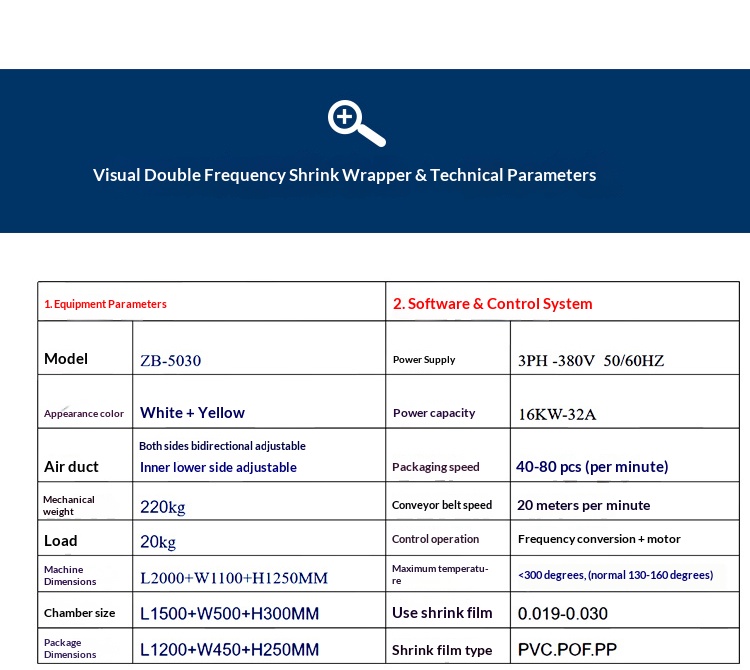

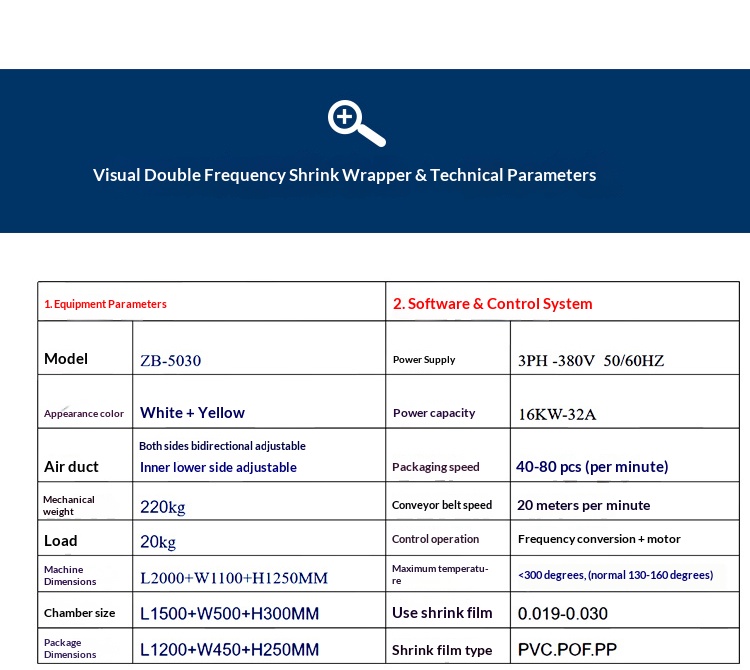

Heat Shrink Packaging Machine, Hardware Fittings Packaging Box Shrink Wrapper, Tableware & Daily Necessities Heat Shrink Film Packaging Machine

The Visual Window Dual-Inverter Heat Shrink Packaging Machine is a heat shrink packaging equipment integrated with visual operation and dual-inverter control functions. It is mainly used for heat shrink packaging of various products to achieve protective effects such as sealing, moisture resistance, and impact resistance, while enhancing the product's aesthetic appearance. Below is its detailed introduction:

The core principle of the heat shrink packaging machine is based on the physical properties of heat shrink films. Such films (e.g., PE, POF, PVC) exhibit ductility at room temperature but shrink rapidly and adhere tightly to the object surface when heated. By precisely controlling the heating temperature and time, the equipment enables uniform film shrinkage, forming a seamless wrapping layer. Its workflow consists of four stages: film conveying and forming, product positioning and wrapping, heat shrink treatment, and cooling setting & output.

