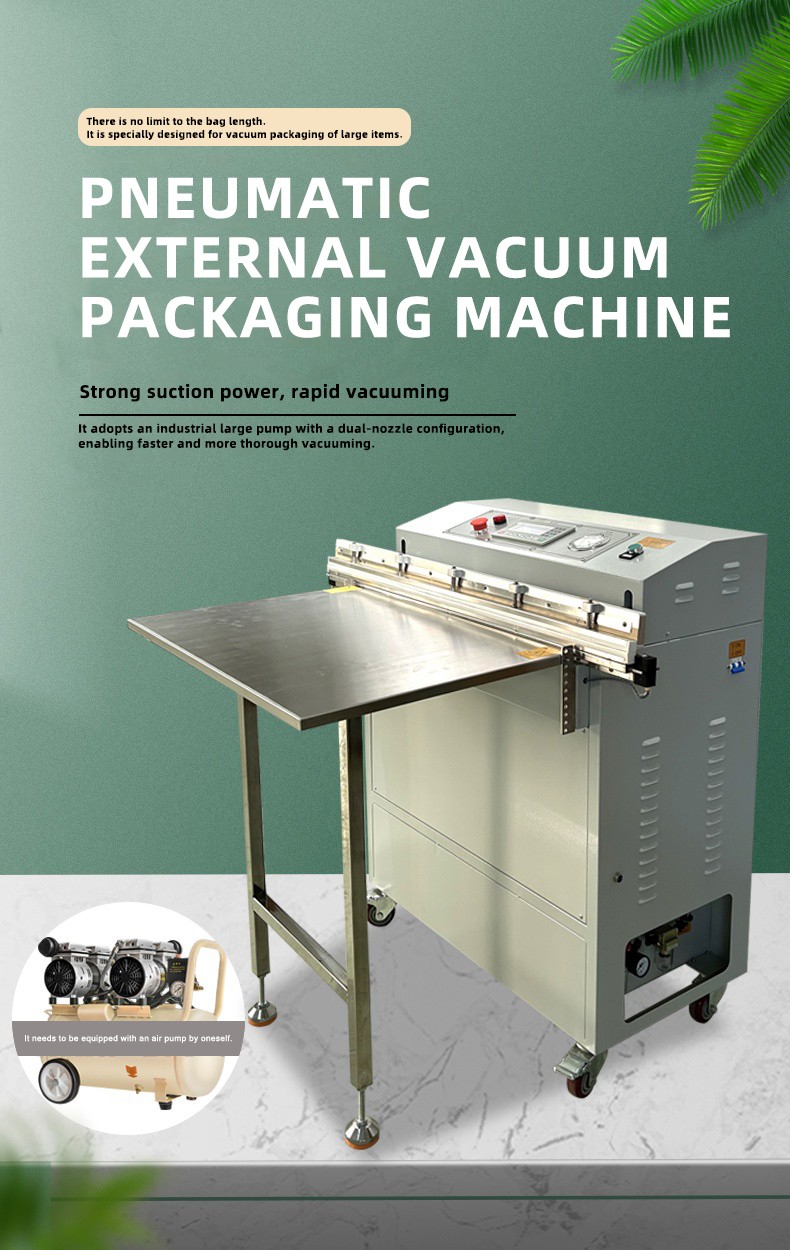

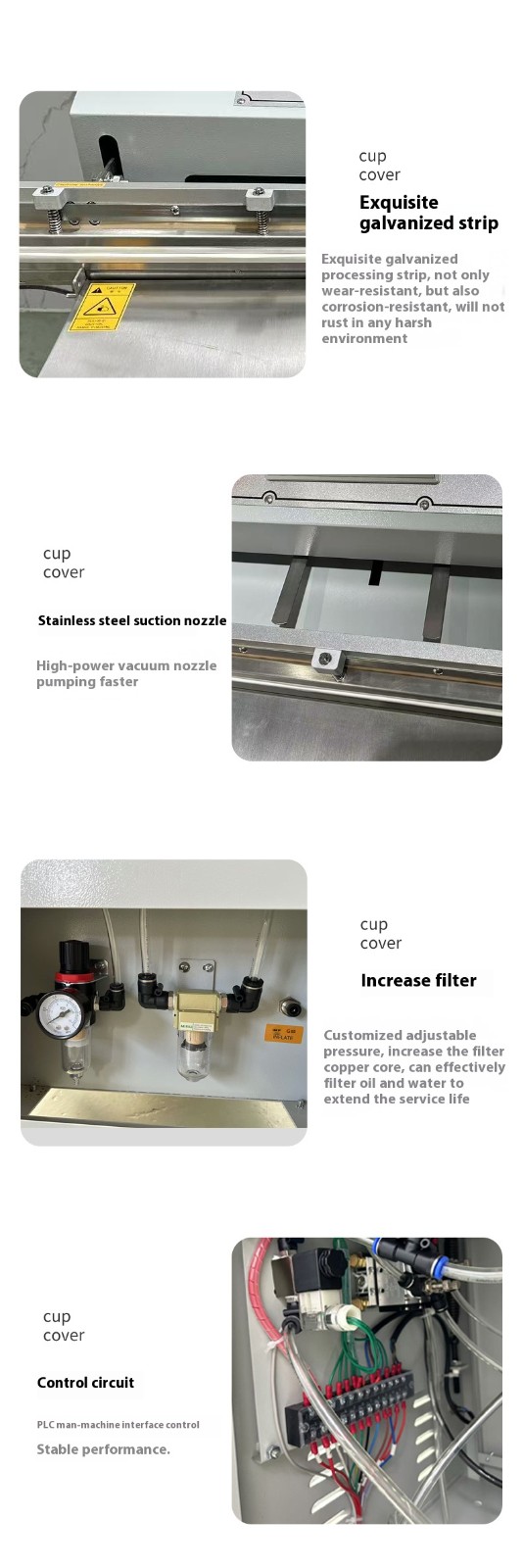

In a vertical external vacuum packaging machine, the vacuum filter device serves as a "critical protective component" that ensures stable equipment operation, extends the service life of core parts, and adapts to the packaging needs of various product categories. Its functions revolve around three core objectives: "filtering impurities, protecting the system, and optimizing packaging results," which can be specifically broken down into the following four dimensions:

