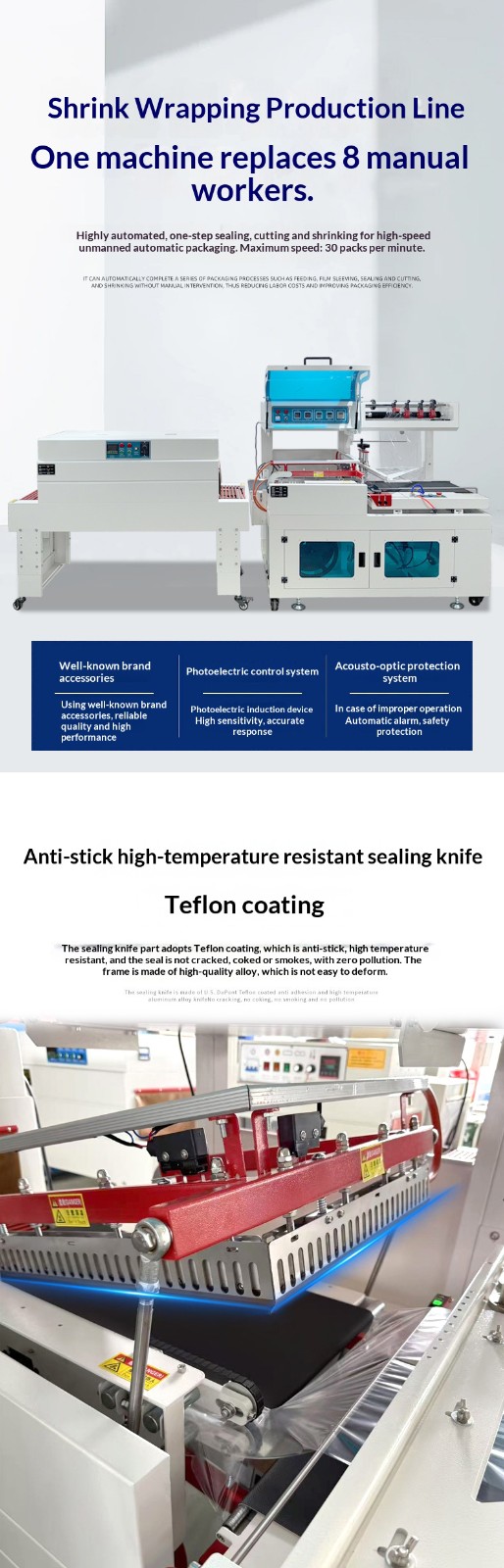

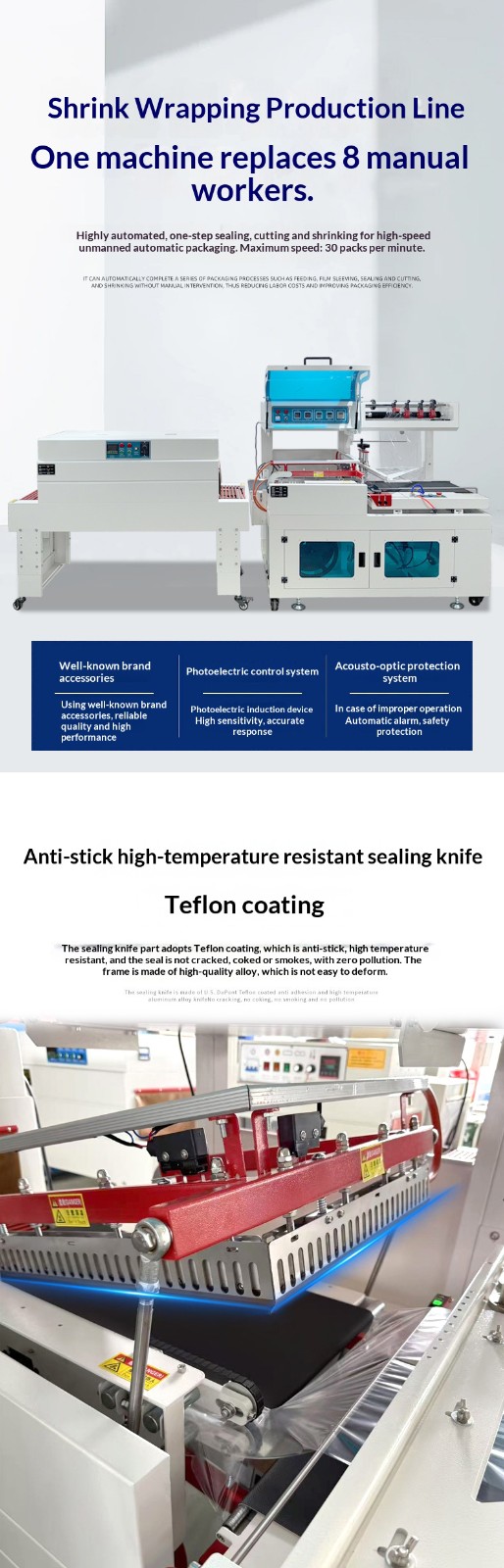

The automatic sealing, cutting and heat shrink packaging machine is a modern packaging equipment integrating automatic feeding, intelligent film sleeving, precise sealing & cutting, constant-temperature heat shrinking, and finished product discharging. Leveraging core technologies such as touch screen control, photoelectric sensing positioning, and multi-zone temperature control, it realizes fully automated unmanned assembly line operation throughout the entire process. Widely applied to batch packaging needs in industries including food, pharmaceuticals, daily chemicals, hardware, and electronics, it serves as a core equipment to replace traditional manual packaging, improve production efficiency, and enhance packaging quality.