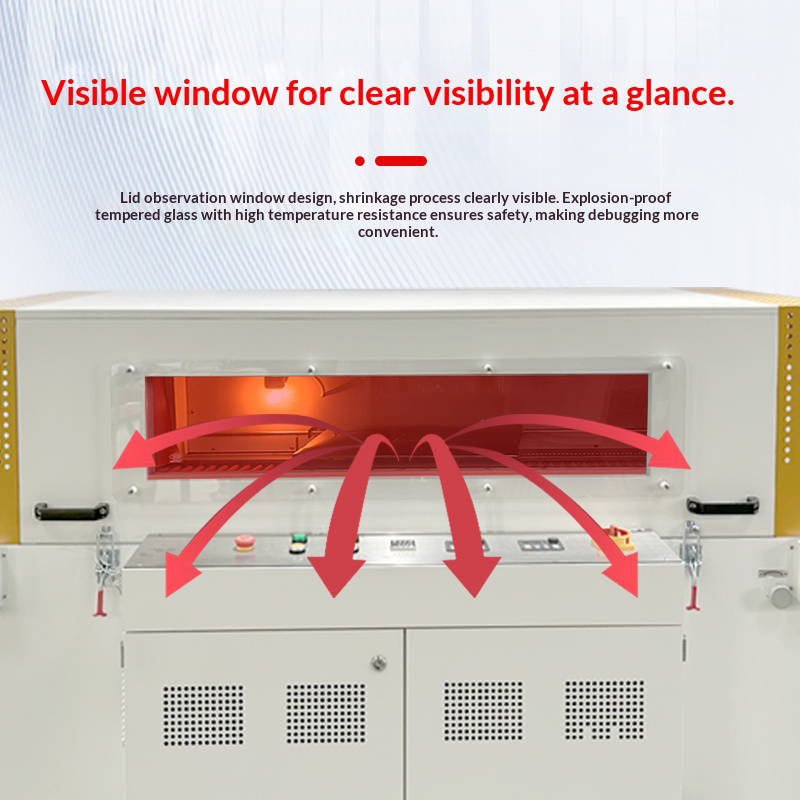

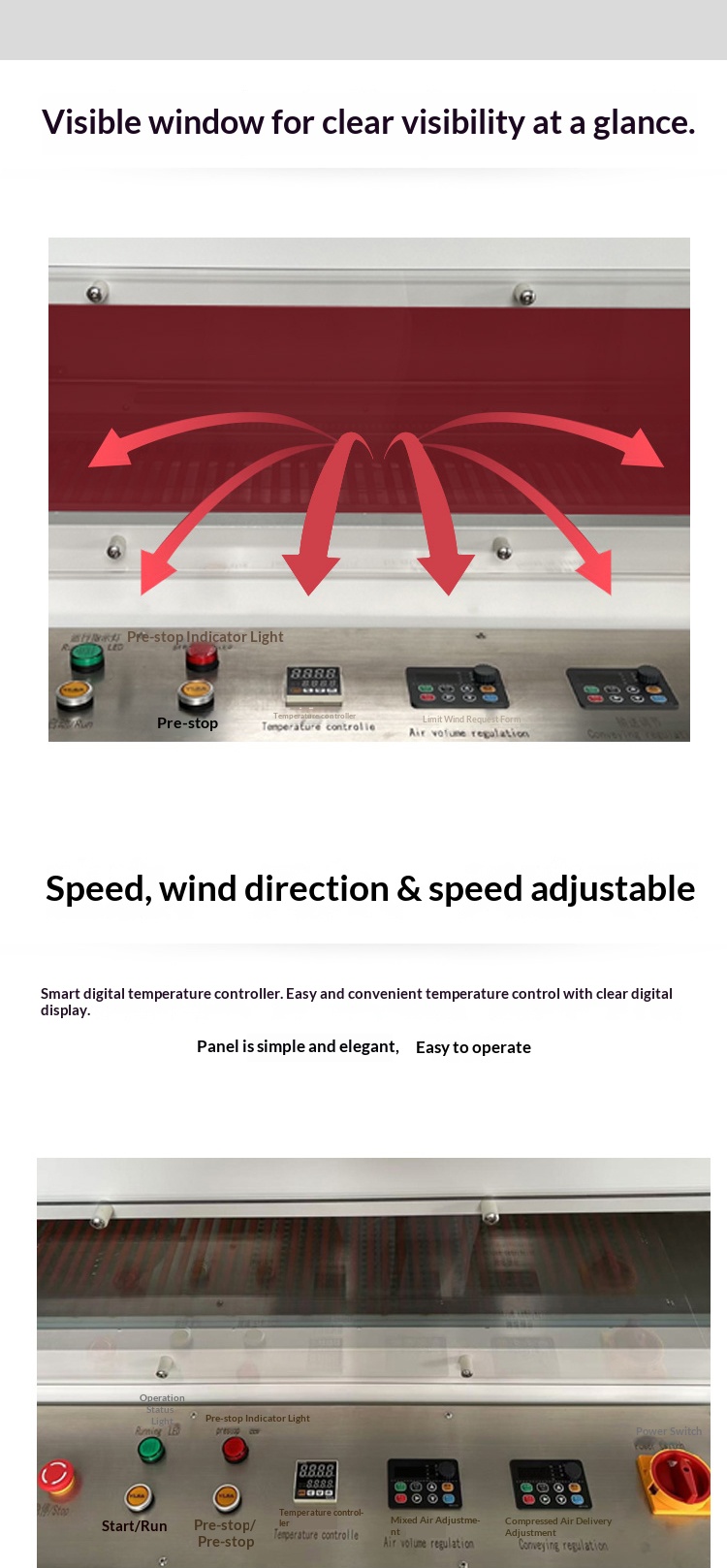

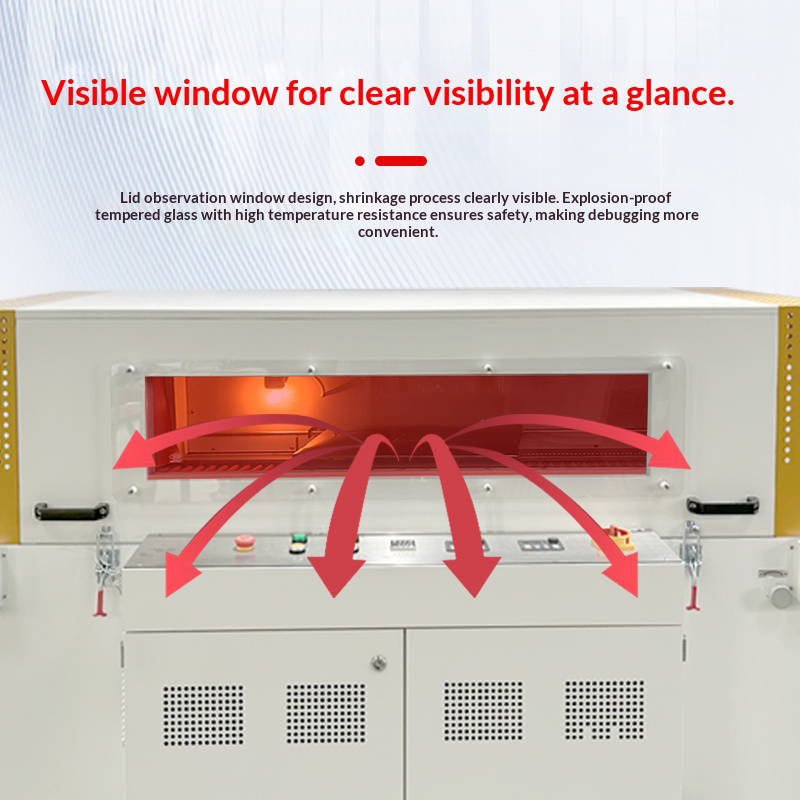

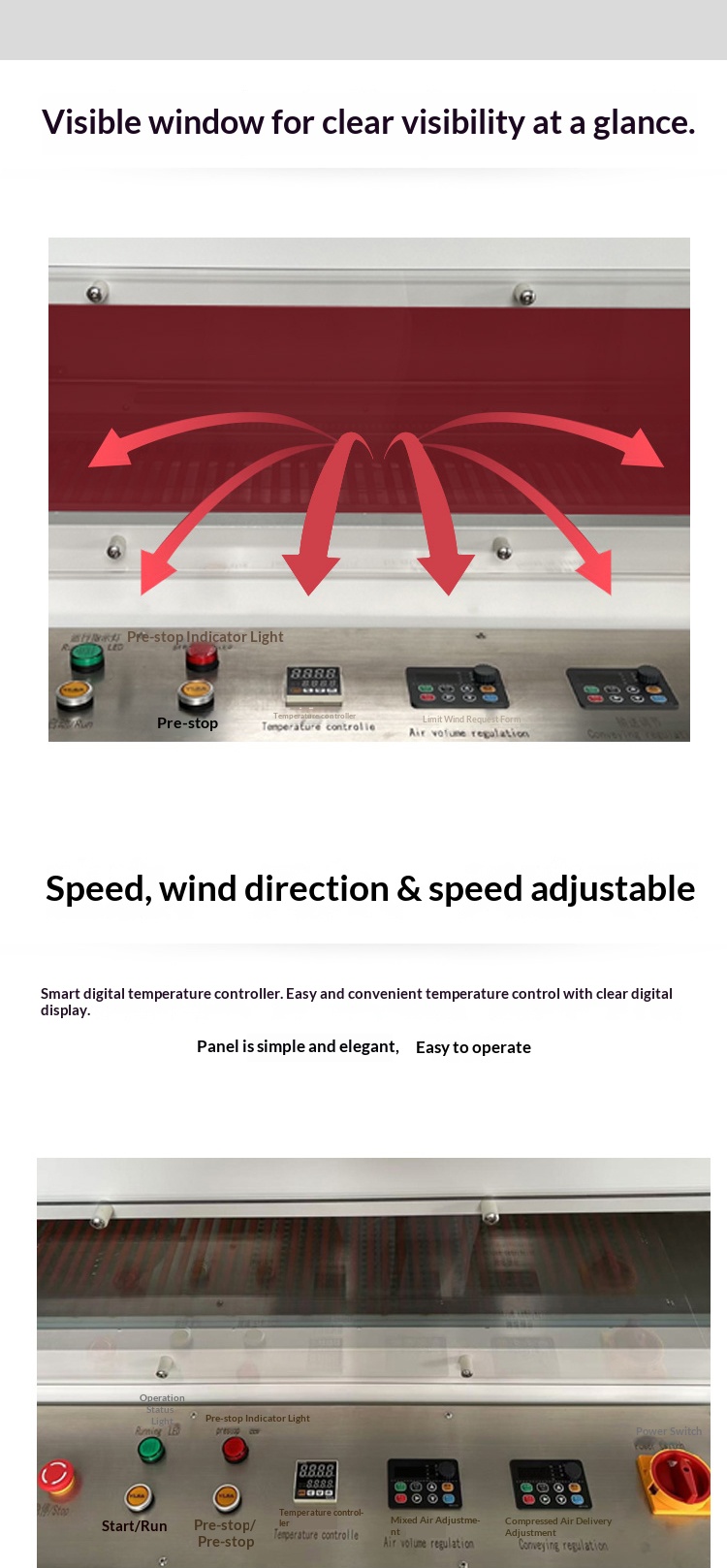

- Visual Window Design: Equipped with a visual window, allowing operators to clearly observe the shrinkage process. This facilitates timely detection and adjustment of issues arising during packaging, ensuring consistent packaging quality.

