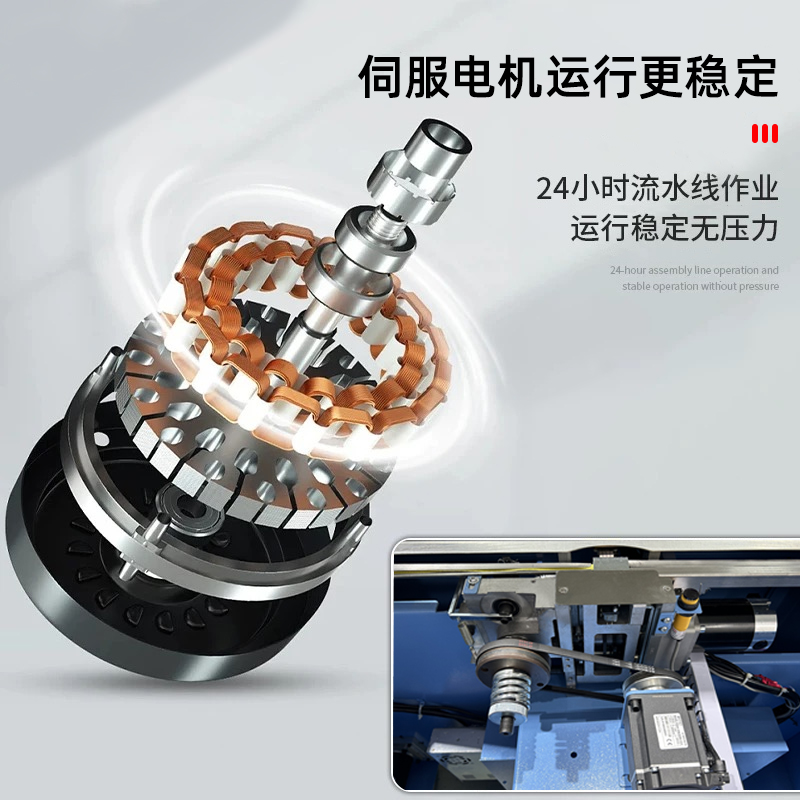

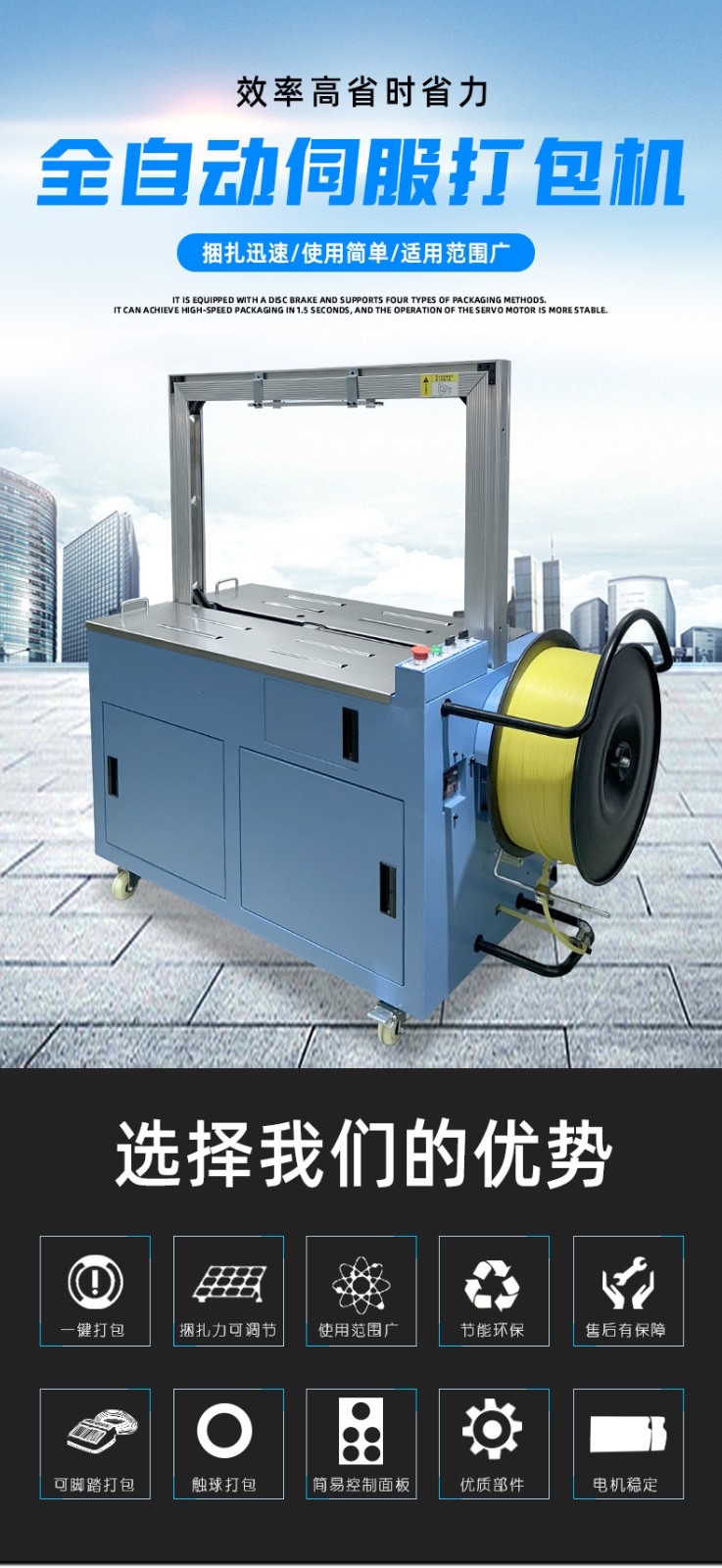

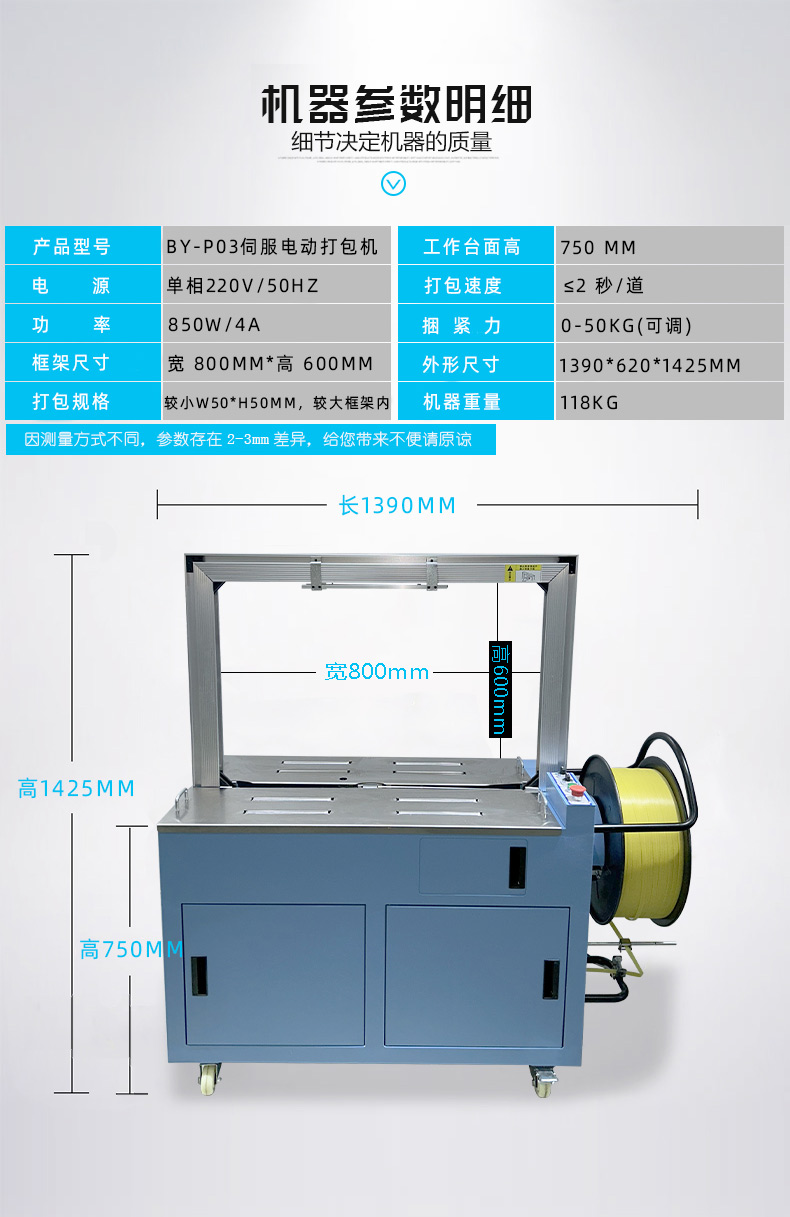

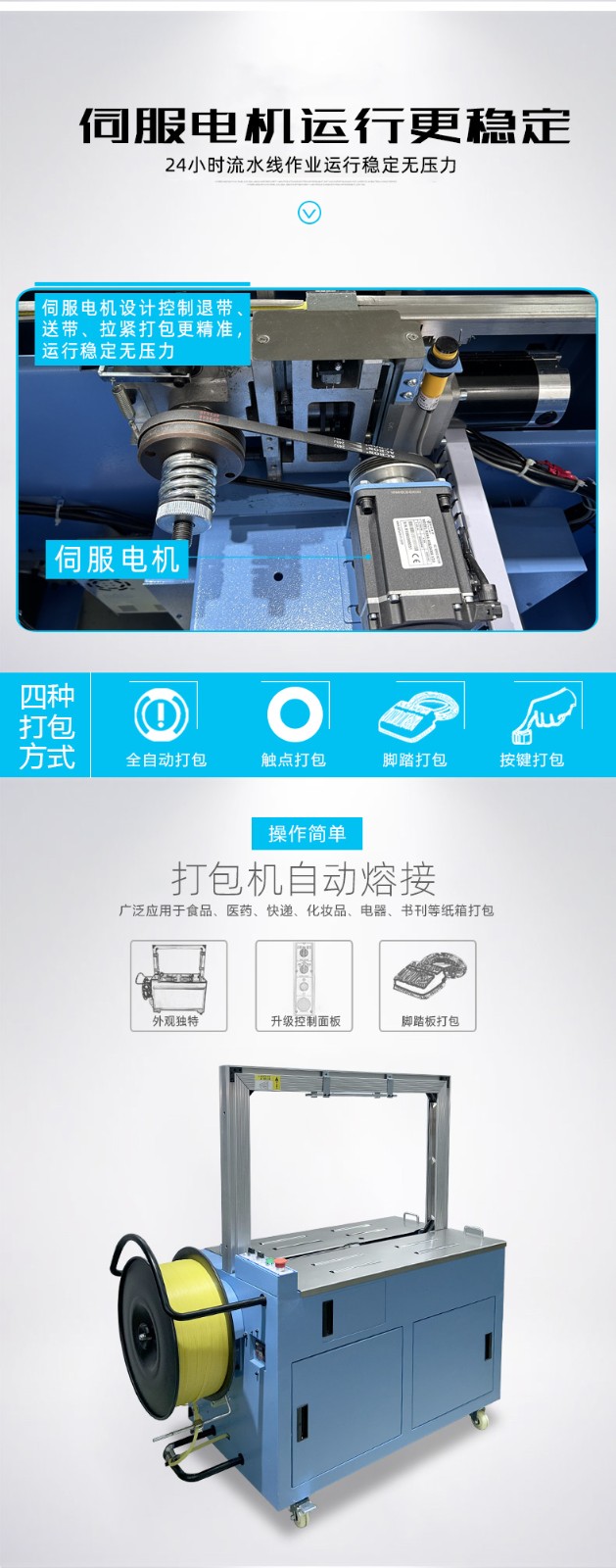

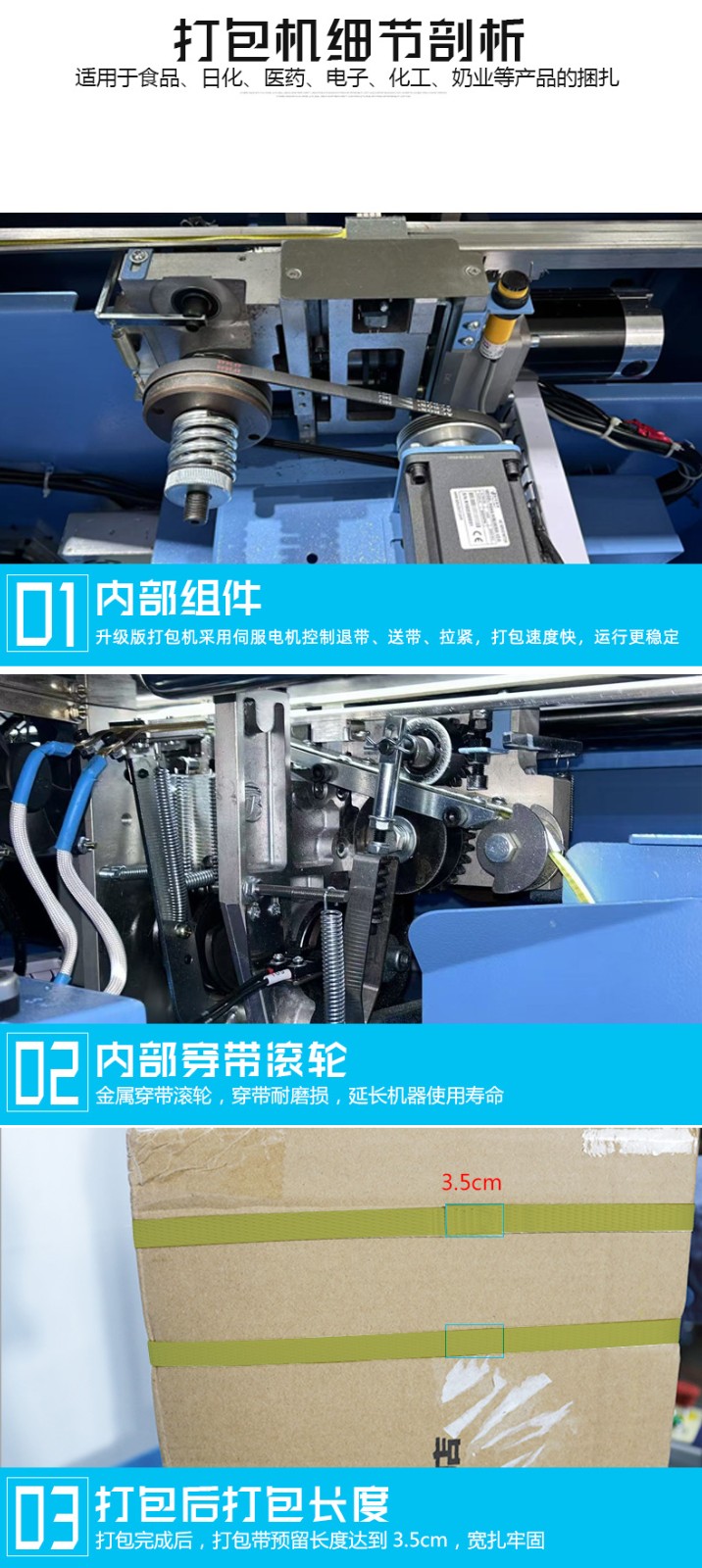

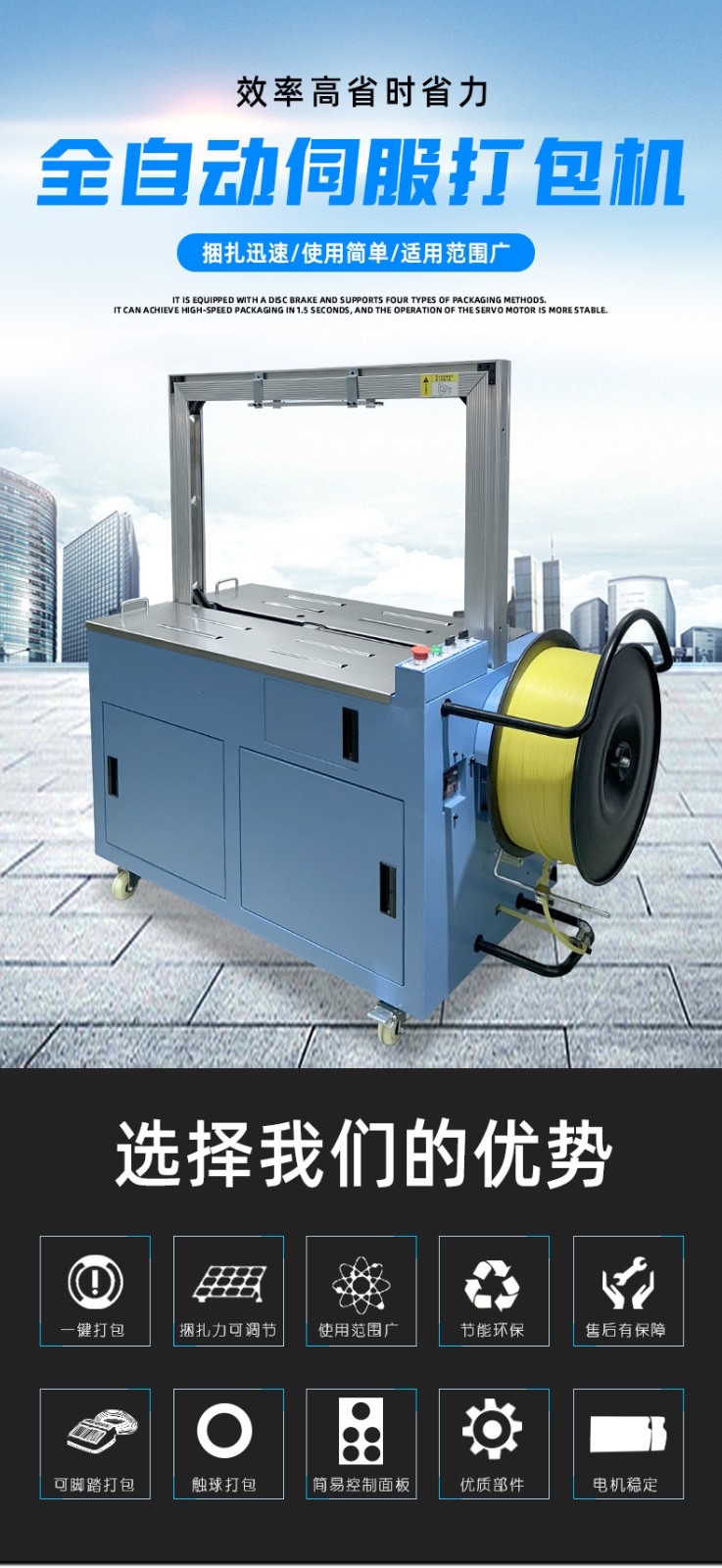

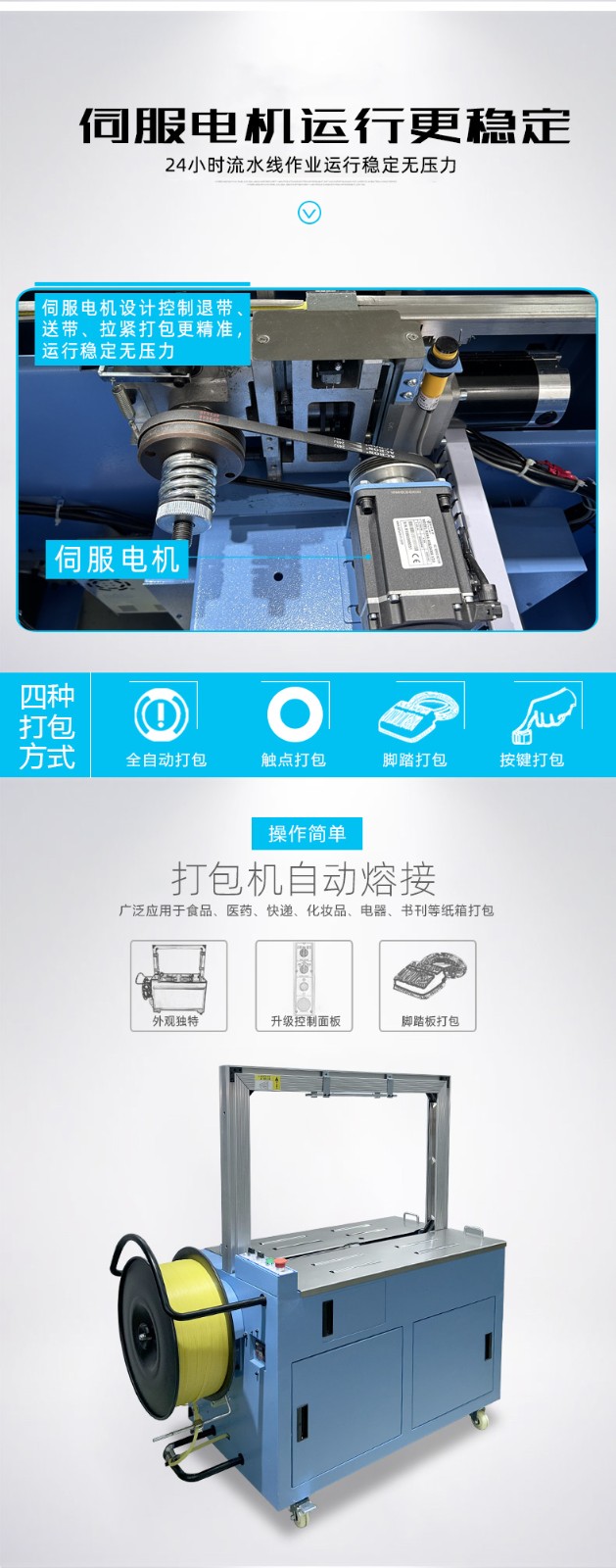

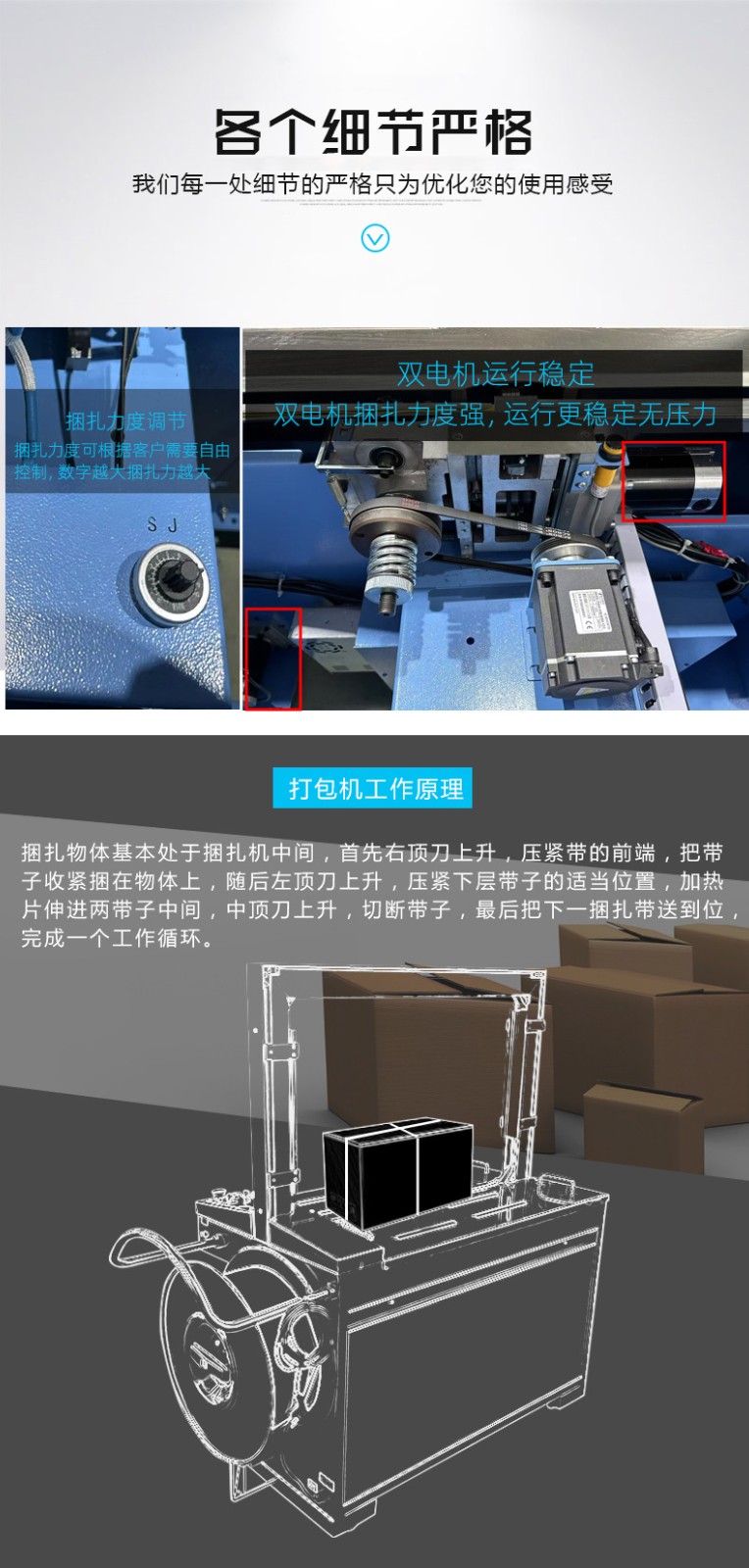

