The advantages of can/box tape sealing machines in the food industry mainly center on the three core requirements of food packaging: safety, freshness retention, and compliance, while also balancing production efficiency and cost control. Specifically, they can be elaborated from the following 6 dimensions:

The main causes of food spoilage are the invasion of external air (oxygen), moisture, and microorganisms. Can/box tape sealing machines achieve tight bonding between the tape and the can/box opening through mechanical pressing. Compared with manual sealing, which is prone to issues such as "edge leakage" and "uneven bonding", these machines can form a more stable sealing barrier:

- For crispy foods like biscuits and potato chips, they effectively isolate air, preventing moisture absorption (which makes foods soft) and oxidative rancidity;

- For oily foods such as mooncakes and pastries, they reduce the contact between oil and air, delaying rancidity;

- For moisture-sensitive foods like nuts and dried goods, they block moisture penetration from the environment, avoiding mold growth.

This stable sealing performance can extend the food shelf life by 20%-50% (depending on the type of food and storage conditions), reducing losses caused by short shelf lives.

The food industry has strict requirements for "hygiene and safety". During manual sealing, operators' hands (which may carry bacteria, sweat, and foreign objects) inevitably come into direct contact with the can/box openings and tape, posing contamination risks.

Can/box tape sealing machines adopt a fully automated process of conveying, sealing, and cutting, realizing mechanical contact between "can/box - tape - equipment" and reducing manual intervention:

- Prevent food contamination by hand-borne bacteria (e.g., Escherichia coli, Staphylococcus aureus);

- Avoid foreign objects such as hair and dandruff (from manual operations) mixing into the cans/boxes;

- For ready-to-eat foods requiring an aseptic environment (e.g., some pre-prepared food cans/boxes), they can be equipped with aseptic conveyor belts to further improve hygiene levels, complying with the requirement of the Food Safety Law to "reduce cross-contamination" in food packaging.

Food packaging not only affects food safety but also needs to meet industry compliance standards (e.g., clear labeling, complete and traceable seals). Manual sealing is affected by operators' proficiency, physical strength, and mood, and is prone to problems such as "tilted tape", "inconsistent sealing length", and "inadequately sealed cans/boxes", which may lead to:

- Tape falling off during transportation, leaving cans/boxes open and causing food contamination or spillage;

- Irregular packaging appearance, failing to meet the "neat and uniform" shelf requirements of supermarkets and e-commerce platforms for food packaging.

