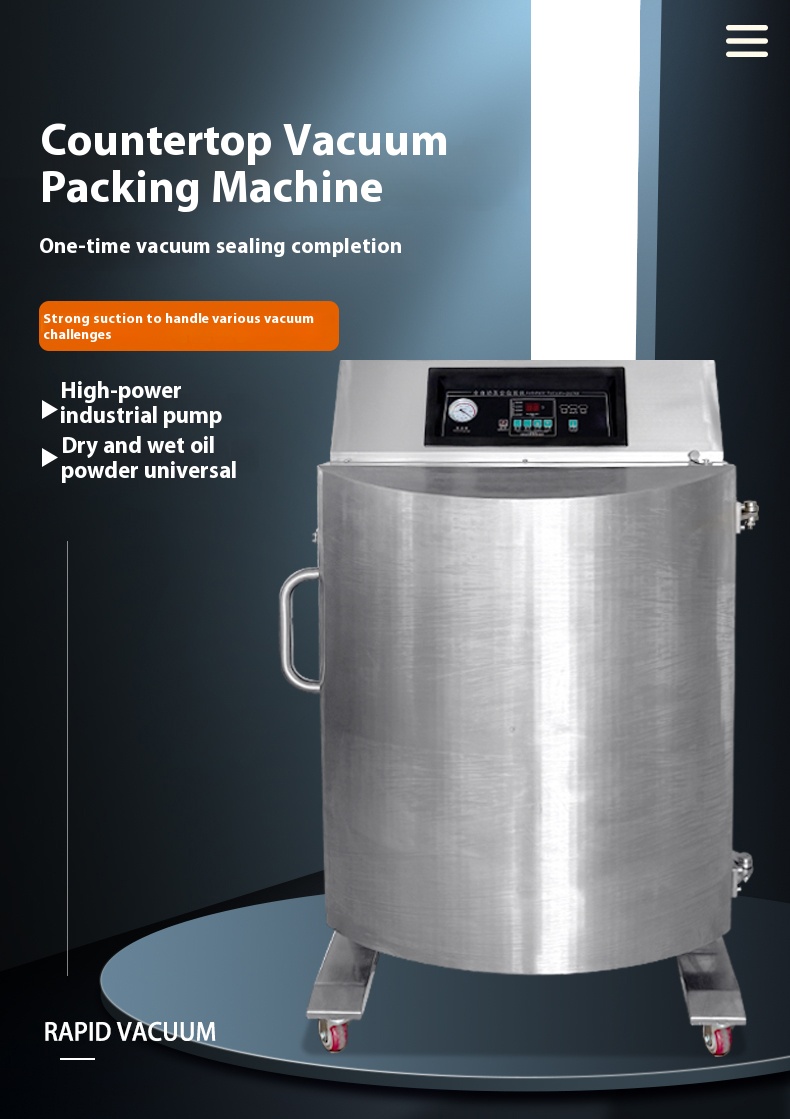

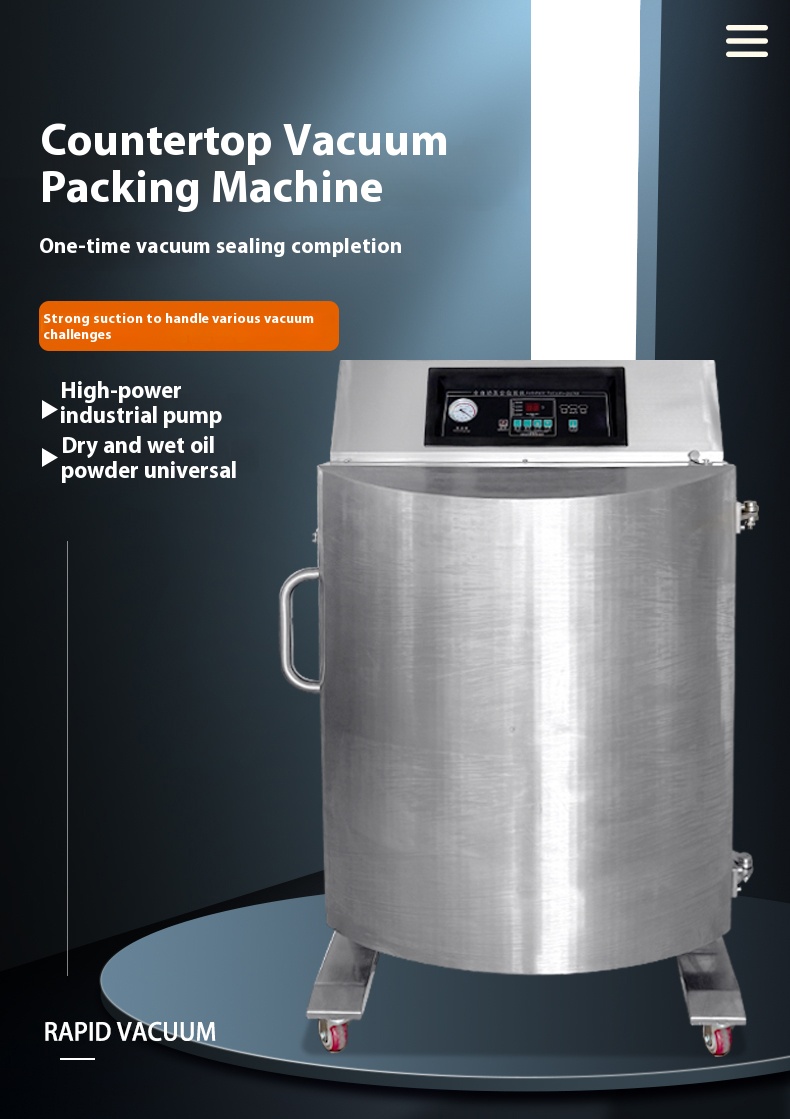

Commercial Vertical Vacuum Sealer for Large-Bag Food Preservation (Internal Vacuum Type for Powders, Granules and Grains)

