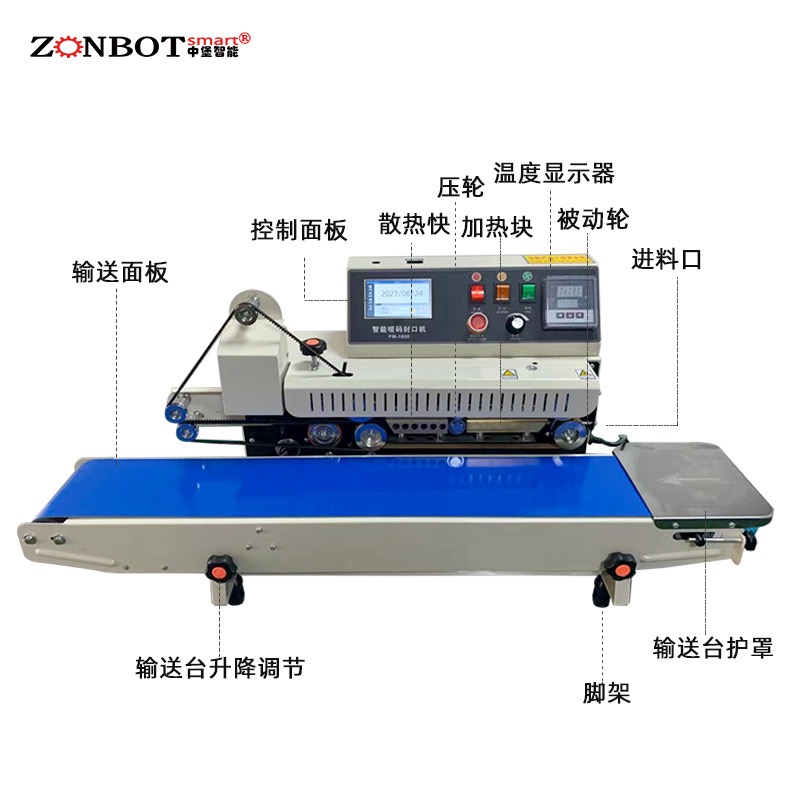

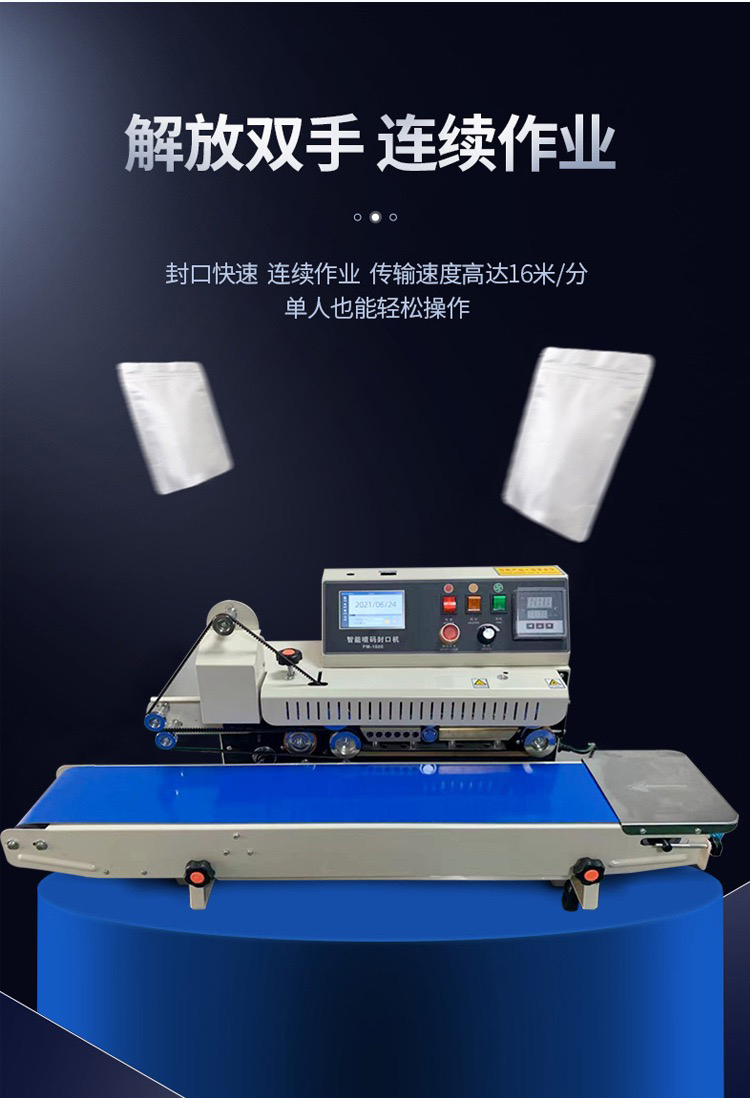

The intelligent inkjet coding and sealing all-in-one machine, as an automated device integrating inkjet coding and sealing functions, has become an efficient choice for multiple industries due to its "one-stop" packaging capability. Its core advantage lies in integrating the originally independent inkjet coding and sealing processes, reducing the equipment's floor space while eliminating process connection errors through linked control, thus significantly improving production continuity. From material feeding to sealing forming and information marking, no manual intervention is required throughout the process, and a single device can complete the packaging closed loop. It is particularly suitable for enterprises with limited production line space or those pursuing ultra-simple processes.

