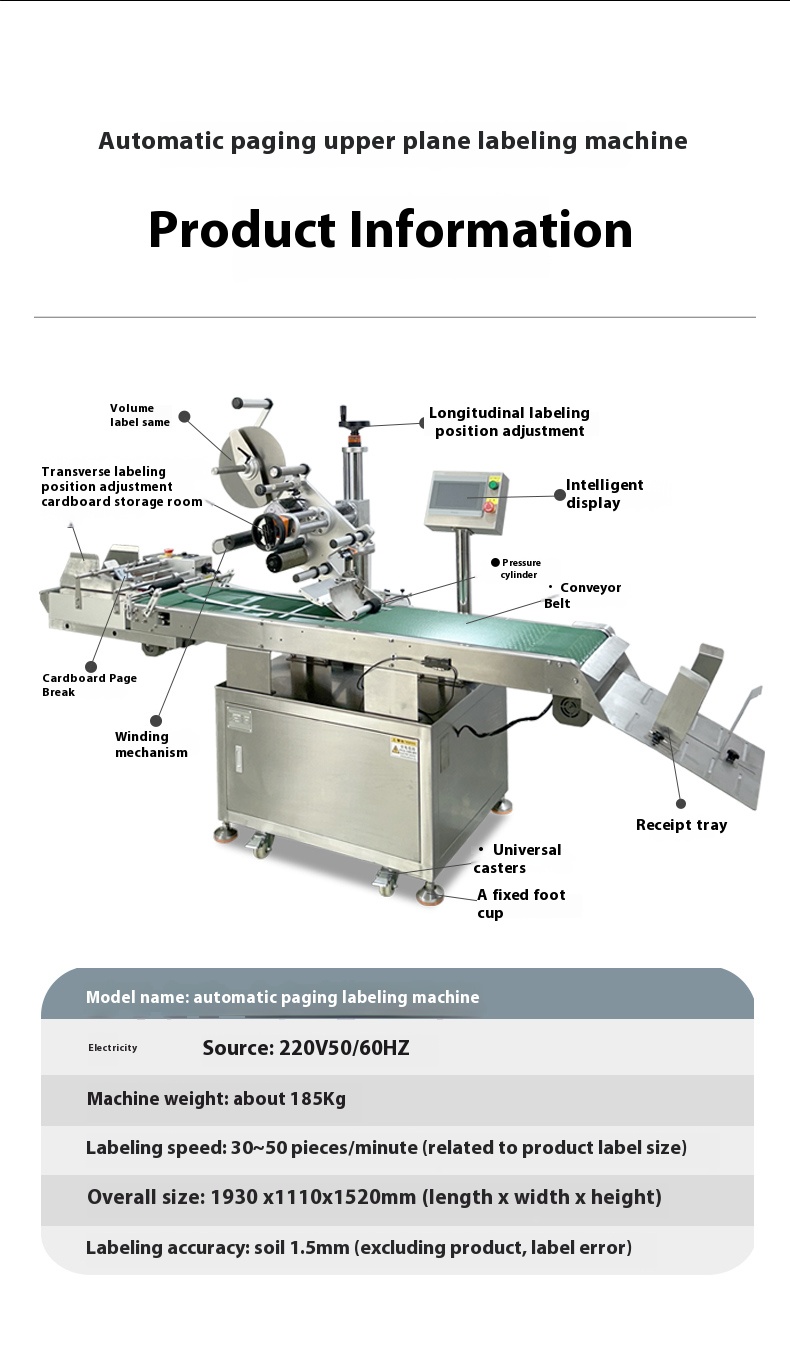

Automatic Sheet-Feeding Top-Surface Labeling Machine - Labeling Machine for PE Bags, Plastic Bags, Cartons, Packaging Boxes and Color Boxes

With its automated design and precise control, the automatic sheet-feeding labeling machine offers significant advantages in industrial production. Its core features can be categorized into the following five aspects, covering key dimensions such as accuracy, efficiency, applicability, operability, and stability:

