Here is the English version of the introduction to the continuous pneumatic sealing and cutting machine:

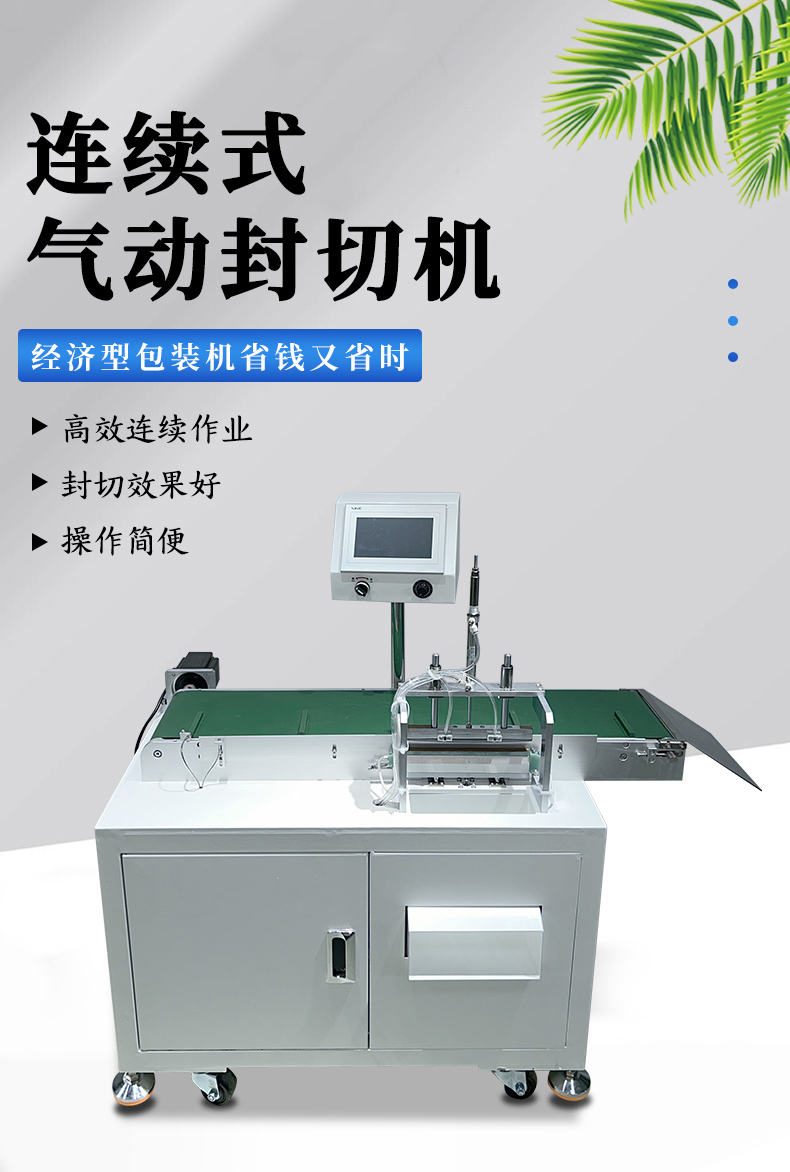

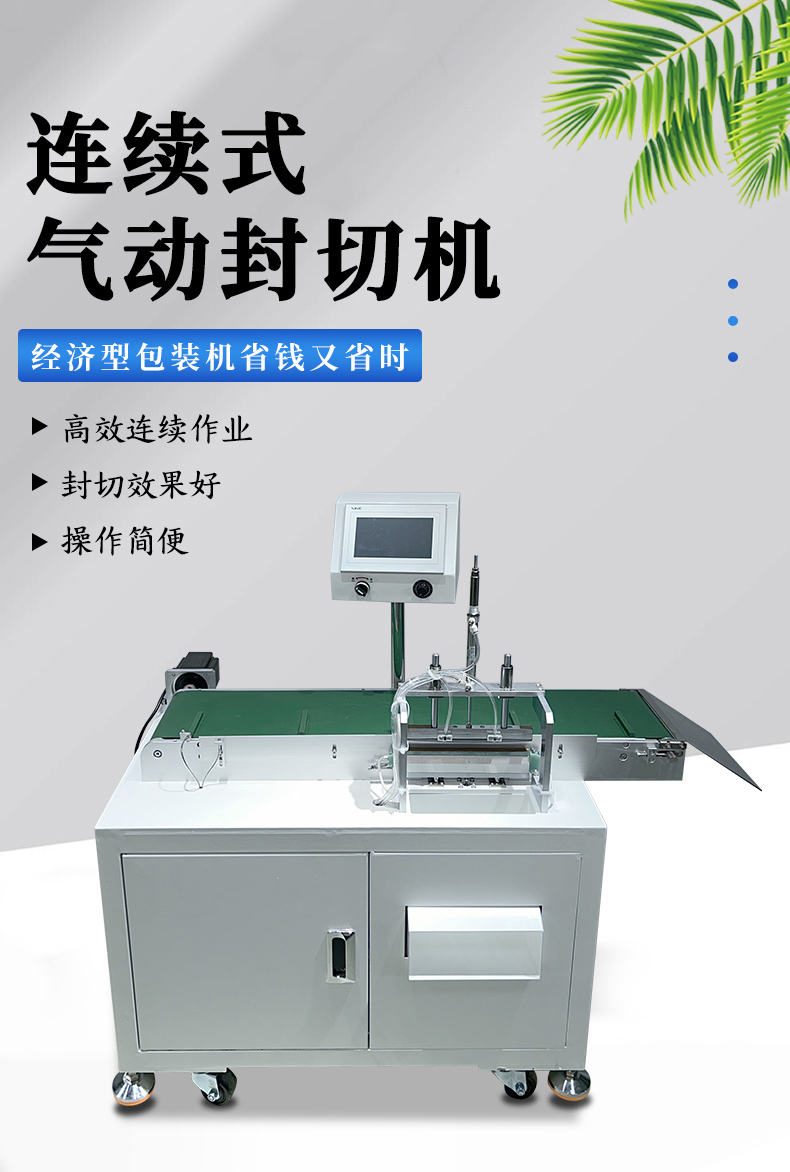

The continuous pneumatic sealing and cutting machine mainly uses pneumatic control technology and heat sealing technology to achieve the sealing and cutting of packaging materials. The machine drives the sealing and cutting mechanism through pneumatic components, using compressed air as power to enable the sealing and cutting knife to complete the sealing and cutting actions quickly and accurately. During the sealing and cutting process, the packaging material is usually heated to achieve sealing under pressure, and then cut to divide the continuous packaging material into individual packaging units.