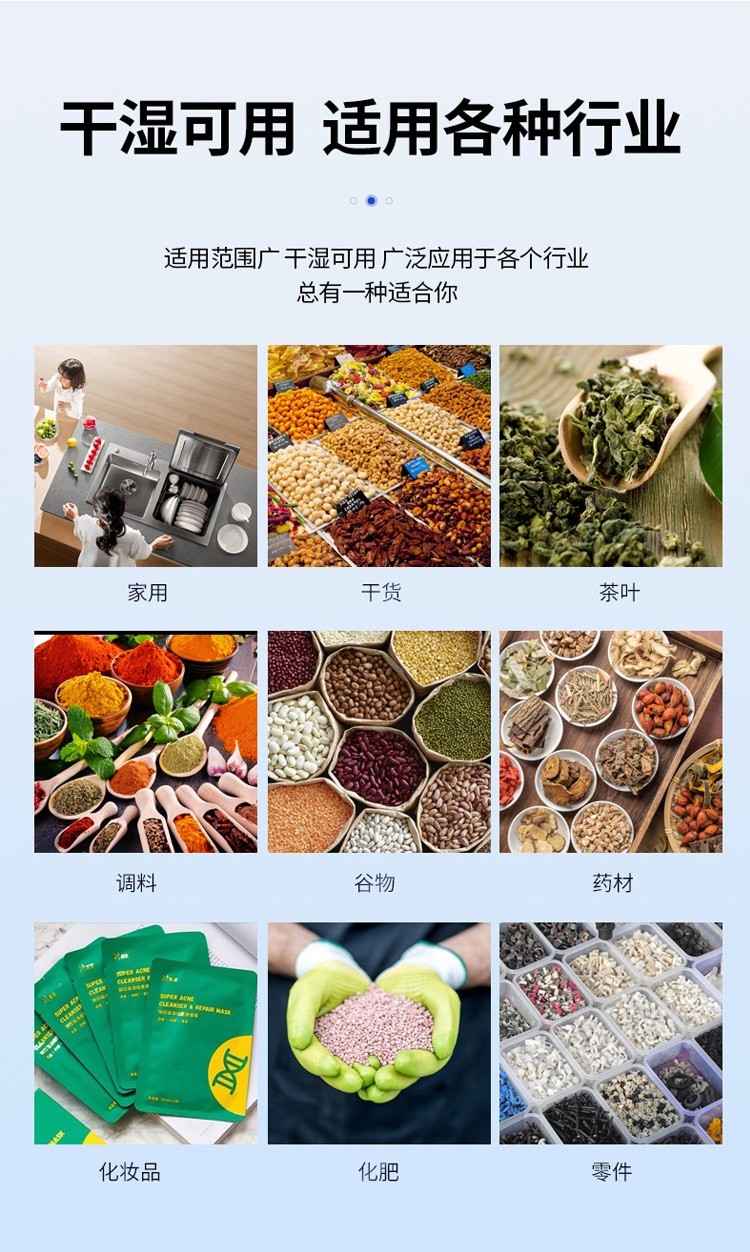

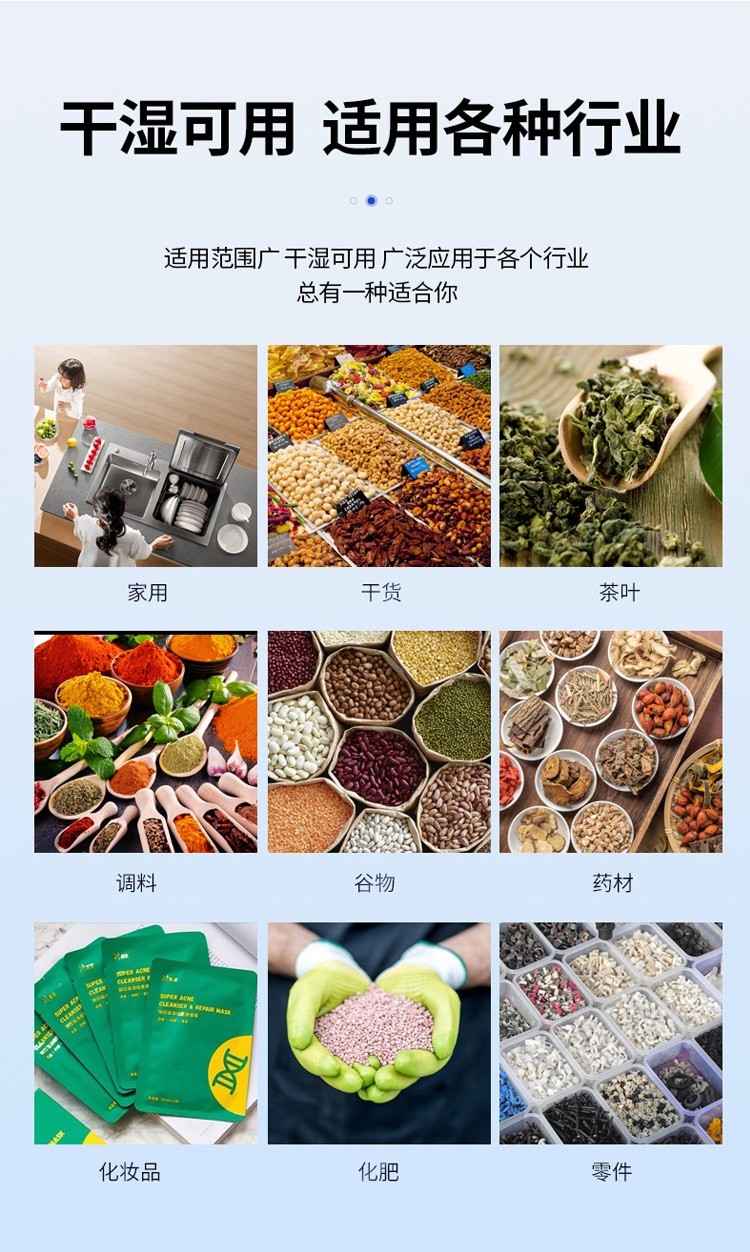

In the food industry, the equipment demonstrates strong adaptability to different packaging forms: when handling puffed food packaging bags, it can cope with the easily scalded characteristics of OPP composite films through adjustable heat-sealing parameters, while high-speed printing production dates and traceability QR codes; when sealing sauce glass bottles, its sealing module can be switched to the electromagnetic induction aluminum foil sealing mode, and cooperates with food-grade ink to print the shelf life on the bottle body, which not only meets the needs of sealing and moisture-proofing but also complies with food safety traceability standards.

