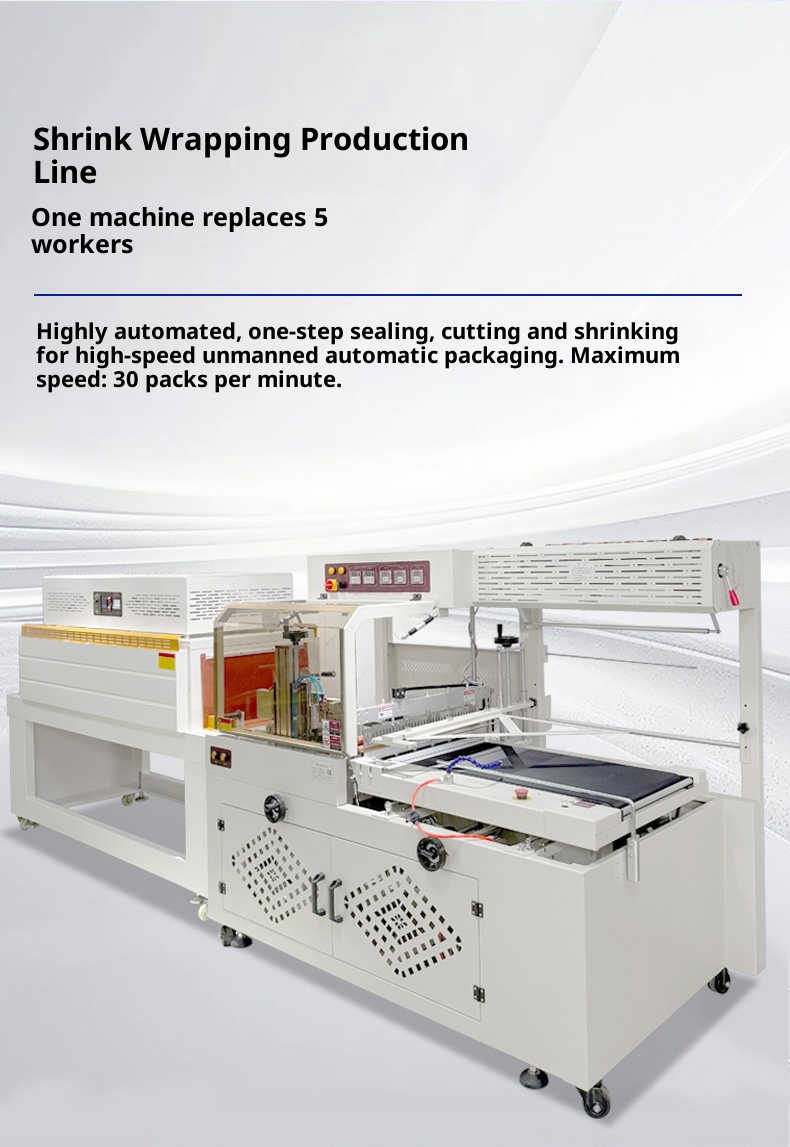

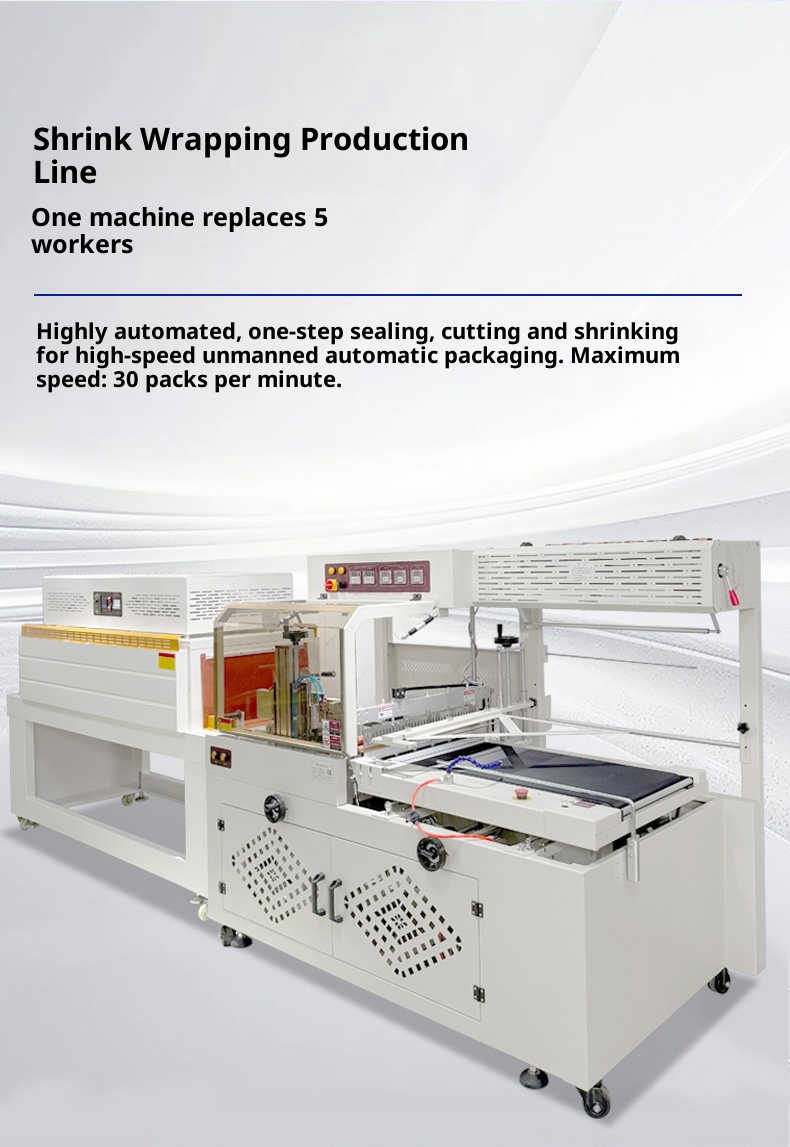

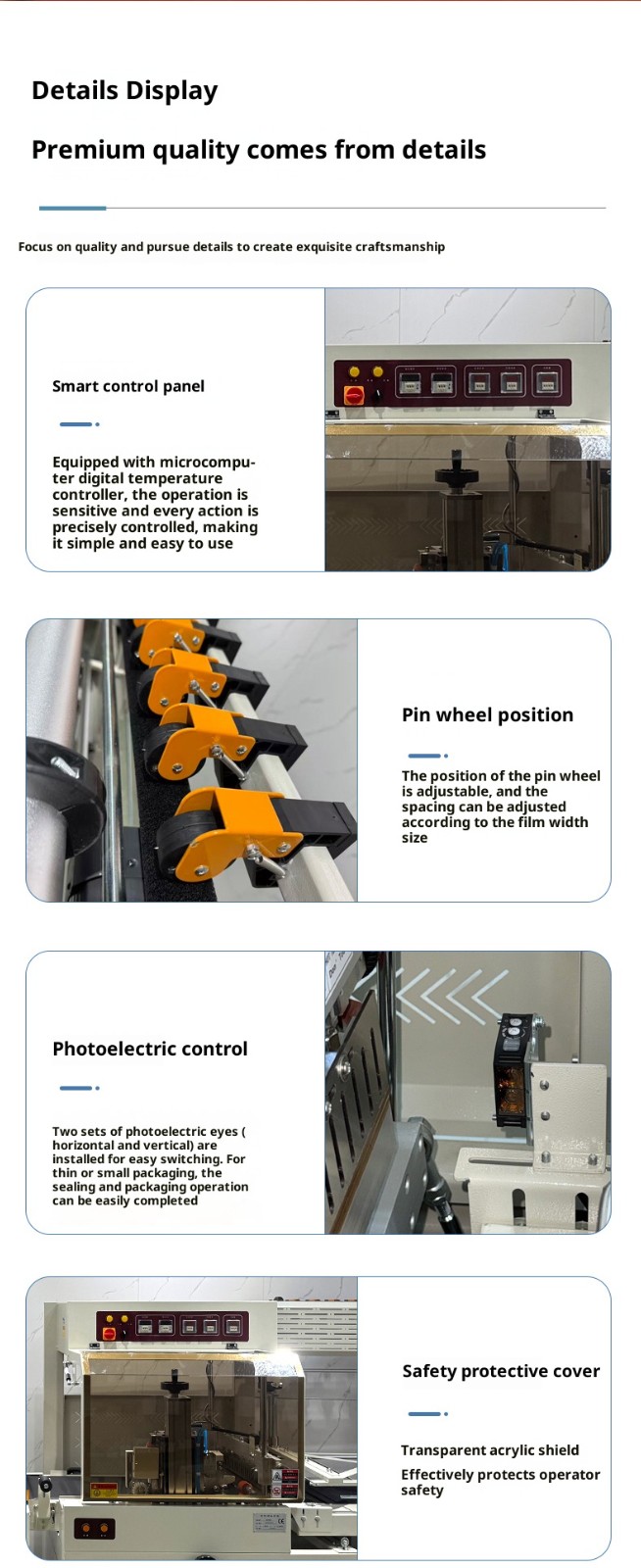

High degree of automation: Usually adopts PLC programmable logic controller and touch screen control, with functions such as automatic feeding, automatic cutting, automatic film covering, and automatic sealing. It is easy to operate and can reduce manual operations.