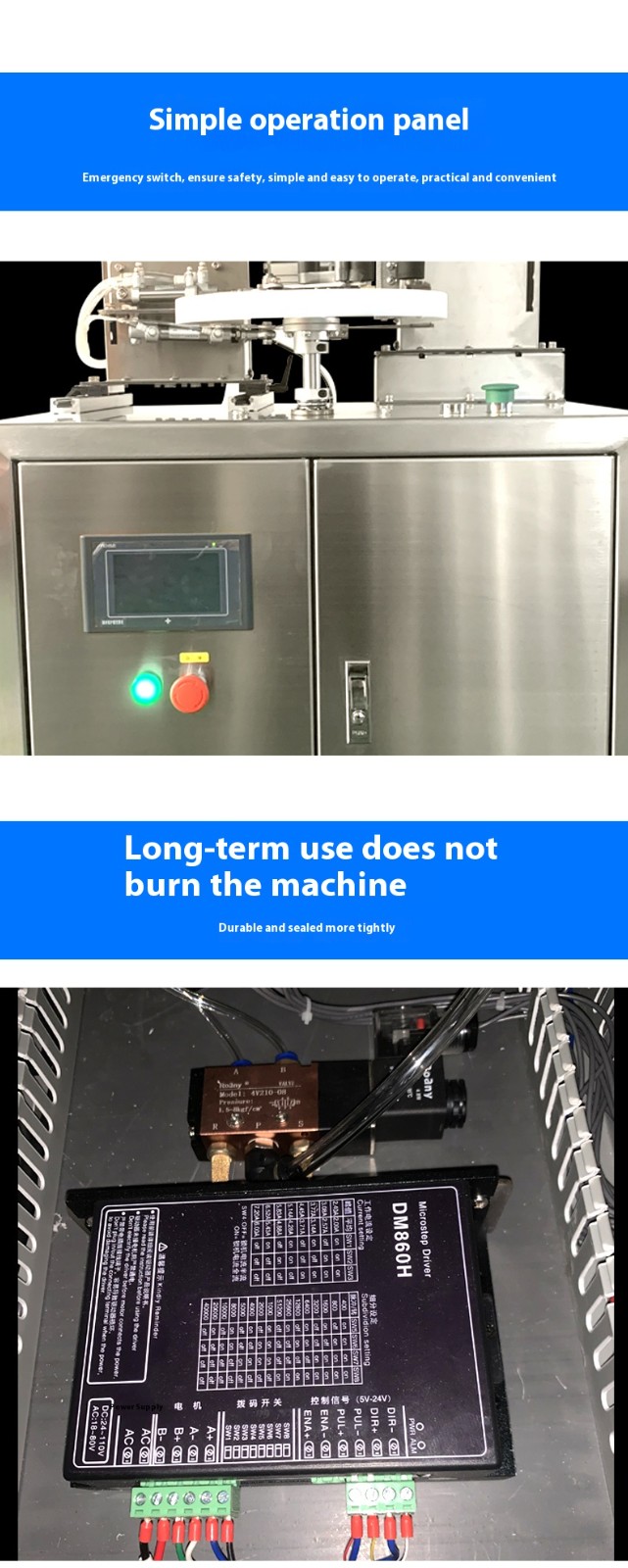

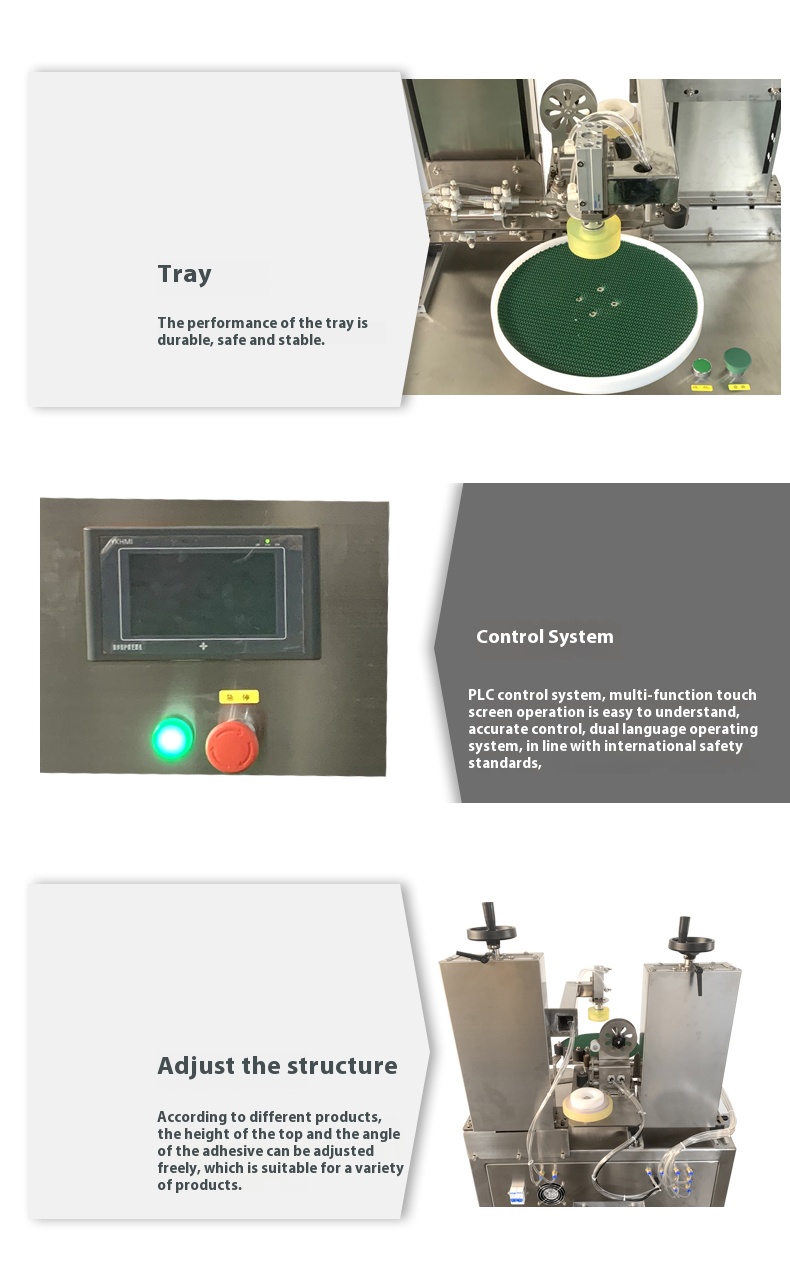

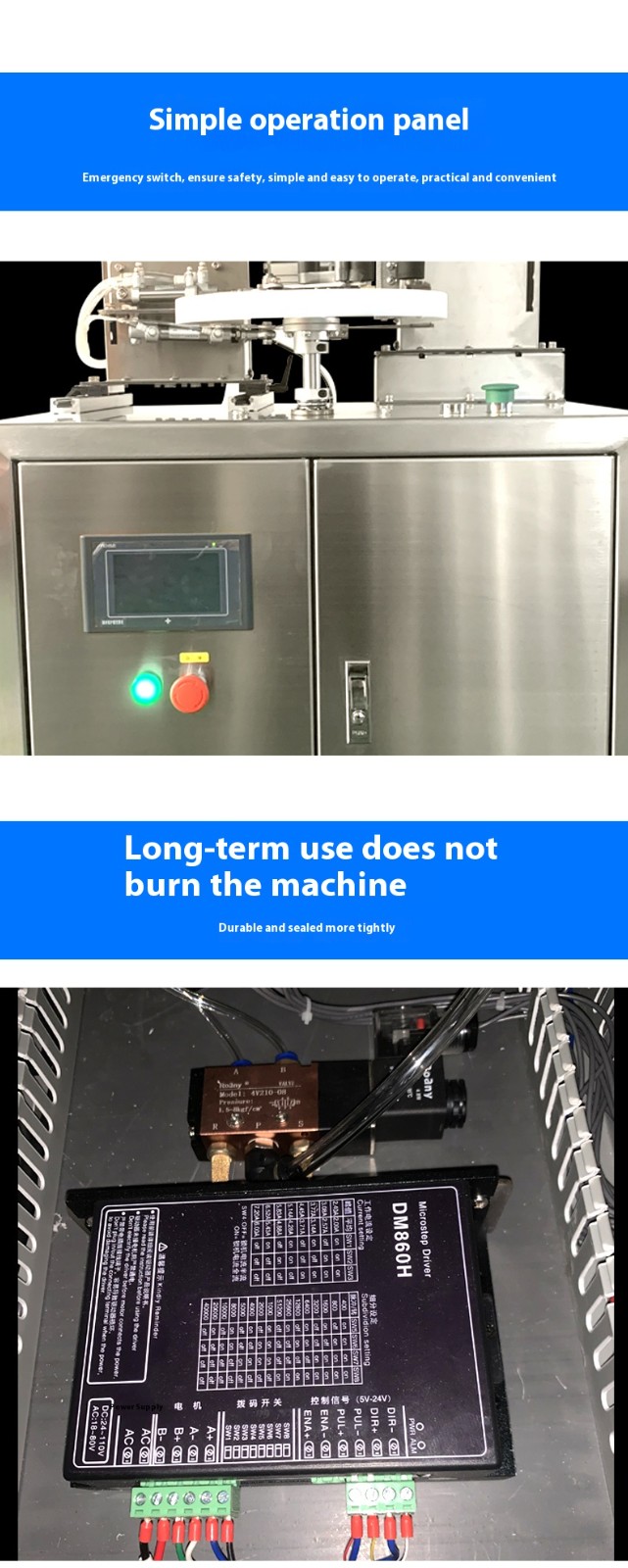

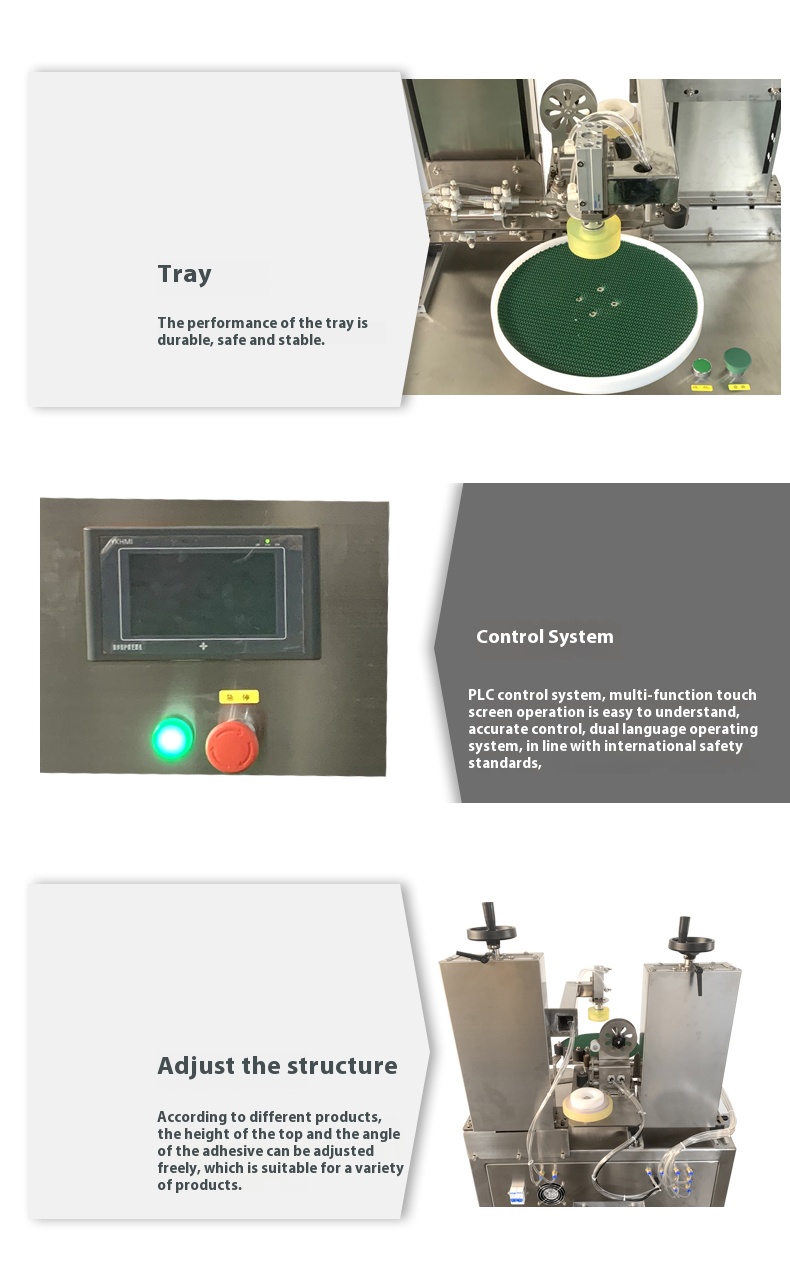

Can/box tape sealing machines use a PLC (Programmable Logic Controller) control system combined with sensors (e.g., infrared sensors to detect the position and size of cans/boxes). They can accurately set parameters such as tape length, pressing force, and sealing position, ensuring that the seal of each can/box meets the following standards:

- The tape is centered and bonded without obvious tilt (deviation ≤ 1mm);

- Consistent sealing width and tightness, with no leakage or incomplete sealing;

- Flat tape cuts without burrs. This not only ensures a neat packaging appearance but also prevents consumers from being scratched by burrs when opening the packages, meeting the dual requirements of "humanization" and "compliance" for food packaging.