The equipment accurately responds to the strict precision requirements in the pharmaceutical field: for aluminum-plastic blister packaging, the coding head adopts 300DPI high-precision printing to ensure that information such as drug batch numbers and expiration dates is clearly distinguishable and meets GMP certification standards; when sealing vials, the digital control of sealing pressure and temperature can achieve a temperature control accuracy of ±0.5℃, avoiding the risk of drug deterioration caused by improper heat sealing. The coding content can also be linked with pharmaceutical companies' ERP systems to realize real-time upload of production data.

The diverse packaging needs of the daily chemical industry are also well met: when sealing cosmetic hoses, the equipment can first complete the hose tail pressing through the heat-sealing module, then print brand logos and ingredient descriptions on the hose body, supporting special inks such as gold and silver to adapt to PET materials; when handling detergent plastic bottles, its coding system is compatible with curved surface printing, clearly displaying expiry dates on the bottle shoulder curvature, and the sealing module adapts to the tightening needs of bottle caps of different calibers through adjustable torque.

In the miniaturized packaging scenarios of the electronics industry, the flexibility of the equipment is more prominent: when sealing anti-static bags for electronic components, the microcomputer-controlled sealing knives can precisely cut and seal 0.5cm narrow edges, while the coding head prints tiny serial numbers on the bag surface; for circuit board packaging boxes, its coding function supports the printing of dot-matrix QR codes, which include production batch and testing information, and cooperates with tamper-proof ink to meet the stringent requirements for electronic traceability.