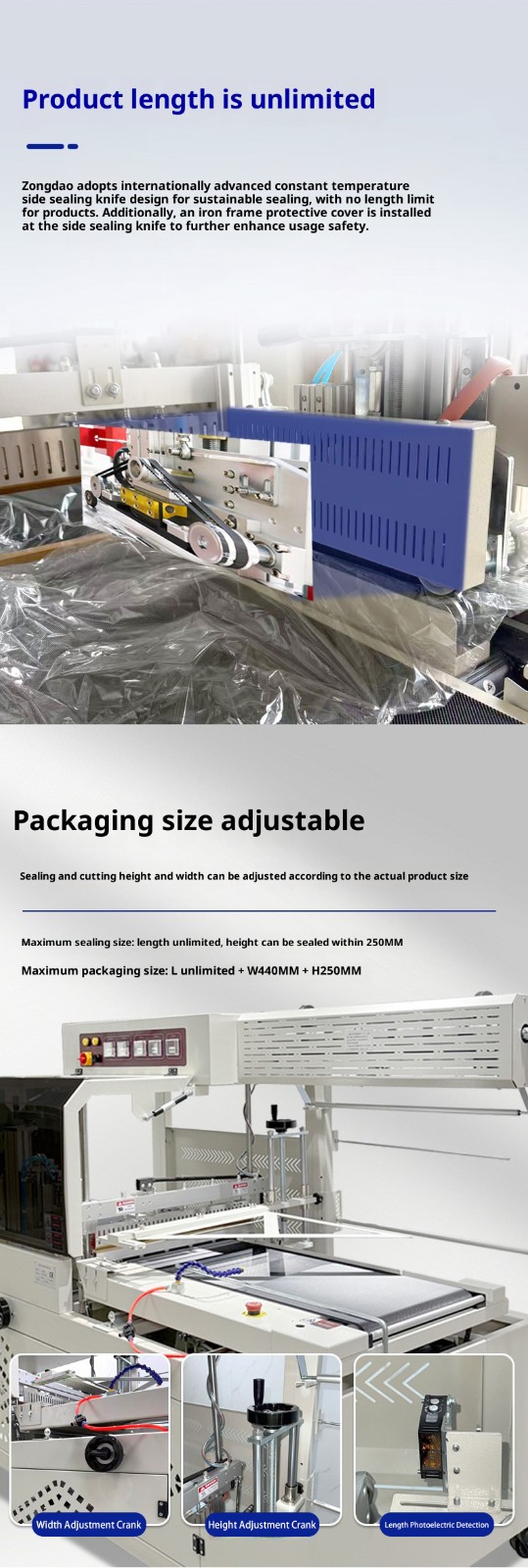

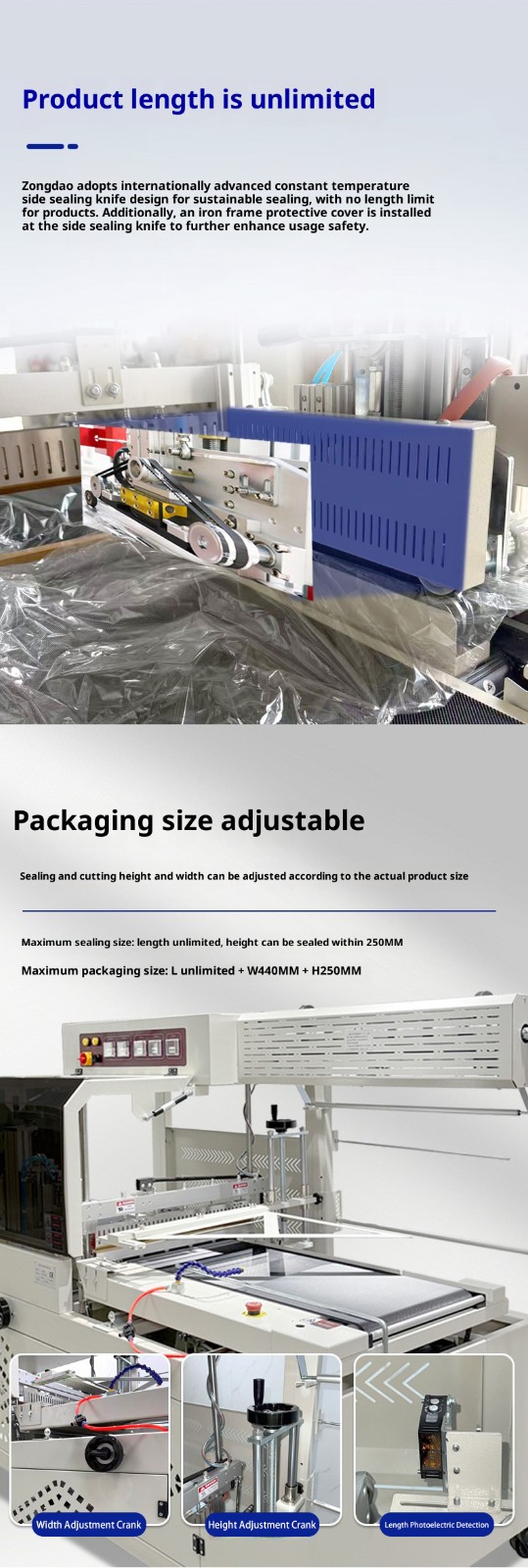

Wide packaging range: Adopts side-sealing design, with no limit on the packaging length of products. The height of the sealing line can be adjusted according to the height of the packaged items, enabling packaging of products with different widths and heights without replacing molds or bag makers.

