How to choose a suitable can and box tape sealing machine for yourself

Release date:2025-06-16

- For large-scale and continuous production, it is recommended to choose a fully automatic can and box tape sealing machine. It can realize a series of operations such as automatic feeding, sealing, and discharging, with high production efficiency, capable of completing the sealing of hundreds or even thousands of cans/boxes per hour.

- For small to medium-scale production or situations with fluctuating output, a semi-automatic can and box tape sealing machine is more suitable. It has a relatively lower price, meets certain production needs, but requires manual assistance for part of the operations.

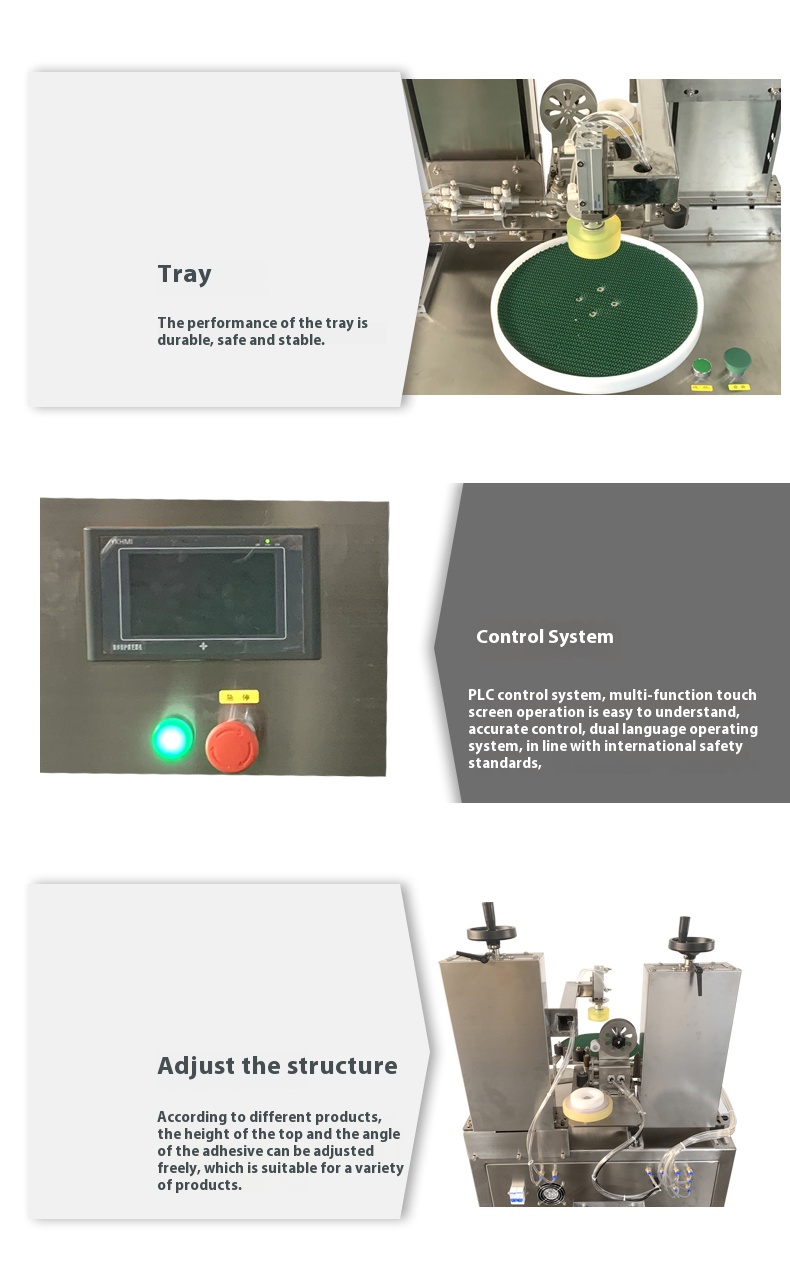

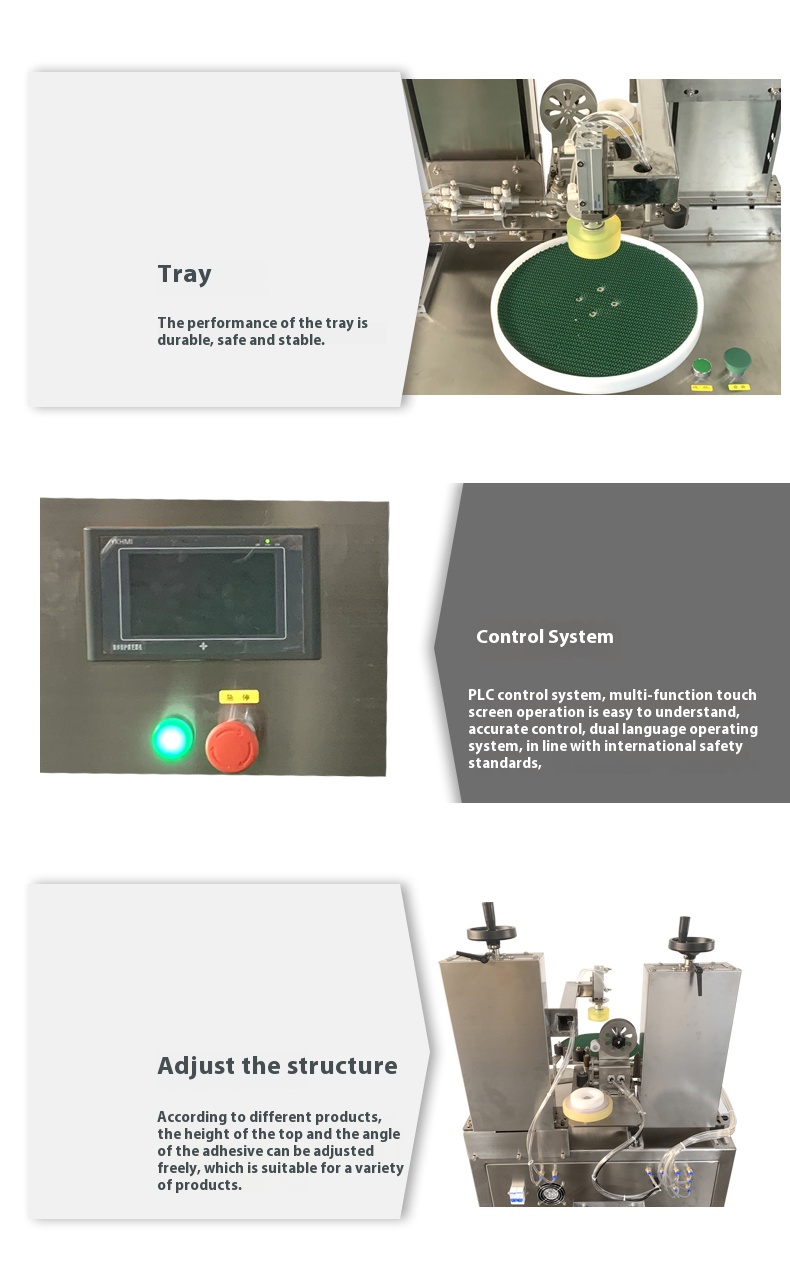

- Different shapes (such as square, round, special-shaped) and sizes (height, diameter, side length, etc.) of cans/boxes require different adaptability from the sealing machine.

- For example, round cans/boxes need the sealing machine to have good circumferential fitting and sealing capabilities.

- For cans/boxes with large size differences, it is best to choose equipment with flexibly adjustable sealing parameters (such as sealing position, tape length, etc.) to ensure that different specifications of cans/boxes can be sealed smoothly.

- A high-quality sealing machine should ensure that the tape fits tightly with the can/box without bubbles, wrinkles, or degumming. You can check the sample sealing effect of the equipment or understand the reputation of the model in practical applications.

- In addition, sealing machines with constant pressure and temperature control functions can better ensure the stability of sealing quality.