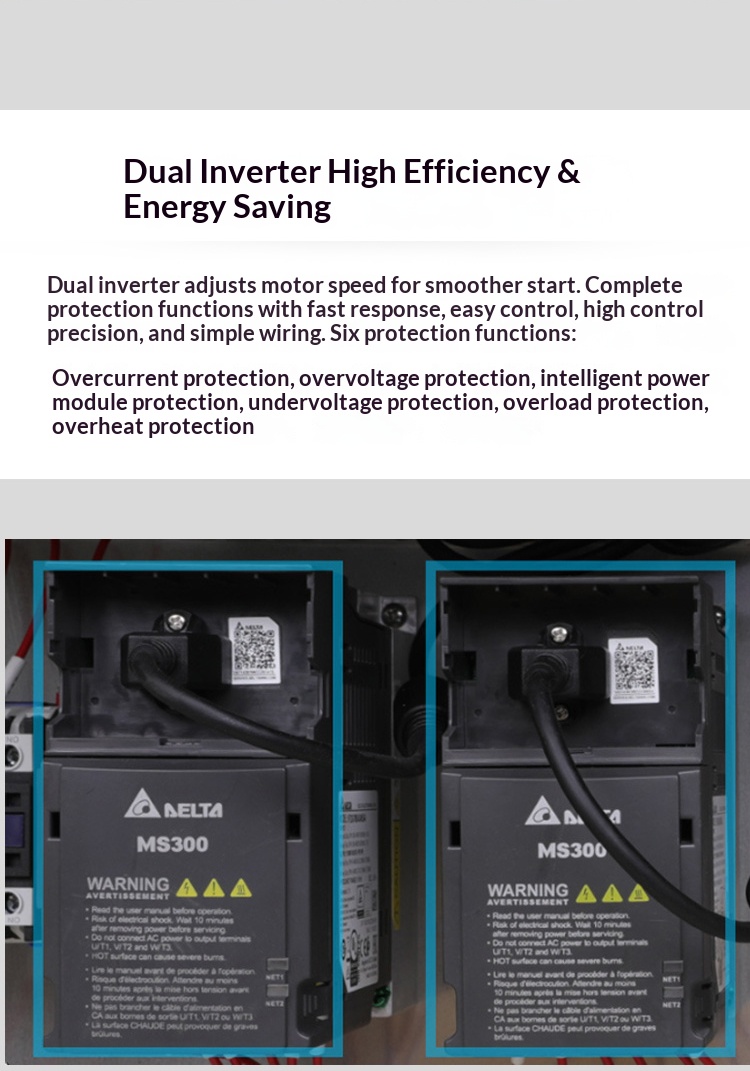

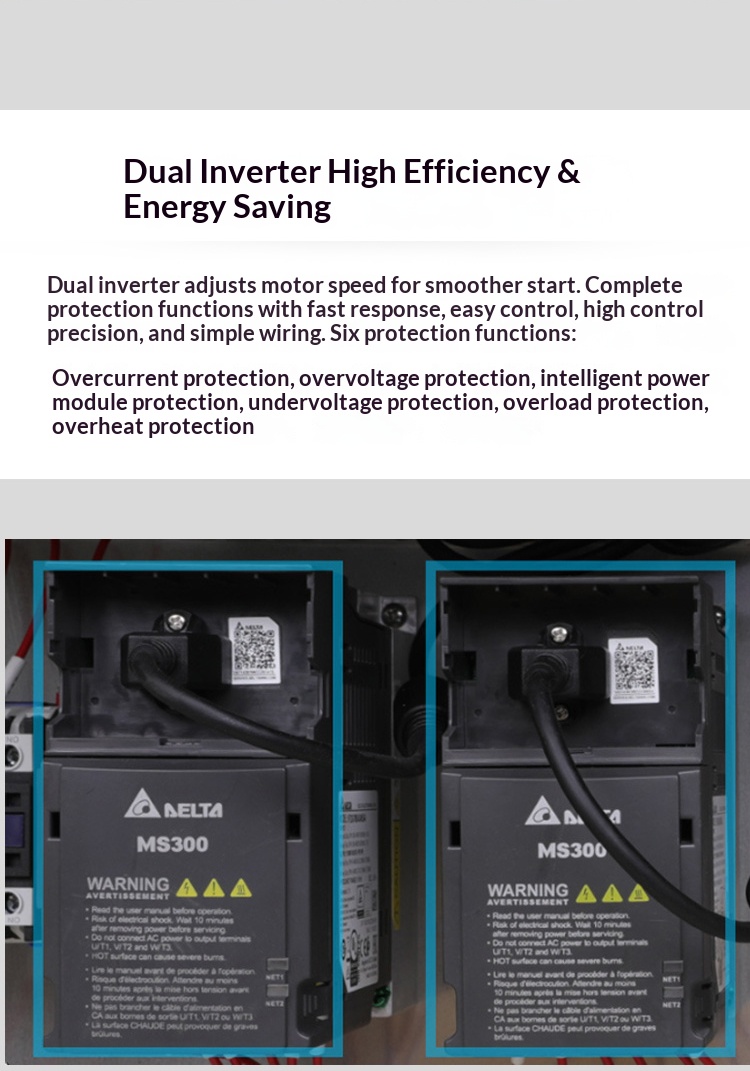

- Dual-Inverter Control: Adopts dual inverters to separately control the conveying speed and the power of the air blower motor. It enables stepless adjustment of conveying speed and air volume with stable speed regulation performance, better adapting to the requirements of different products and packaging films for optimal packaging results.