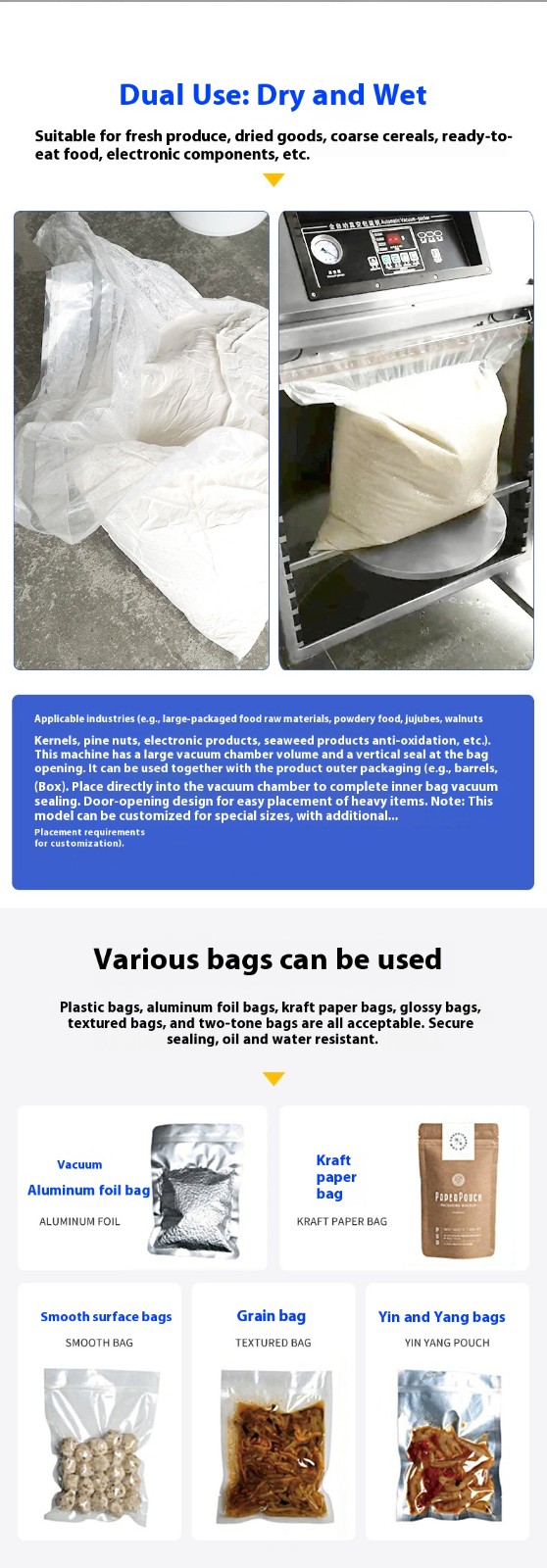

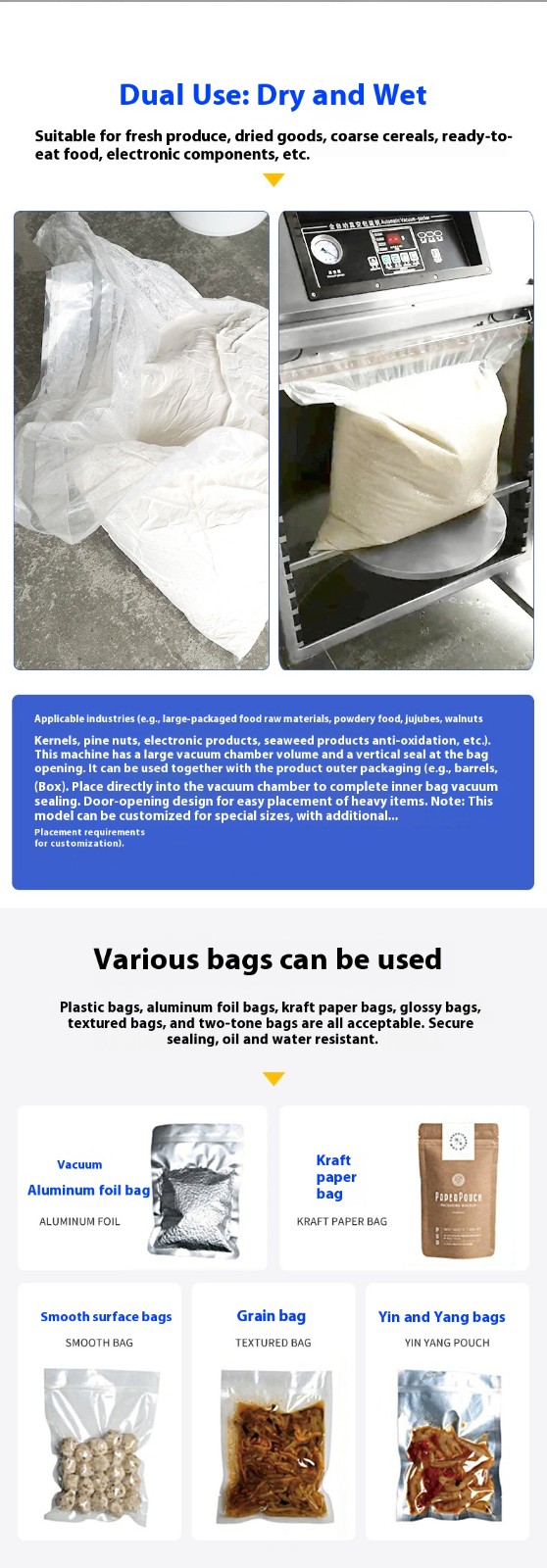

It usually features an open-type transparent high-strength organic glass cover, which allows easy observation of the packaging process inside the vacuum chamber. A vertical pneumatic sealing system is adopted, and the vacuum chamber has a large effective size—capable of accommodating even outer packaging buckets, cartons, and other containers (with pre-packed items inside) for integrated vacuum packaging.

- Place the packaging bag (containing the item) into the vacuum chamber.

- Close the vacuum cover to initiate the air extraction process.

- Once the pre-set vacuum level is reached, the machine proceeds to heat-seal the bag.

- After the packaging cycle is completed, the vacuum cover opens automatically.