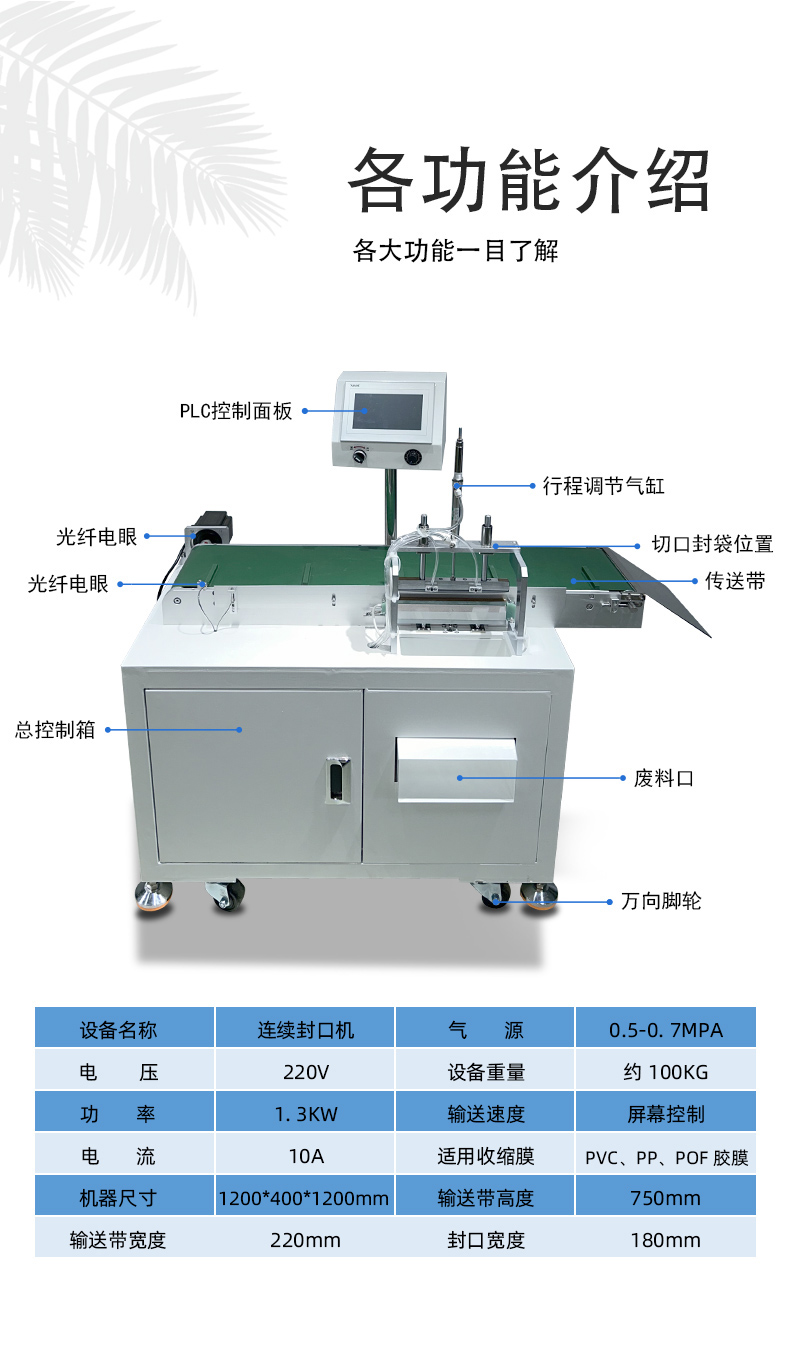

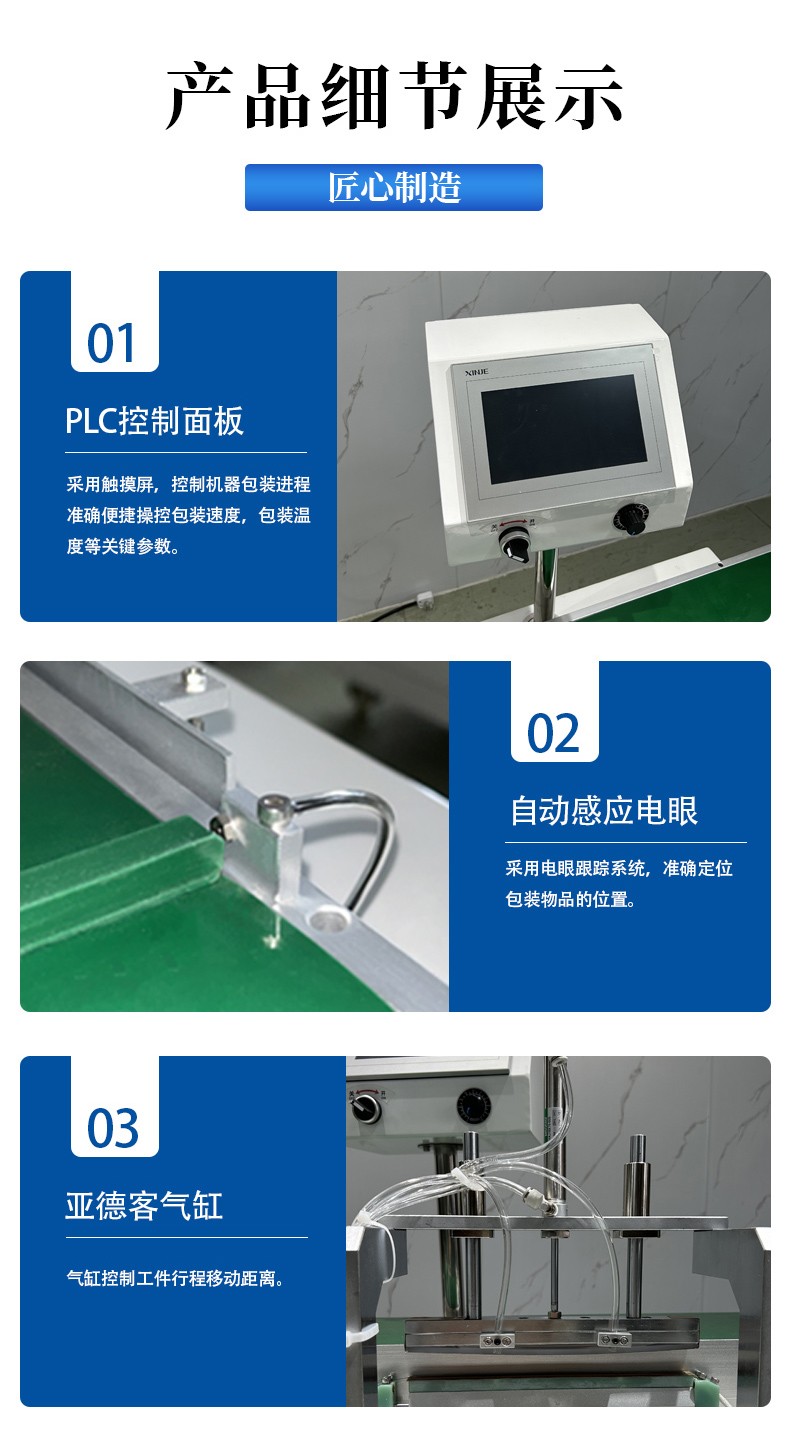

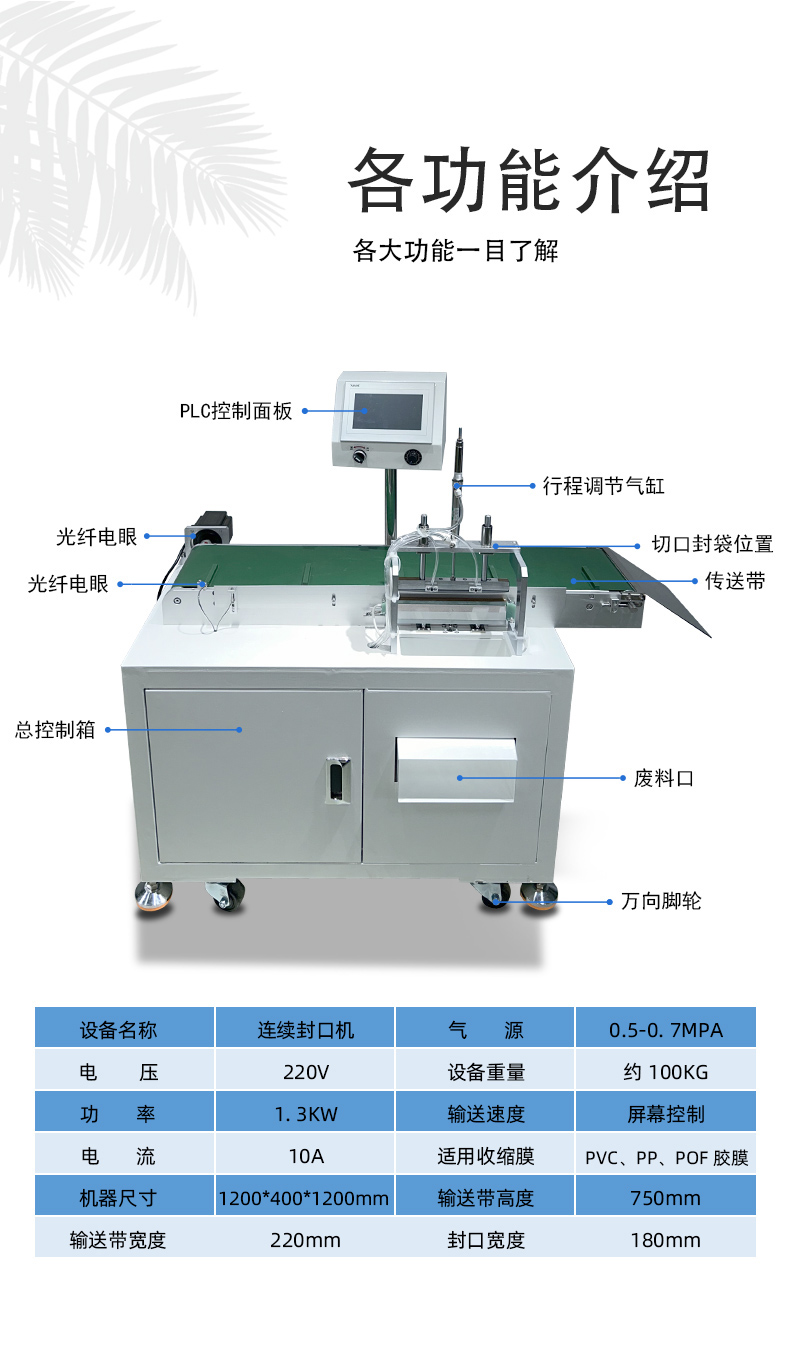

