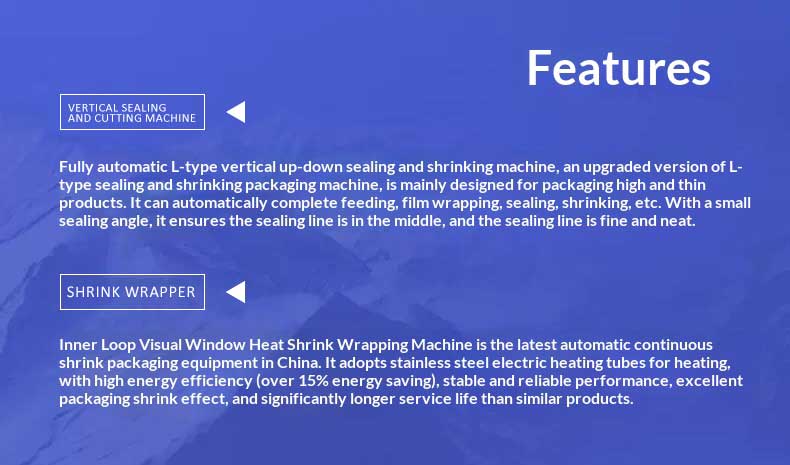

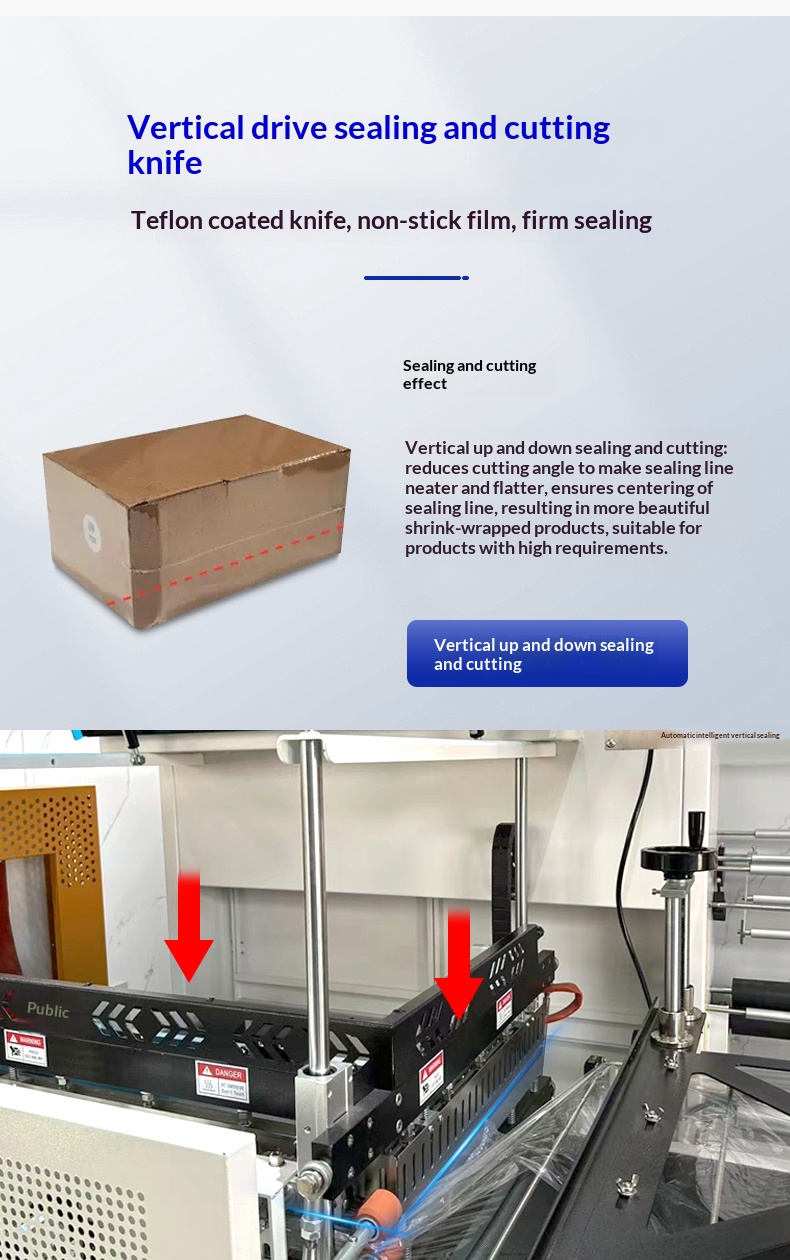

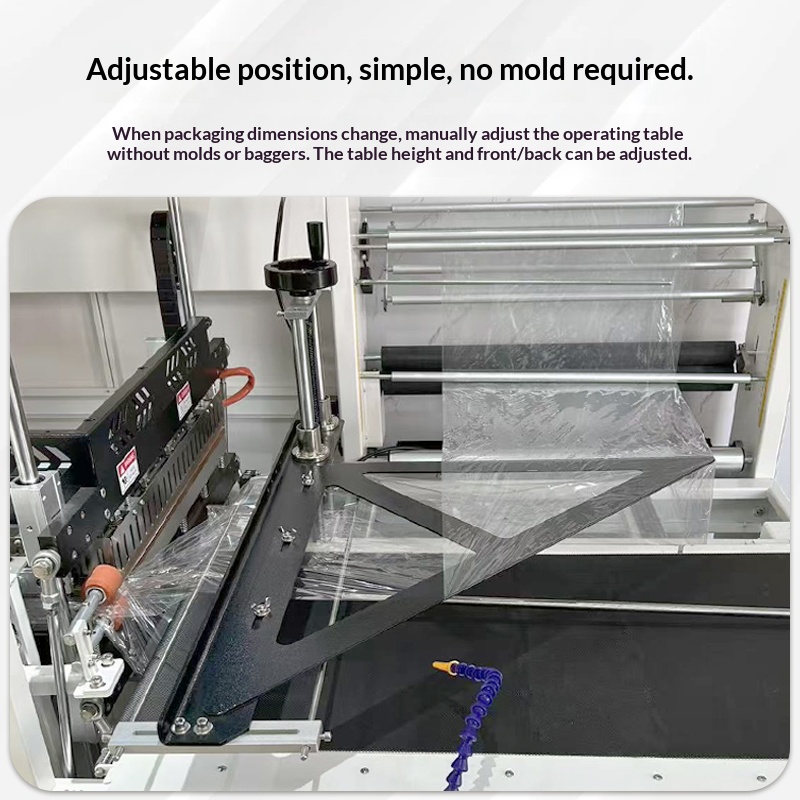

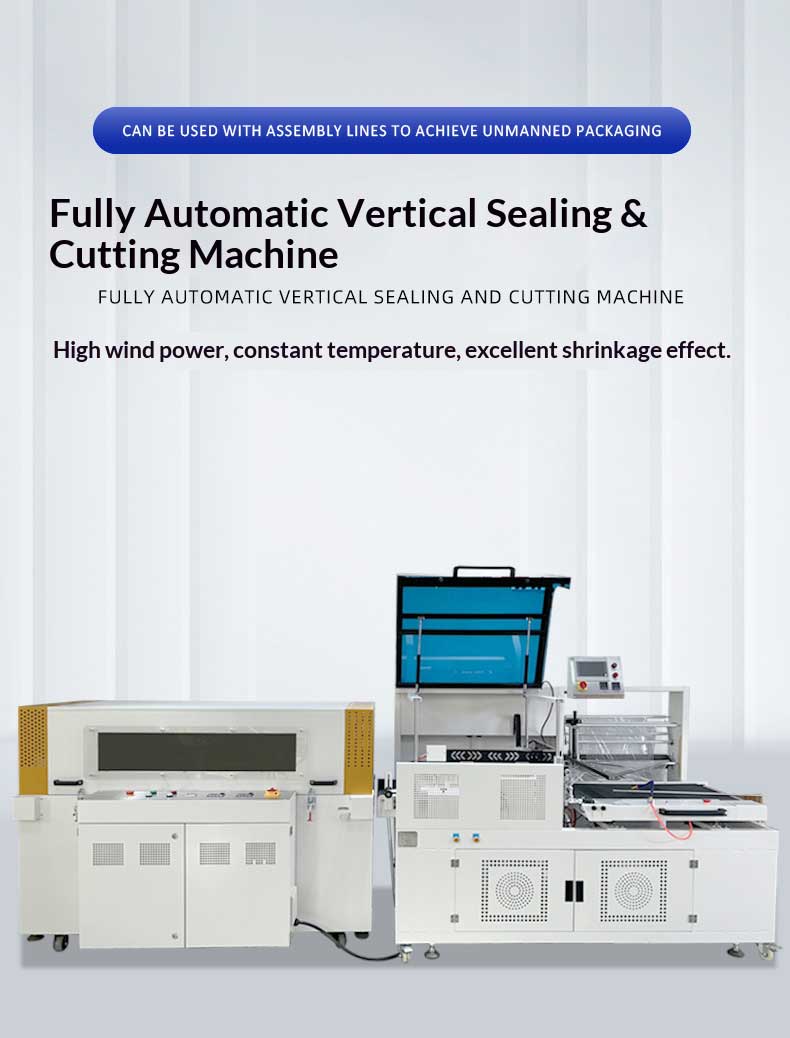

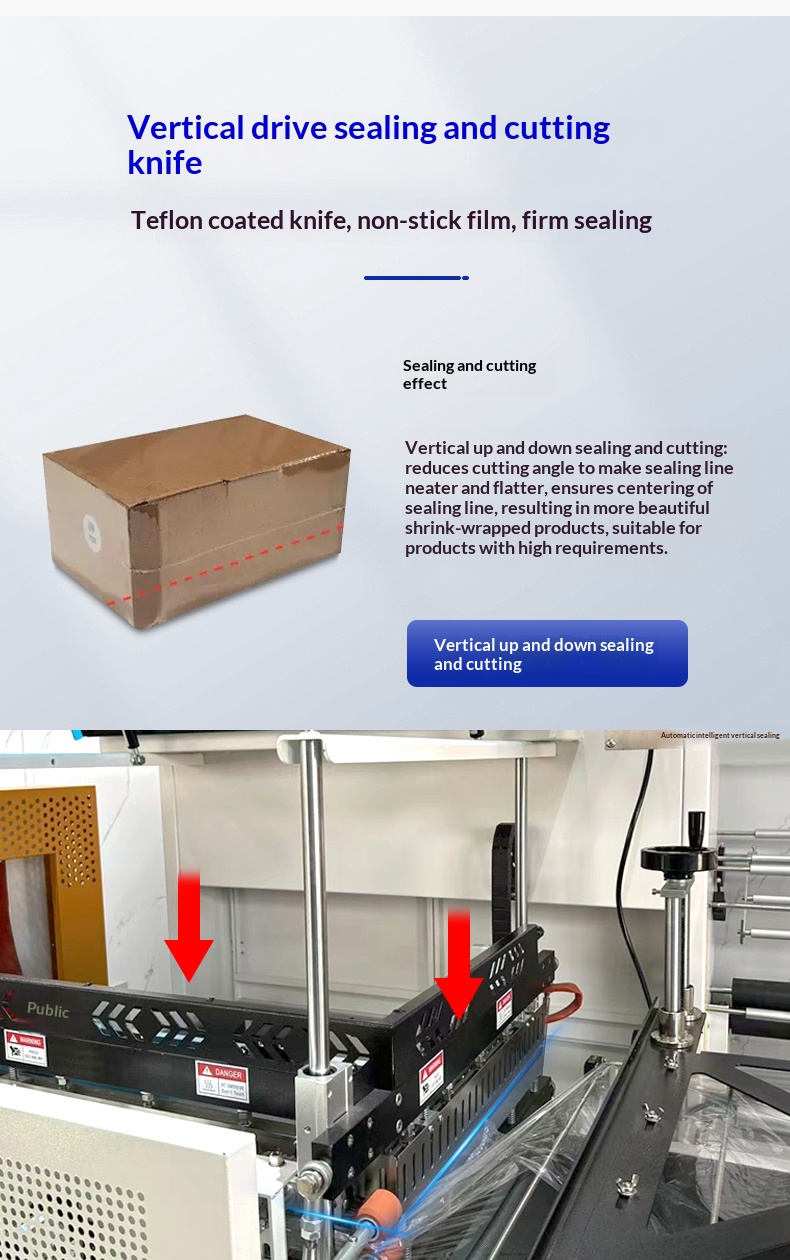

The Automatic Vertical Sealing and Cutting Machine adopts an up-and-down vertical drive sealing and cutting structure, ensuring uniform force on the sealing contact surface. It can effectively solve common problems of traditional L-shaped sealing and cutting machines, such as film wrinkling, sealing line deviation and uneven edges.

Release date:2025-12-25

The Automatic Vertical Sealing and Cutting Machine adopts an up-and-down vertical drive sealing and cutting structure, abandoning the horizontal push-pull sealing and cutting method of traditional L-shaped sealing and cutting machines. Instead, it relies on symmetrically arranged upper and lower drive modules to drive the sealing and cutting knives for synchronous movement, ensuring uniform force application across the entire contact surface between the knives and the film.