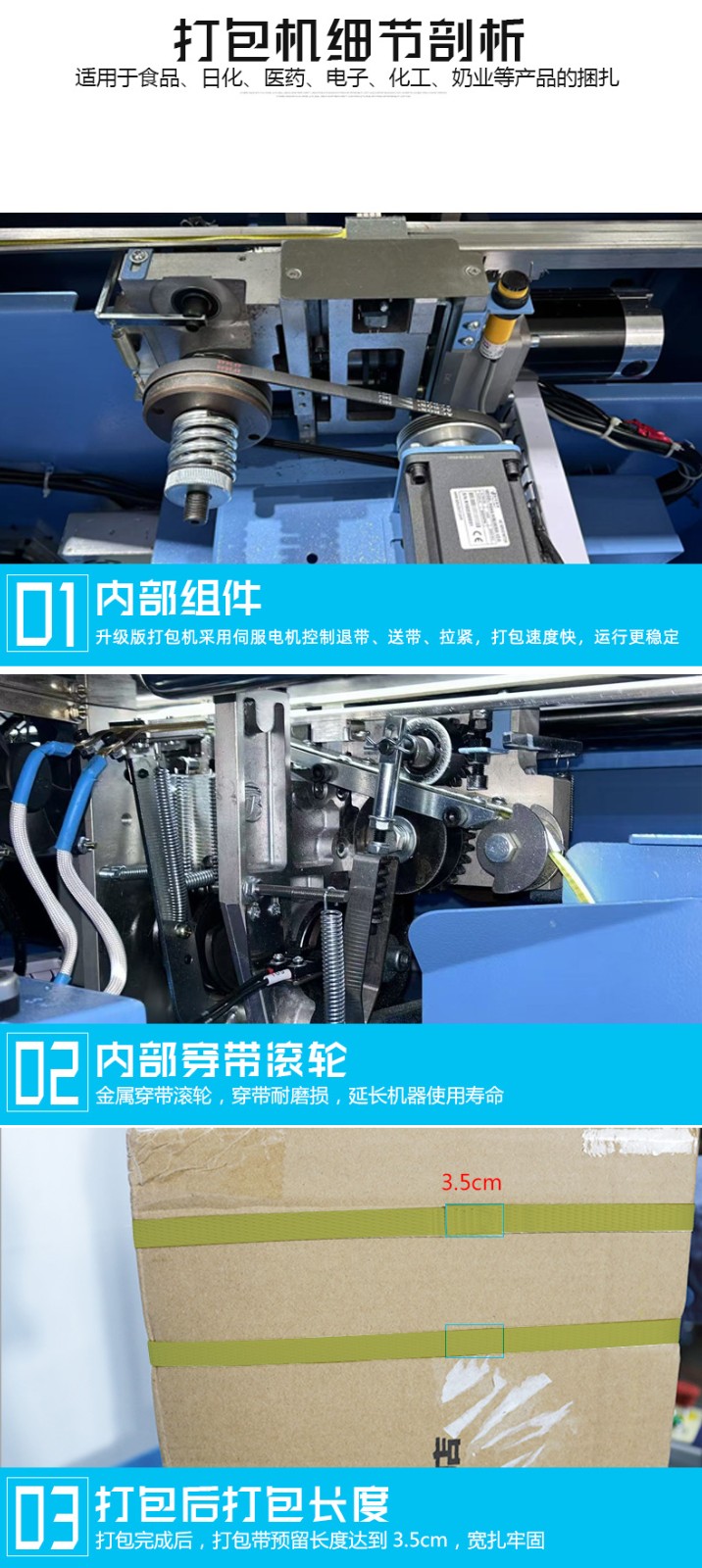

Servo electric strapping machines:

They adopt servo motor drive and real-time feedback of position, speed and torque through encoders, which can precisely control the strapping force (with an accuracy of ±1N), strap feeding length (with an error of ≤1mm) and strapping position. For instance, for fragile