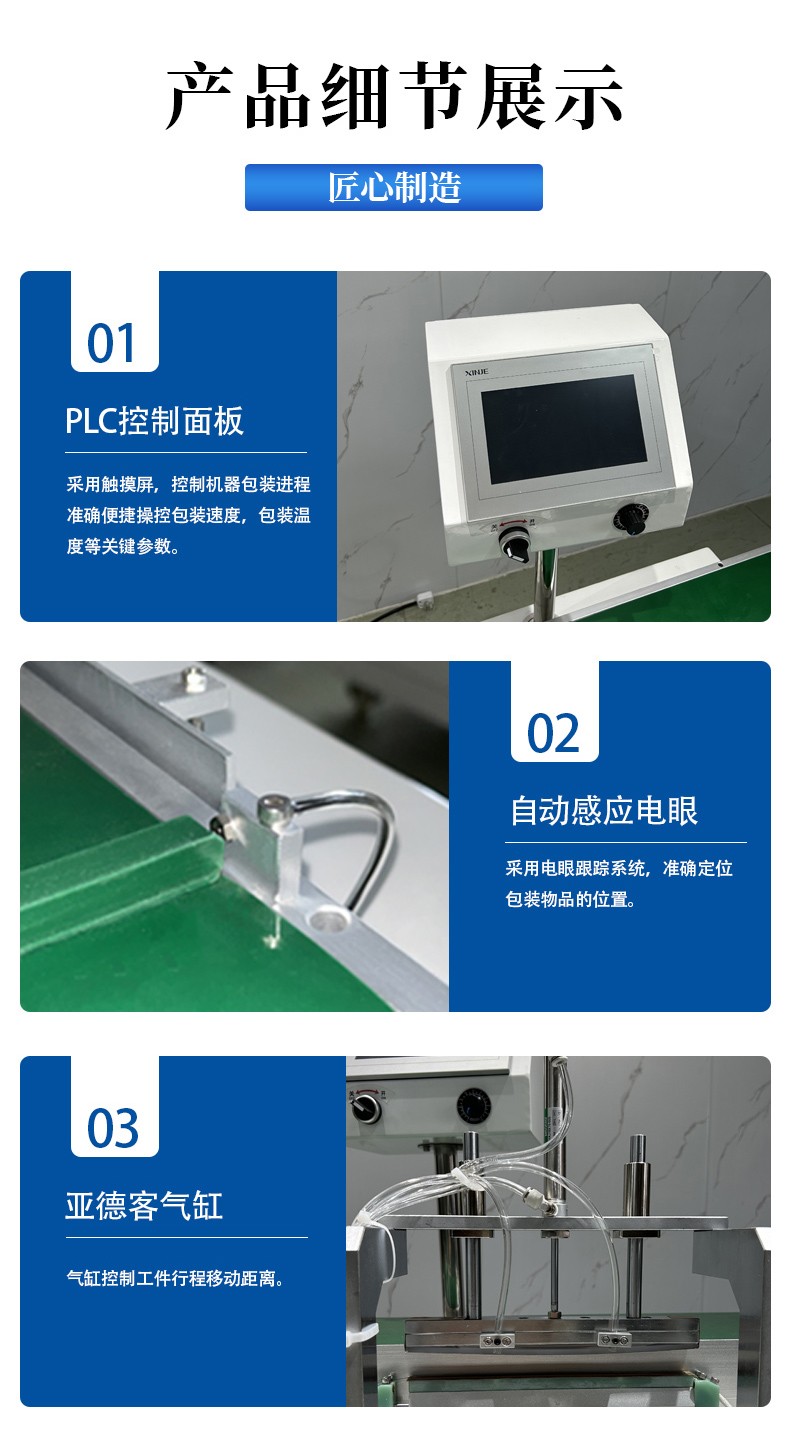

- Pneumatic System: Includes components such as air compressors, air tanks, pneumatic valves, and cylinders, mainly responsible for providing power and controlling the movement and execution of the sealing and cutting knife.

