Small-Sized Steam Shrink Machine | Heat Shrink Packaging Machine for Cosmetics, Daily Necessities & Wine Bottle Labels | PET/PVC Films Compatible

A steam shrink machine generates steam by heating water, which is then sprayed under a certain pressure onto the shrink film covering the packaged items. The shrink film shrinks rapidly upon heating and tightly wraps around the items, achieving the goals of fixing, protecting the items and enhancing the aesthetics of the packaging.

Key Features

- High-Efficiency Shrinkage: It can quickly generate a large volume of steam, enabling the packaging film to shrink fast and fit tightly to the products, thus improving production efficiency.

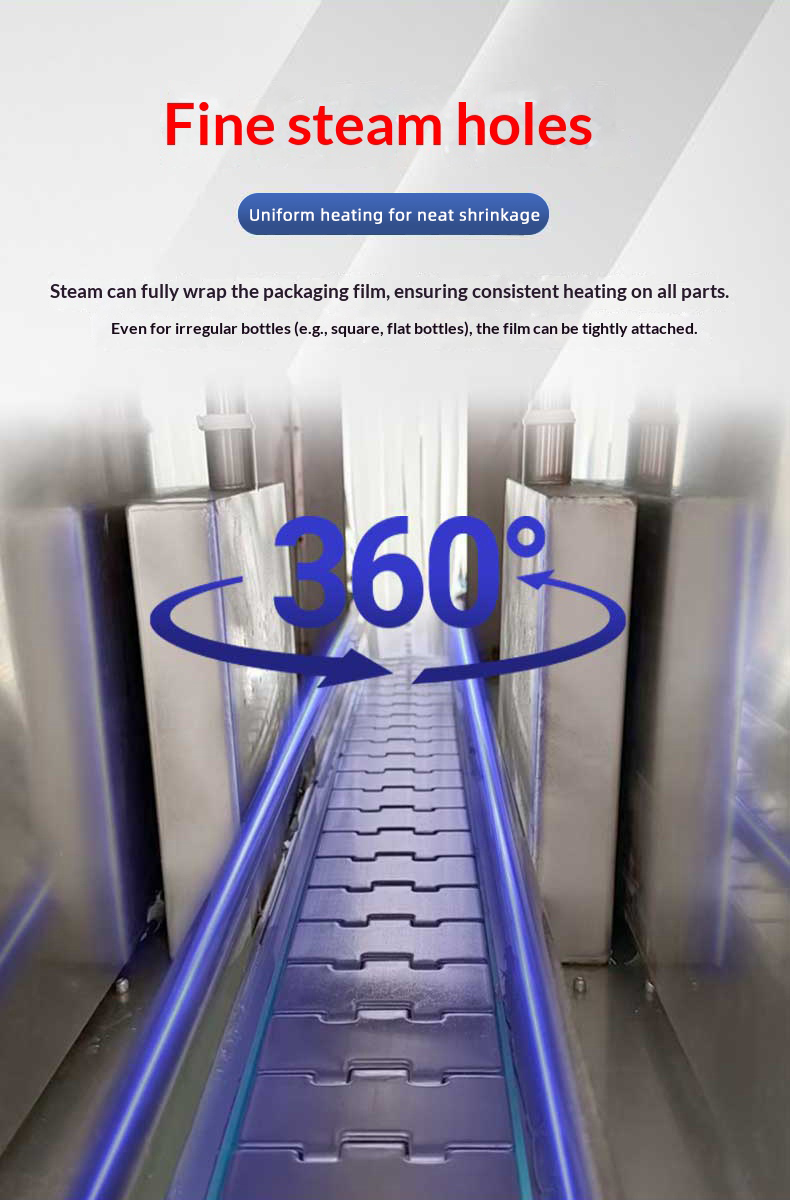