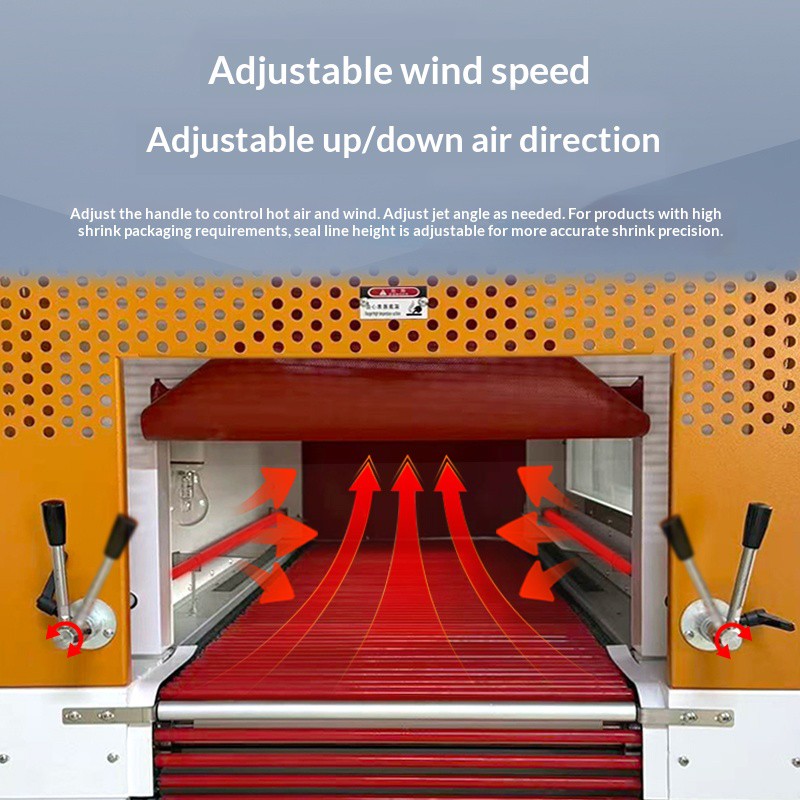

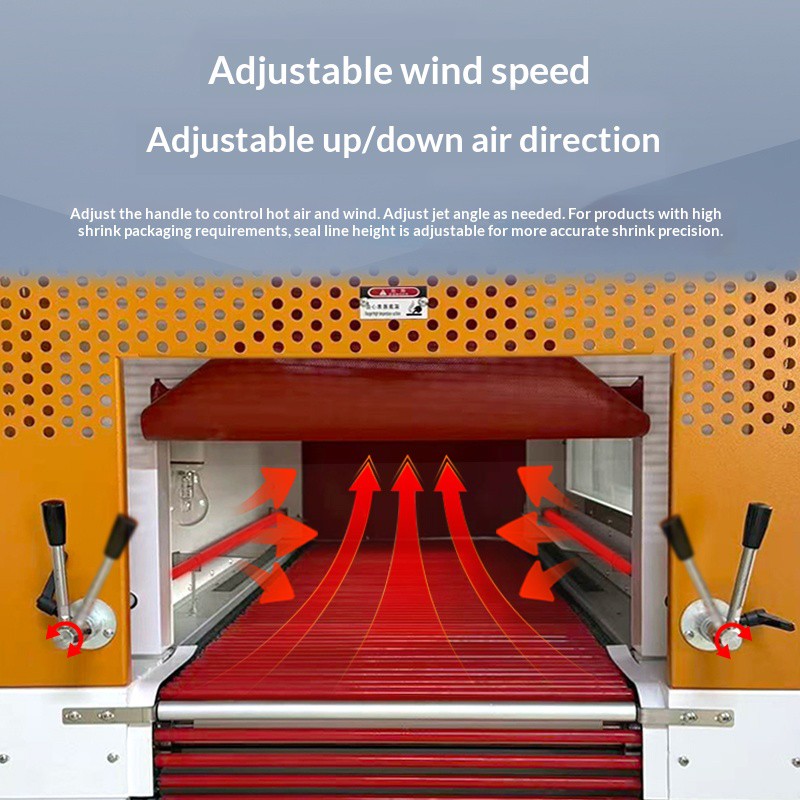

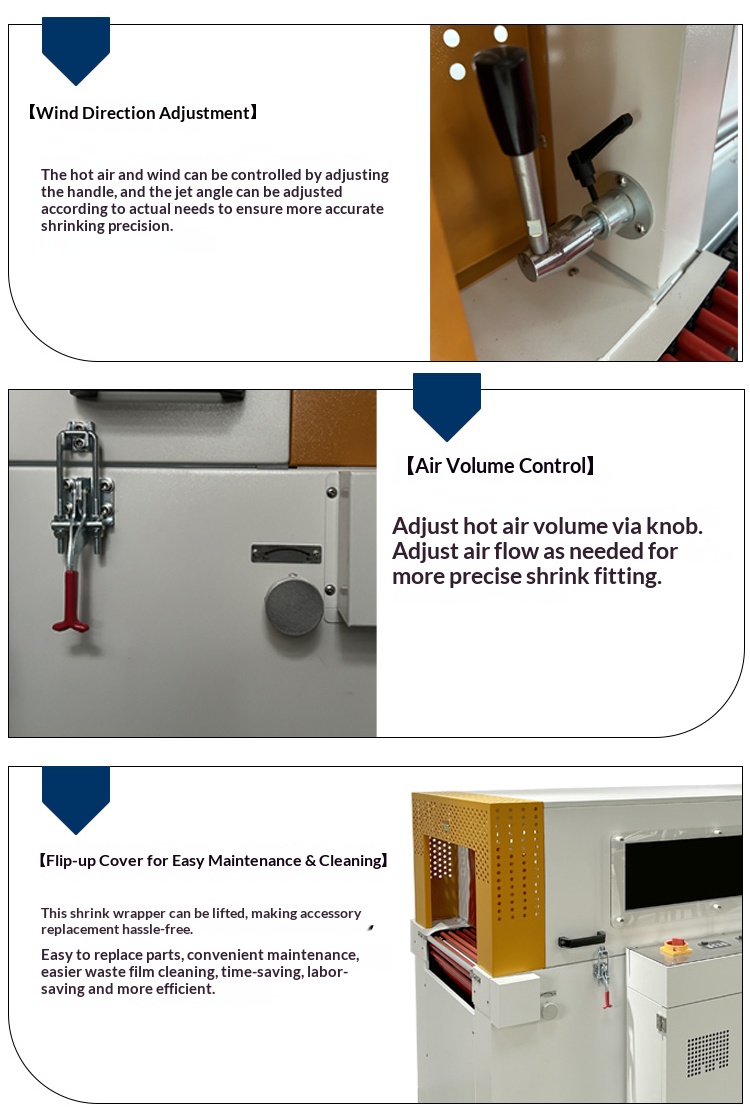

- Excellent Shrinkage Effect: Typically adopts a hot air circulation heating method, combined with an adjustable air duct design. This ensures uniform temperature distribution inside the shrinkage furnace, enabling the film to shrink evenly and adhere tightly to the product, achieving a smooth and aesthetic packaging finish.

- Precise Temperature Control: Equipped with a high-precision temperature controller (e.g., Omron digital display temperature controller) for adjustable and directly displayable shrinkage temperature. The high temperature control accuracy effectively avoids packaging defects caused by excessively high or low temperatures.