- Heat Sealing Mechanism: Composed of heating elements, heat-sealing silicone strips, thermal insulation materials, etc., used to heat and seal the packaging material to ensure packaging tightness.

- Cutting Mechanism: Generally uses sharp blades or toothed knives to cut the packaging material into specified sizes and shapes after sealing.

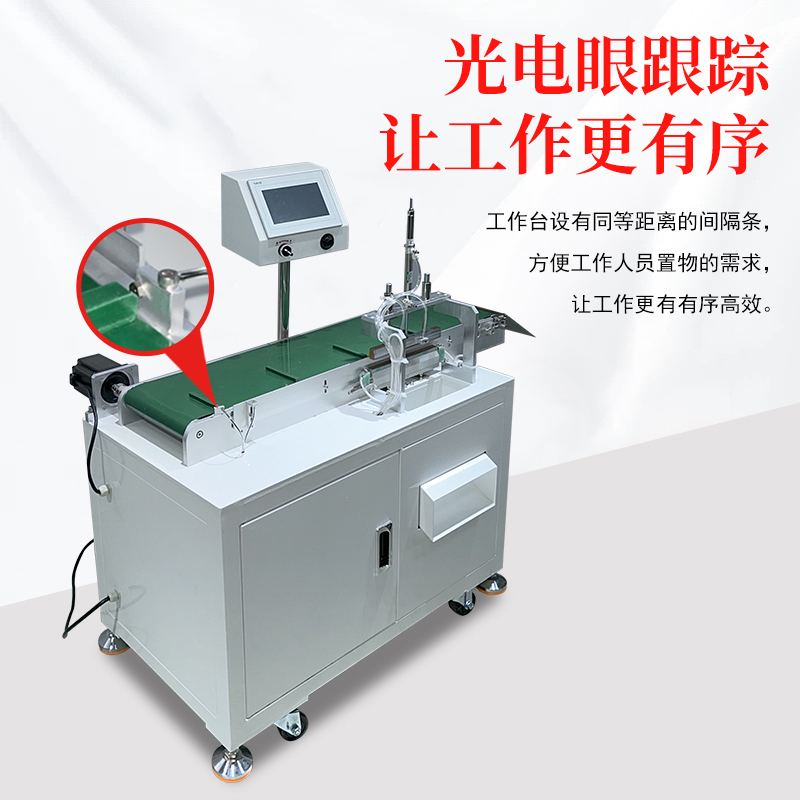

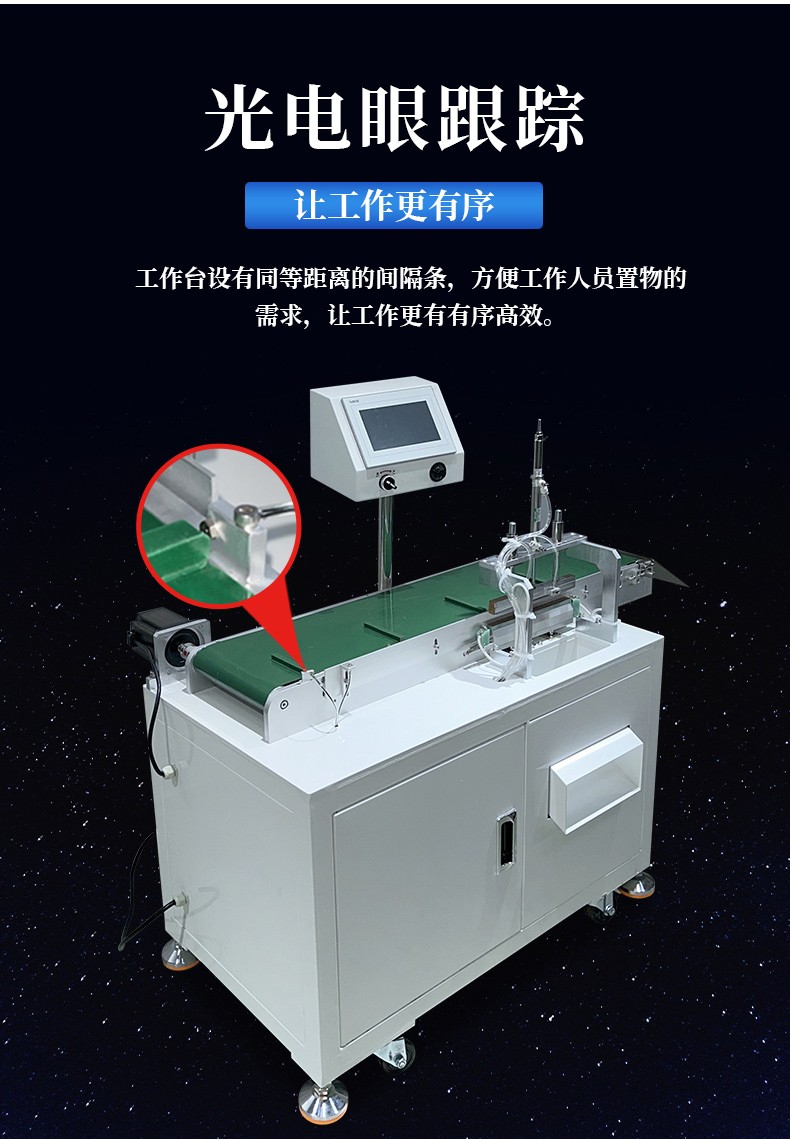

- Conveying Device: Usually composed of conveyor belts, rollers, etc., used to transport the products to be packaged and packaging materials, enabling them to move at a set speed and direction to ensure the continuity of sealing and cutting work.