electronic products or precision instruments, it can accurately set the minimum strapping force (such as 50N) to ensure both firmness and no damage to the products; for heavy goods (such as building materials), it can stably output a force of more than 3000N, and the batch consistency error is less than 2%.

Traditional strapping machines:

Pneumatic or mechanical structures have slow response, and there is a delay in the connection between actions (such as the time-consuming switching of strap feeding, tightening, and welding). The single-cycle strapping speed is usually 15-25 times per minute, and the speed is prone to decrease due to component wear during continuous operation.

Servo electric strapping machines:

The start/stop response time of the servo motor is less than 0.1 seconds, and various actions (strap feeding, tightening, cutting) can be seamlessly connected. The single-cycle speed can reach 30-60 times per minute, and some high-speed models even exceed 80 times per minute. At the same time, the servo system can automatically adjust the speed according to the load, and the speed attenuation is less than 5% after 8 hours of continuous operation, which is suitable for high-speed production in assembly lines (such as sorting lines in the food and logistics industries).

Traditional strapping machines:

The adjustment of strapping parameters (force, strap length, strapping position) is cumbersome, requiring manual replacement of mechanical components (such as cams, baffles). When adapting to products of different sizes and materials, the model change time is as long as more than 30 minutes, making it difficult to cope with multi-variety and small-batch production.

