The high automation of the fully automatic side-seal heat shrink packaging machine is mainly reflected in closed-loop process automation and intelligent operation. It can significantly reduce manual participation and improve production efficiency and stability:

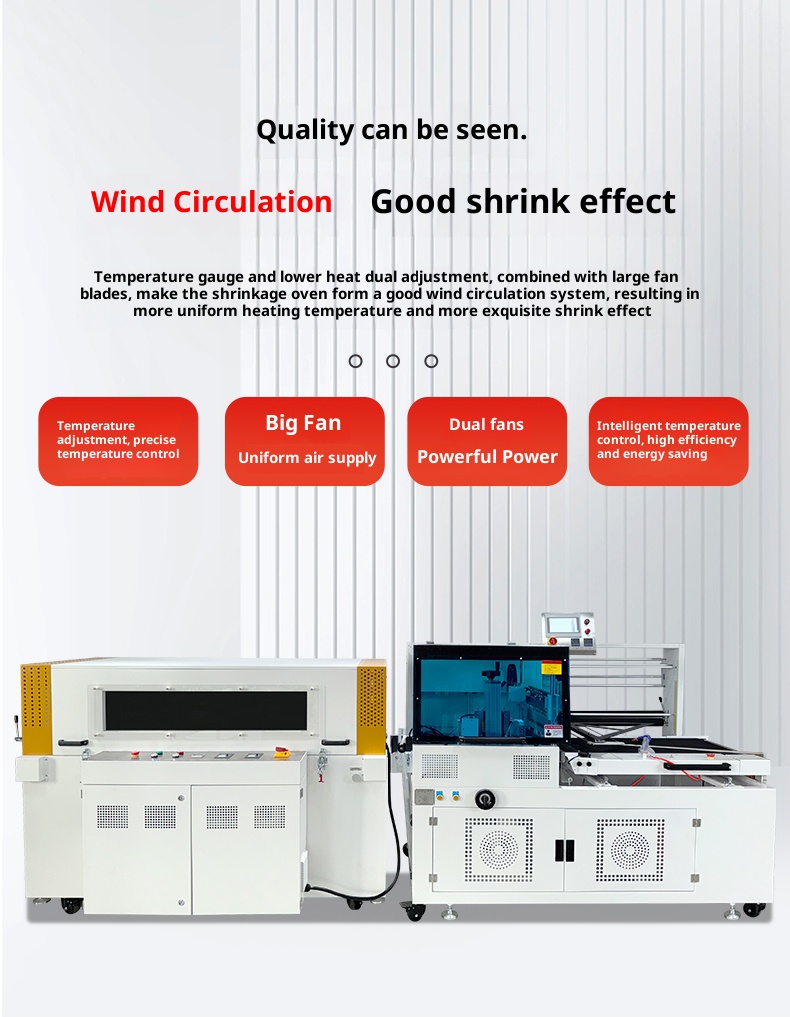

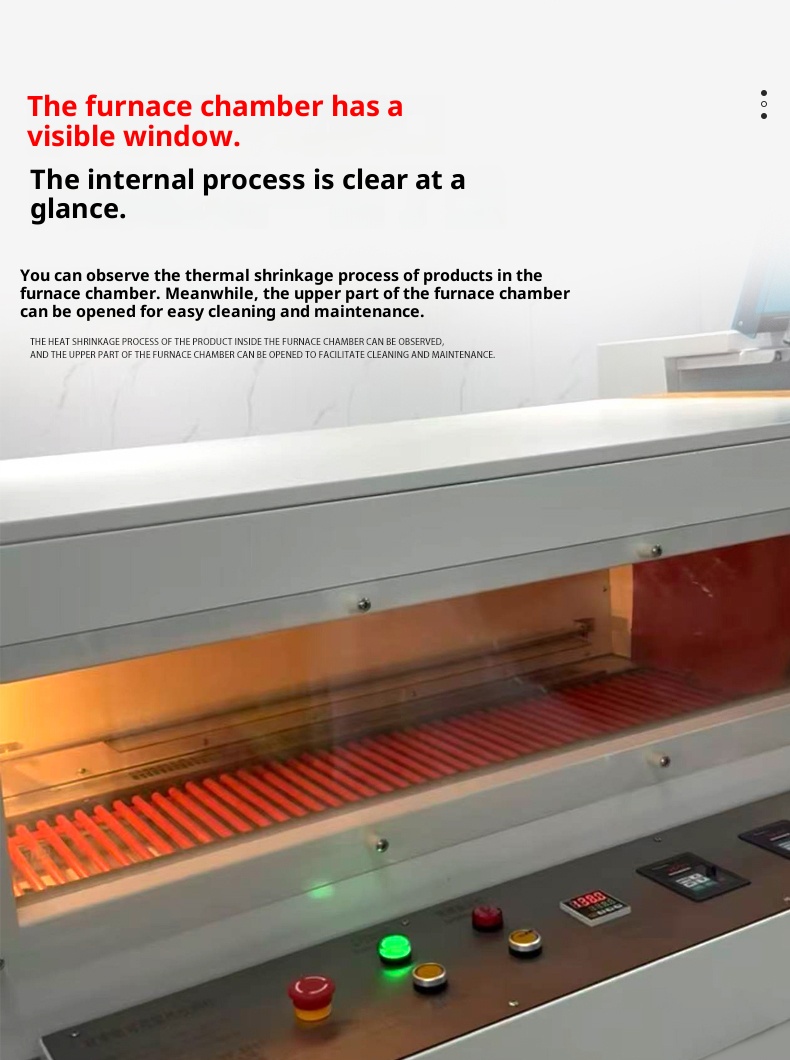

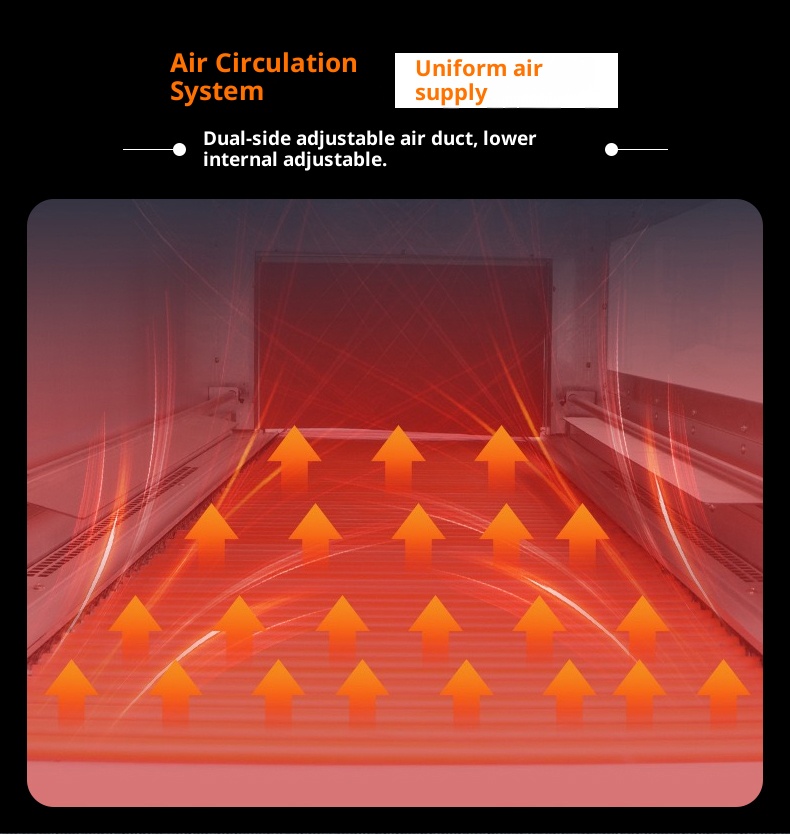

Full-process Automatic Packaging: Simply place the products to be packaged on the feeding conveyor belt. The equipment automatically detects the position and size of the products through imported photoelectric sensors (with dual horizontal and vertical design for flexible switching). It then sequentially completes the entire process of "automatic film feeding → precise film covering → side-seal cutting → automatic waste film winding → heat shrinking → finished product output". No mid-process manual intervention is required, and it can be directly connected to the factory production line to achieve unmanned continuous production.