Centered on the dual processes of "sealing & cutting + heat shrinking", the equipment achieves a closed-loop process through an automated system:

- Products automatically enter the packaging channel via the conveyor belt, and the photoelectric sensor triggers the film sleeving mechanism after detecting the product position;

- Shrink film (such as POF/PE/PVC) is released according to preset parameters, the film guiding mechanism completes full-wrap packaging of the product, and the film tension is adjusted automatically;

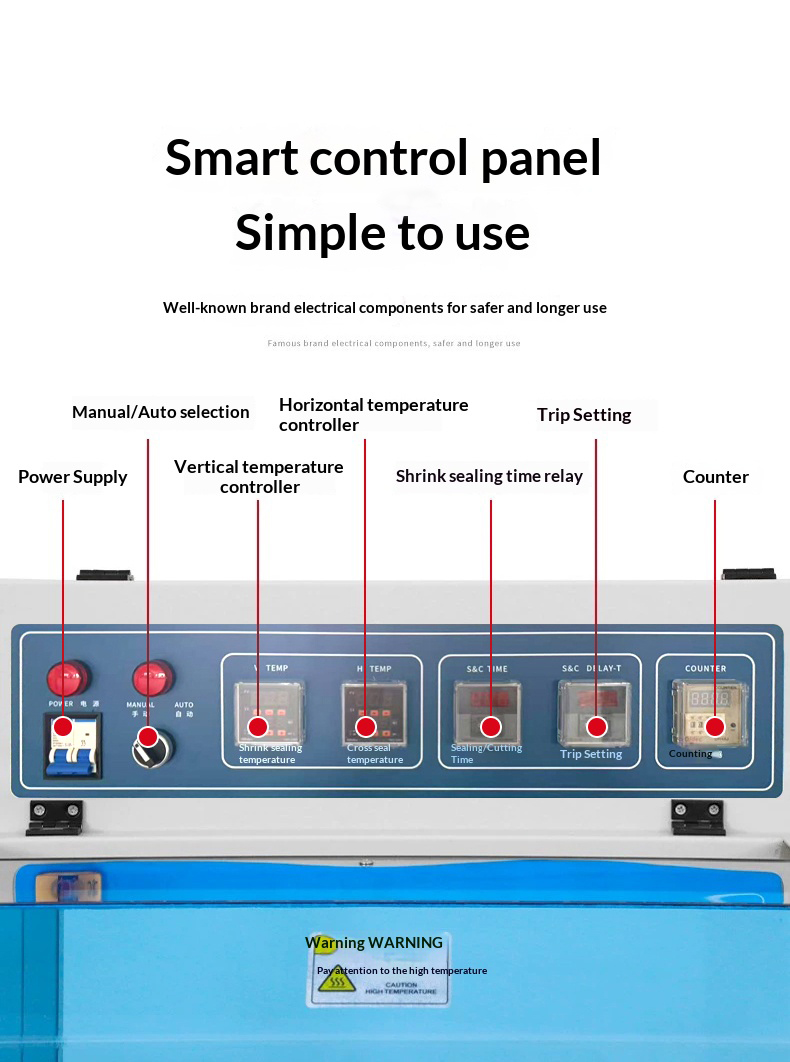

- The special alloy sealing & cutting blade set (Teflon-coated to prevent film adhesion) completes heat sealing and cutting along the trajectory, with real-time adjustable sealing temperature;

- Sealed and cut products automatically enter the multi-zone constant-temperature shrink tunnel, where the stable temperature field inside the tunnel enables the film to shrink uniformly and adhere tightly to the product surface;

- After shaping in the cooling section, finished products are automatically conveyed to the finished product area via the discharge conveyor belt. The entire process requires no manual intervention and supports 24/7 continuous operation.

