The work efficiency of automatic pallet strapping machines is influenced by factors such as equipment models, cargo specifications, and packaging processes. Their core efficiency indicators include strapping speed, automation level, and stability. The following analysis breaks down these dimensions with real-world data for reference:

- Standard Operation Cycle:

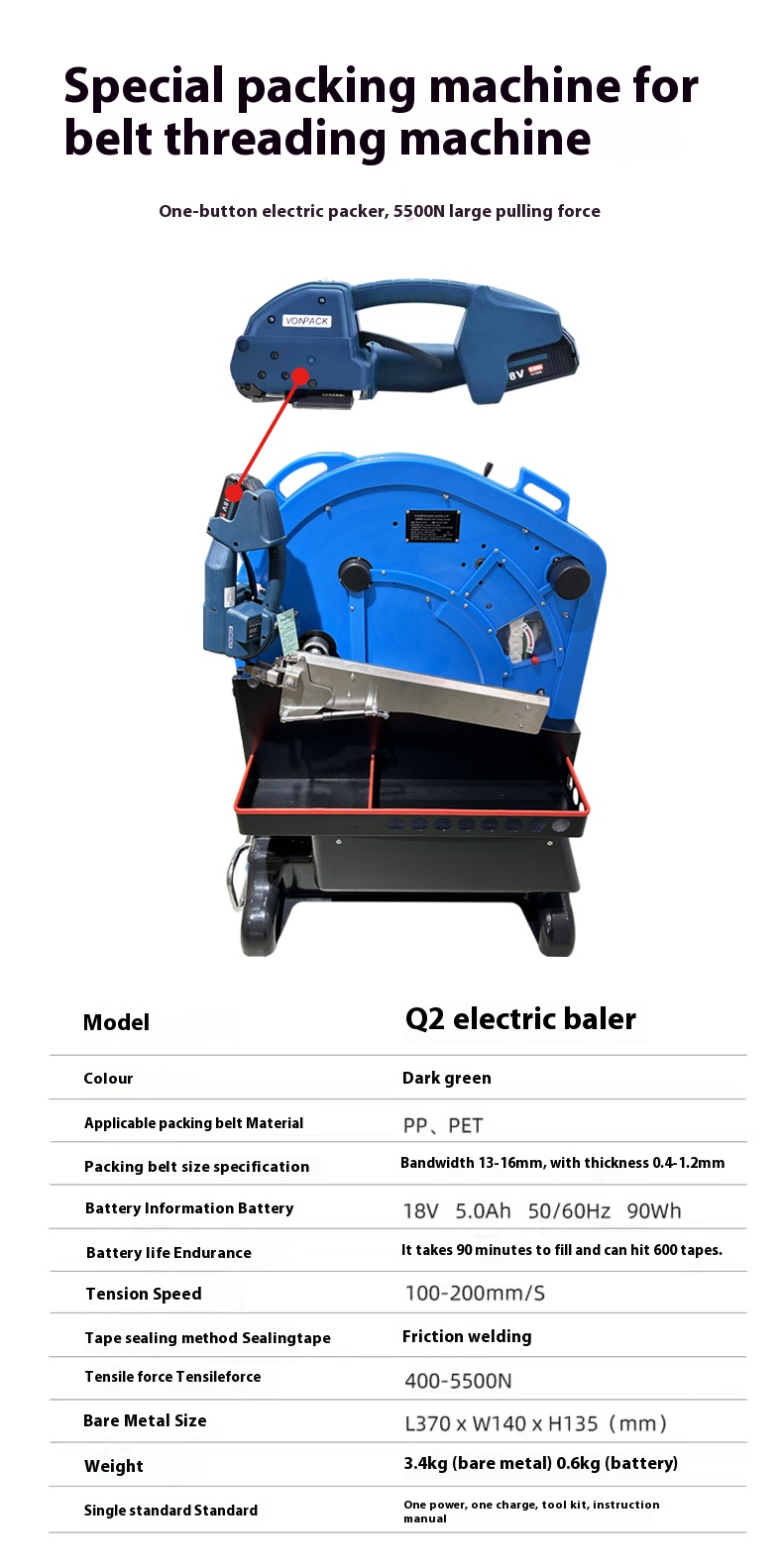

A single strapping process (strap threading → tensioning → welding → cutting) takes 15–40 seconds per pallet, depending on:- Threading Method:

- Bottom threading (through pallet forklift slots): Suitable for standard pallets, taking 20–30 seconds per cycle.