Excellent Packaging Effect: The vertical pneumatic sealing prevents the leakage of contents from the bag. It ensures uniform pressure application on the seal, resulting in a flat, neat, and wrinkle-free seal. Additionally, the chamber-type packaging design typically achieves a higher vacuum level compared to external suction-type machines. This effectively removes air from the bag, preventing material oxidation, mold growth, and other quality issues.

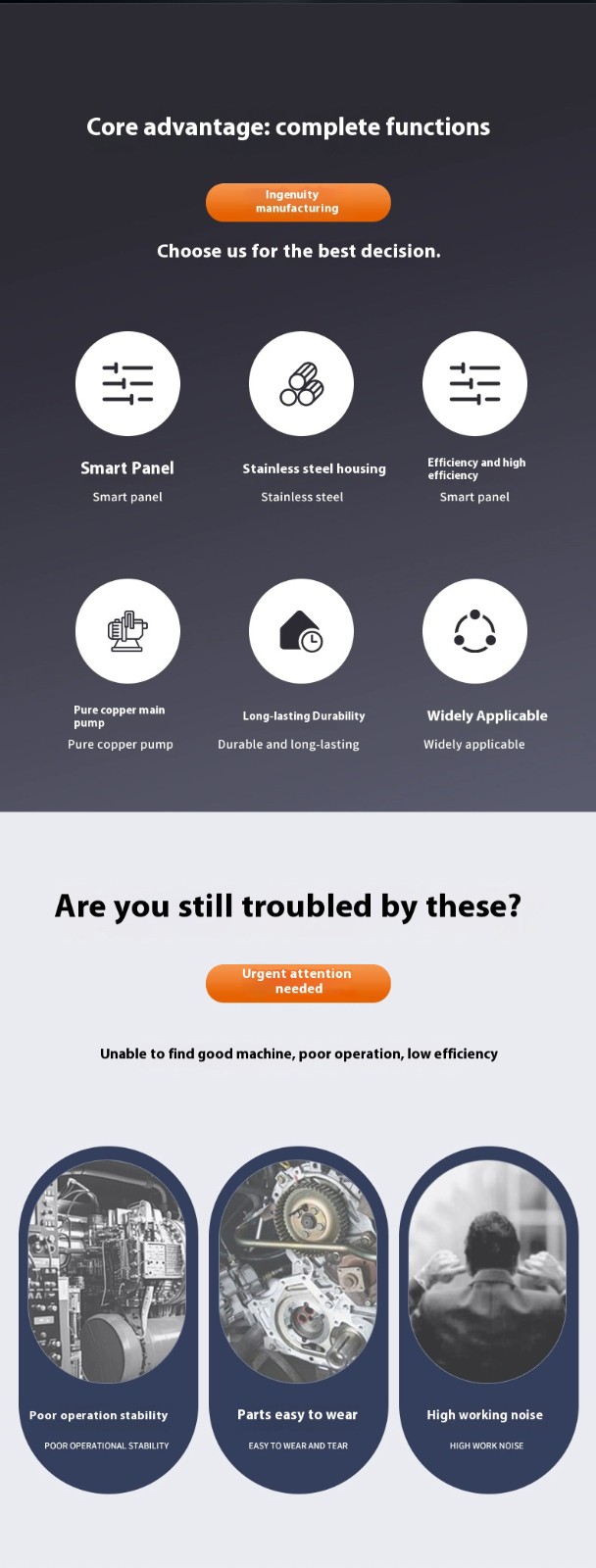

Easy Operation: Equipped with a PLC touchscreen control system, it enables precise adjustment of vacuuming time, heating duration, and cooling time. The vacuum level can also be directly monitored and controlled via an electric contact vacuum gauge, ensuring convenient operation and high stability.