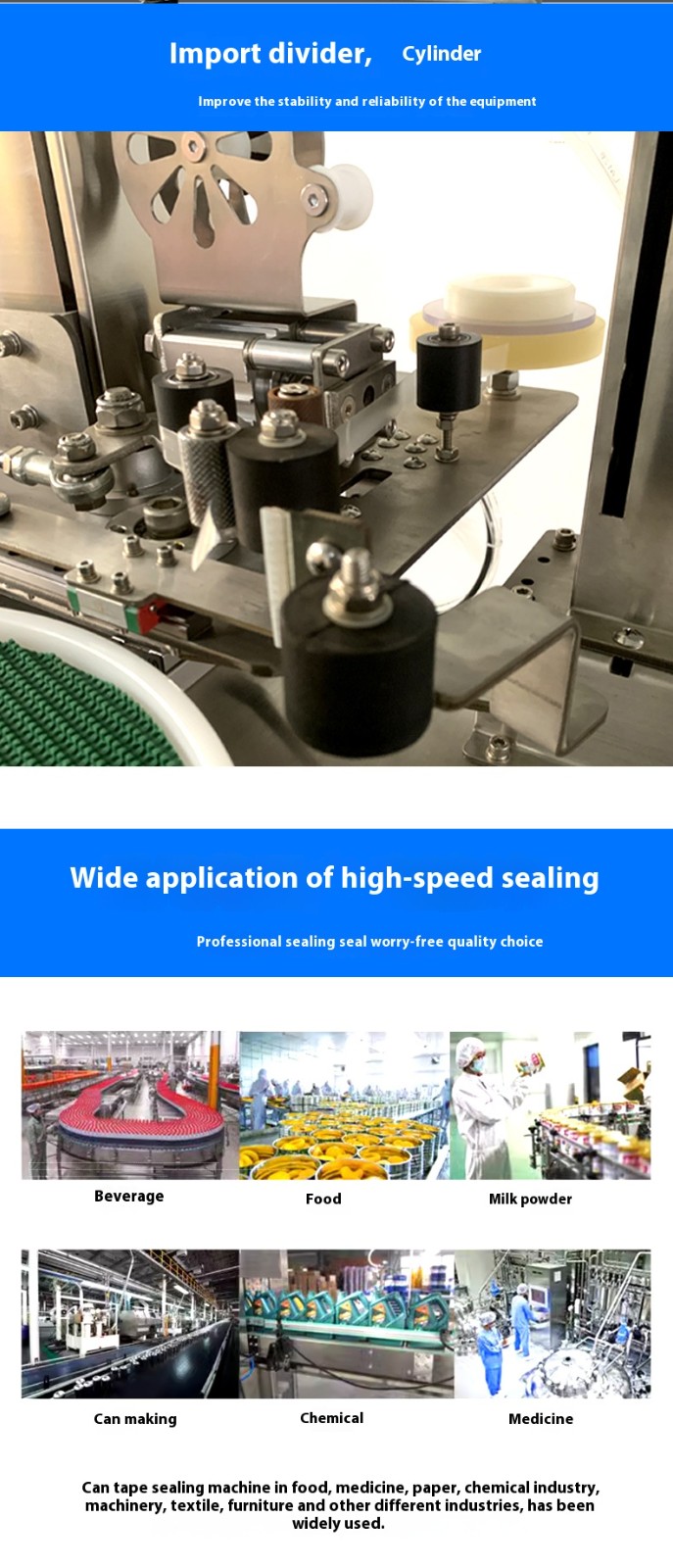

In the food industry, cans/boxes come in diverse forms, covering different materials (cartons, iron cans, plastic cans, foam boxes), shapes (circular, square, oval, irregular), and sizes (from small candy cans to large gift boxed mooncake boxes). The "high adaptability" of can/box tape sealing machines enables them to perfectly match these differences:

- The conveyor belt speed and pressing device height can be quickly adjusted via a touch screen. No need to replace a large number of accessories to switch between sealing cans/boxes of different sizes (e.g., switching from a candy can with a 5cm diameter to a mooncake gift box with a 20cm diameter takes ≤ 5 minutes);

- The tape tension adjustment mechanism can adjust the force according to the can/box material (e.g., light pressing for paper cans/boxes to prevent deformation, and appropriate pressure increase for iron cans to enhance sealing), avoiding sealing failure caused by material differences.

This flexibility allows enterprises to avoid purchasing separate sealing equipment for different food categories, reducing equipment investment costs.

The food industry has obvious "seasonal production peaks" (e.g., mooncakes before the Mid-Autumn Festival, candies and biscuits before the Spring Festival). Manual sealing is inefficient (about 30-80 cans/boxes per person per hour), making it difficult to meet the short-term surge in production demand and potentially leading to order delays.

The automated features of can/box tape sealing machines significantly improve efficiency:

- Ordinary models can seal 200-500 cans/boxes per hour, while high-speed models can reach 800-1200 cans/boxes per hour—3-15 times the efficiency of manual sealing;

- They can operate continuously 24 hours a day (only requiring regular tape replacement), making them suitable for "two-shift" or "three-shift" production during peak periods;

- They can be linked with front-end food filling equipment and back-end labeling/packing equipment to form an automated production line, further shortening the production cycle.

For example, after adopting a sealing machine, a biscuit factory increased its daily production capacity from 50,000 boxes to 150,000 boxes before the Mid-Autumn Festival, easily meeting the peak order demand.

From the perspective of long-term operation, can/box tape sealing machines can significantly reduce costs compared with manual sealing:

- Labor costs: One sealing machine can replace 3-5 workers. Based on a monthly salary of 5,000 yuan per worker, annual labor costs can be saved by 180,000-300,000 yuan;

- Material costs: By accurately controlling the tape length (avoiding the waste of "excessive tape pulling" in manual sealing), the tape loss rate can be reduced from 15%-20% (in manual sealing) to less than 5%. Based on an annual tape consumption of 100,000 yuan, annual material costs can be saved by 10,000-15,000 yuan;

- Loss costs: The rate of food rework and scrapping caused by substandard sealing is reduced from 8%-10% (in manual sealing) to less than 1%, reducing food waste due to packaging problems.