- Side threading (through side slots): For pallets without bottom forklift slots, taking 25–40 seconds per cycle.

- Strap Type: PET straps take 5–10 seconds longer per cycle than PP straps due to higher tension and welding time.

- Cargo Stability: Irregularly shaped cargo may require manual positioning, adding 10–20 seconds per cycle.

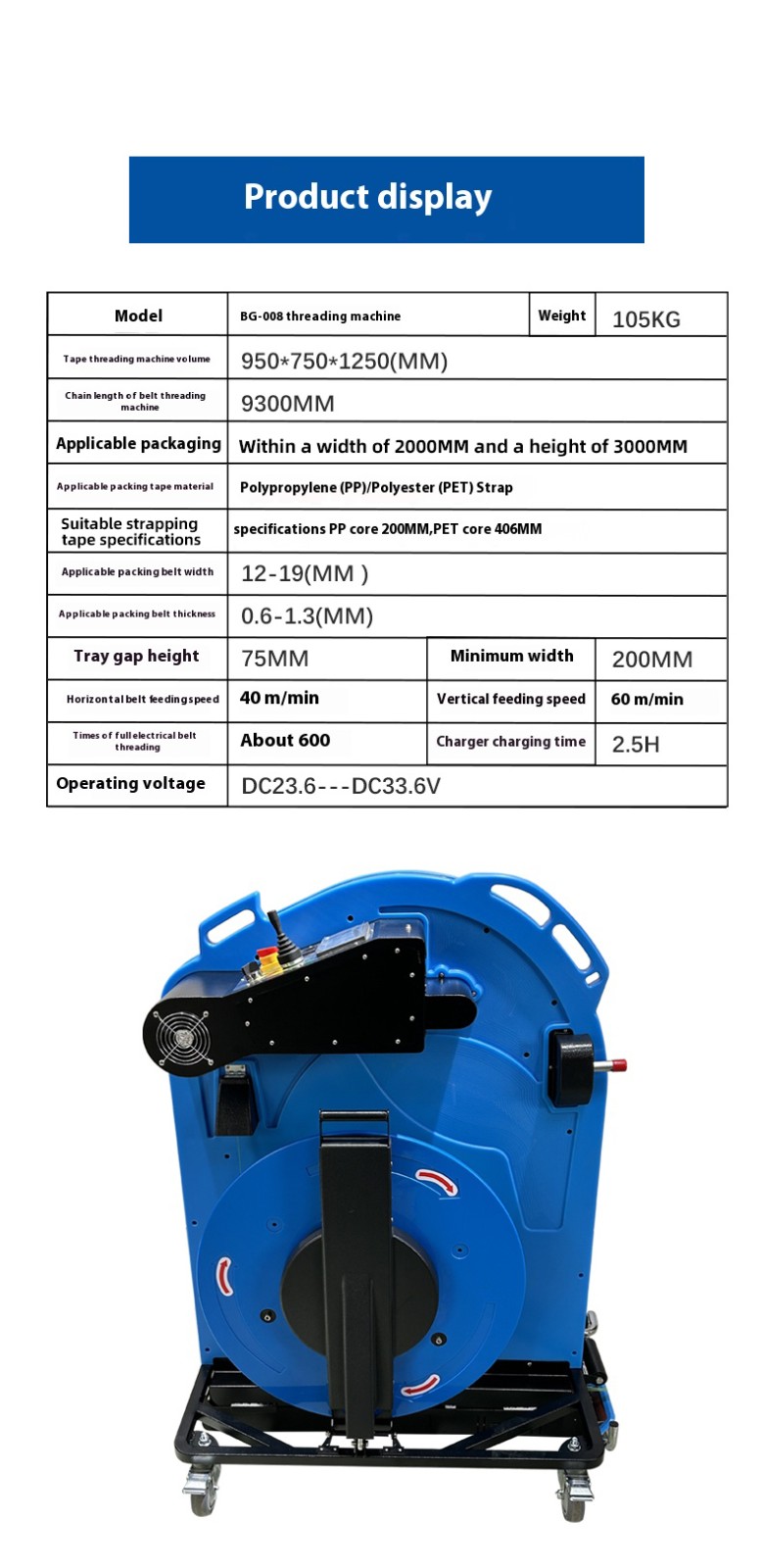

- Single-Machine Hourly Throughput:

At an average of 25 seconds per pallet, a single machine can complete 144–240 pallets per hour (with continuous operation and no downtime).

- Fully Automated Process:

High-end models support fully unattended operations (automatic pallet detection → strap threading → intelligent tension adjustment → finished product output), reducing manual intervention.- Case: A logistics warehouse with 3 fully automatic strapping machines and assembly lines processes 600+ pallets per hour (including palletizing, strapping, and conveying).

- Semi-Automatic Assistance:

Basic models require manual pallet placement and threading adjustments, with efficiency at 60%–70% of fully automatic models, suitable for small-to-medium scenarios.

- Failure Rate:

High-quality equipment has an average time between failures (MTBF) of >5,000 hours and an annual failure rate <5%; low-end models may see failure rates rise to 10%–15% due to mechanical wear or control system issues. - Maintenance Impact:

Regular maintenance (e.g., weekly lubrication of threading mechanisms and cleaning of welding units) reduces downtime. A single maintenance session typically takes 0.5–2 hours, affecting daily capacity by 5%–10%.