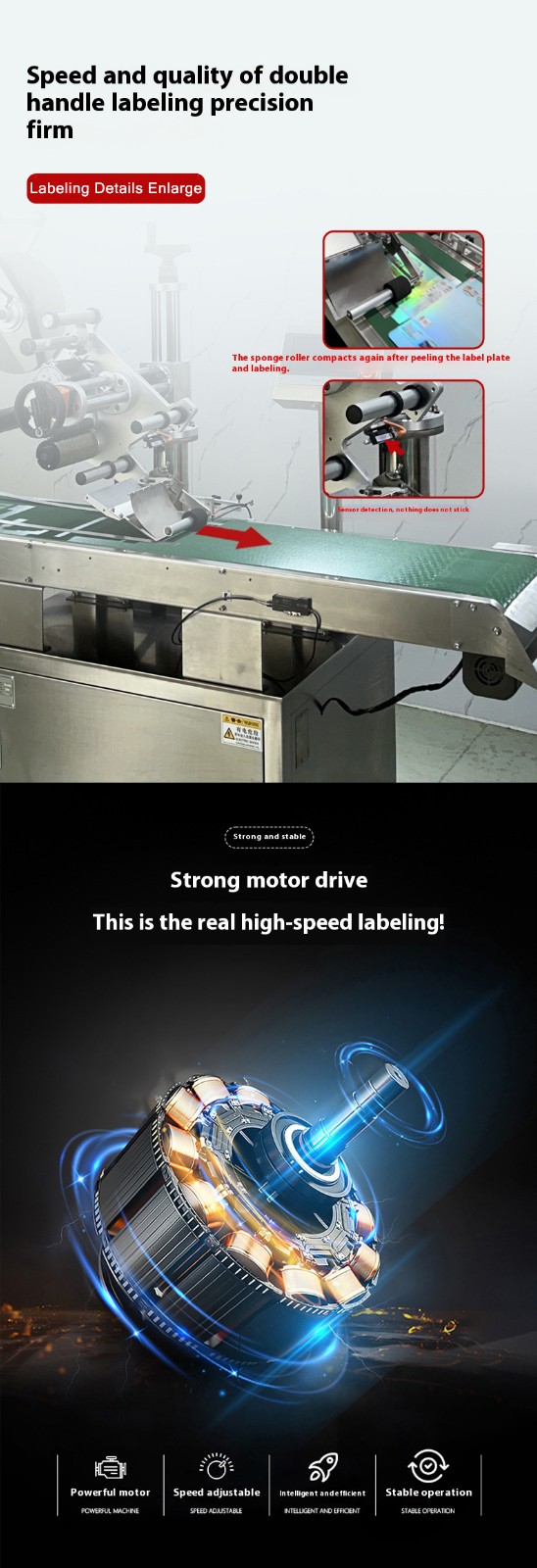

It delivers high accuracy in labeling position: the precision of conventional equipment can reach ±1 to 2 millimeters, and some advanced models, through optimized mechanical structures and sensor calibration, can even achieve zero-error labeling. Meanwhile, it ensures labels are attached smoothly without bubbles, wrinkles, or misalignment, effectively improving the neatness and visual texture of product packaging. This meets the strict packaging precision standards of industries like food and pharmaceuticals.