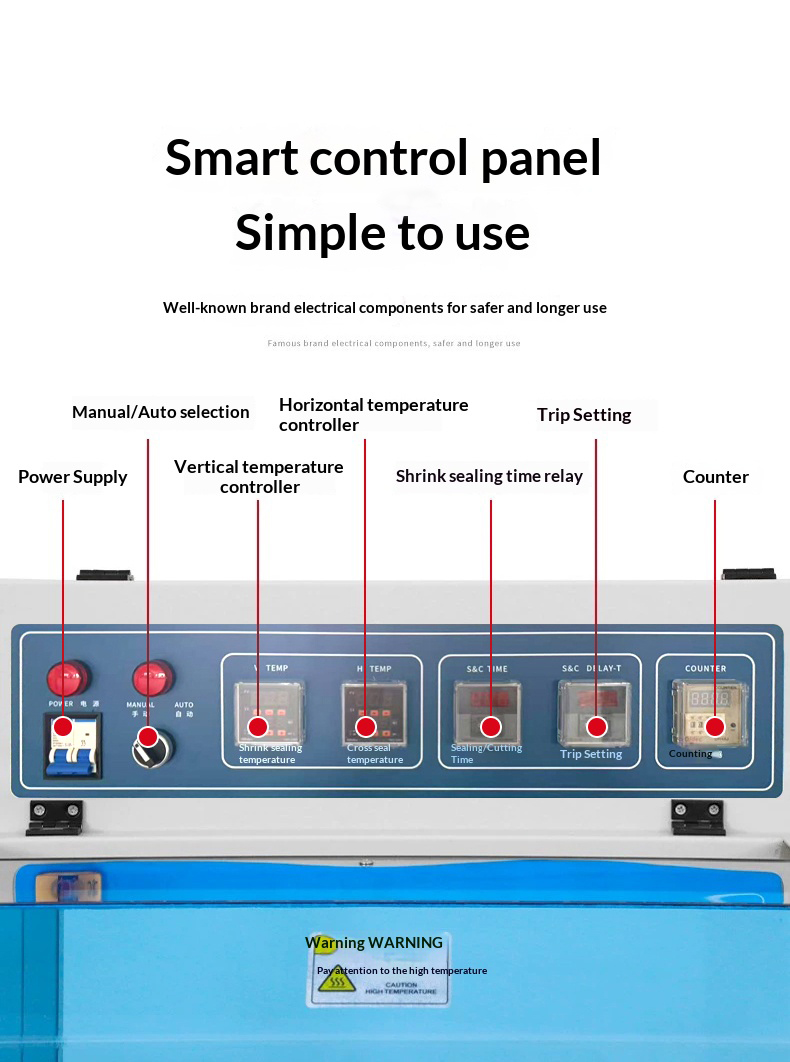

Dual protection of photoelectric sensing + infrared positioning ensures a product positioning accuracy of ±0.1mm, adapting to products of different sizes and shapes (including cuboids, cylinders, and irregular parts);

Seamless integration with upstream production lines (sorting machines, filling machines) and downstream palletizing equipment, integrating into the overall production line to achieve full-plant automated collaboration.

- Sealing & Cutting System: Teflon-coated sealing & cutting blades + constant-temperature heating technology ensure firm and leak-proof seals, neat cutting edges, and thin sealing lines (1-2mm). The blades are wear-resistant with a long service life;

- Heat Shrink System: Multi-zone temperature control (adjustable from 0-300℃ with an error of ±2℃) supports adaptation to different film materials, delivering flat and wrinkle-free shrink results that fit the product tightly without looseness;

- Energy-Saving Design: Optimized heating tube layout and thermal insulation structure reduce energy consumption by 15%-20% compared to traditional models. Some models are equipped with waste heat recovery systems, complying with low-carbon production requirements.

Key components (motors, temperature controllers, sensors) adopt imported brands, featuring low failure rates and strong stability during continuous operation;

Modular design with easily accessible maintenance windows allows daily maintenance without professional technicians, reducing operation and maintenance costs.

Covering batch packaging scenarios in multiple industries, it meets diverse needs such as single-product packaging, combined set packaging, and batch bundling:

- Food Industry: Snack foods, fresh and frozen foods, grain, oil and dried foods, baked goods (for freshness preservation, moisture proofing, and shelf-life extension);

- Pharmaceutical Industry: Pharmaceutical preparations (boxed collections), medical devices (outer packaging for sterile products), health products (bottled/boxed sets);

- Daily Chemicals & Cosmetics: Skin care products, toiletries, cosmetic gift boxes (enhancing packaging grade and sealing performance);

- Hardware & Electronics: Hardware accessories (preventing rust and scattering), digital products (independent/accessory combination packaging, with optional anti-static film), electrical components (batch storage packaging);

- Other Industries: Printed matter, stationery sets, toys, building materials (preventing scratches and collisions), holiday gifts (outer shrink packaging to enhance texture).

A single unit can replace 3-5 packers, saving hundreds of thousands of yuan in annual labor costs;

Packaging speed ranges from 20-80 pieces per minute (depending on the model), increasing efficiency by over 150% compared to manual packaging and adapting to large-scale production;

Film material utilization rate is improved by 10%-15%, reducing consumable waste and controlling packaging costs.

Automated operation eliminates errors in manual packaging (such as skewed film sleeving, loose seals, and uneven shrinking), achieving a packaging qualification rate of over 99.8%;

Standardized packaging not only enhances product appearance but also improves moisture, dust, and damage resistance, reducing transportation losses.