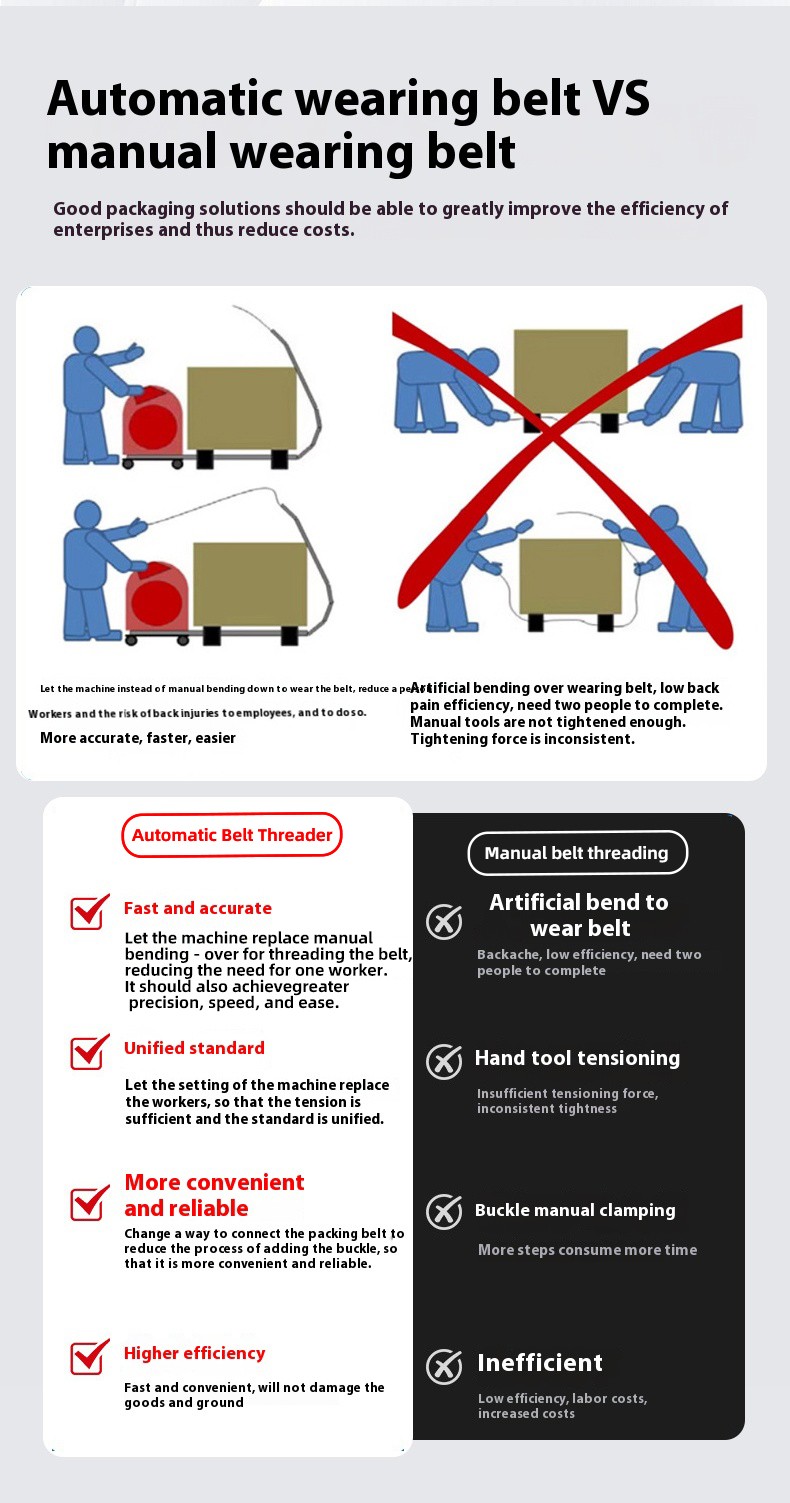

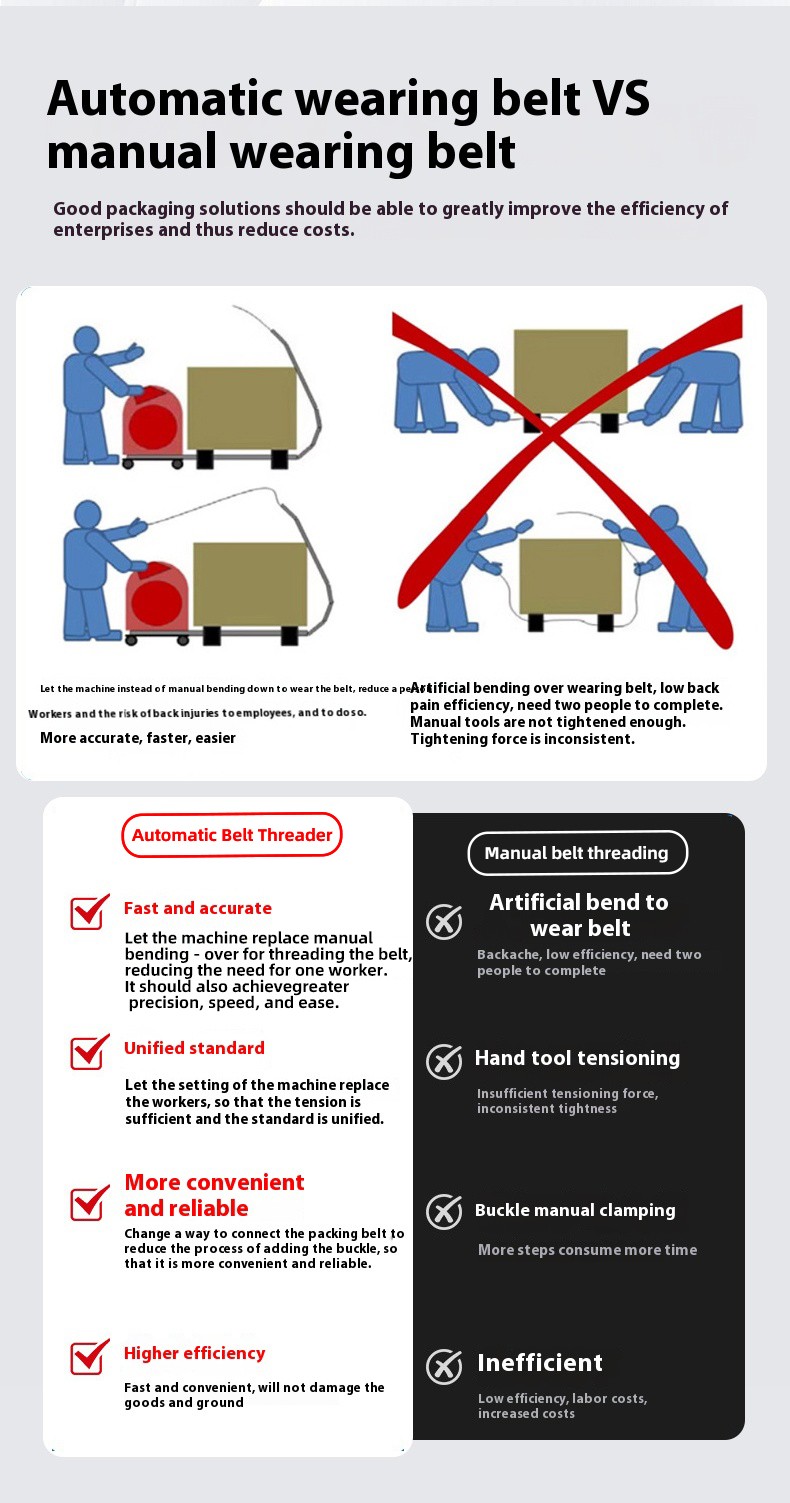

| Indicator | Manual Strapping (3-Person Team) | Automatic Pallet Strapping Machine (Single Unit) | Efficiency Improvement |

|---|

| Single pallet time | 1.5–2 minutes | 25–40 seconds | 2.25–3× faster |

| Hourly throughput | 30–40 pallets | 90–144 pallets | 2.25–3.6× higher |

| Labor cost | ~¥200/hour (3 workers) | ~¥20/hour (power + maintenance) | 90% reduction |

| Consistency | Error rate 5%–8% (worker-dependent) | Error rate <1% | — |

| Labor intensity | High repetitive strain | Low (no manual strap handling) | — |

- Threading Mechanism Performance:

- Hydraulic-driven mechanisms (500–1,000 kg thrust) suit heavy cargo and thread straps 3–5 seconds faster per cycle than pneumatic models.

- Servo motor-driven systems (positioning accuracy ±1mm) reduce idle time for precision equipment strapping.

- Tension Control System:

Intelligent tension adjustment (automatically matching 100–3,000N tension to cargo weight) avoids over-tightening (damaging cargo) or under-tightening (loose straps), reducing rework time by 10%–15%.

- Pallet Conveyor Design:

Automated lines integrated with conveyors and palletizers achieve seamless "pallet loading → strapping → unloading," improving efficiency by 30%–50% over standalone machines. - Multi-Machine Collaboration:

Large warehouses using "multi-strapping machines + AGV transport" can operate 24/7, achieving daily throughputs of >10,000 pallets.

- Skilled workers reduce debugging time by 5–10 seconds per pallet via pre-set parameters (e.g., tension values for different cargo types).

- Novice operators may increase rework rates by 20%–30% due to improper parameter settings (e.g., strap breakage).