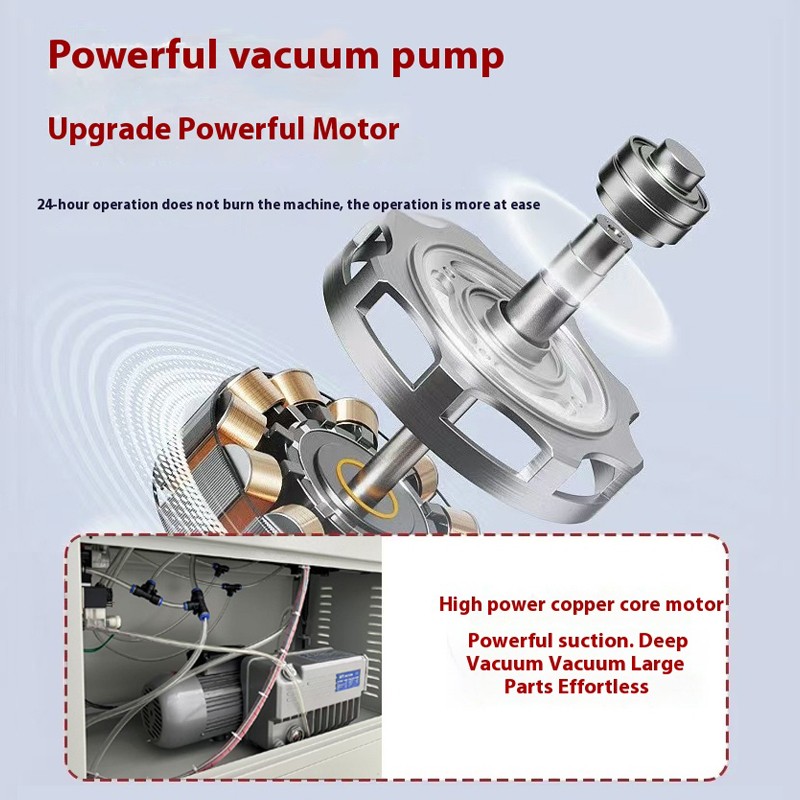

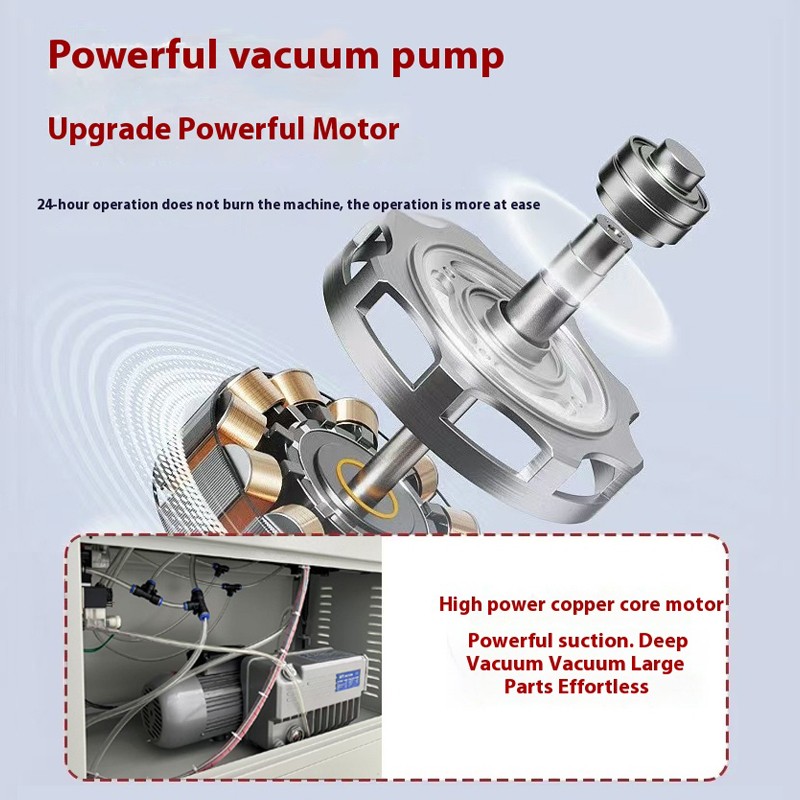

The vacuum pump is the core power component of the vertical external vacuum packaging machine. If it inhales impurities (such as dust, liquids, and debris), it will directly cause wear to internal parts and contamination of oil, and in severe cases, lead to jamming or even scrapping of the vacuum pump. Through physical interception and graded filtration, the vacuum filter device blocks foreign objects from entering the vacuum pump at the source:

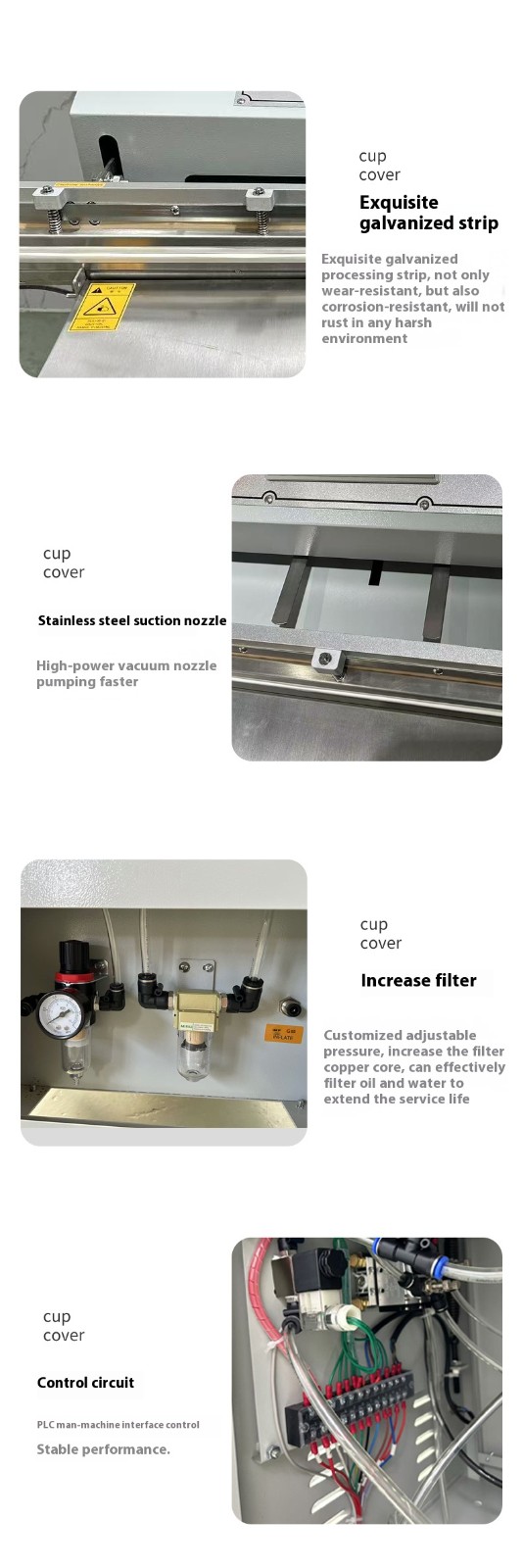

- For dust-containing products (e.g., flour, coffee powder, traditional Chinese medicine powder, and hardware metal debris): The filter device is equipped with a built-in "micron-level filter screen" (with a common pore size of 5-10μm), which can intercept more than 99% of dust particles. This prevents the particles from entering the vacuum pump with the air flow, avoiding filter screen blockage and impeller wear.

- For liquid/moisture-containing products (e.g., fresh meat, sauces, and thawed frozen foods): Some filter devices are equipped with a "condensate collection chamber" or a "hydrophobic membrane," which can condense and separate liquids in the air flow. This prevents liquids from mixing into the vacuum pump oil (which would cause oil emulsification and a drop in vacuum degree).