During operation, after the film is wrapped around the product in place, the upper and lower sets of sealing and cutting knives close precisely in the vertical direction. Pressure is applied to the film sealing area simultaneously from the top and bottom, and the pressure value can be accurately adjusted via the control system to ensure consistent force at every point in the sealing zone. This force application mode fundamentally addresses the technical pain points of traditional L-shaped sealing and cutting machines:

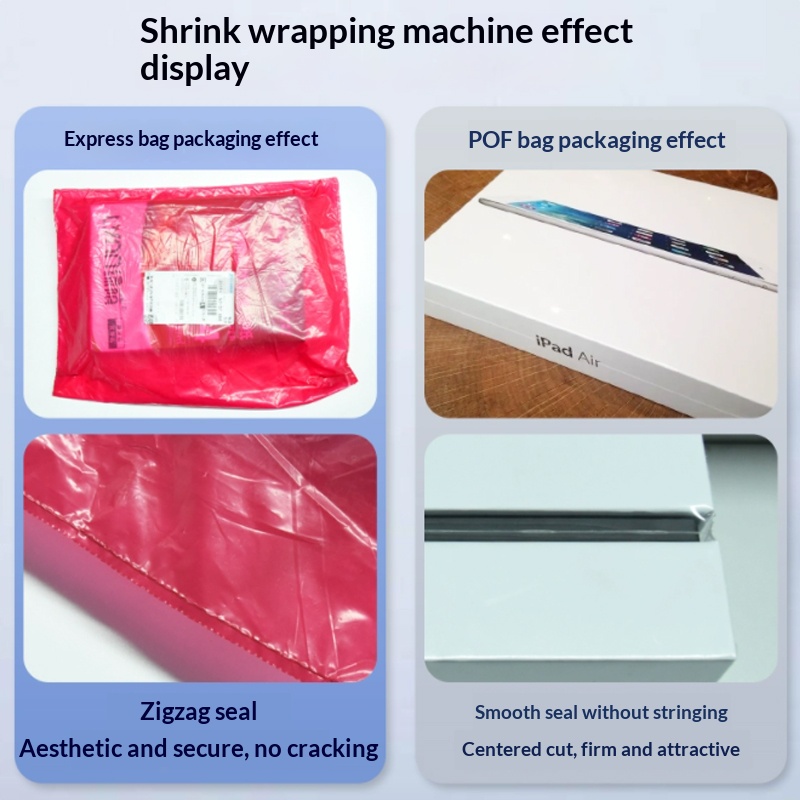

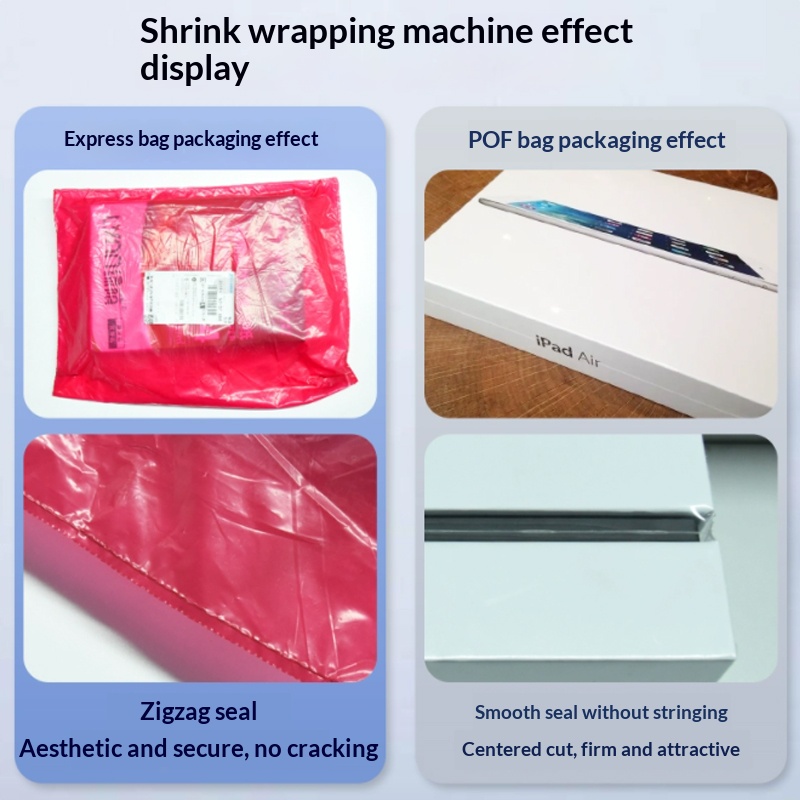

- Film wrinkling issueThe horizontal sealing knife of L-shaped machines tends to cause uneven tension and stretching during advancement, leading to local film stacking and wrinkling. In contrast, the vertical drive structure maintains film flatness through balanced upper and lower pressure, eliminating wrinkles caused by uneven force distribution. It is particularly suitable for high-precision sealing and cutting of thin POF films.

- Sealing line deviation issueThe unidirectional drive of L-shaped machines is susceptible to mechanical gaps and product placement errors, resulting in sealing line deviation from the preset position. The upper and lower tool rests of the vertical sealing structure adopt dual-guide positioning, combined with a high-precision photoelectric alignment system, which controls the sealing line position error within ±0.5mm and completely eliminates deviation problems.

- Uneven edge issueThe edge sealing of L-shaped machines is completed in sequential steps, which often leads to insufficient or excessive edge pressure, causing sealing edges to warp and become unstable. The upper and lower tool rests of the vertical sealing structure use integrated formed cutter heads at the edges, applying balanced pressure to the edges synchronously. This ensures that the sealing edges maintain the same flatness and firmness as the main sealing line, eliminating the need for manual trimming after sealing.