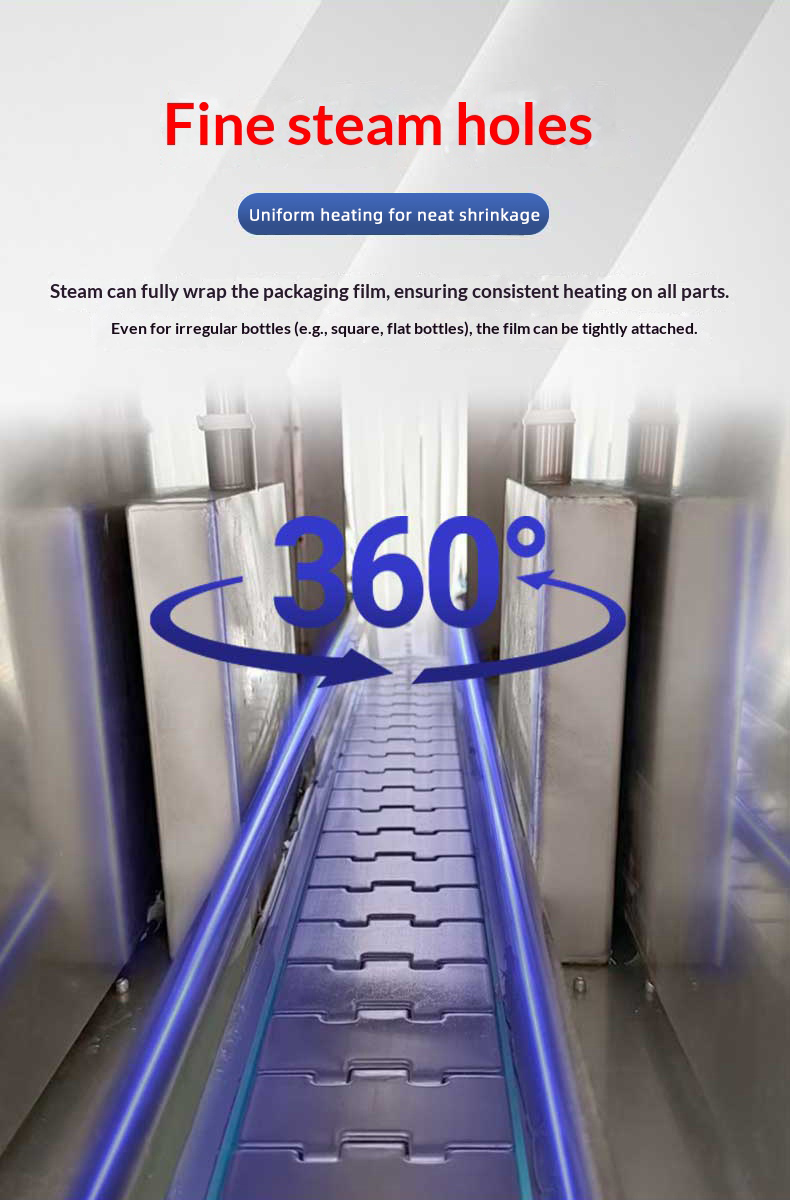

- Uniform Shrinkage: The steam is evenly distributed, ensuring consistent shrinkage of the packaging film across all parts of the products, resulting in more attractive and sturdy packaging.

- Strong Applicability: It is compatible with various common heat shrink films such as PVC, POF and PP, and suitable for packaging regularly shaped products (e.g., boxes, bottles) as well as irregularly shaped items.

- Easy Operation: The equipment features a user-friendly interface. Operators can master the operation after simple training. Some models even support a full automatic process including feeding, shrinking and discharging, reducing labor intensity.