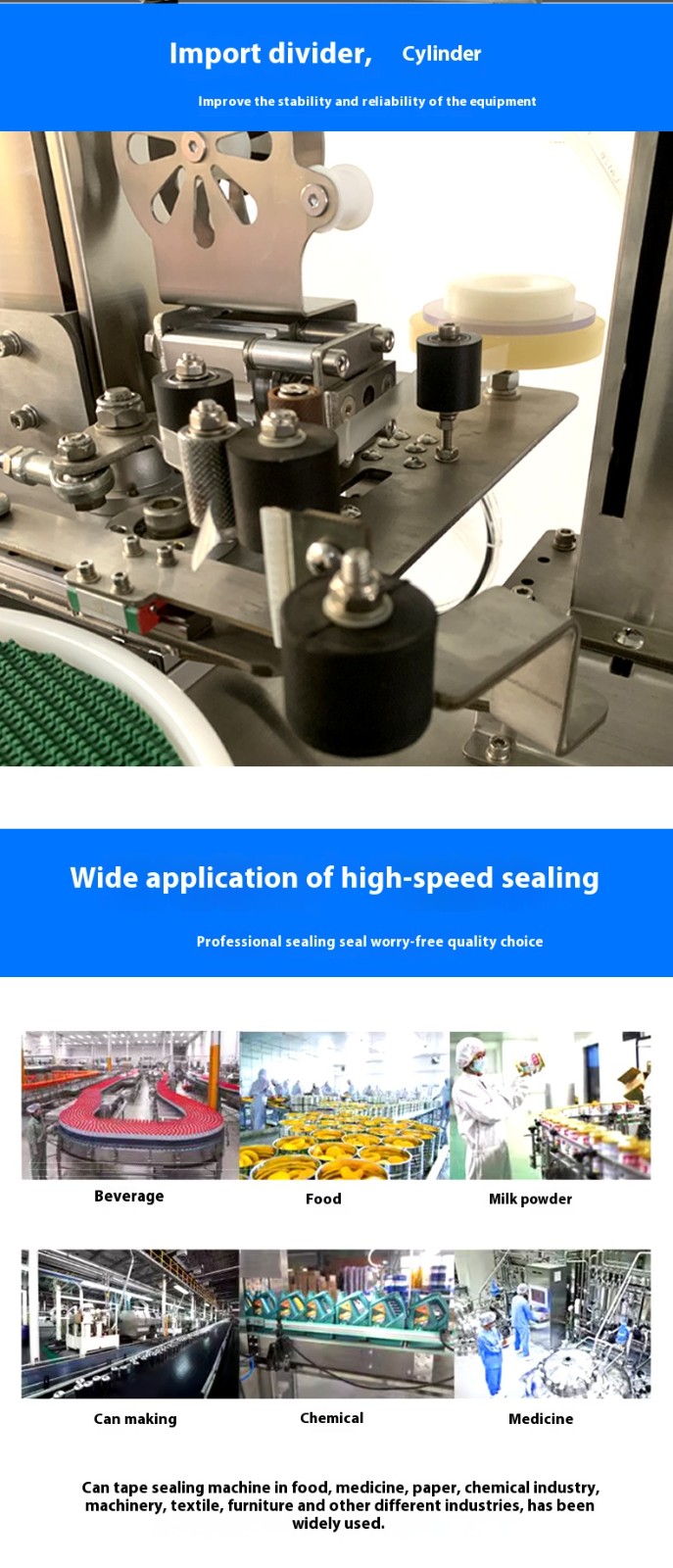

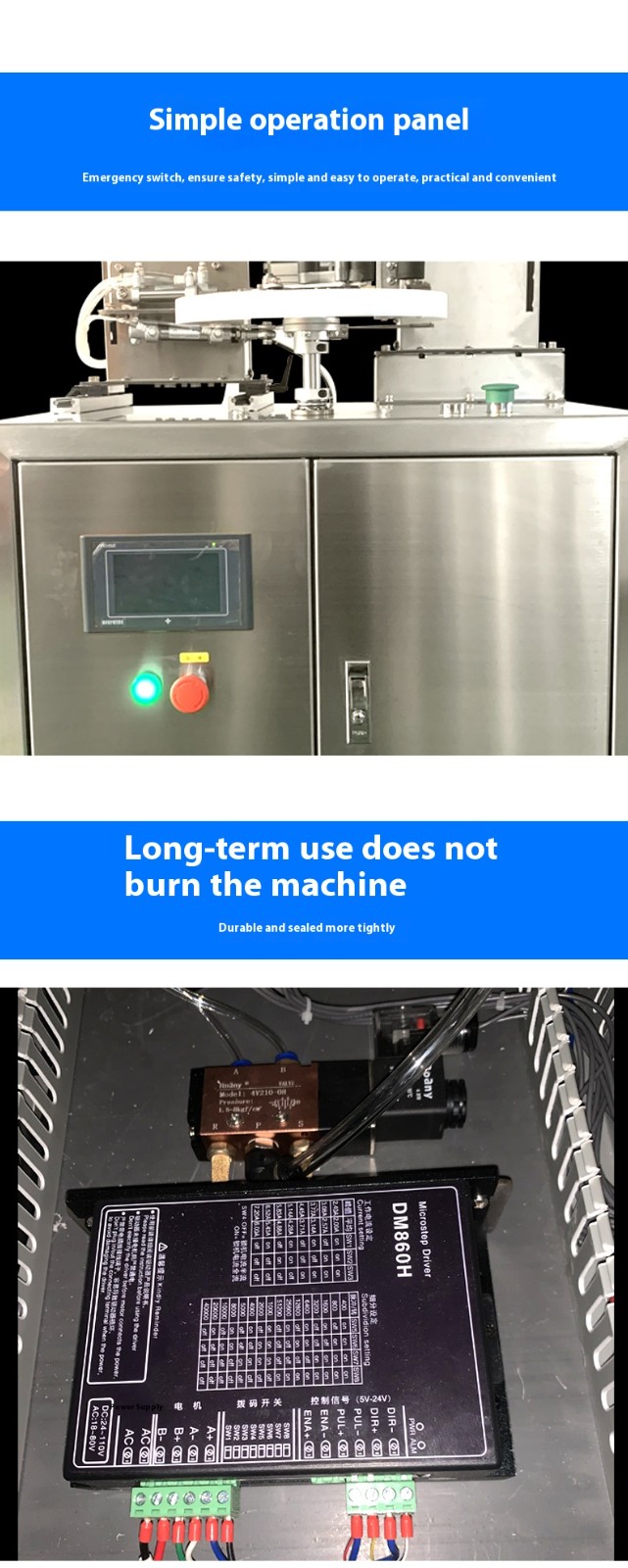

- The stability of the machine directly affects production efficiency and maintenance costs. Prioritize sealing machines using high-quality components and reasonable structural designs.

- You can refer to the manufacturer's production process, quality control system, and feedback from other users on the durability of the equipment.

