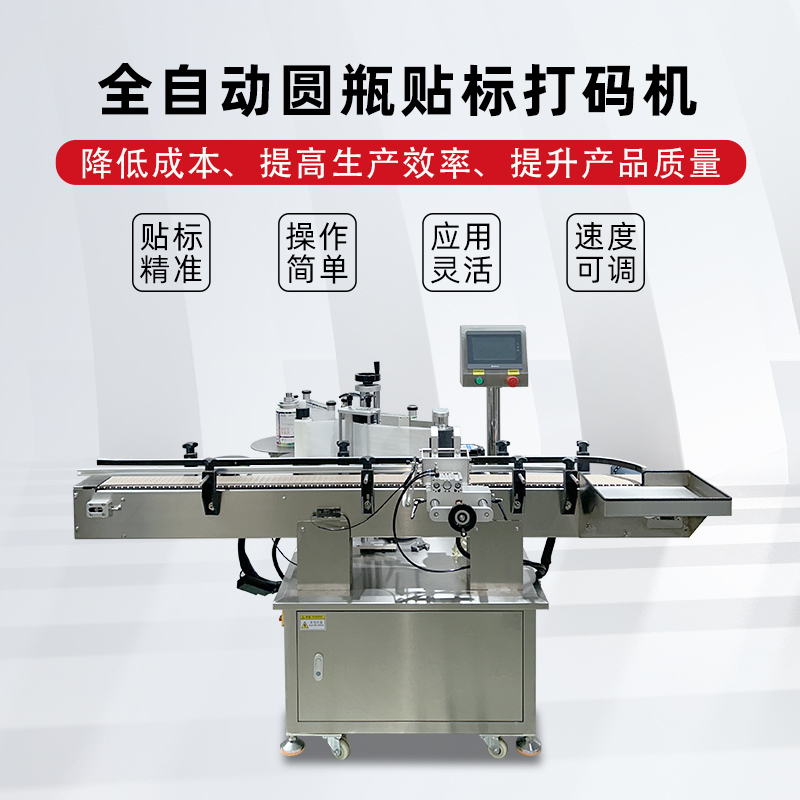

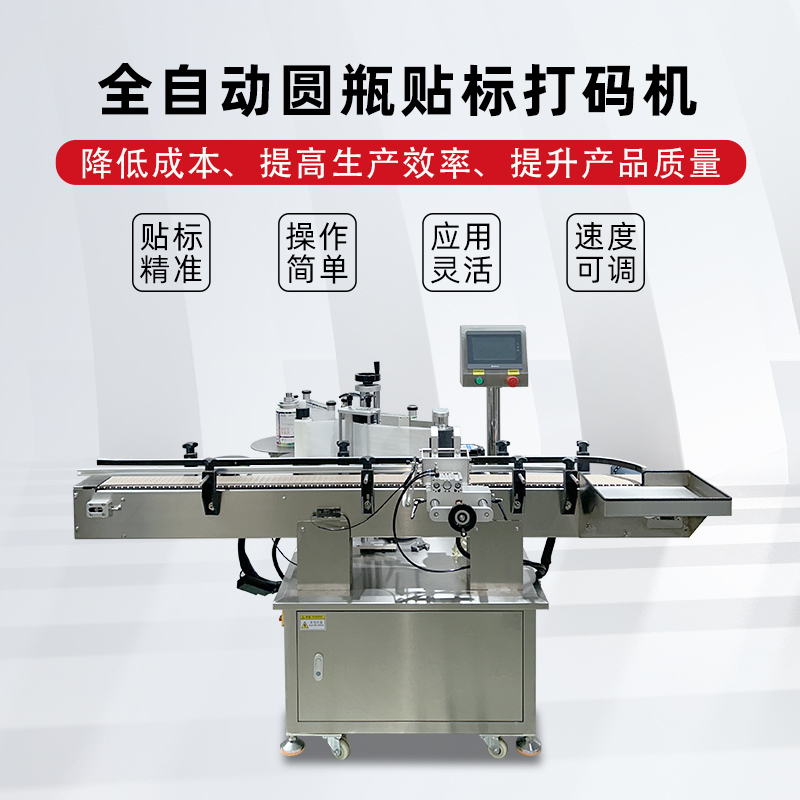

The automatic round bottle positioning labeling machine has become a key equipment for large-scale production in industries such as food and beverage, pharmaceuticals, and daily chemicals, relying on its core advantages of "stable operation", "efficient production" and "fast labeling speed". Its performance advantages stem not only from precise mechanical design but also from the collaborative role of intelligent control systems. The following is an analysis from three core dimensions:

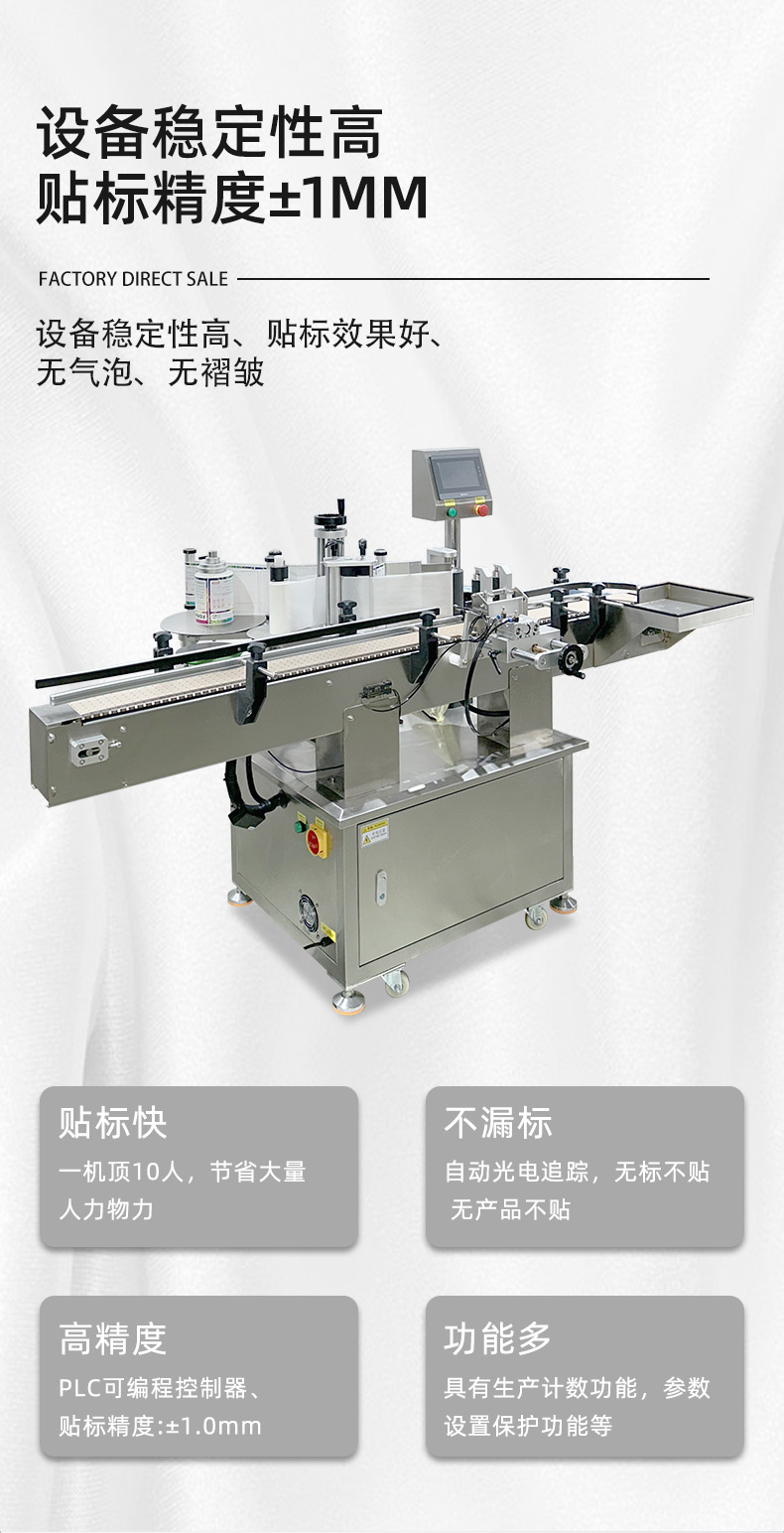

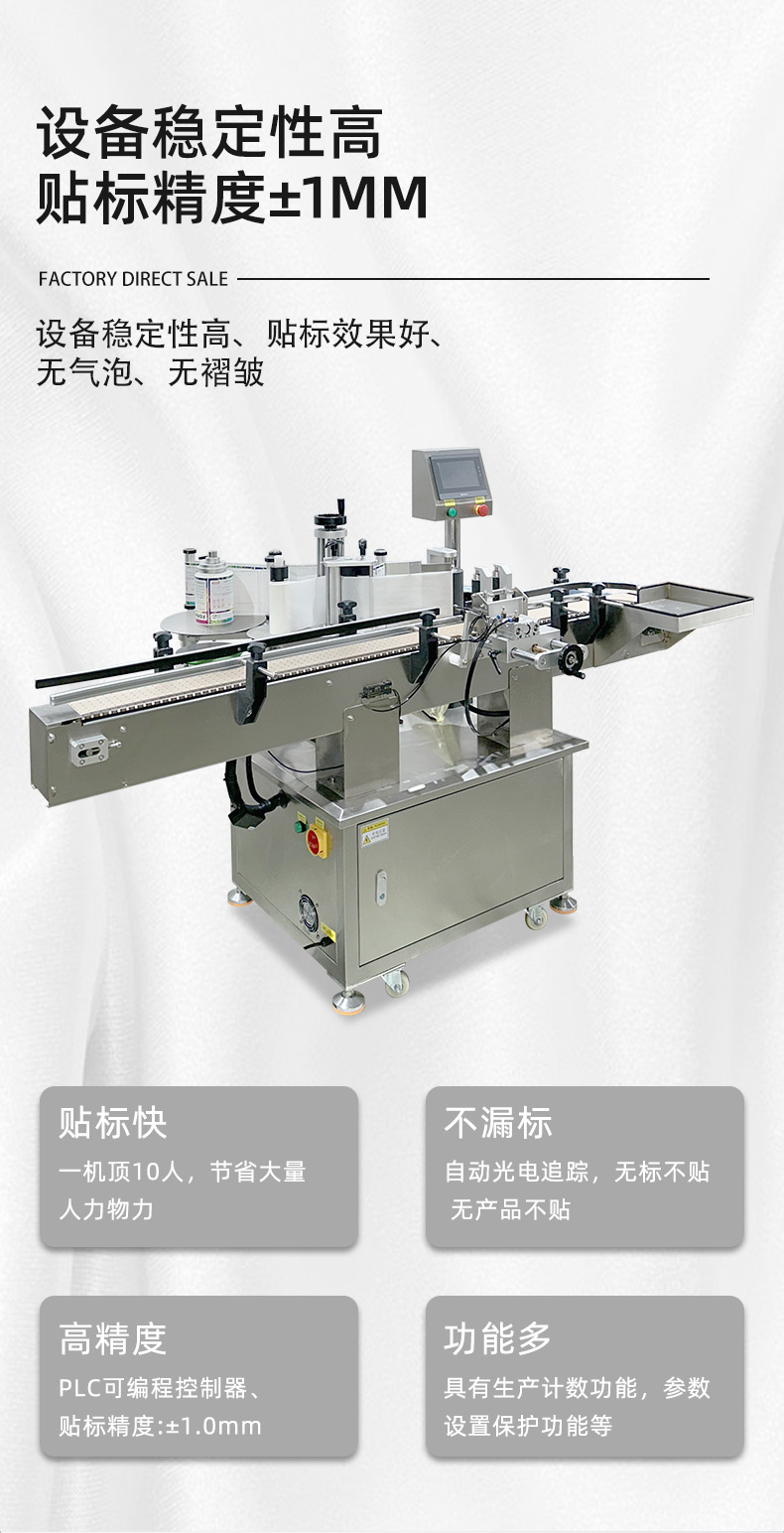

Stability is the foundation of labeling quality. Through the optimization of mechanical structure and intelligent control technology, the equipment avoids problems such as labeling deviation, wrinkling, and air bubbles from the source, ensuring the consistency of long-term continuous operation.

- Core transmission components (such as conveyor belts, bottle-separating mechanisms, and labeling heads) adopt a combination of high-precision servo motors and ball screws, replacing traditional gear transmission. This reduces operational errors caused by mechanical wear, improving the transmission accuracy to the level of 0.01mm.