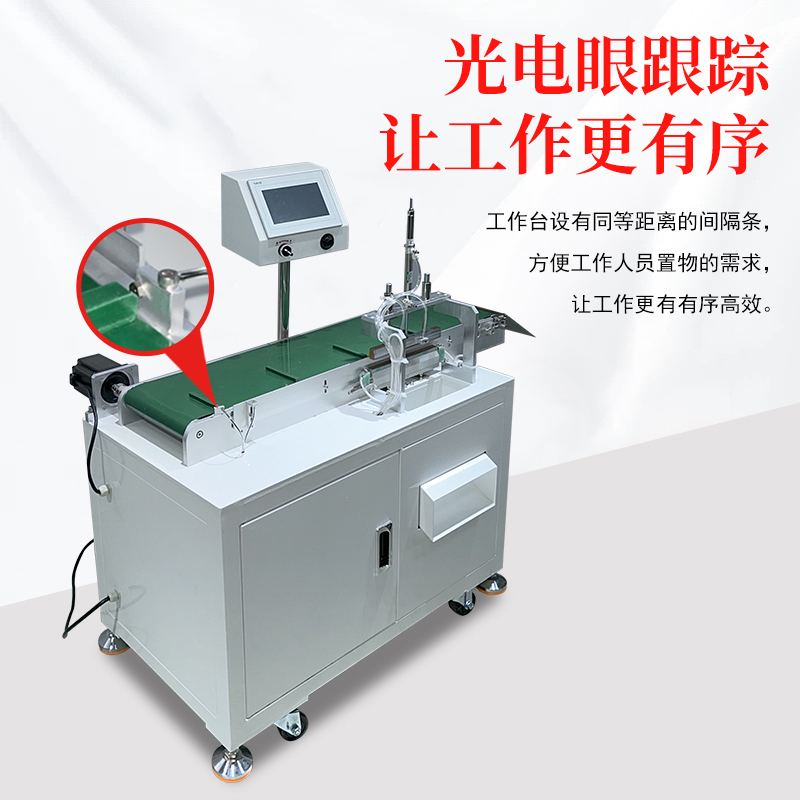

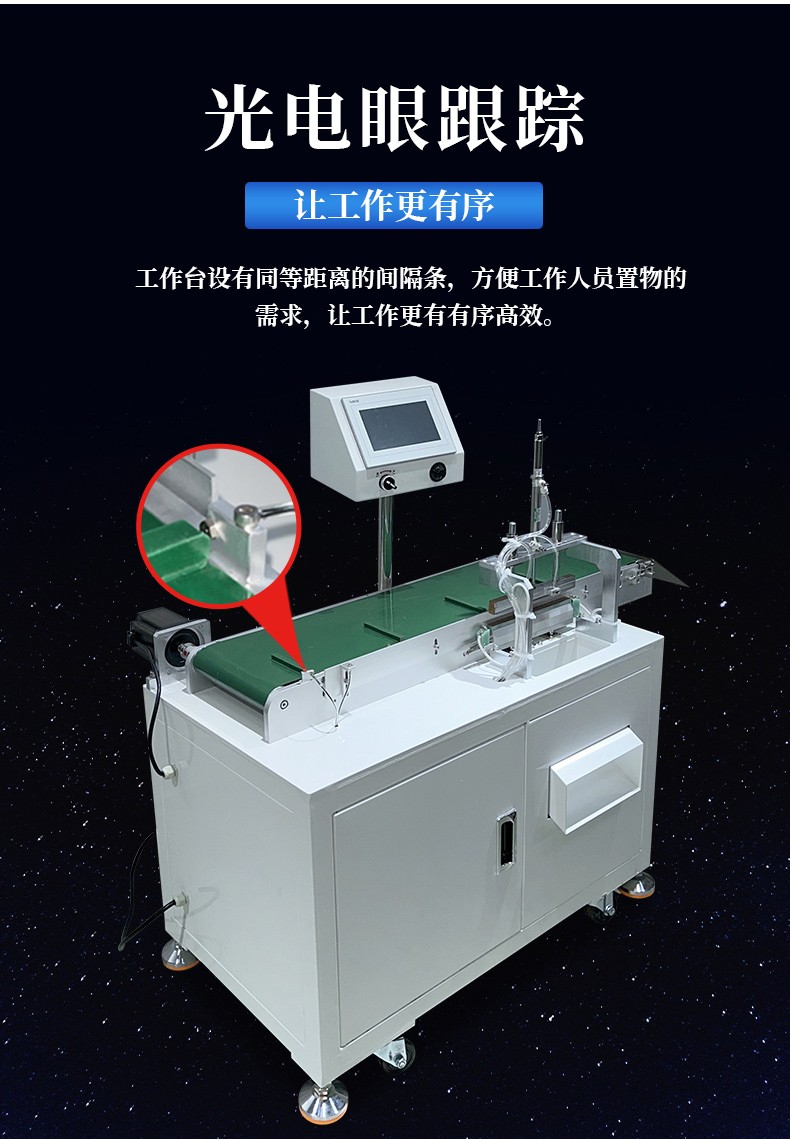

- Control System: Includes control panels, controllers, sensors, etc., which can set and adjust various parameters of the sealing and cutting machine, such as sealing and cutting temperature, sealing and cutting time, conveying speed, etc., and can also monitor the operating status of the machine and diagnose faults.

- High Sealing and Cutting Precision: Pneumatic control enables precise control of sealing and cutting force and position, ensuring tight sealing and neat cutting. For products with high packaging precision requirements, such as pharmaceuticals and electronic components, continuous pneumatic sealing and cutting machines can well meet packaging needs.

- Fast Speed: Capable of continuous sealing and cutting operations, usually much faster than manual or semi-automatic sealing and cutting machines, which can greatly improve production efficiency and is suitable for large-scale production enterprises.

- Strong Adaptability: The sealing and cutting force can be adjusted according to different packaging materials and product requirements, and can adapt to various packaging materials, such as plastic films, aluminum foils, composite films, etc.

- Simple Operation: Equipped with a user-friendly control panel. Staff only need to set relevant parameters on the control panel, and the machine can automatically complete the sealing and cutting work without complex operation skills, reducing labor costs and intensity.

- Good Stability: Using high-quality components and advanced manufacturing processes, the machine has high operating stability and low failure rate, capable of long-term continuous operation, reducing downtime and maintenance time, and improving production efficiency.

- Food Industry: Used for packaging various foods, such as biscuits, candies, bread, meat, vegetables, fruits, etc., which can effectively maintain the freshness and taste of foods and extend their shelf life.

- Pharmaceutical Industry: Can be used for blister packaging, medicine bottle packaging, medicine bag packaging, etc., to ensure that medicines are not contaminated during storage and transportation and guarantee the quality and safety of medicines.

- Daily Necessities Industry: Suitable for packaging daily necessities such as cosmetics, skin care products, shampoo, shower gel, toothpaste, etc., to enhance the appearance image and market competitiveness of products.

- Electronics Industry: Used for packaging electronic components and products, such as mobile phones, computer accessories, circuit boards, etc., which can play a protective role such as moisture-proof, dust-proof, and anti-static.