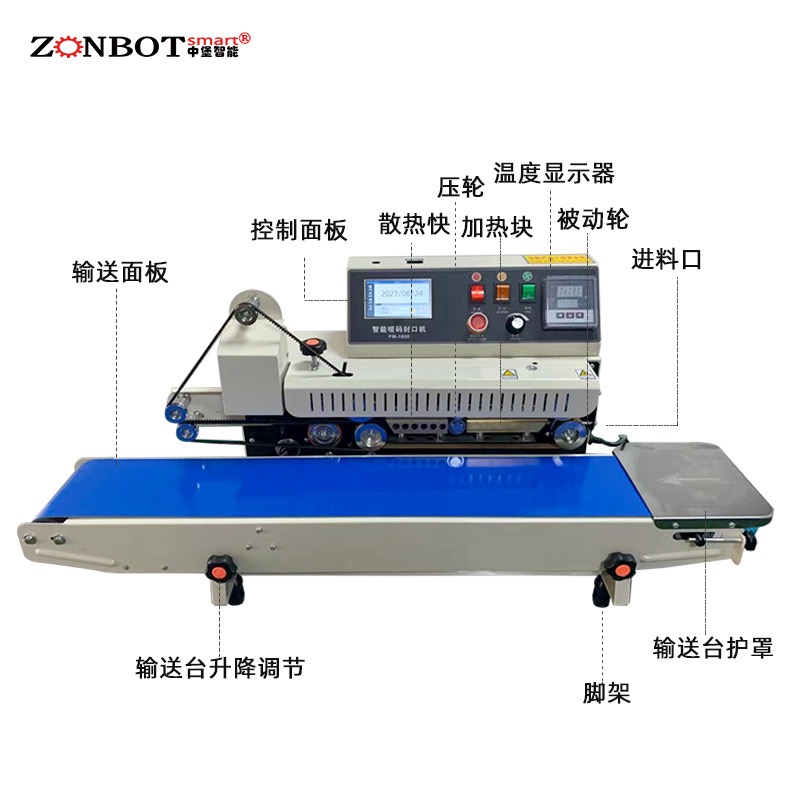

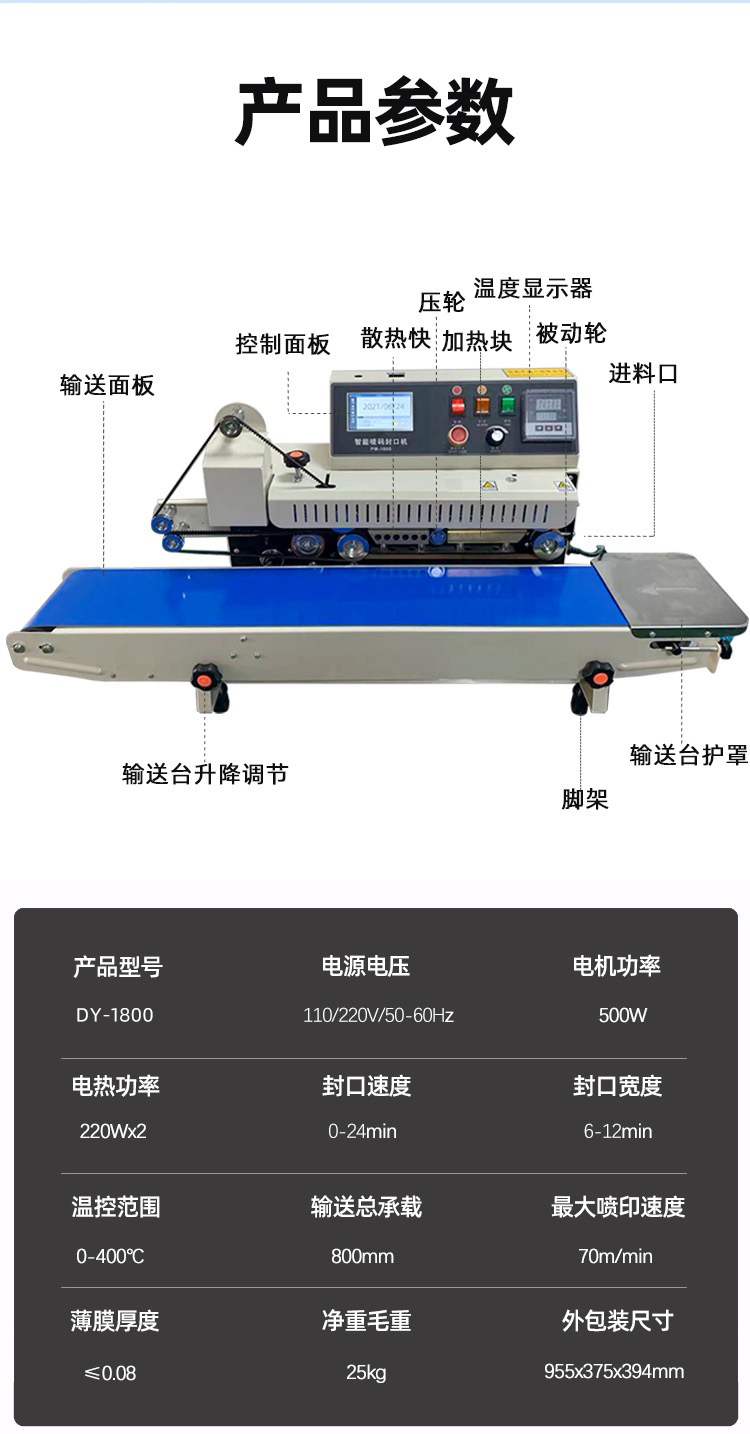

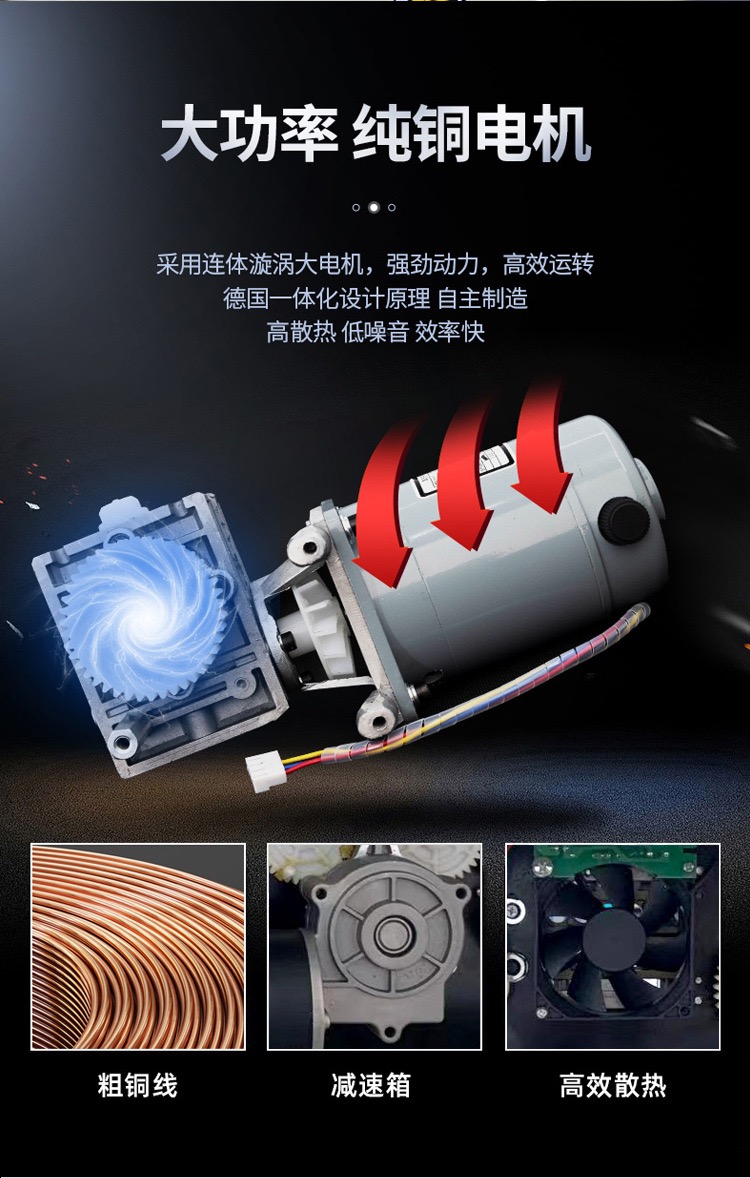

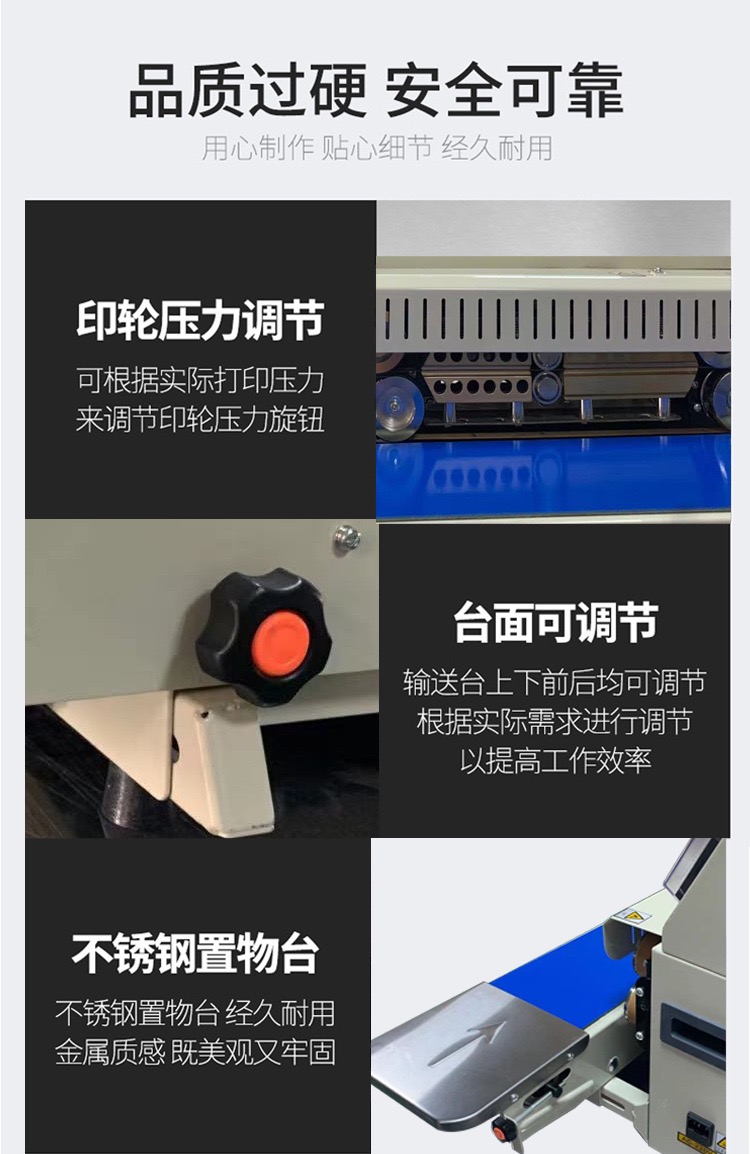

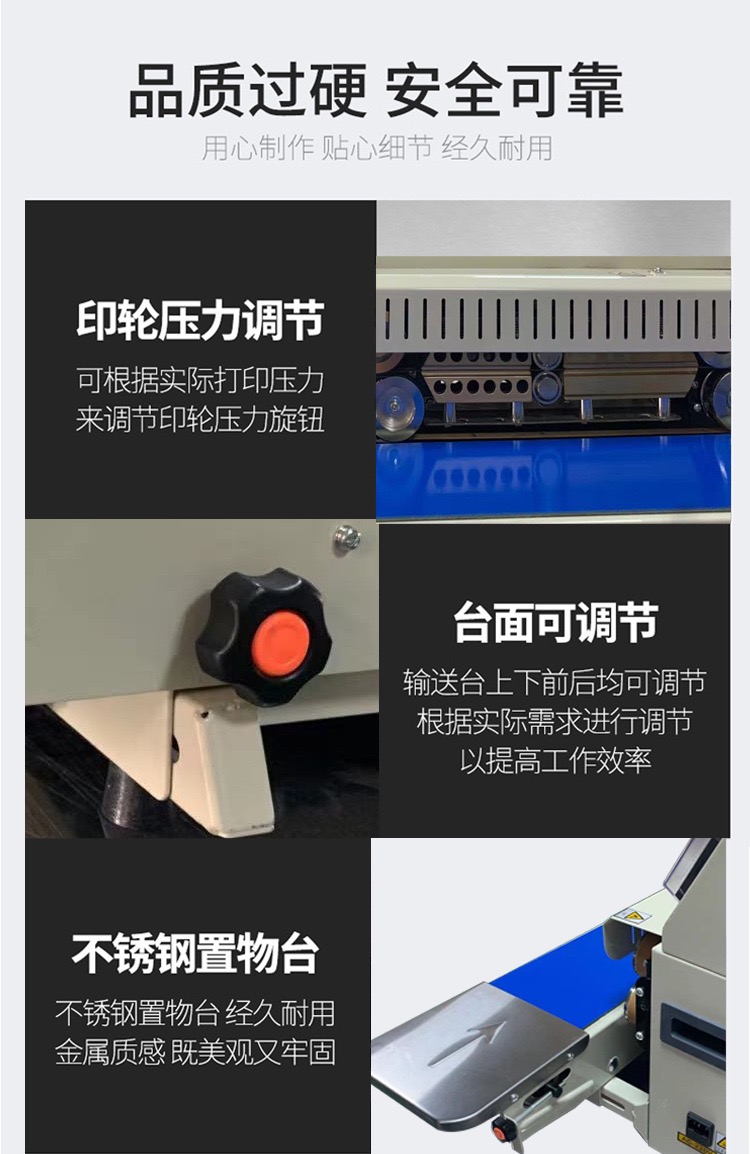

From film bags to rigid containers, and from normal temperature to low-temperature environments, the intelligent inkjet coding and sealing all-in-one machine realizes function switching through modular design—replacing different nozzles can adapt to various inks such as water-based and solvent-based inks, and adjusting the heat-sealing molds can cope with material thickness differences from 0.1mm to 5mm. This "one machine with multiple capabilities" feature enables it to meet both the high-speed mass production needs of the food industry and the high-precision standards of the pharmaceutical industry, making it a core equipment for flexible packaging across multiple fields.