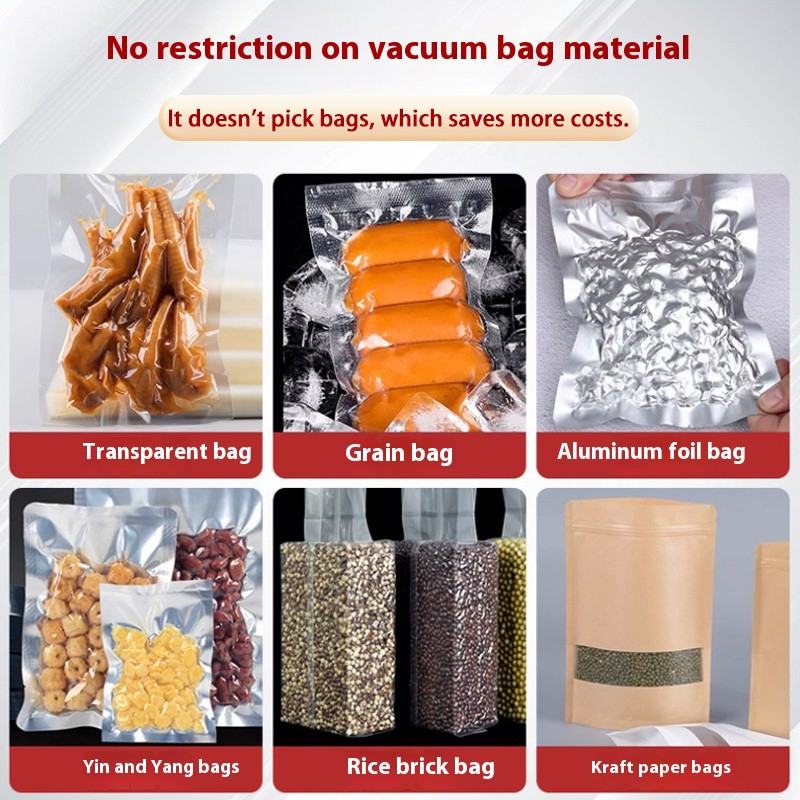

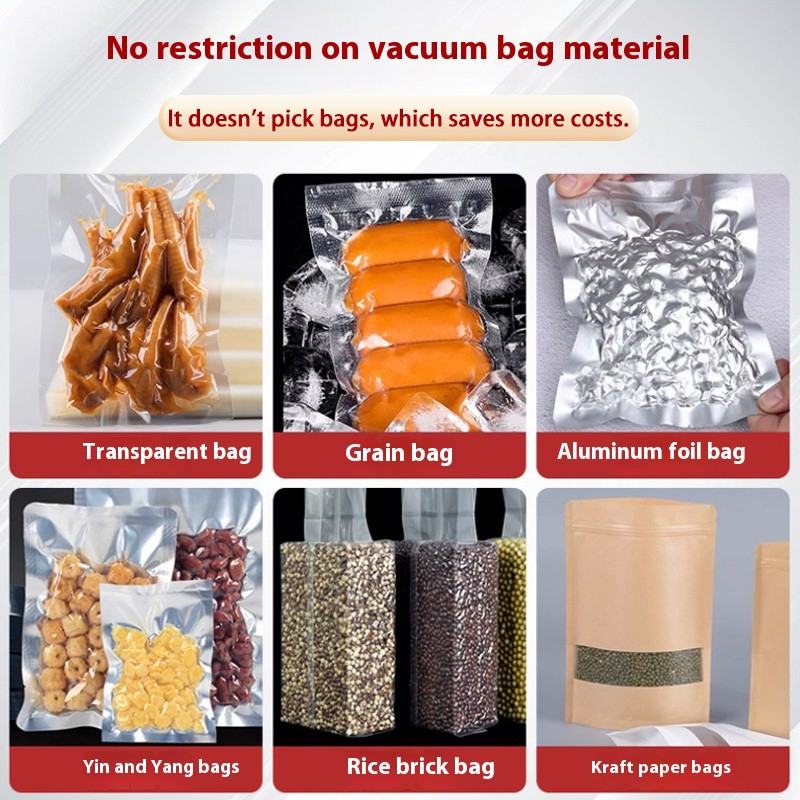

Wide Application Range: Suitable for vacuum or gas-flushing packaging of materials in various forms, including ultra-fine powders, granules, liquids, and pastes. It is widely used in industries such as chemicals, food processing, electronics, and pharmaceuticals.

High-Quality Materials: The external structure of the whole machine is mostly made of stainless steel, which facilitates cleaning and prevents residual stains. High-quality internal components are used to ensure stable and long-term operation of the equipment.