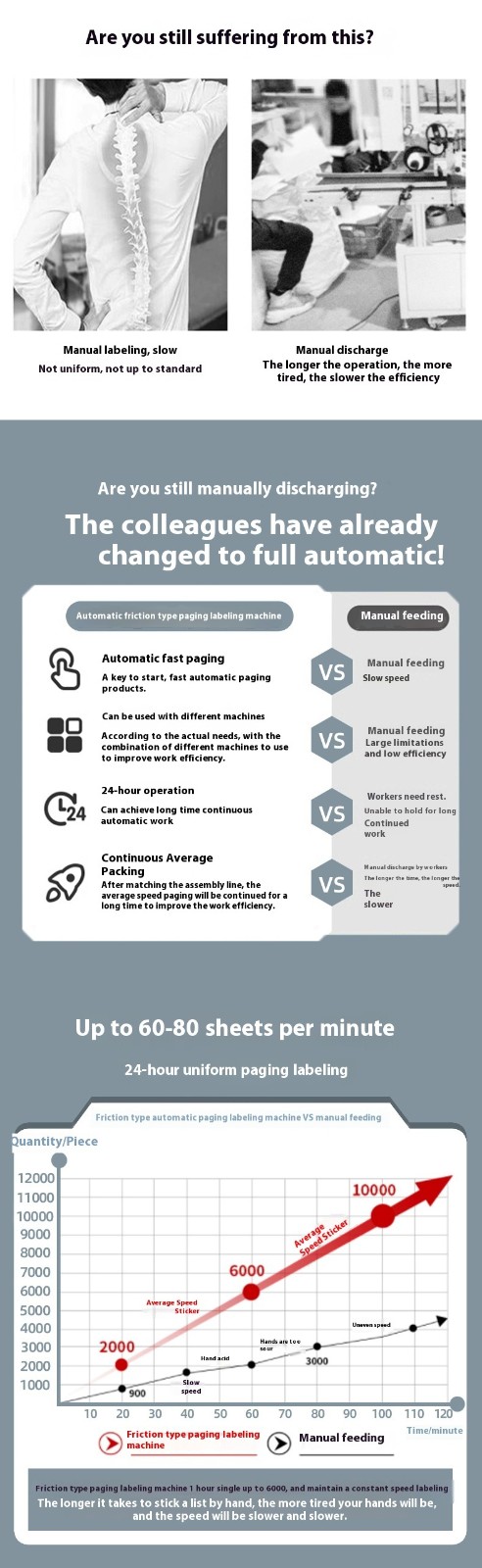

The equipment boasts outstanding operational efficiency: its labeling speed generally exceeds 100 pieces per minute (the specific speed can be fine-tuned based on product size and label type), which is more than 10 times faster than manual labeling. It can operate stably for long continuous periods, avoiding issues such as fatigue and pauses in manual operations. Seamlessly integrating with production lines, it significantly shortens the packaging cycle of bulk products.

- Broad product compatibility: It can handle various sheet-like or small-to-medium-sized products with a width of 70-150 millimeters and a thickness of 0.2-5 millimeters, including plastic bags, paper cards, carton sheets, electronic component housings, and hardware parts.

- Strong label compatibility: It supports labels with a width of 20-100 millimeters and a length of 50-300 millimeters, and is compatible with labels made of multiple materials such as paper, plastic, and scratch-off film. Production requirements can be switched without frequent replacement of core components.