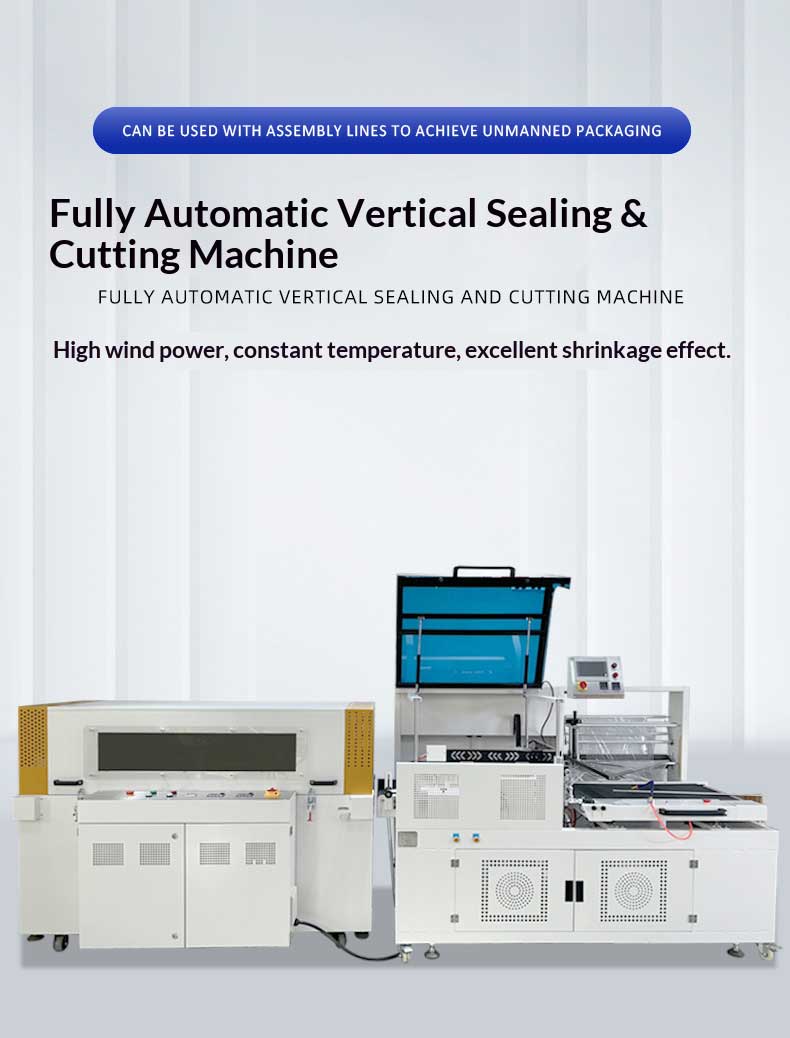

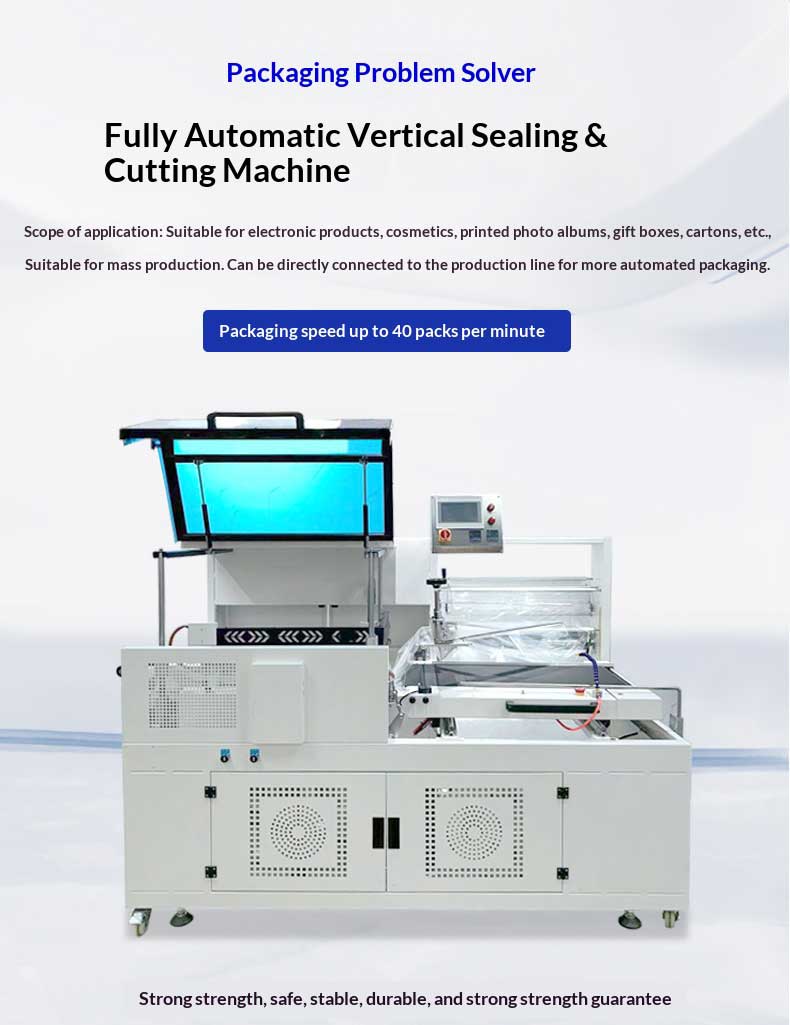

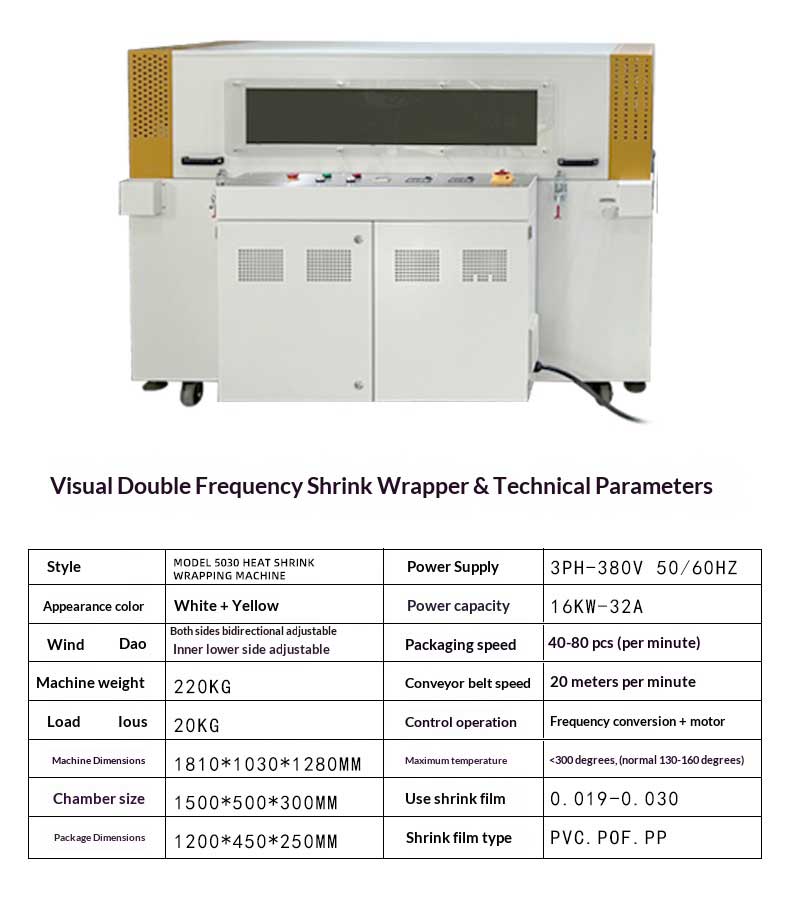

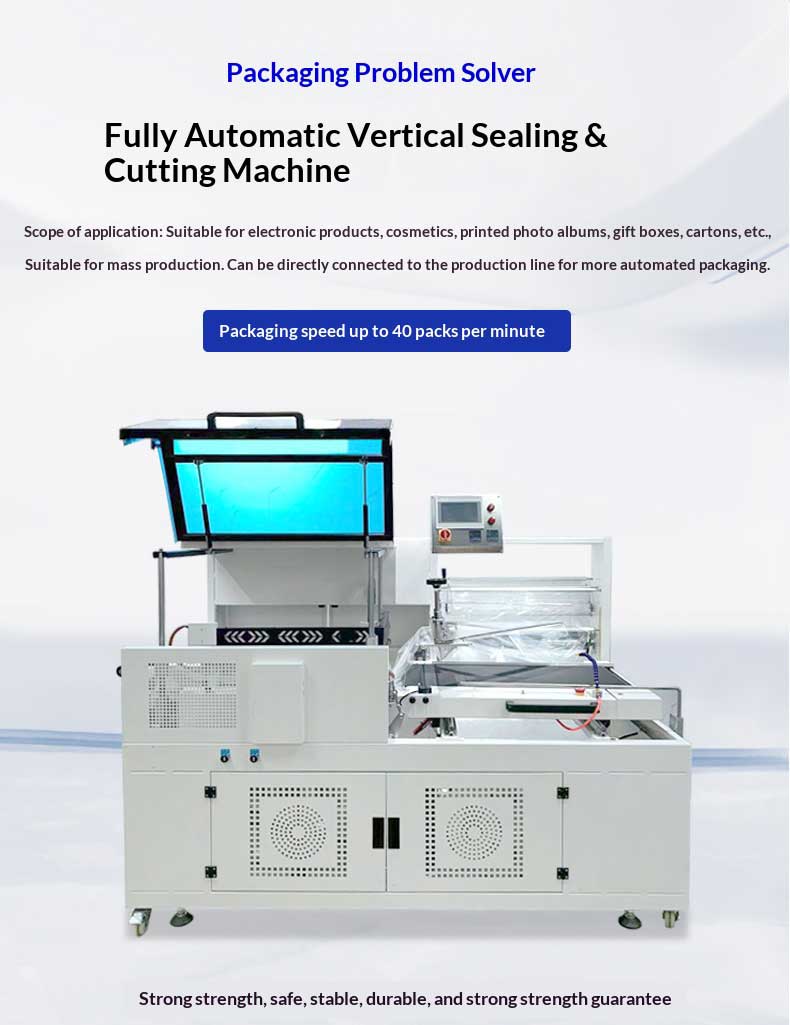

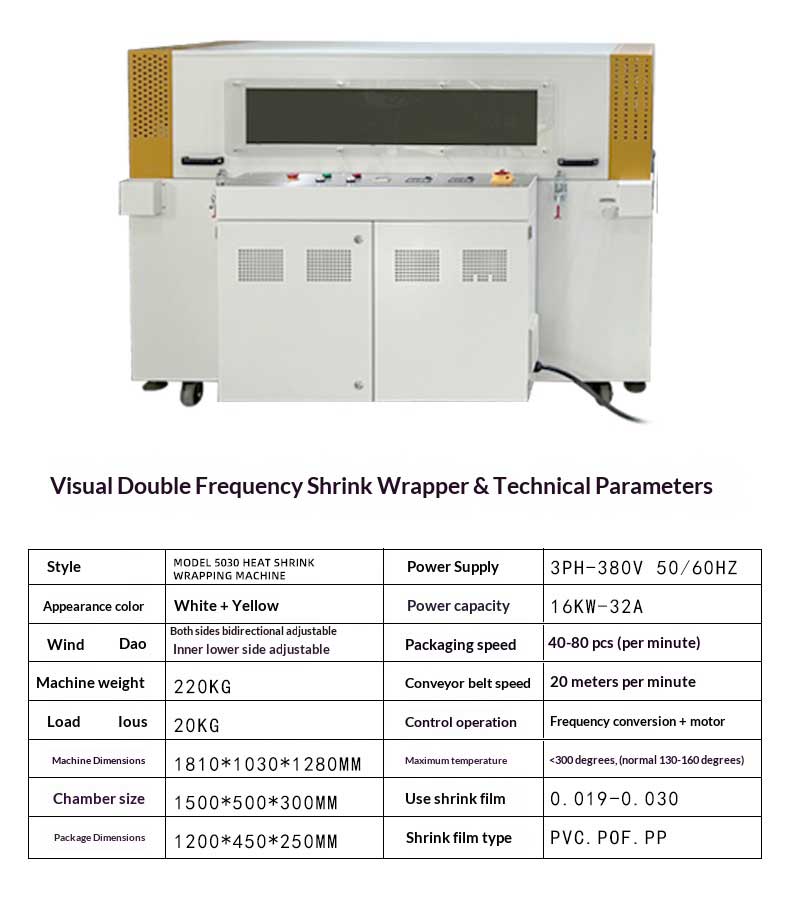

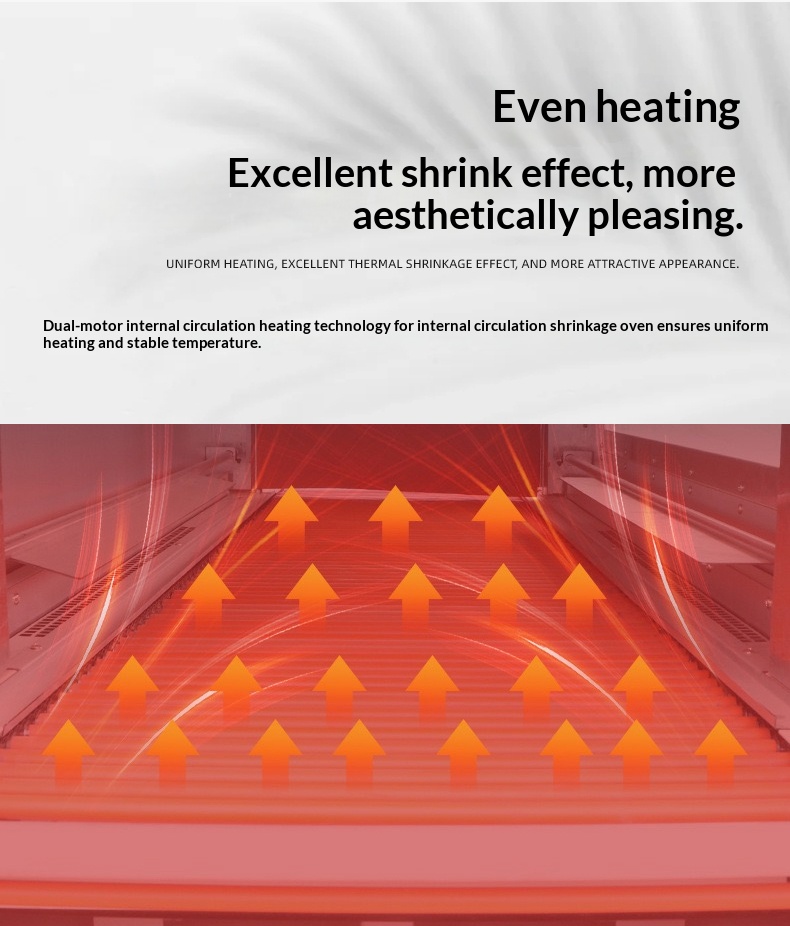

The Automatic Vertical Sealing and Cutting Heat Shrink Packaging Machine features high-efficiency