- The main body of the machine is made of 304 stainless steel and aviation-grade aluminum alloy, formed by an integral casting process. The deformation of the machine body under load is less than 0.1mm, avoiding labeling position deviation caused by equipment vibration.

- Equipped with a double top-pressing guiding mechanism: it clamps round bottles synchronously from top and bottom (the top uses elastic silicone pressure wheels, and the bottom is an anti-slip conveyor belt). Even for bottles made of light and slippery materials such as PET, it can prevent them from tipping over or rotating and deviating during high-speed conveying, with a positioning stability of over 99.8%.

- Adopts dual positioning feedback of vision and photoelectricity: The vision camera captures the bottle body features (such as logos, grooves, and scale lines) in real time, while the photoelectric sensor synchronously monitors the bottle spacing and rotation speed. The data from both are analyzed in linkage through the PLC, which automatically compensates for positioning deviations caused by bottle diameter errors (within ±2mm) and conveyor belt speed fluctuations.

- Closed-loop control of label tension: The pressing mechanism has a built-in tension sensor that detects the label tape tension (ranging from 5-20N) in real time. When the label tape tension fluctuates due to changes in the diameter of the label reel, the servo motor automatically adjusts the traction speed to ensure constant tension during the label peeling and bonding process, avoiding label stretching or wrinkling.

Efficiency is reflected in the optimization of all production links. By reducing manual intervention, shortening model changeover time, and lowering the defective rate, the effective output per unit time is improved.

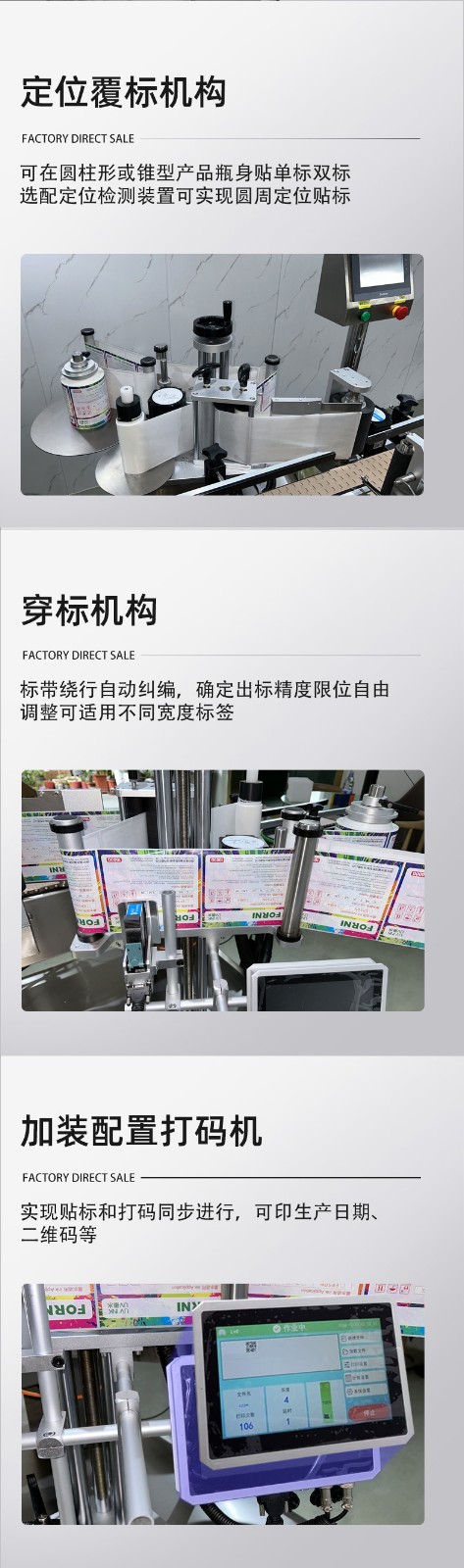

- Realizes full automated connection from "feeding - bottle separating - positioning - labeling - inspection - rejection - discharging": The automatic feeding system arranges the disordered round bottles in an orderly manner at an adjustable spacing of 10-50mm through a frequency-conversion conveyor belt and a bottle-separating mechanism; after labeling, the visual inspection unit completes the inspection of label position (offset greater than 0.5mm is judged as unqualified) and integrity (whether there is missing labeling or damage) within 0.1 seconds. Unqualified products are automatically rejected by a pneumatic push rod, without the need for manual sorting.