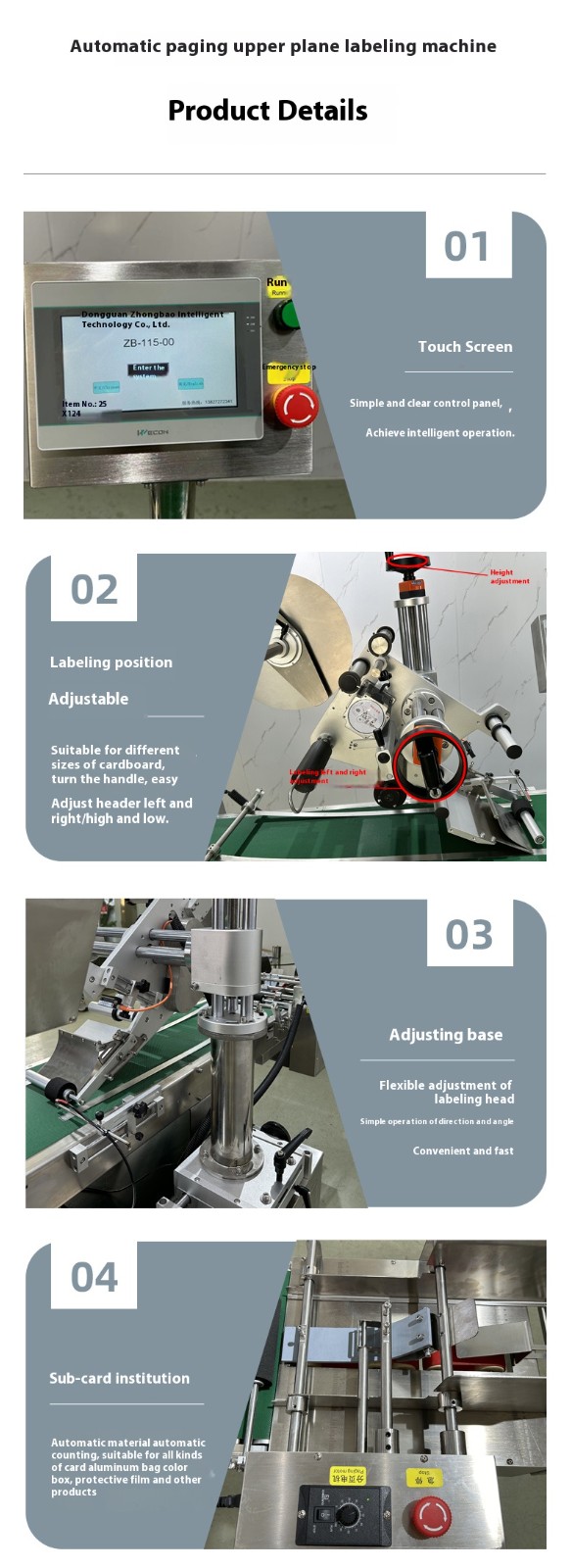

Equipped with a Human-Machine Interface (HMI), operators can intuitively set parameters such as labeling speed, position, and pressure via the touchscreen. The interface features clear logic, requiring no professional programming knowledge. Real-time display of equipment operating status (e.g., number of labeled items, fault alerts) facilitates monitoring and adjustment. Even novice operators can master the operation in a short time, reducing personnel training costs.

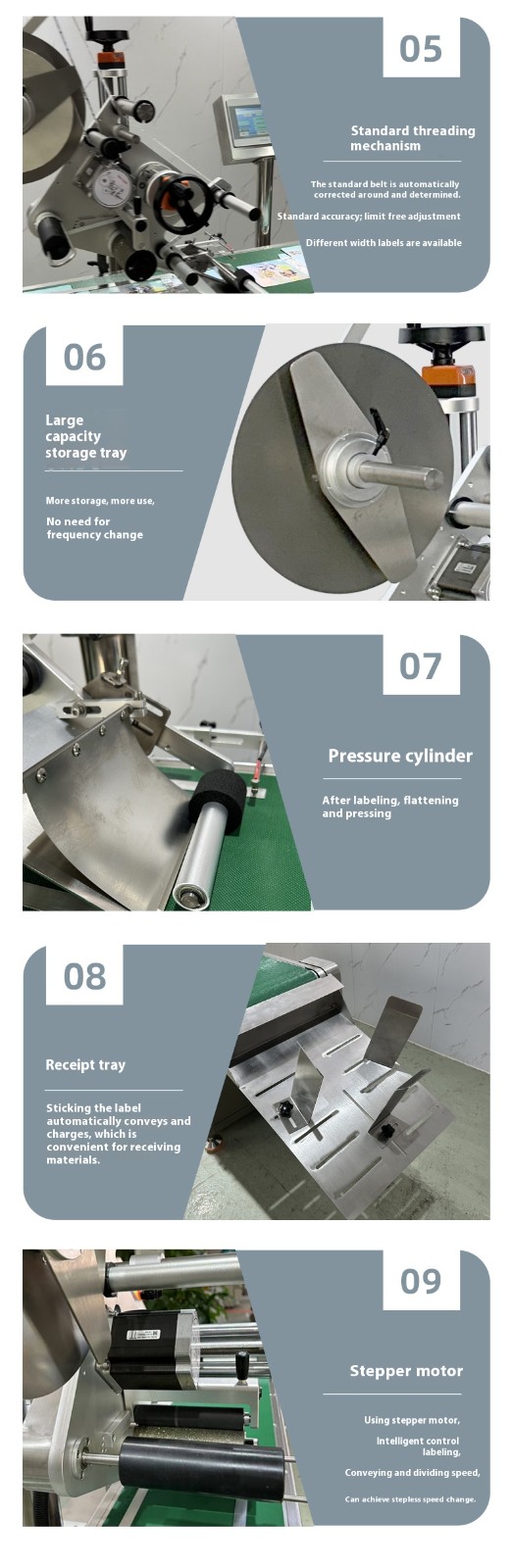

- Durable mechanical structure: Core components (such as paper-feeding wheels, conveyor rollers, and labeling heads) are made of high-wear-resistant materials, which have strong anti-abrasion capabilities and extend the equipment’s service life.

- Intelligent control system: With a Programmable Logic Controller (PLC) as the core, combined with real-time sensor feedback, it can automatically correct minor deviations, identify abnormalities (e.g., missing labels, product misalignment), and trigger alarms—reducing the incidence of faults. It maintains stable precision even during long-term continuous operation, minimizing production losses caused by downtime for maintenance and indirectly lowering labor and maintenance costs.