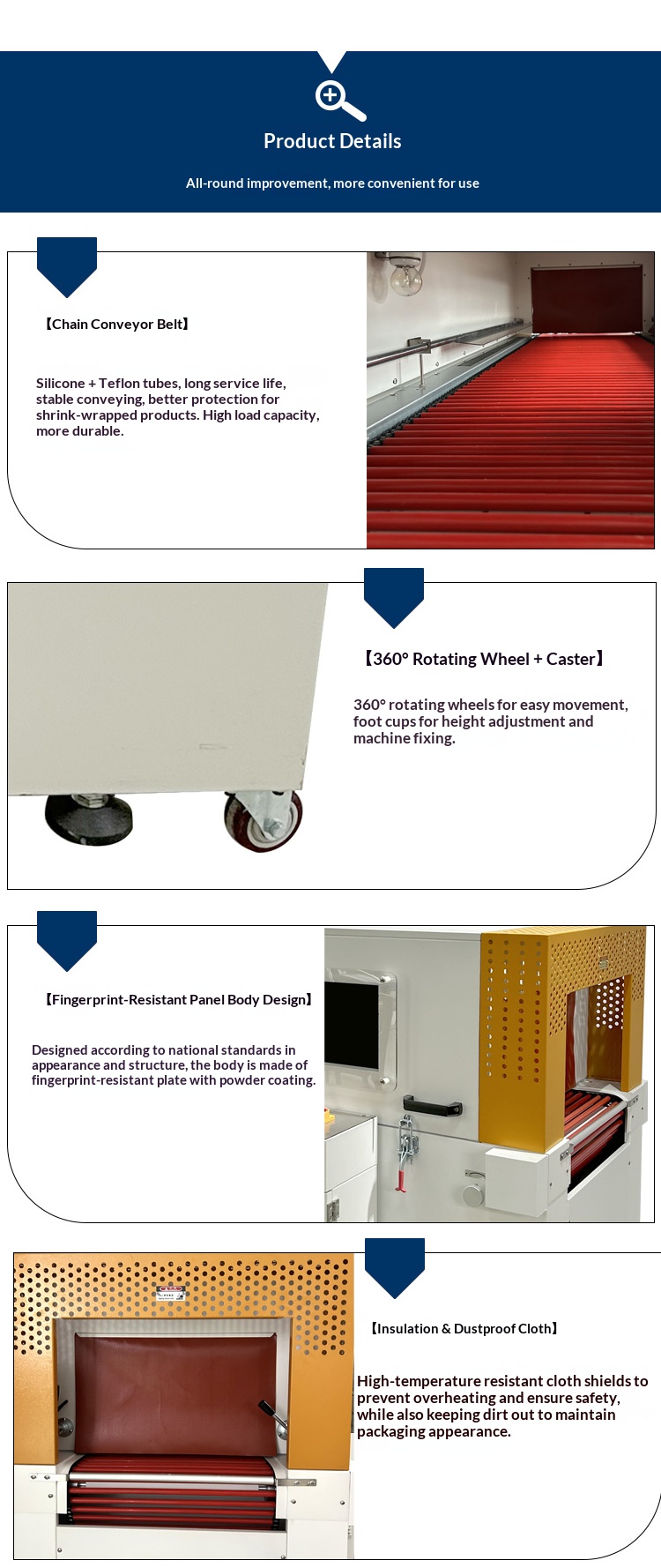

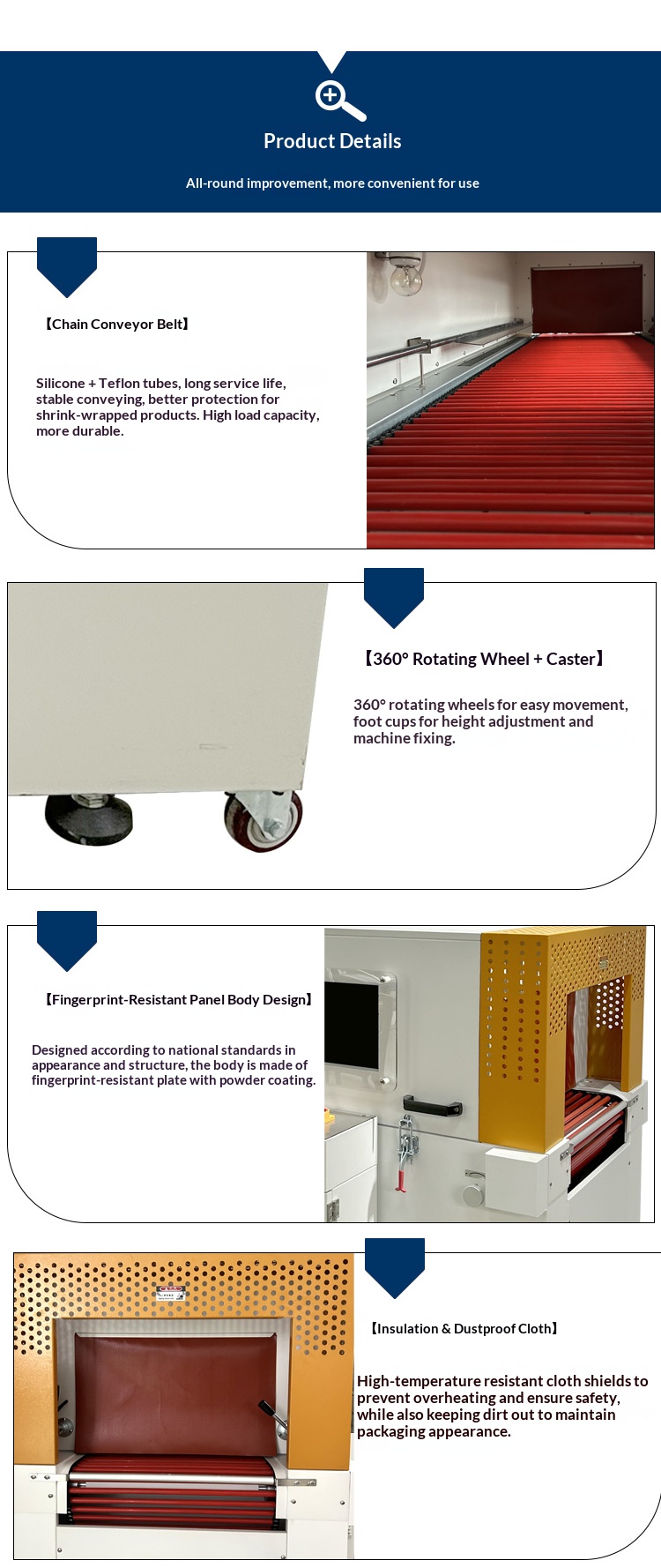

- Stable Conveying System: Utilizes new-type rollers with imported fiber sleeves or high-temperature resistant silicone sleeves. These rollers feature high temperature resistance, wear resistance, no film scalding, and no deformation, ensuring long-term reliable use. Additionally, the rollers can be set to rotate or remain stationary to meet the shrinkage requirements of different products.

Widely used in industries such as food, beverages, pharmaceuticals, daily chemicals, electronics, electrical appliances, stationery, and toys. It is suitable for packaging various regular or irregular items, including glass bottles, cartons, toys, electronic components, and daily necessities. Compatible packaging films include POF, PVC, PP, PE, etc.