- Equipped with intelligent label reel early warning: When the remaining number of labels is less than 50, the touch screen automatically pops up a prompt and triggers a buzzer alarm; when the backing paper rewinding mechanism is fully rolled, the equipment automatically stops and cuts off the power supply, avoiding production interruption caused by material exhaustion.

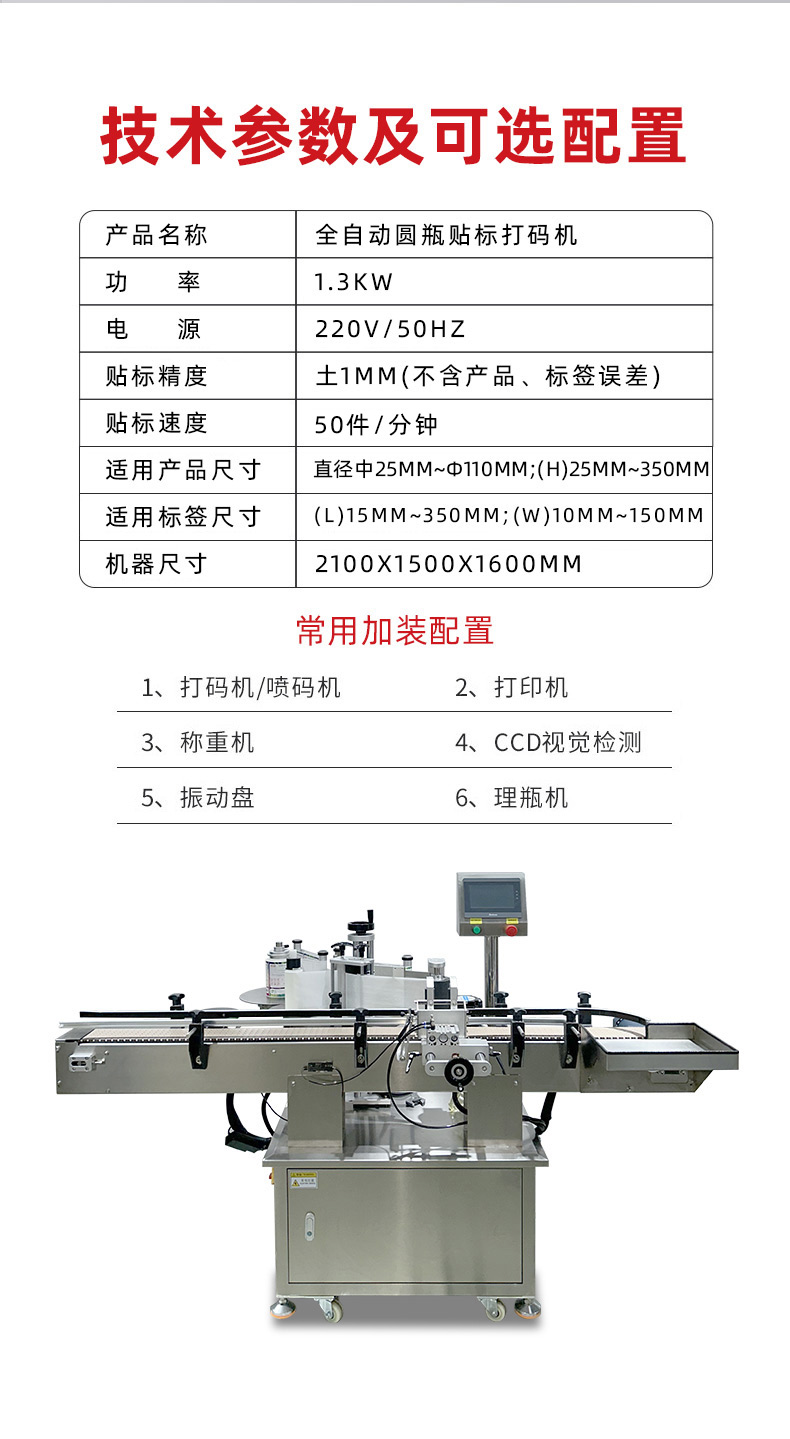

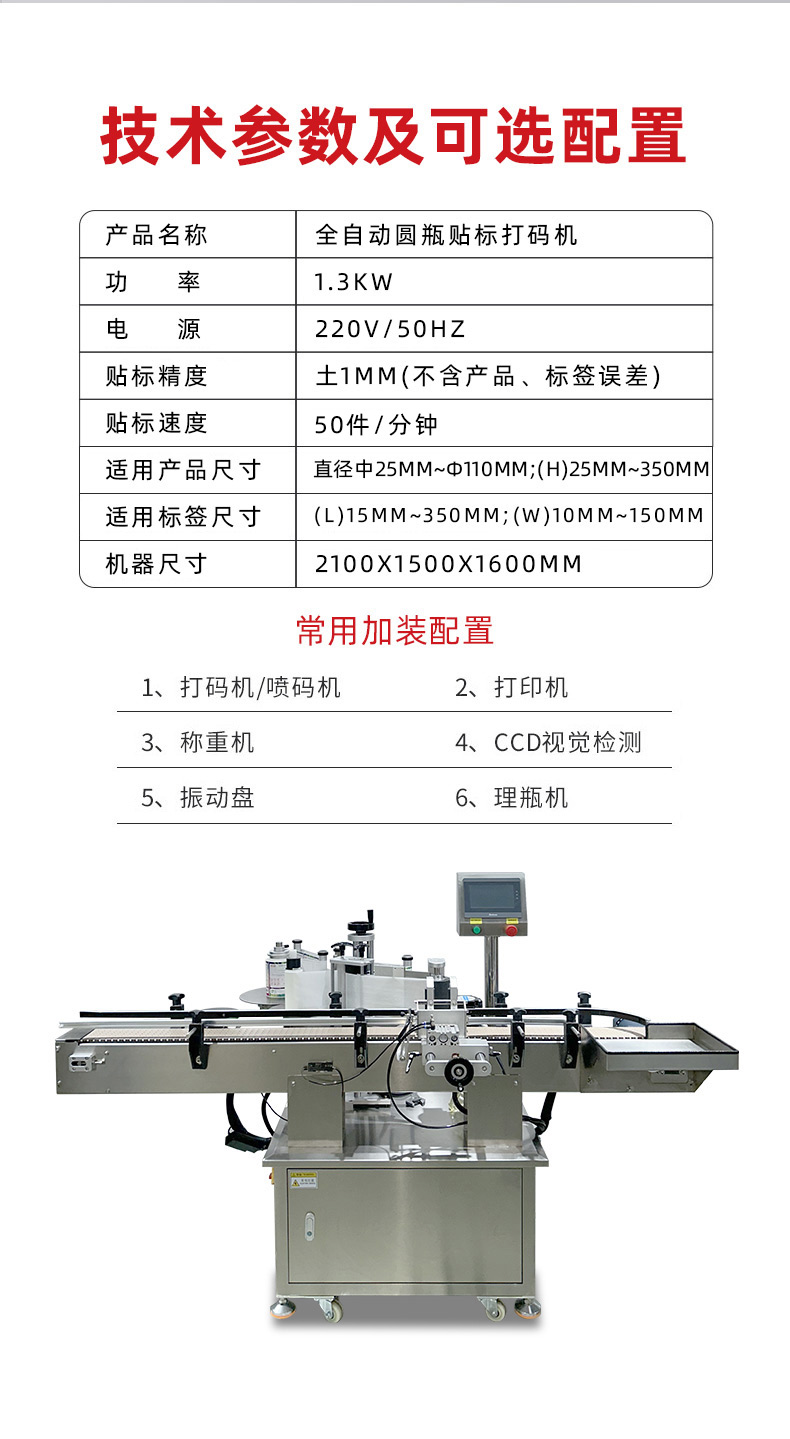

- For round bottles of different diameters (25-120mm) and heights (50-300mm), during model changeover, it is only necessary to call the preset parameters (storage capacity ≥ 100 groups) through the touch screen and manually adjust the guide rod spacing and pressure wheel height (equipped with scale marks, adjustment time < 2 minutes). There is no need to replace molds or perform complex mechanical adjustments, which meets the needs of multi-batch and small-batch production.