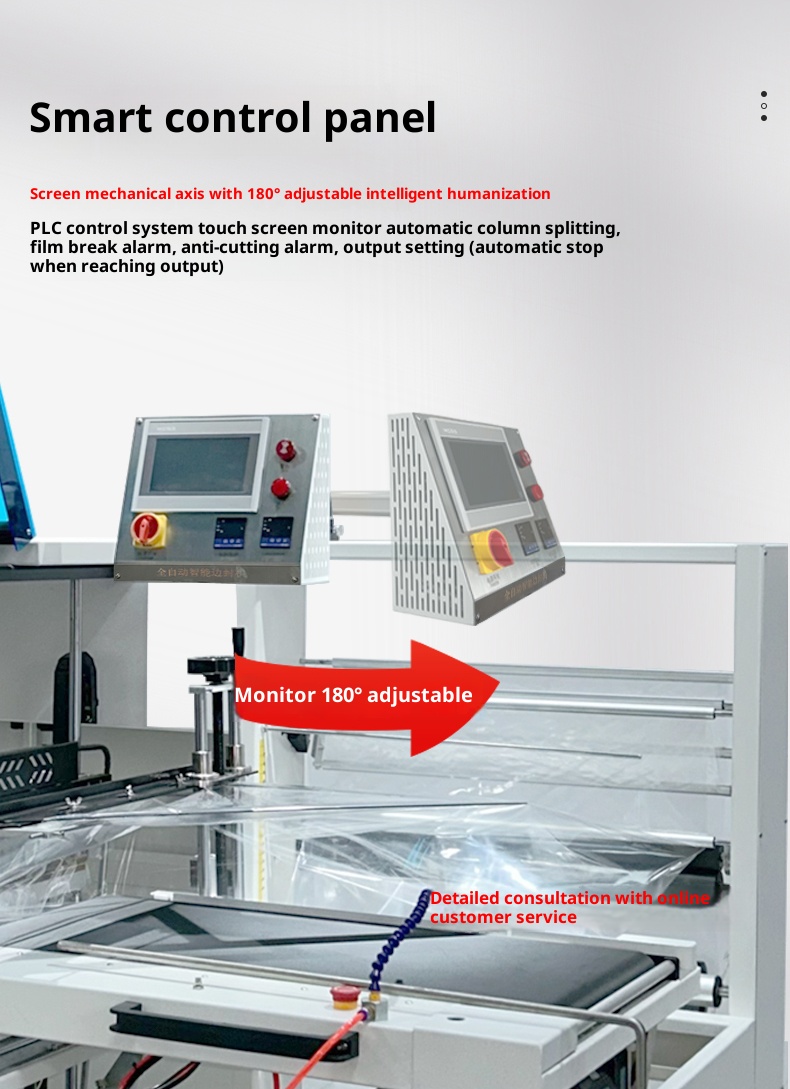

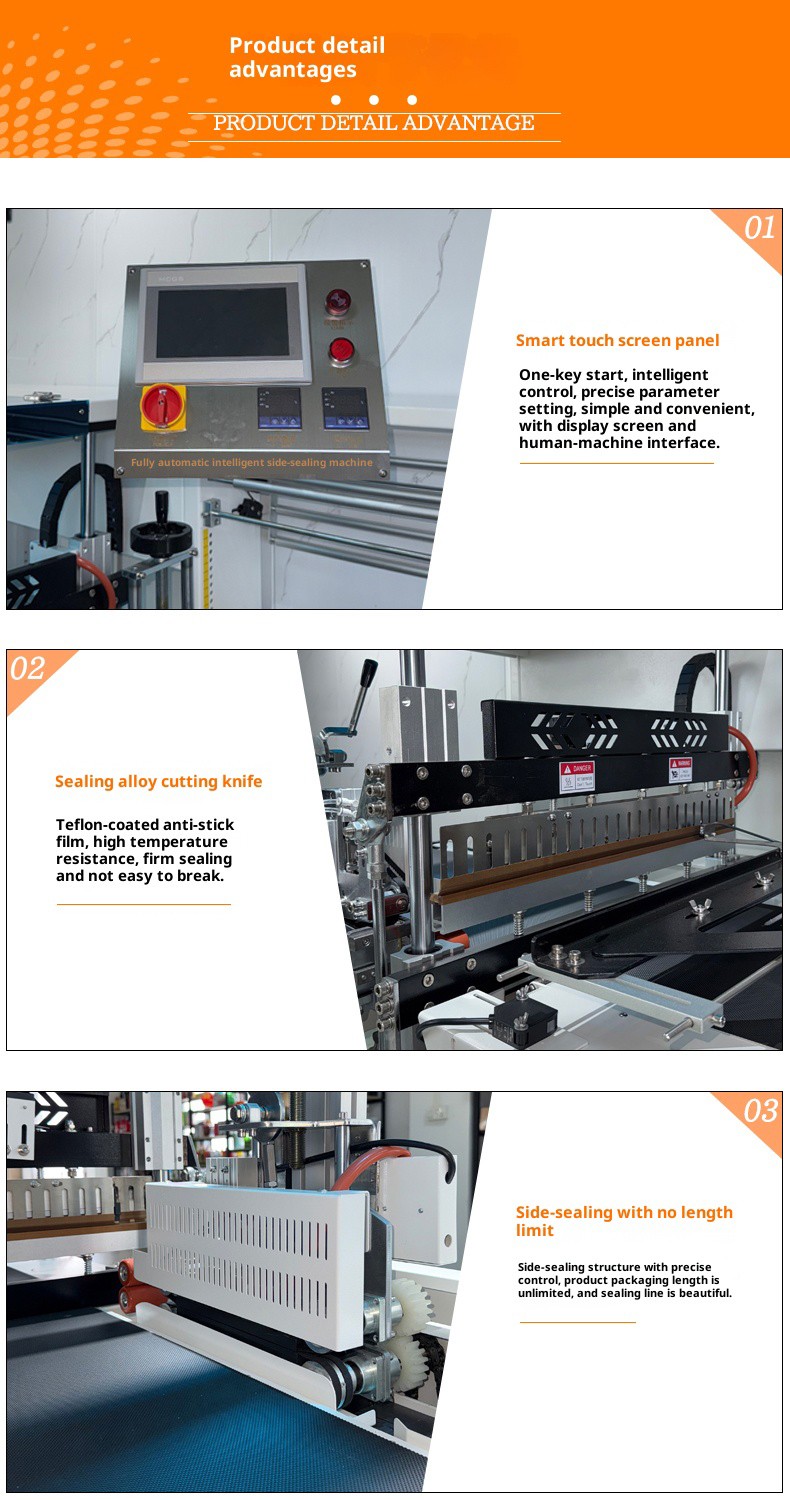

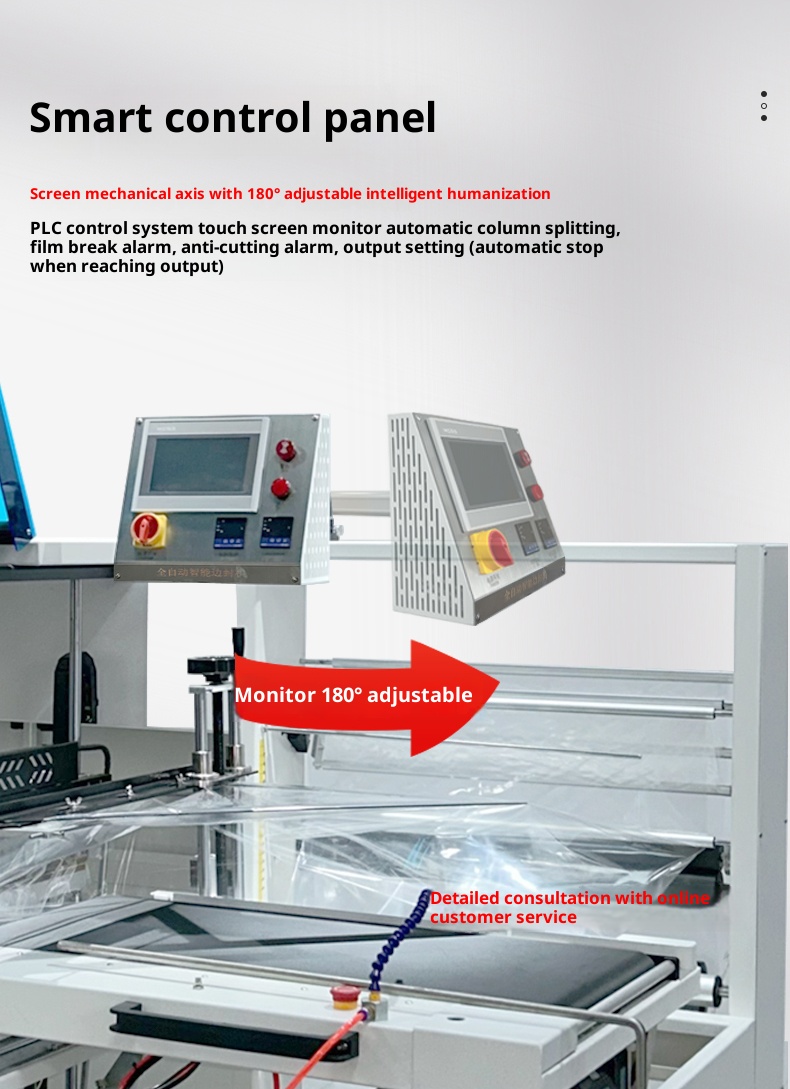

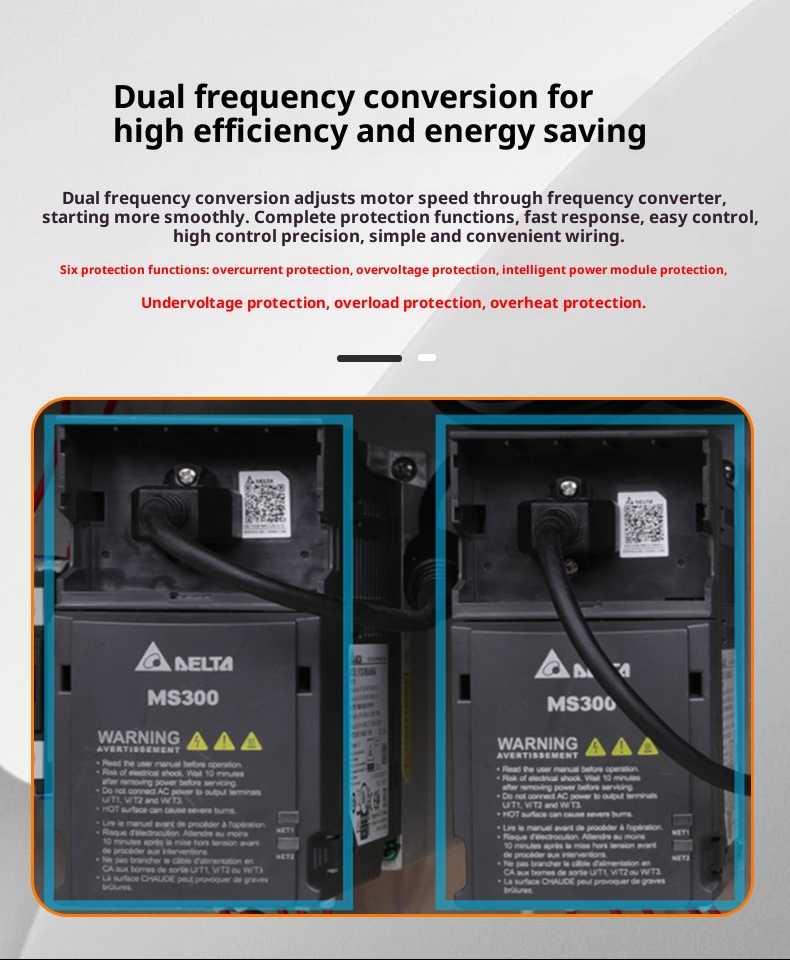

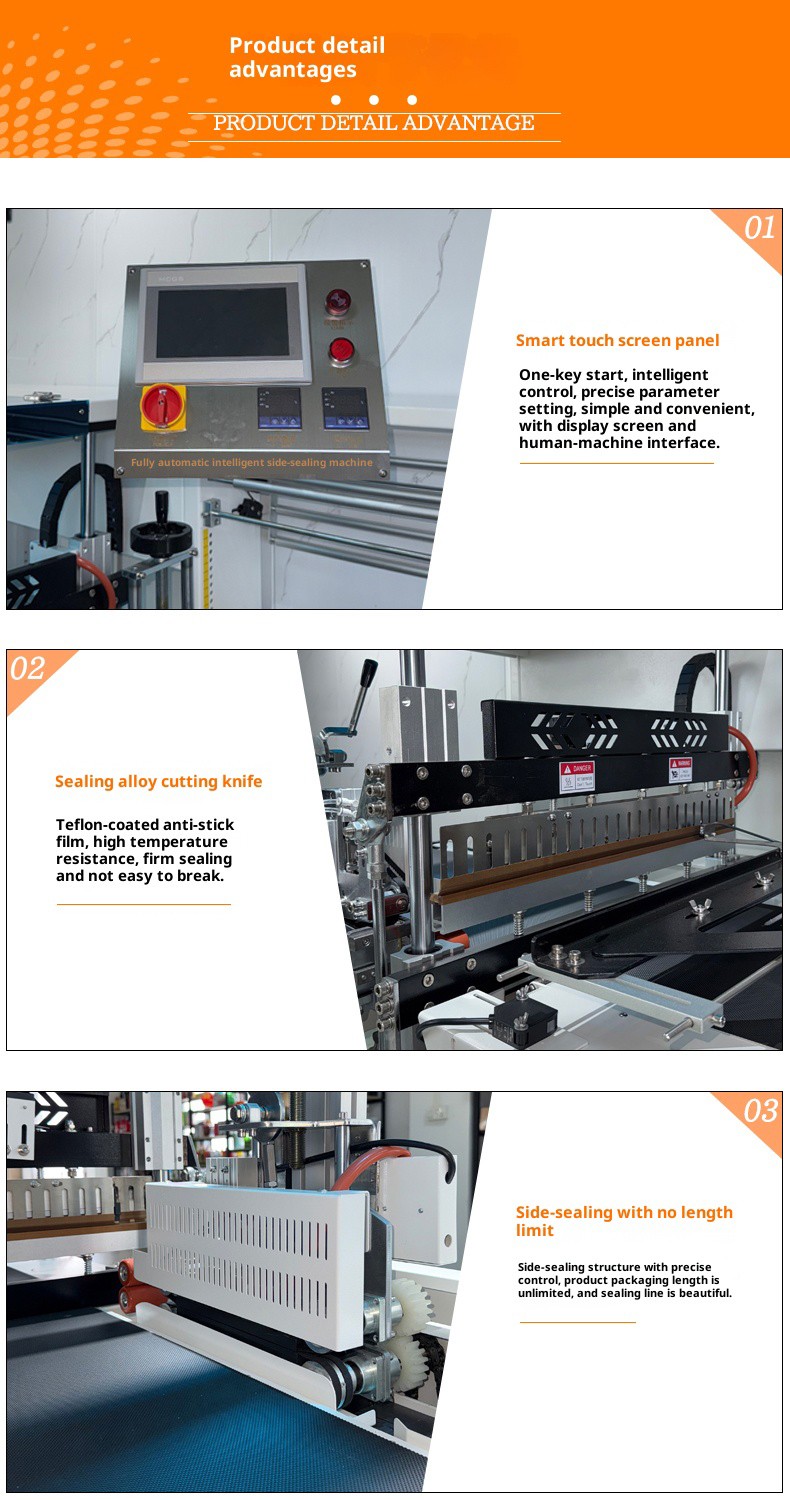

Intelligent Operation and Regulation: It adopts a PLC (Programmable Logic Controller) + touch screen control system. Key parameters such as temperature, packaging speed, and film feeding length can be set with one click and adjusted in real time on the screen. These parameters can also be stored and memorized, eliminating the need for repeated debugging when changing products. Meanwhile, it is equipped with safety protection and alarm devices (such as accidental cutting protection for the sealing knife and fault alarm) to ensure stability and safety during high-speed operation.

Automatic Adaptability Adjustment: Through designs such as height adjustment of the film guiding device and lifting of the feeding conveyor platform, it can automatically adapt to products of different widths and heights without replacing molds or bag makers. Some models are also equipped with an automatic hole-punching and air-release device, which automatically discharges air inside the package according to product needs to ensure a smooth shrinkage effect.

Traditional packaging equipment (such as pillow-type packaging machines) is often restricted by their sealing and cutting structure and cannot meet the packaging needs of long-sized products. However, the side-seal design achieves "unlimited" packaging length through an innovative sealing logic:

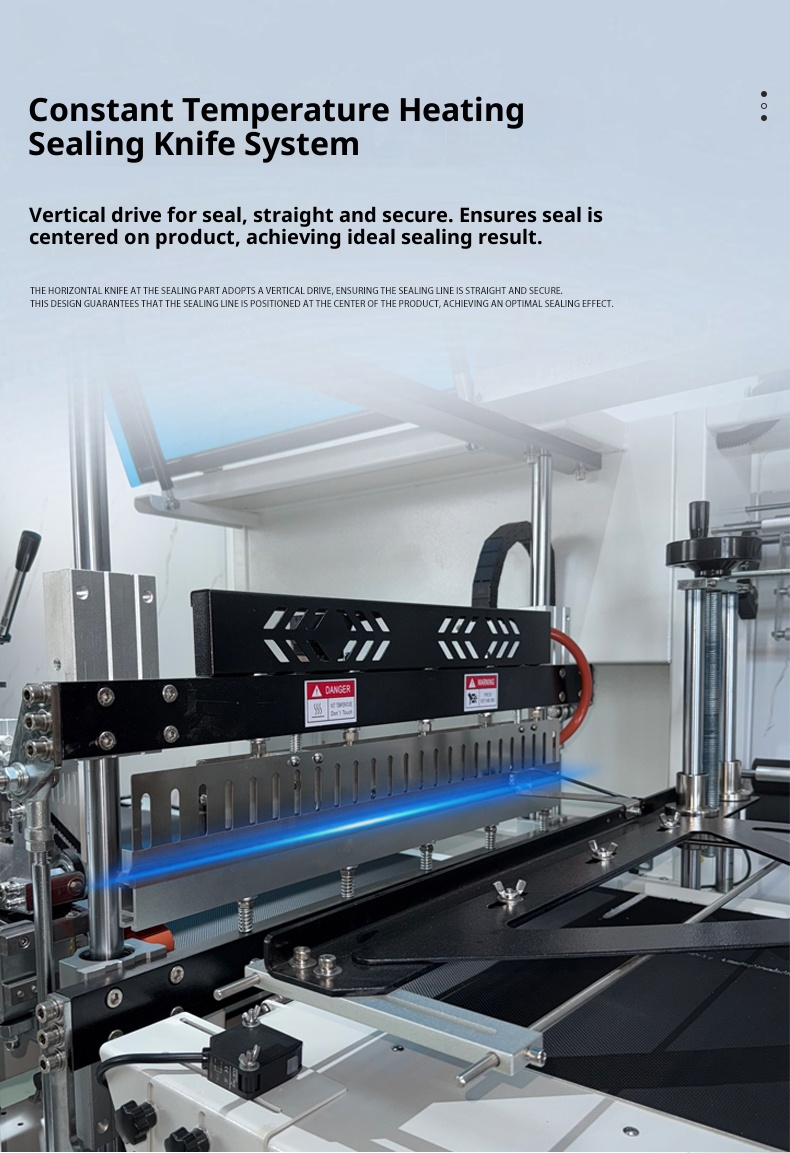

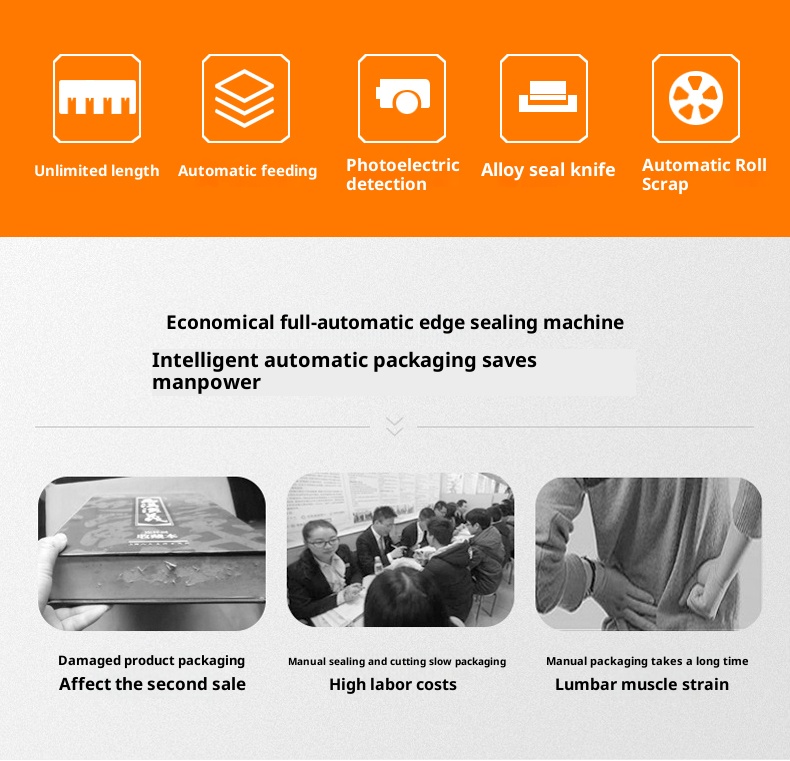

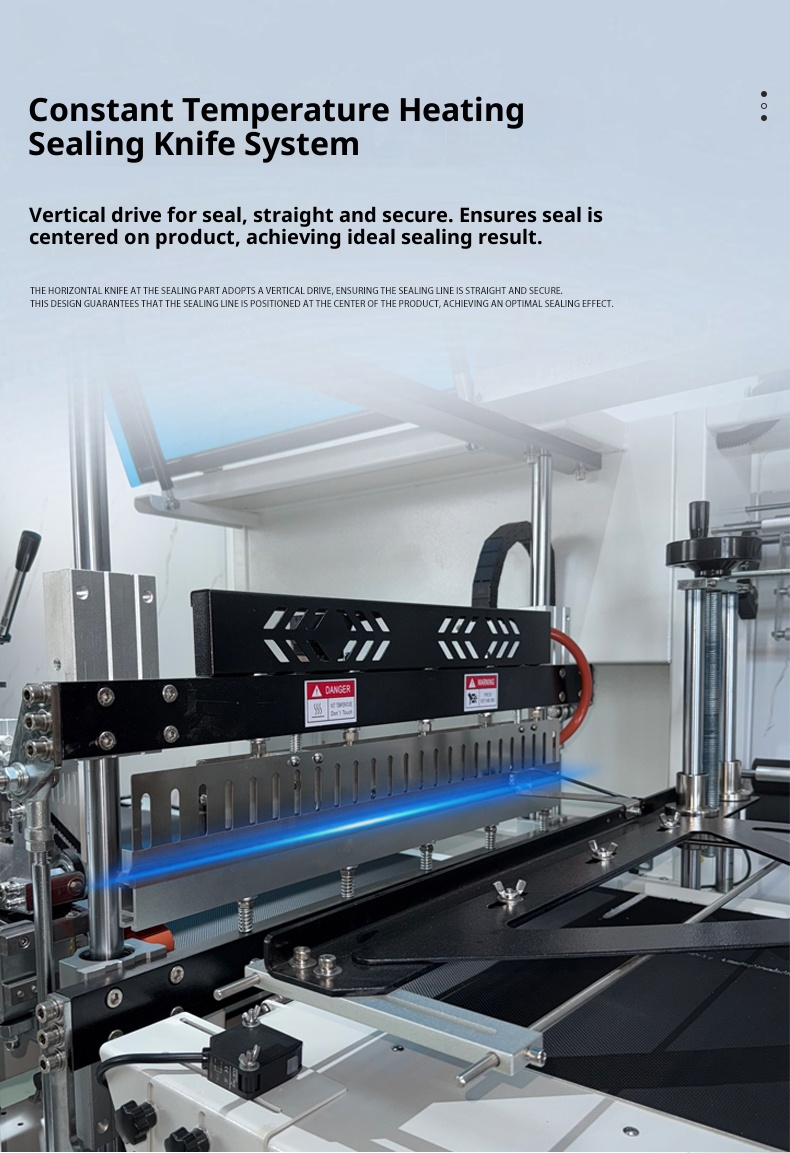

Sealing Principle: Longitudinal Continuous Sealing & Cutting, Independent of Product Length: The sealing knife of the side-seal machine adopts a "longitudinal side-seal" design. The sealing and cutting action is completed longitudinally along the side of the product, rather than cutting the entire film transversely. The sealing knife can work continuously without interruption. As long as the product can be conveyed through the conveyor line, side-sealing and film wrapping can be completed simultaneously. Whether the product is 1-meter-long aluminum profiles, 2-meter-long wood flooring, or longer pipes and photo frames, complete packaging can be achieved, completely breaking the length limitation of traditional equipment.

Supporting Design: Flexible Adaptation to Different Specifications: The height of the sealing line can be freely adjusted according to the product height to ensure the seal is always at the center of the product, guaranteeing sealing firmness. At the same time, the conveyor line uses a special conveyor belt that is wear-resistant and high-temperature resistant (e.g., made of imported German materials with a silicone tube outer layer), which can stably carry long-sized products and prevent deviation or damage during transportation.

Typical Application Scenarios: Thanks to the advantage of unlimited length, this equipment is particularly suitable for the mass packaging of "wide and long products" such as wood flooring, aluminum profiles, pipes, large photo frames, and long strip-shaped hardware. It solves the pain points of traditional packaging equipment, such as "inability to fit" and "unreliable sealing".

High Automation: Reduces labor costs (one person can monitor multiple devices simultaneously), improves packaging consistency (avoids manual operation errors), and adapts to assembly line production (meets large-scale production capacity requirements).

Unlimited Length: Expands the scope of packaging applications, especially solves the packaging problems of long-sized and irregular long-strip products, while maintaining the effects of firm sealing and smooth shrinkage.