- For products with debris (e.g., nuts, crispy bone snacks, and small hardware parts): A "coarse filter grid" (with a pore size of 1-2mm) is often designed at the front end of the filter device. It first intercepts large debris particles, and then fine filters remove tiny impurities, providing double protection for the vacuum pump.

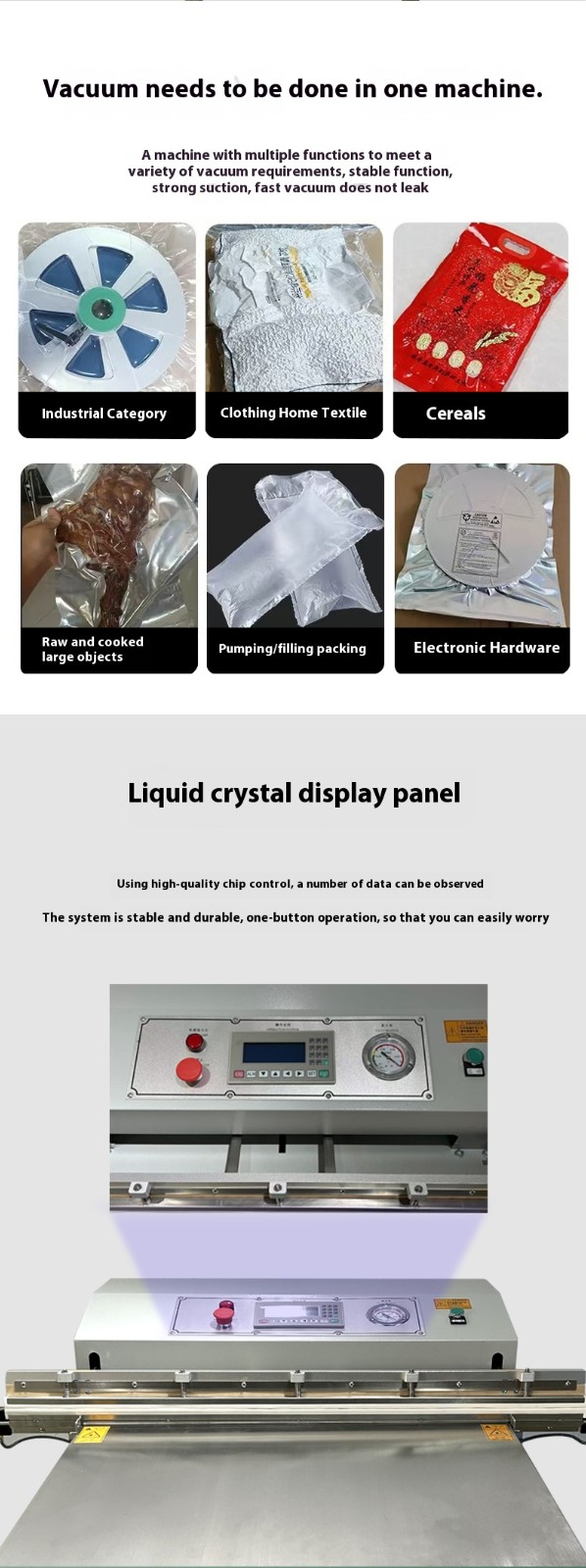

Without a filter device, impurities will gradually accumulate at the air inlet of the vacuum pump and in the pipelines, leading to "blockage of the air flow channel" — the air suction speed slows down, and the preset vacuum degree may even fail to be reached. Eventually, residual air remains in the packaging bag, affecting the fresh-keeping/protective effect (e.g., food oxidation and deterioration, or moisture damage to electronic products). By keeping the air flow unobstructed, the vacuum filter device indirectly ensures the stability of the vacuum degree:

For example, when packaging cooked food, if minced meat or oil particles enter the pipeline, they will adhere to the inner wall of the pipeline, increasing air suction resistance. As a result, the vacuum degree may drop from "≤5mbar" to "≥20mbar," making it impossible to fully evacuate the packaging bag. However, the filter device can intercept these impurities, ensuring the air suction channel remains unobstructed at all times. This keeps the vacuum degree stable within the qualified range for a long time, and no air bubbles appear when the sealed packaging bag is immersed in water (meeting the sealing standards).

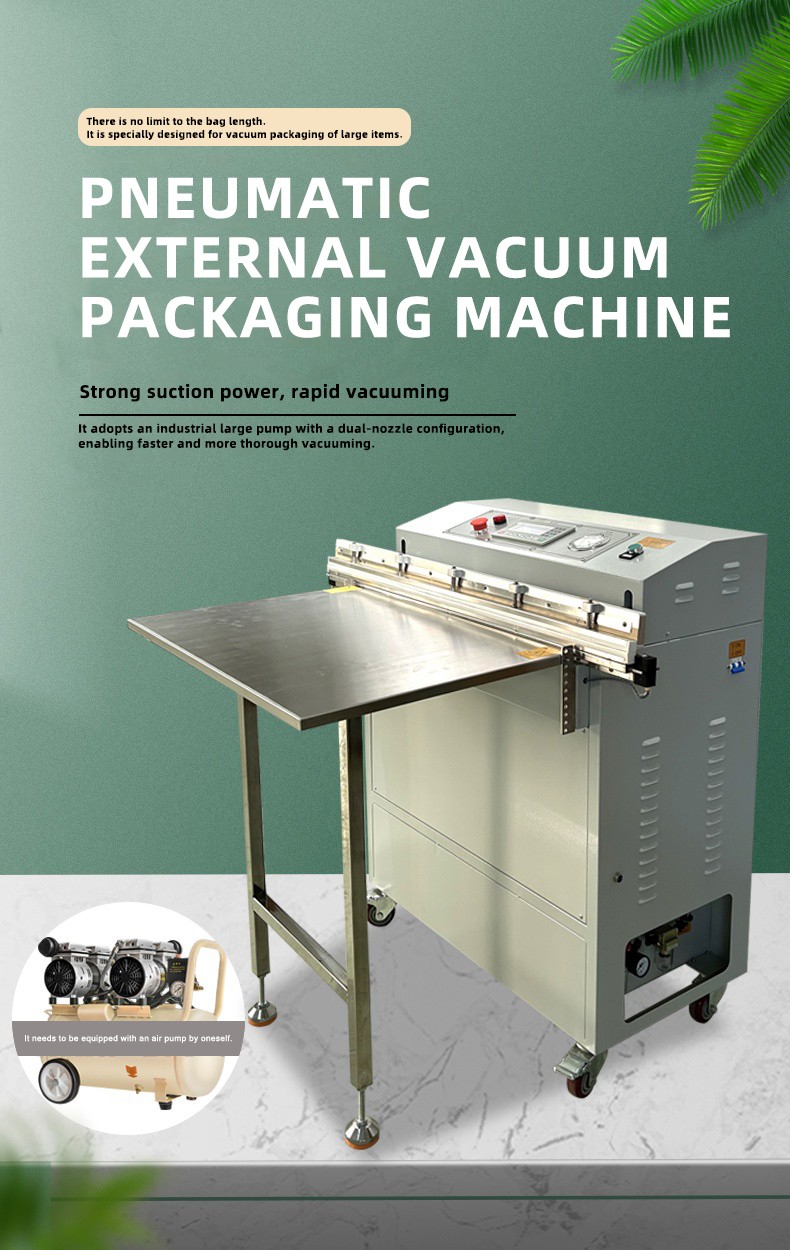

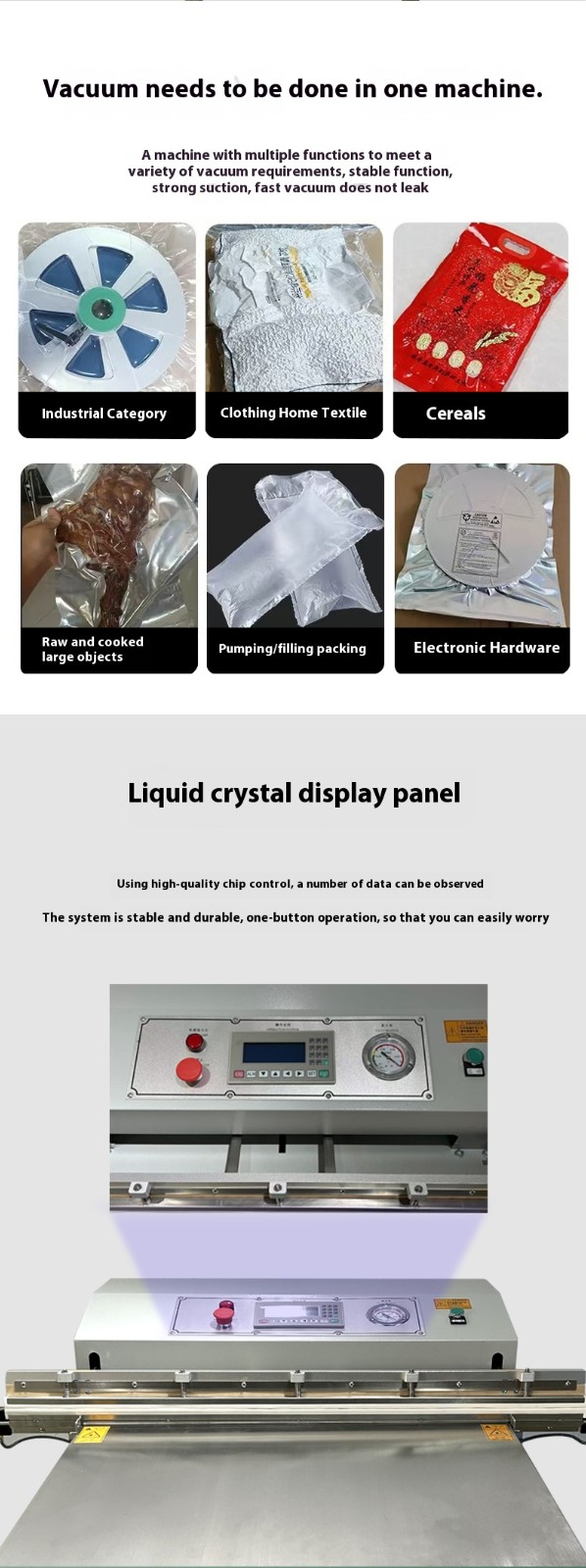

A core advantage of the vertical external vacuum packaging machine is its "strong versatility." However, without a filter device, its application range will be greatly limited — it can only package dry, impurity-free products (e.g., textiles and intact parts) and cannot handle products containing dust, liquids, or debris. The vacuum filter device is equivalent to "unlocking more packaging scenarios" for the equipment:

After installing the filter device, the equipment can smoothly package products in the following fields:

- Food industry: Flour, milk powder, crushed nuts, sauce packets, and fresh meat.

- Industrial field: Metal powder, small screws (with debris), and electronic components (with solder dross).

- Pharmaceutical field: Traditional Chinese medicine powder and granular instant medicines (preventing dust from contaminating the vacuum pump while complying with hygiene standards).

Without a filter device, the vacuum pump requires frequent maintenance due to impurity contamination:

- When the vacuum pump oil is emulsified, it needs to be replaced every 1-2 months (the normal replacement cycle under regular working conditions is 3-6 months). Each oil change requires stopping the machine and cleaning the internal parts, which not only increases consumable costs (the unit price of vacuum pump oil is relatively high) but also affects production efficiency.

- If impurities cause wear to the vacuum pump impeller, the cost of replacing the impeller can reach 1/3 to 1/2 of the total equipment price, and the maintenance cycle is long.