automation, flat sealing, and a wide application range, meeting product packaging needs across multiple industries. It is especially suitable for items requiring batch packaging, a neat appearance, or moisture and dust protection. The vertical up-and-down drive sealing and cutting ensures uniform, wrinkle-free sealing, making it ideal for products with large vertical dimensions. In comparison, L-shaped sealing and cutting machines offer higher efficiency and are suitable for batch packaging of flat small items.

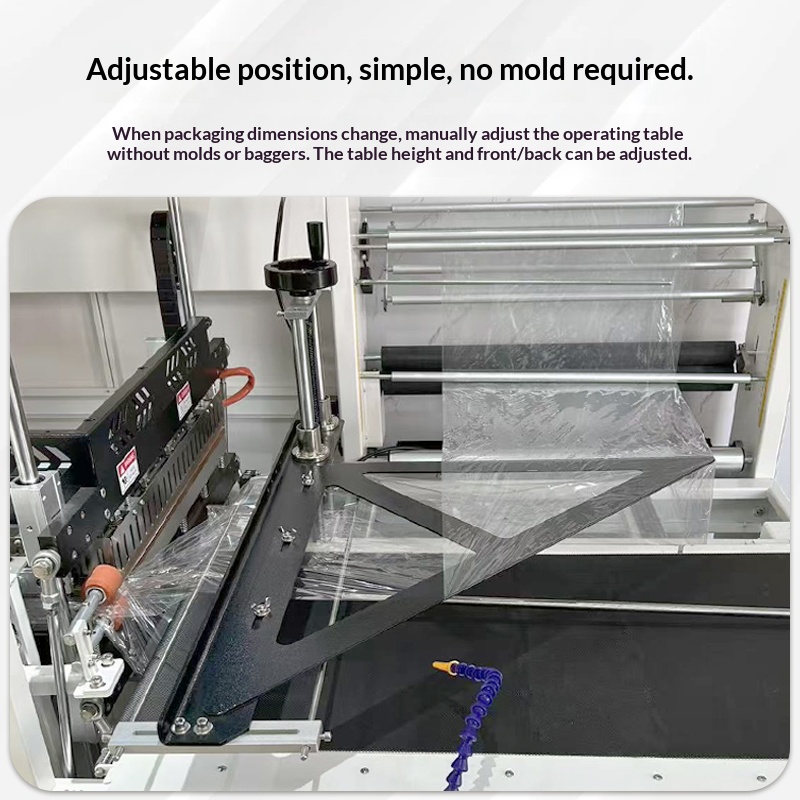

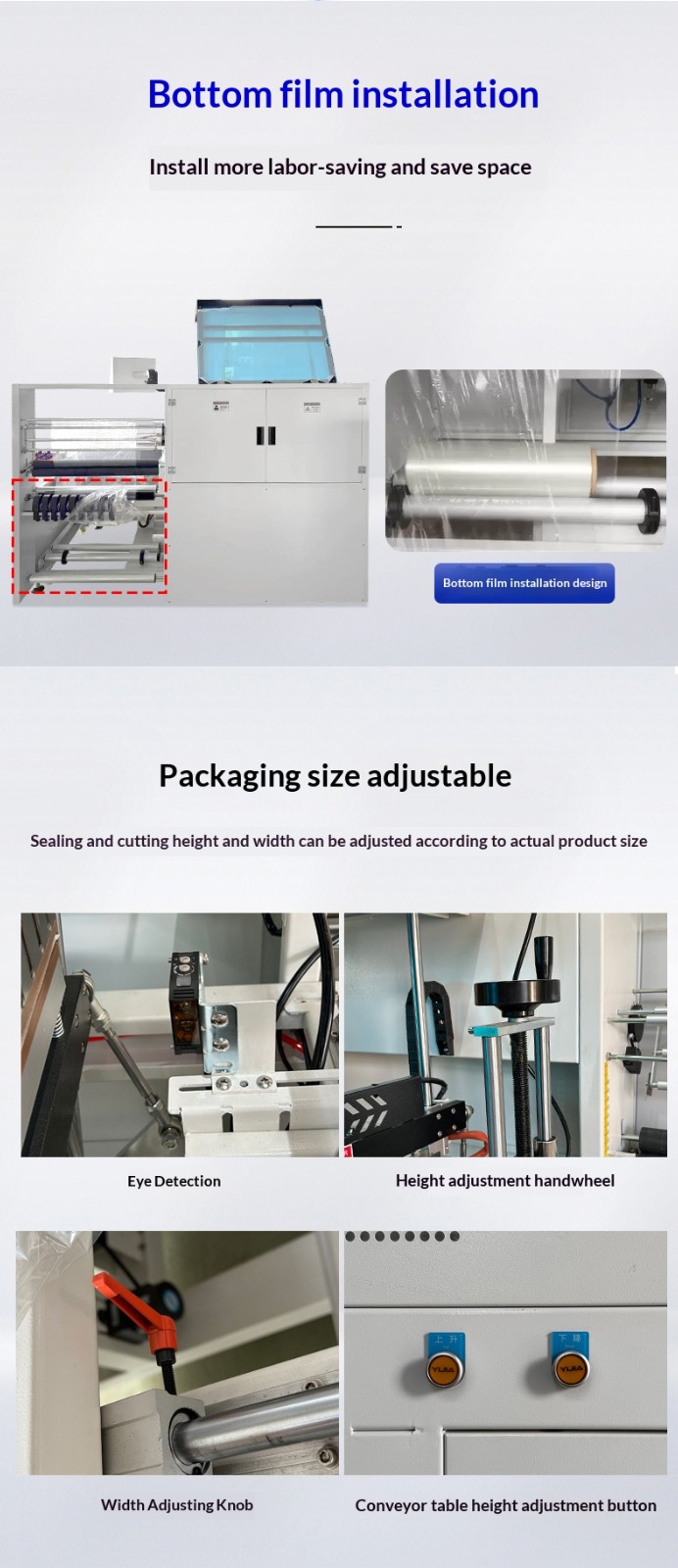

- Conveyor Belt: Transports items with adjustable speed and a smooth surface to minimize friction.