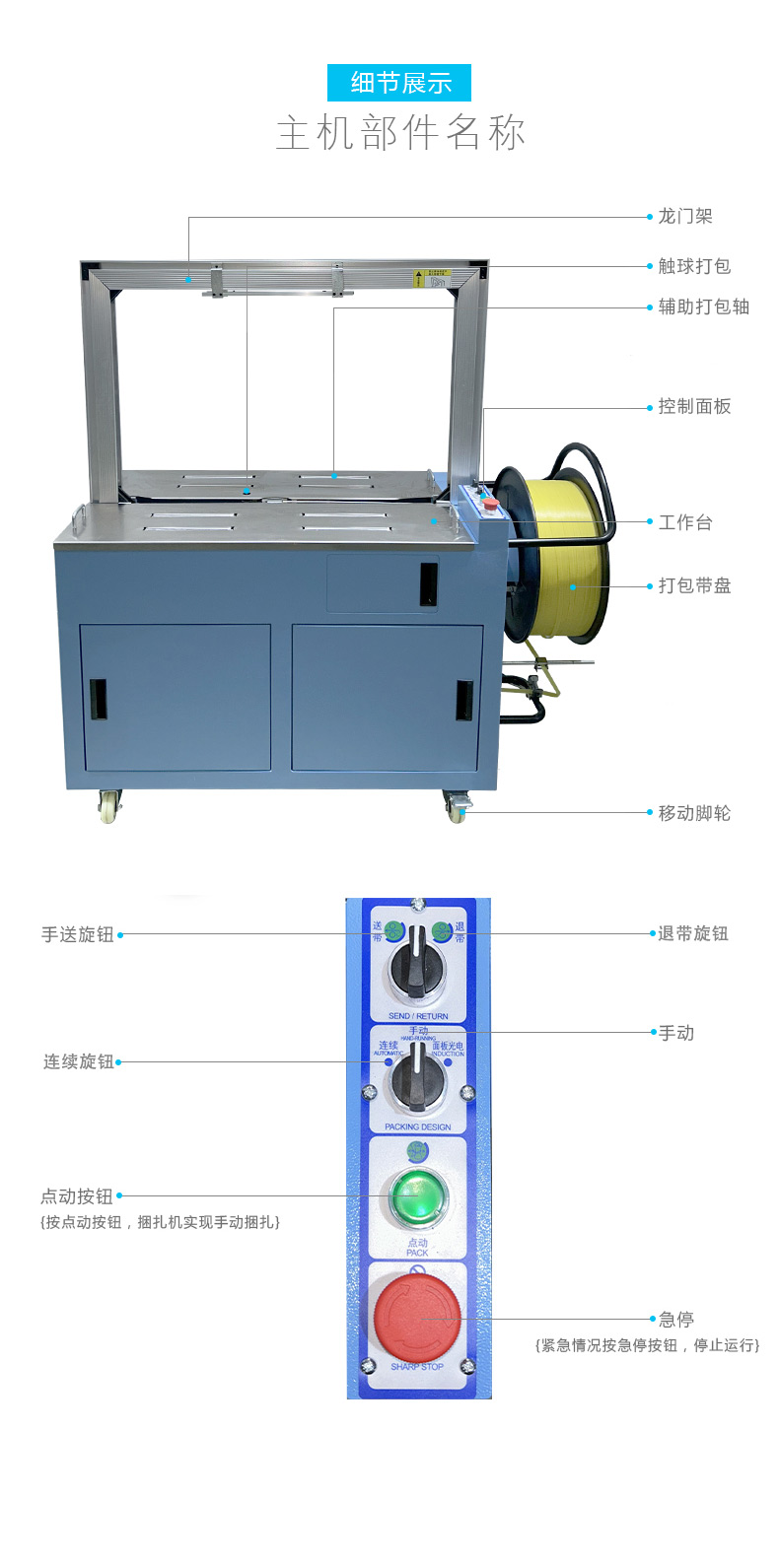

Servo electric strapping machines:

Parameters can be set with one click through the human-machine interface (HMI), supporting the storage of more than 100 types of product strapping schemes (such as parameters of cartons and plates of different specifications), and the model change time is less than 5 minutes. For example, the same equipment can quickly switch to the strapping modes of "light cartons (50N force)" and "heavy steel (2000N force)" without mechanical adjustment.

Traditional strapping machines:

The cylinders and sealing rings of pneumatic models are prone to wear and need to be replaced frequently (on average 1-2 times a month); the gears and cams of mechanical transmission wear quickly due to hard contact, and their service life is usually 10,000-20,000 cycles.

Servo electric strapping machines:

The servo motor has no mechanical contact loss. The core components (such as guide rails and cutters) are made of wear-resistant materials. Combined with intelligent fault early warning (such as overload protection and strap 余量 reminder), the service life can reach 50,000-100,000 cycles, and the maintenance frequency is reduced by more than 70%. For example, when the cutter wears to the critical value, the system will automatically prompt for replacement to avoid sudden shutdown.