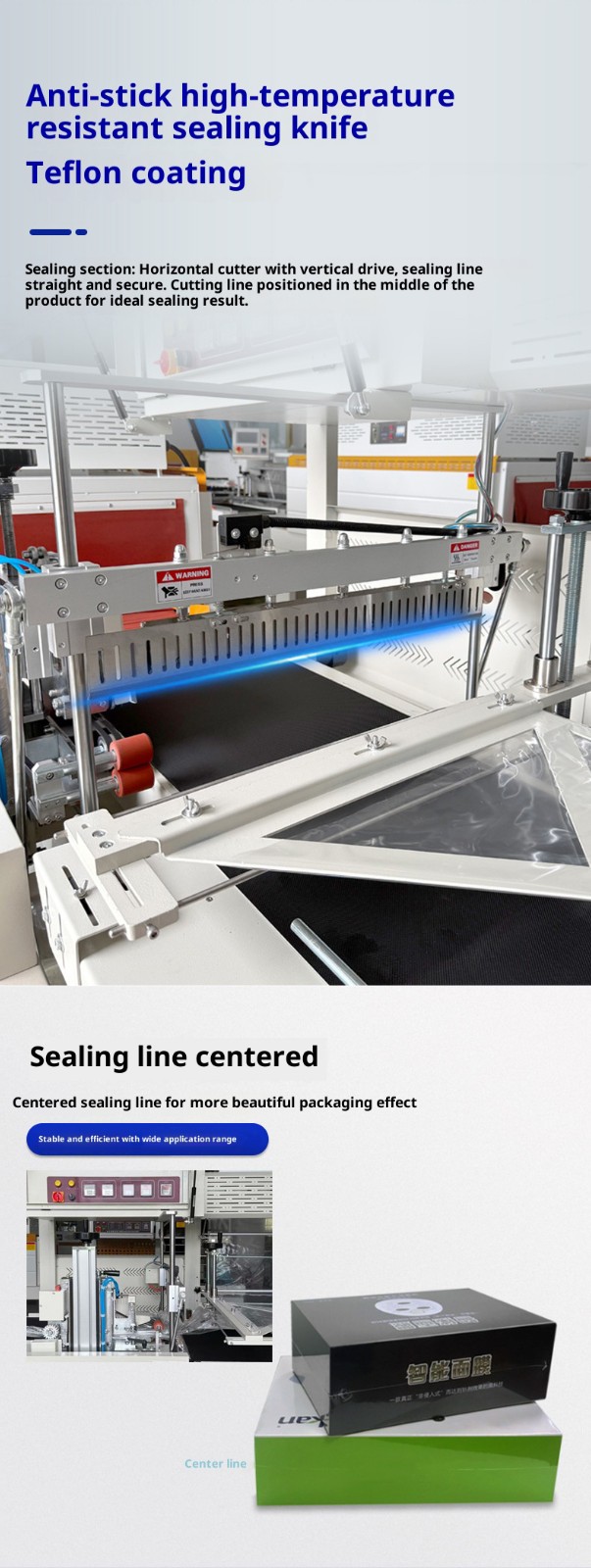

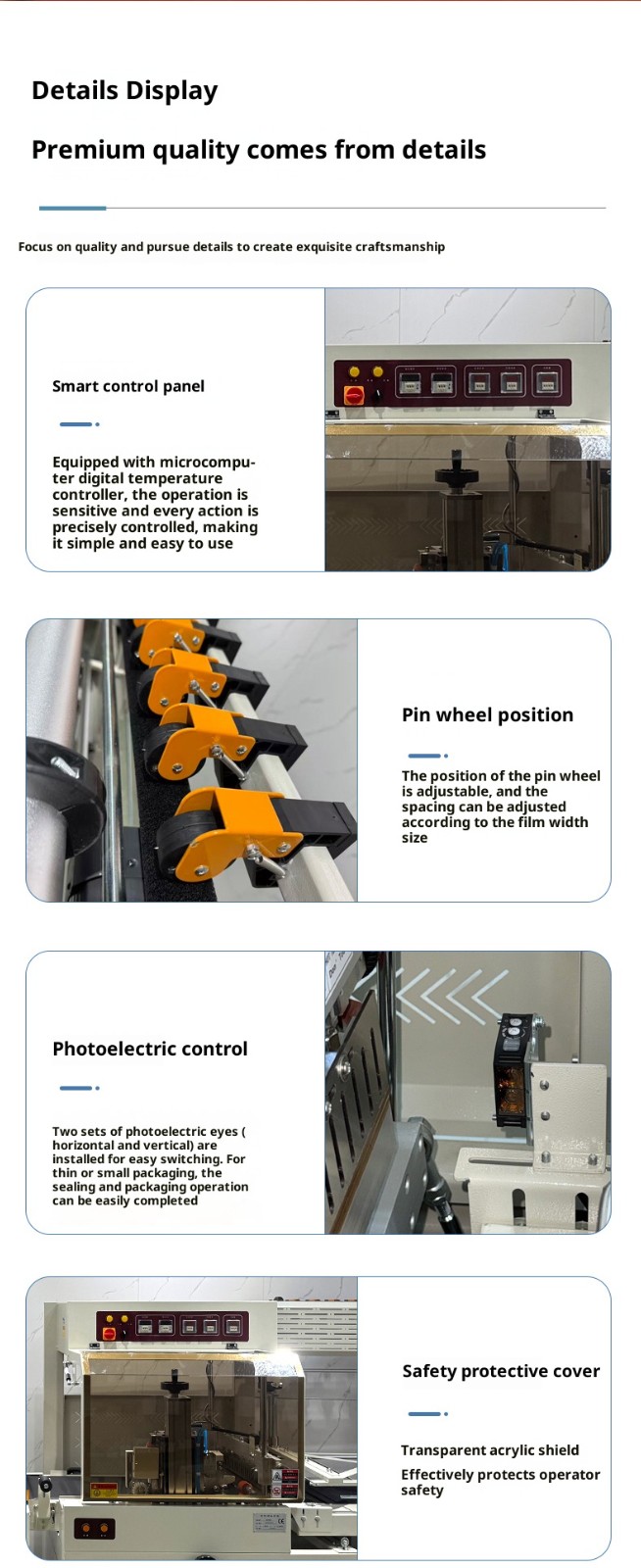

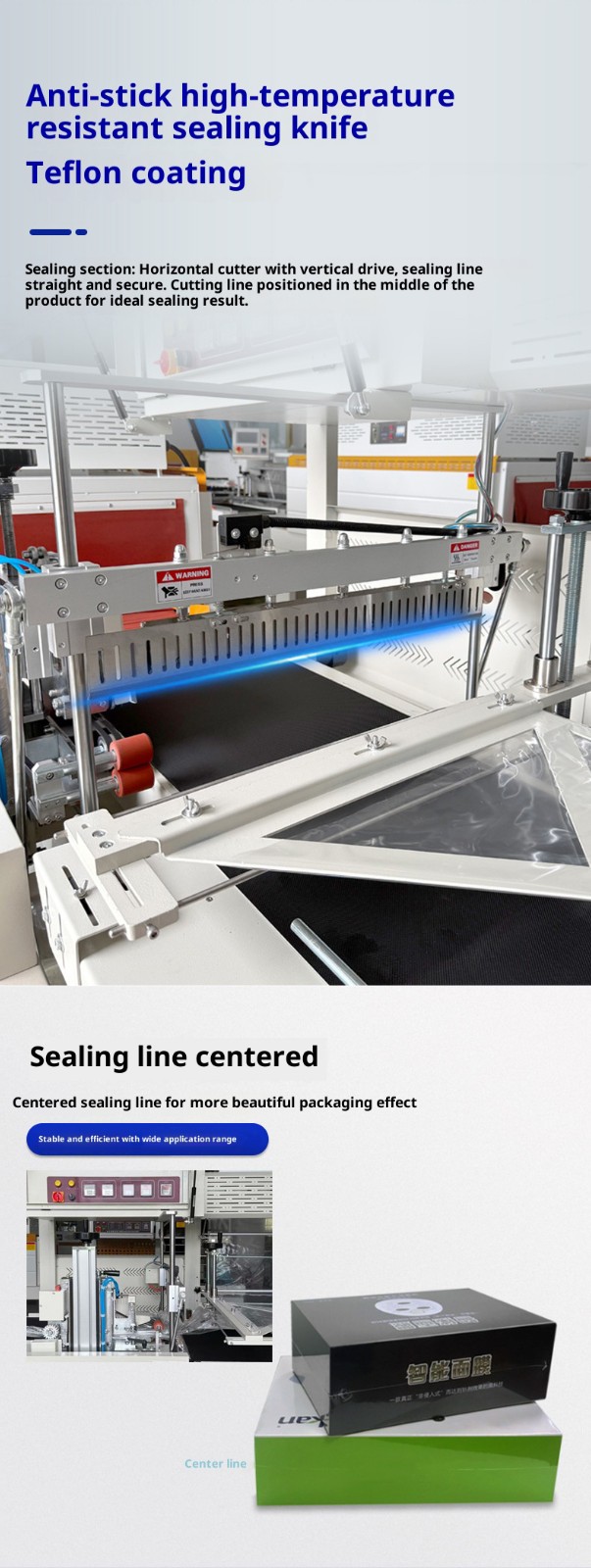

Excellent sealing performance: The sealing and cutting knife is usually coated with DuPont Teflon non-stick coating (USA), ensuring no cracking or charring of the seal. It also has an automatic protection function to prevent accidental cutting of packaged items.

Fast packaging speed: The packaging speed can reach 20-60 pieces per minute, suitable for mass production.

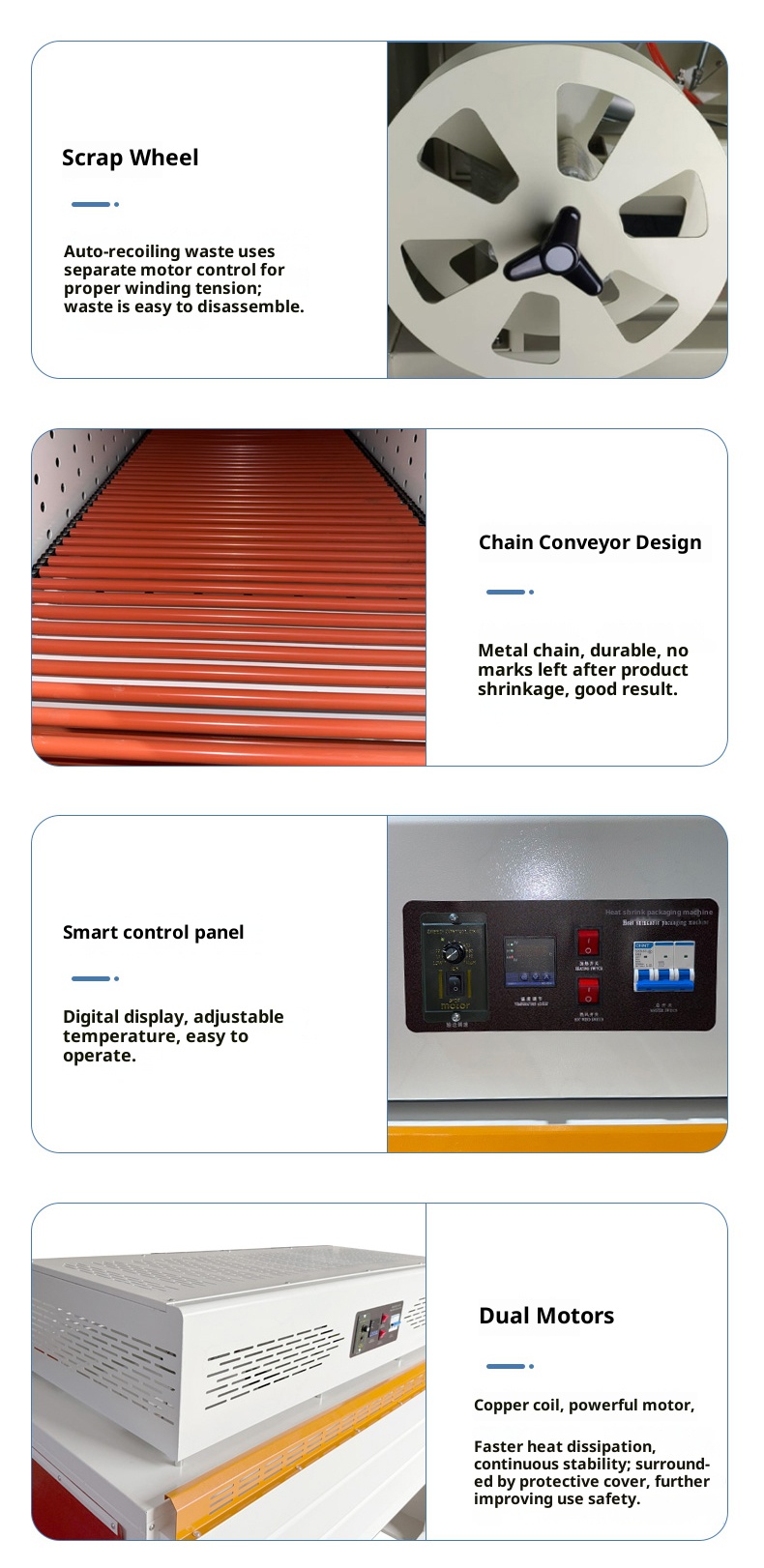

Material saving: The heat shrinkable film can fit tightly against the product edges, reducing material waste. Additionally, the packaged products have a small volume, facilitating transportation and storage.