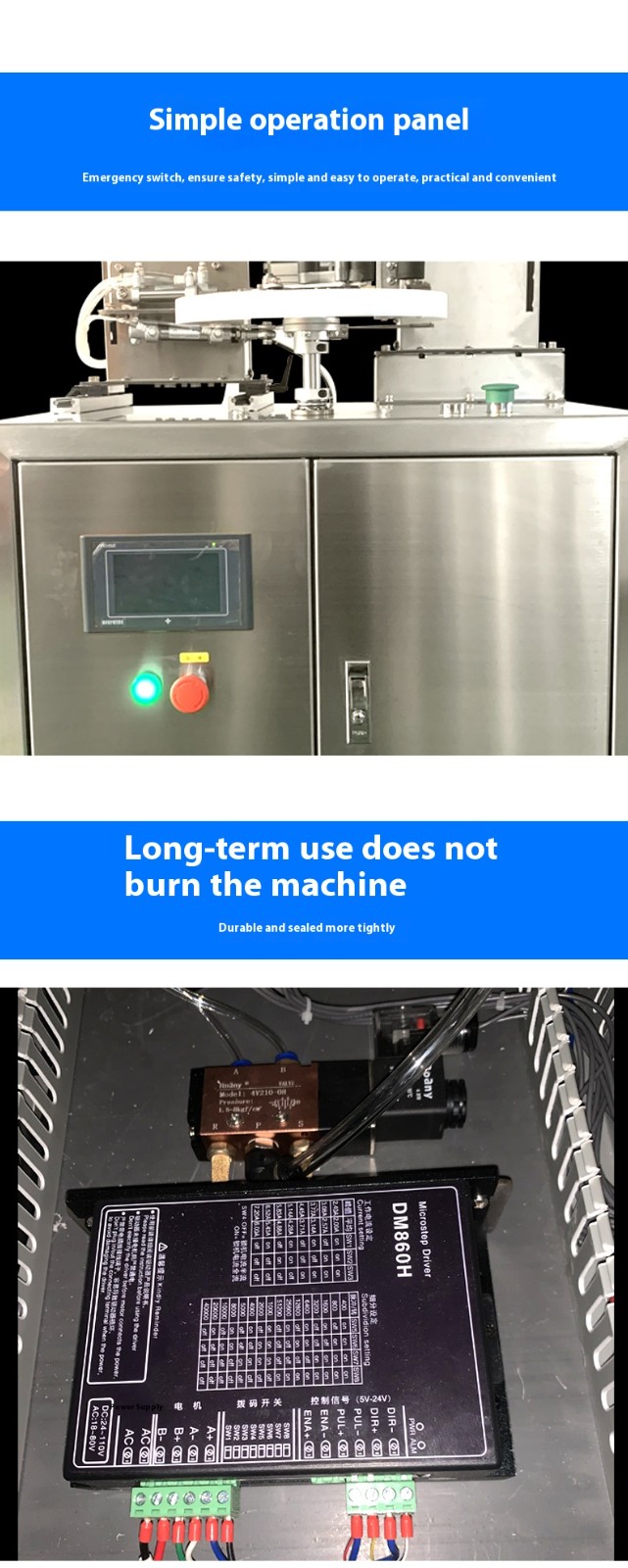

- The operation interface should be simple and clear, facilitating parameter setting, start, stop, and other operations for operators.

- Meanwhile, the maintenance and repair of the equipment should be simple and easy to understand, with easy disassembly, cleaning, and replacement of vulnerable parts, reducing the professional skill requirements for operators