- Strong label adaptability: It supports various self-adhesive labels (including transparent labels, laser labels, and laminated labels) with widths of 10-150mm and lengths of 10-300mm. When changing labels, it is only necessary to adjust the angle of the label peeling plate (adjustable from 0-15°) and the traction speed, and the adaptation process takes less than 1 minute.

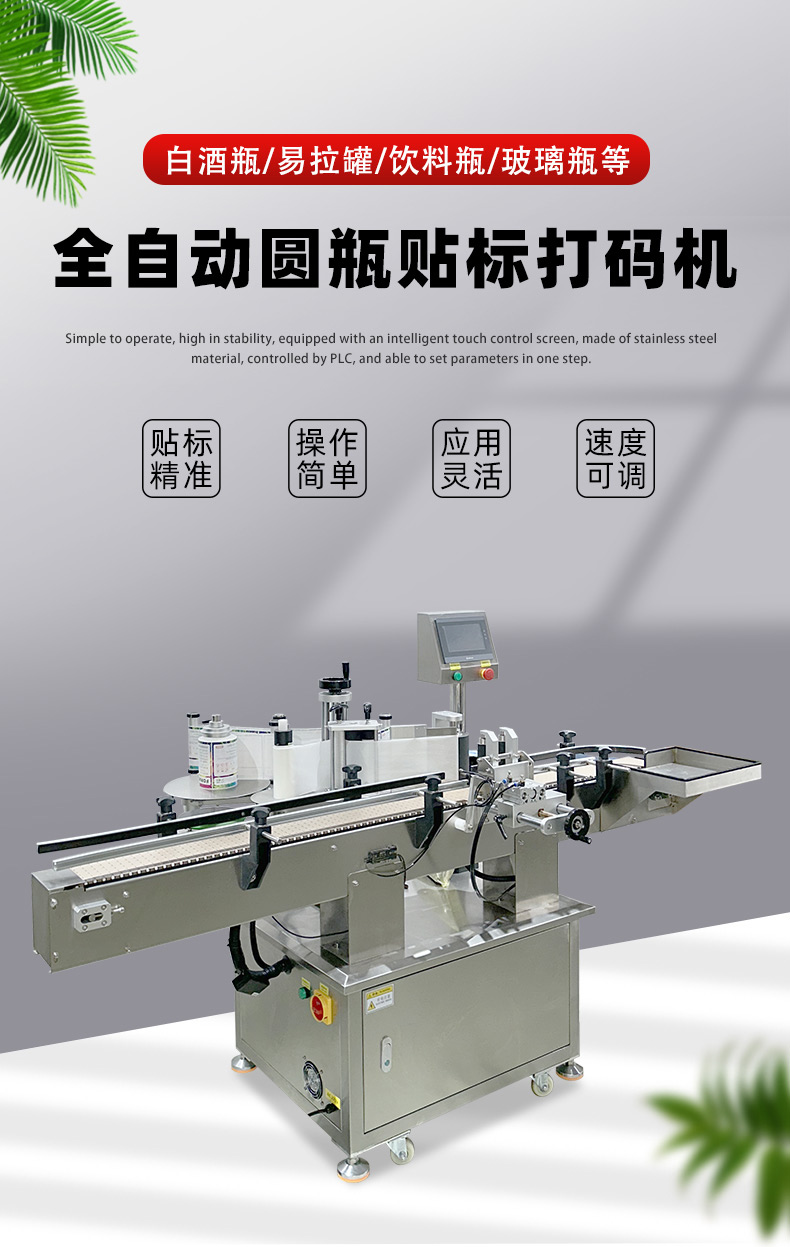

This type of labeling machine with "stability, high efficiency, and high speed" is especially suitable for large-scale continuous production scenarios:

- Food and Beverage Industry: For example, in the production lines of bottled water and carbonated drinks (production capacity: 10,000-30,000 bottles/hour), it can realize seamless connection with filling machines and shrink labeling machines.

- Pharmaceutical Industry: It is used for labeling small-specification products such as oral liquids and ampoules (which require high precision and fast speed), and at the same time meets the strict requirements of GMP (Good Manufacturing Practice) for equipment hygiene and stability.

- Daily Chemical Industry: It is suitable for high-speed labeling of large-diameter round bottles (80-120mm) such as shampoo and body wash, meeting the mass production needs during e-commerce promotion periods.