Fast sealing and cutting speed:

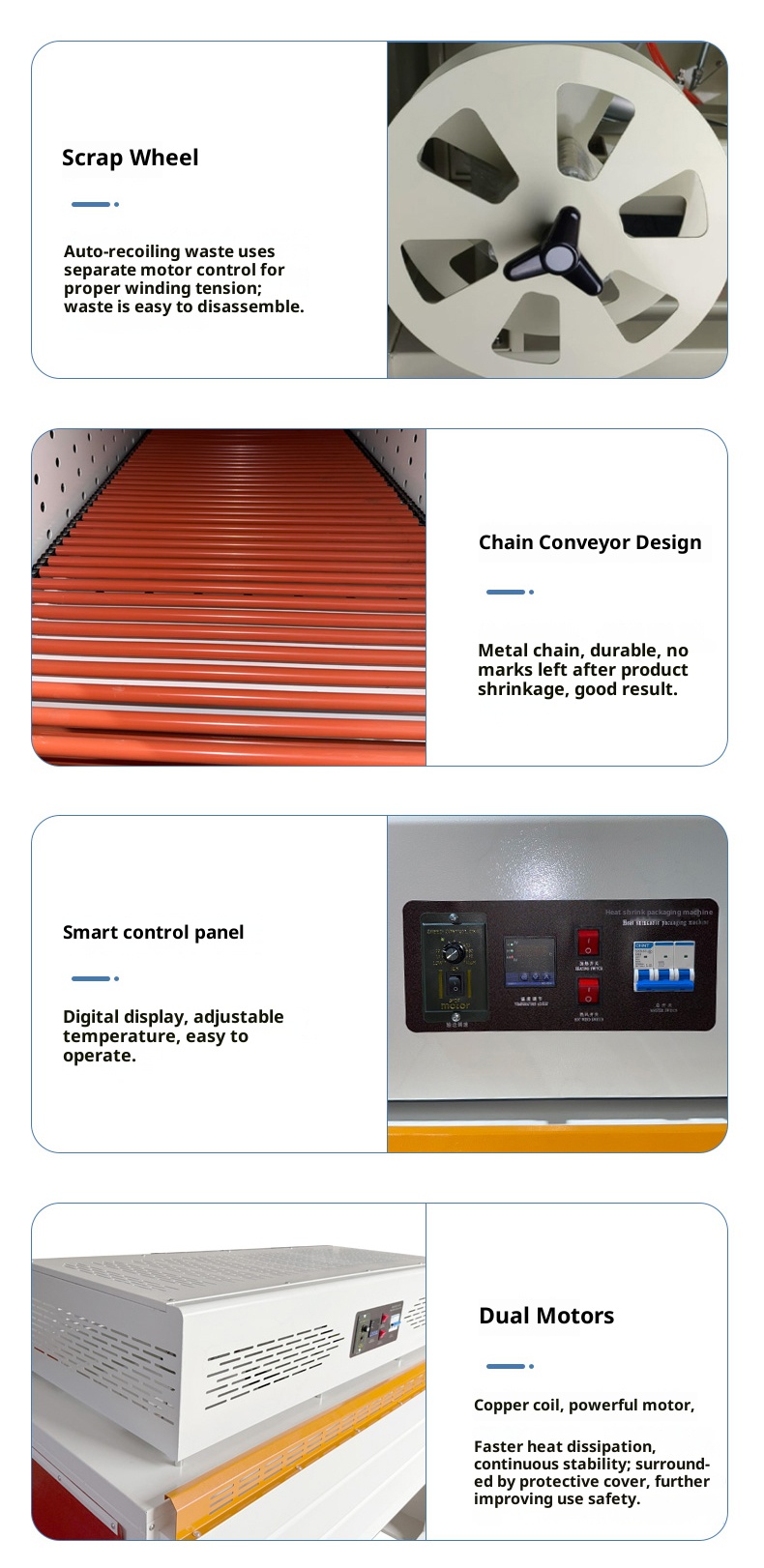

Continuous sealing and cutting structure: The side-sealing machine adopts a design with front-mounted vertical sealing side knives and lifting horizontal sealing knives. The vertical sealing can realize uninterrupted continuous sealing and cutting, while the horizontal sealing knife completes sealing and separation synchronously during product conveying through a chasing-shear reciprocating motion, avoiding efficiency loss caused by frequent start-stop of traditional equipment. For example, the horizontal knife of some models adopts reciprocating continuous cutting, which can cut twice per second, achieving a packaging speed of 40-60 pieces per minute.