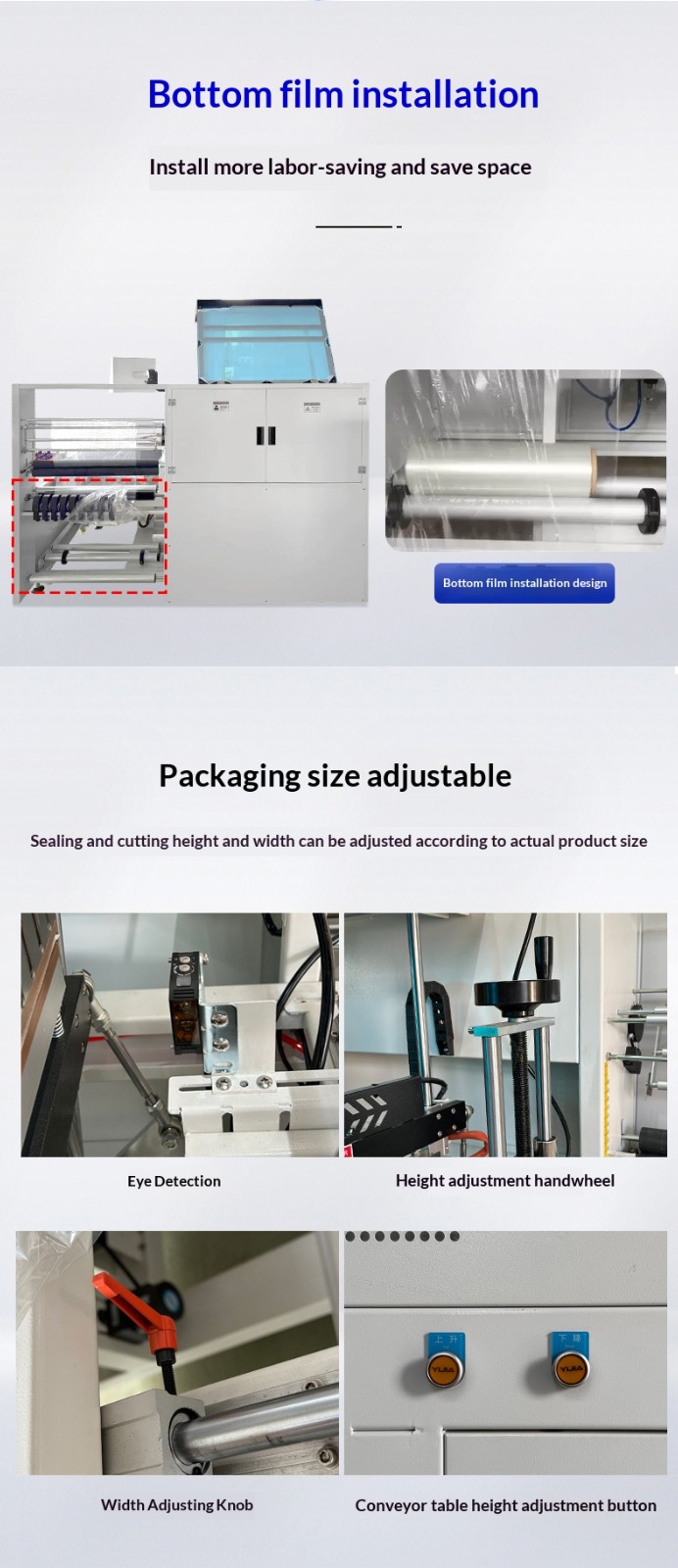

- Film Conveying and Supply System: Consists of a film reel, tension adjustment device, and film guiding mechanism, ensuring stable and accurate delivery of film to the wrapping position.

- Photoelectric Sensing and Positioning System: Real-time monitors item position and posture via photoelectric sensors, enabling precise positioning and triggering subsequent packaging operations.

- Sealing and Cutting Device: The core component, including heating elements, pressure devices, and sealing knives, realizing film heating, sealing, and cutting.