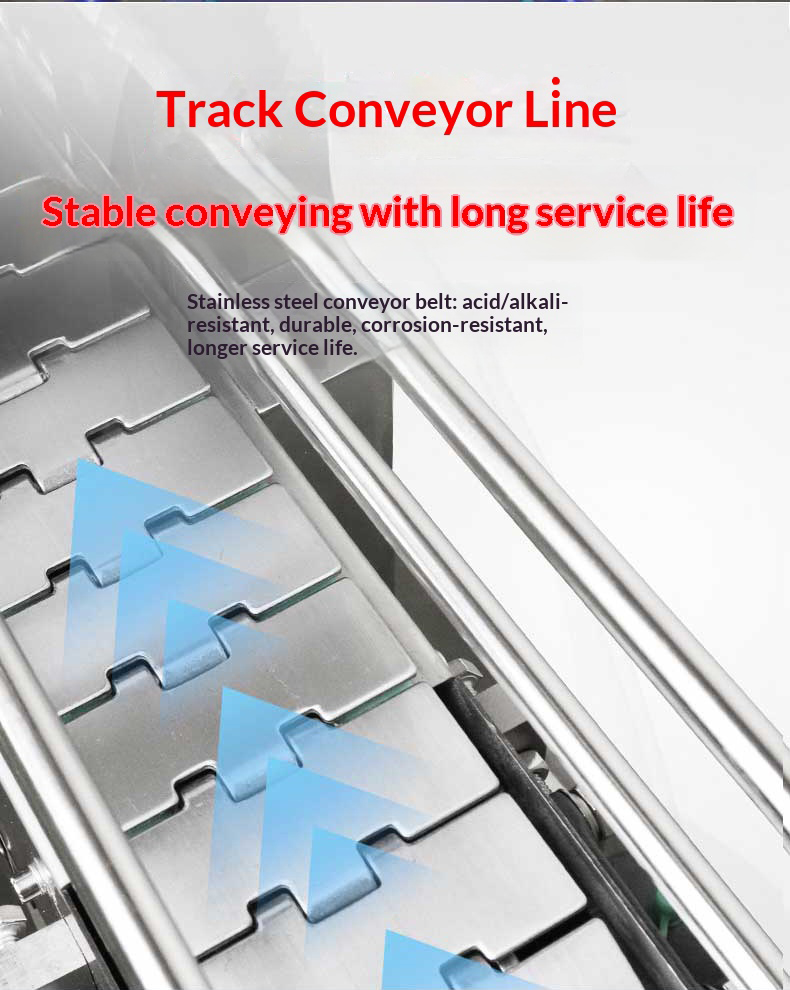

- Safe and Reliable: It is usually equipped with multiple safety protection measures such as overheat protection and pressure protection. The machine body is made of corrosion-resistant and high-temperature-resistant materials, ensuring a long service life.

- Energy-Saving and Environmentally Friendly: Optimized design enhances steam utilization efficiency and reduces energy consumption. Moreover, no harmful substances are produced during the steam shrinkage process.

Core Components

- Steam Generator: The power core of the equipment, responsible for generating high-temperature steam.

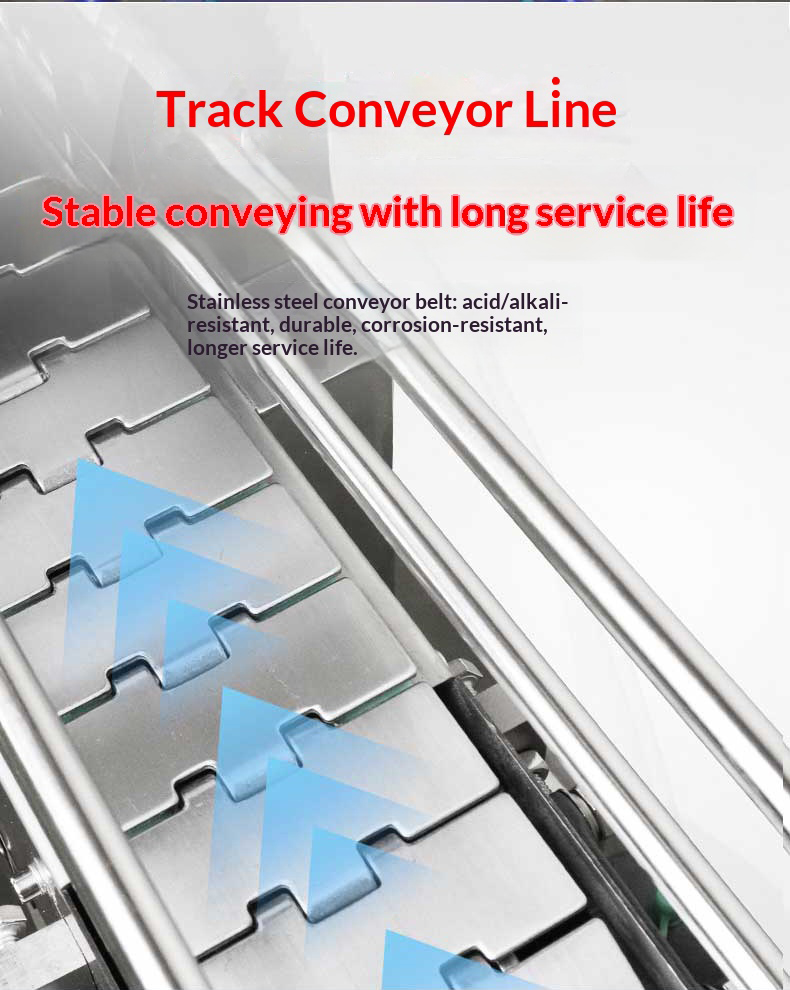

- Conveying System: Used to stably transport the products to be packaged, ensuring they are uniformly exposed to steam in the shrink chamber.

- Shrink Chamber: The area where products are subjected to steam, realizing the shrinkage of packaging materials.

- Control System: Precisely regulates parameters such as steam temperature, pressure and conveying speed, ensuring consistent and stable shrinkage results.

Application Fields

- Food and Beverage Industry: Applied to the shrink packaging of bottled drinks, canned foods, boxed pastries, etc. It can effectively prevent products from moisture and deterioration, extending the shelf life.

- Pharmaceutical Industry: Used for the shrink packaging of medicines and medical devices, ensuring the hygiene and safety of products.

- Daily Chemical Industry: Suitable for the shrink packaging of shampoos, body washes, cosmetics and other products, enhancing the product appearance.

- Electronic Industry: Adopted for the shrink packaging of electronic product boxes, protecting products from damage during transportation and storage.