High-precision drive and control: Mainstream models are equipped with a servo motor control system, which can accurately control the running track and speed of the sealing and cutting knife, ensuring precise sealing and cutting positions during high-speed operation without problems such as film deviation and irregular sealing. At the same time, combined with PLC programmable logic controller and touch screen, sealing and cutting parameters can be quickly set, reducing debugging time and further ensuring the stability of high-speed operation.

Unlimited packaging length:

The side-sealing machine wraps products with folded film to form a film "sleeve" around the product, only sealing and cutting the sides and tail of the product. The tail sealing is completed by the real-time falling of the horizontal sealing knife as the product is continuously conveyed, separating and sealing adjacent products without being restricted by the equipment frame size. In addition, two groups of horizontal and vertical photoelectric sensors automatically detect the product length, enabling smooth packaging of both small items as short as a few centimeters and long items such as aluminum profiles and wood flooring up to several meters, without replacing parts adapted to different lengths.

Strong compatibility:

Adapts to various product sizes: When packaging products of different widths and heights, only manual adjustment of the film guiding system, feeding and conveying platform, and sealing line height is required, without replacing molds or bag makers. For example, after packaging small cosmetic boxes and switching to large photo frames, quick adaptation can be achieved by adjusting the spacing of relevant parts with handwheels, greatly reducing production changeover time.

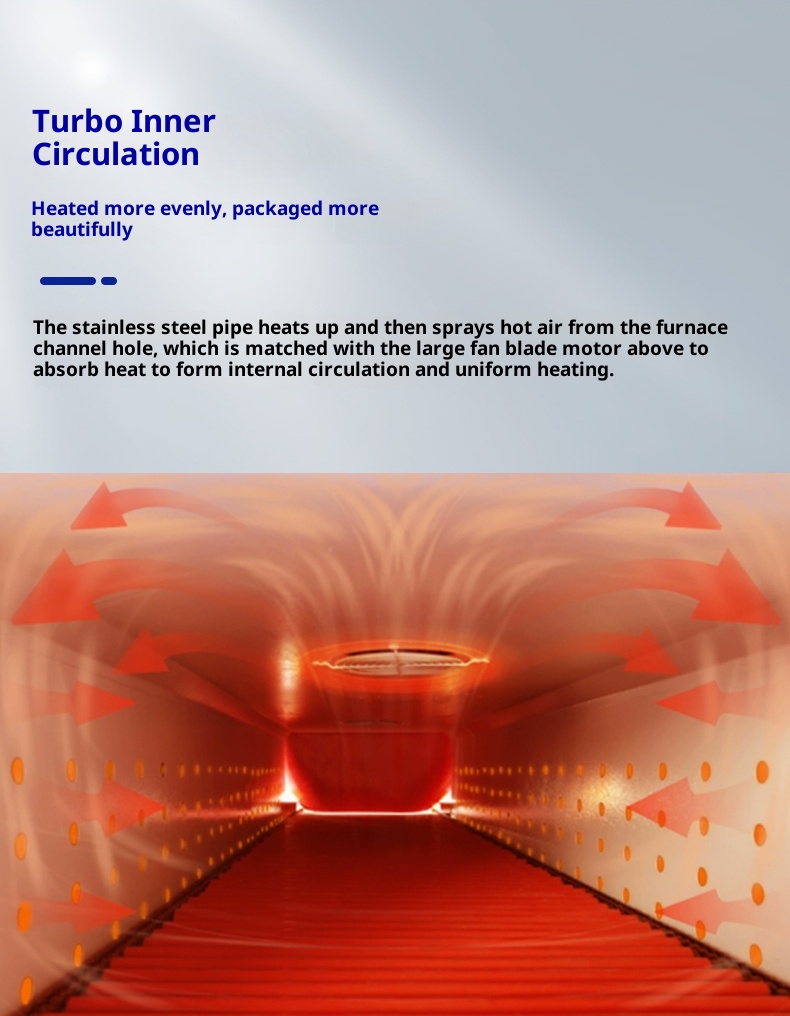

Compatible with multiple packaging films: Its constant temperature heating sealing and cutting system can adapt to various commonly used heat shrinkable films such as PE, PVC, and POF. Moreover, most sealing knives are coated with DuPont Teflon non-stick coating (USA), which can meet the sealing and cutting temperature requirements of different films, avoid film adhesion to the knife, and ensure firm sealing without charring. Even environmentally friendly films like POF that require high sealing and cutting precision can achieve ideal sealing and cutting effects.

Adapts to diverse packaging scenarios: It can not only complete single product packaging independently but also realize multi-product combination packaging; it can be manually fed for small-batch production, or connected to a fully automatic production line for unmanned mass packaging. It is widely applicable to the packaging needs of different products in food, electronics, building materials and other industries.