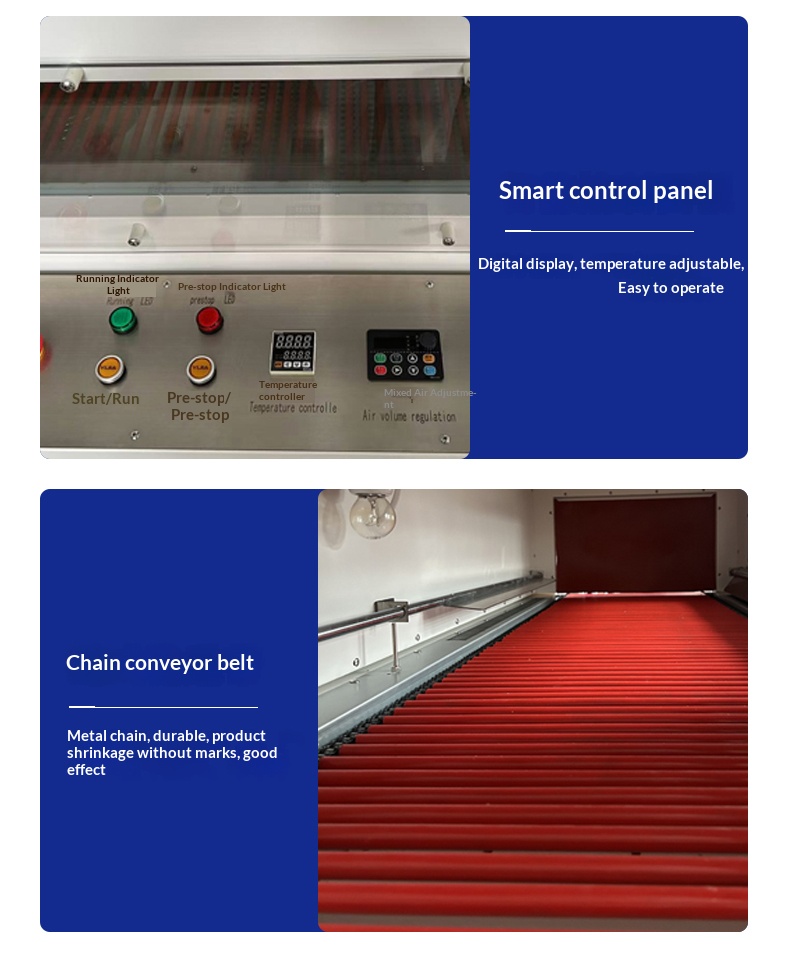

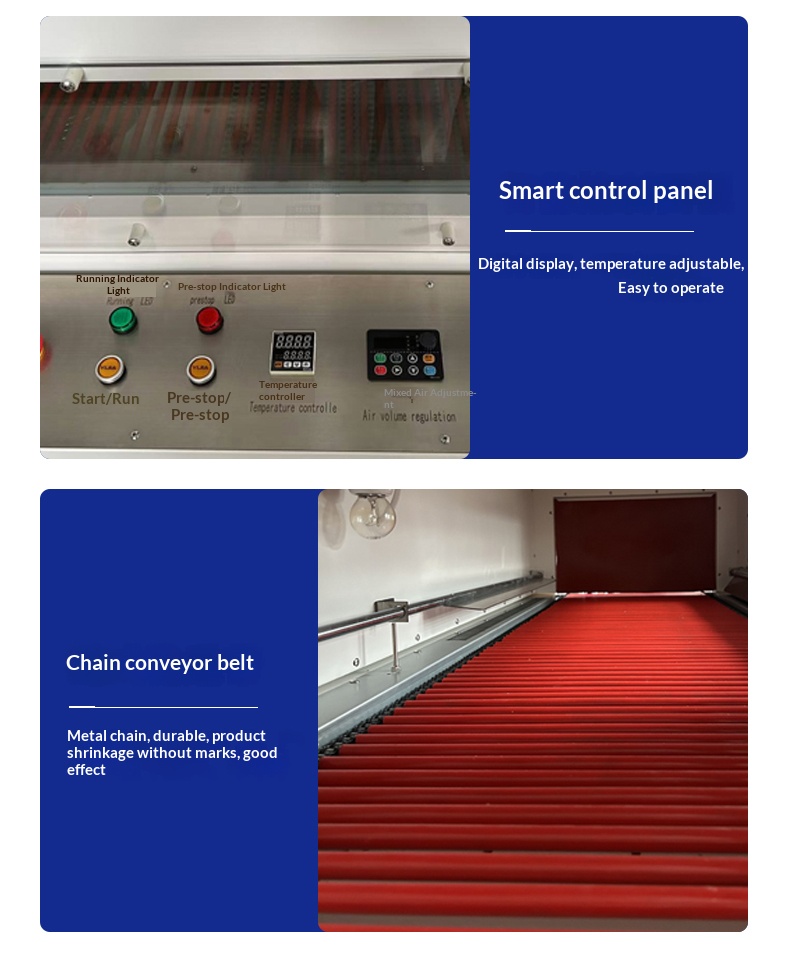

- Control System: Fully controls equipment operation, allows parameter setting and adjustment, and is equipped with fault diagnosis and alarm functions.

- High-Efficiency Automation: Automatically completes the entire packaging process with minimal manual intervention, suitable for mass production and improved work efficiency.

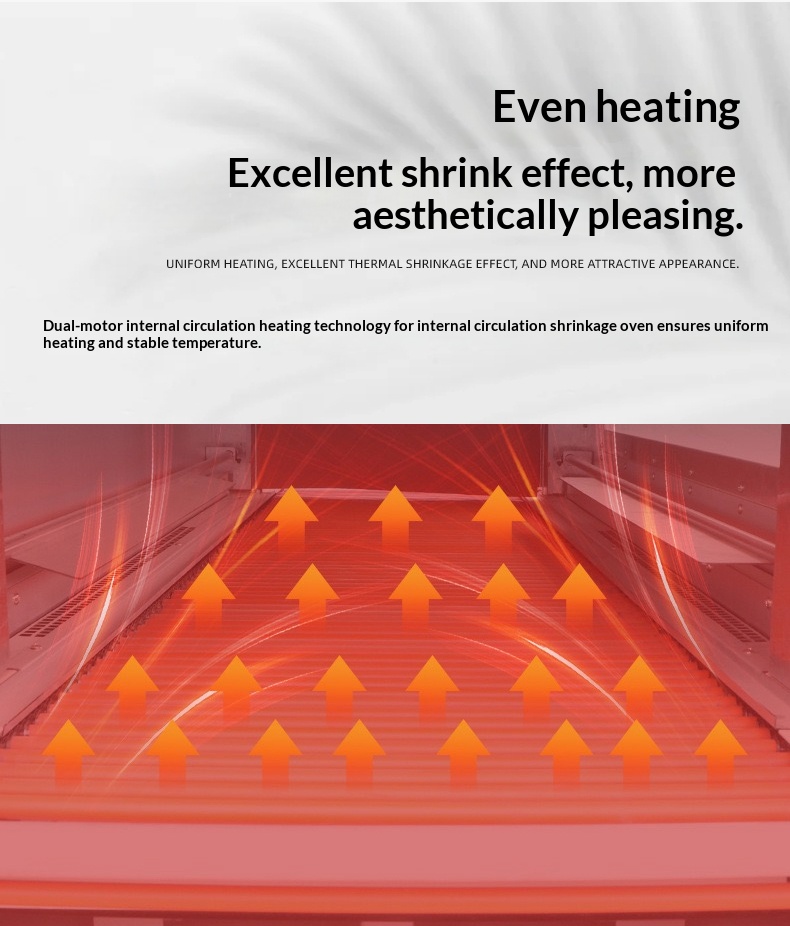

- Excellent Sealing Effect: The vertical up-and-down drive of the sealing section ensures uniform contact surface force, overcoming the wrinkling and sealing line deviation problems associated with traditional L-shaped sealing and cutting machines.

- Easy Operation: Adopts an advanced PLC programmable controller, equipped with safety protection and alarm devices, facilitating simple maintenance and operation.

- Wide Application Range: Can easily seal thin or small packages by installing two sets of horizontal and vertical photoelectric sensors. It can also accommodate products of different heights by adjusting the sealing knife height.

- Versatile Product Compatibility: Suitable for regular/irregular boxed, bottled, and gift boxed products (e.g., food gift boxes, pharmaceutical boxes, daily chemical sets). It is particularly suitable for production lines with a batch capacity of ≥ 300 units/hour and is more effective than L-shaped sealing and cutting machines for products prone to wrinkling and requiring high-precision sealing.