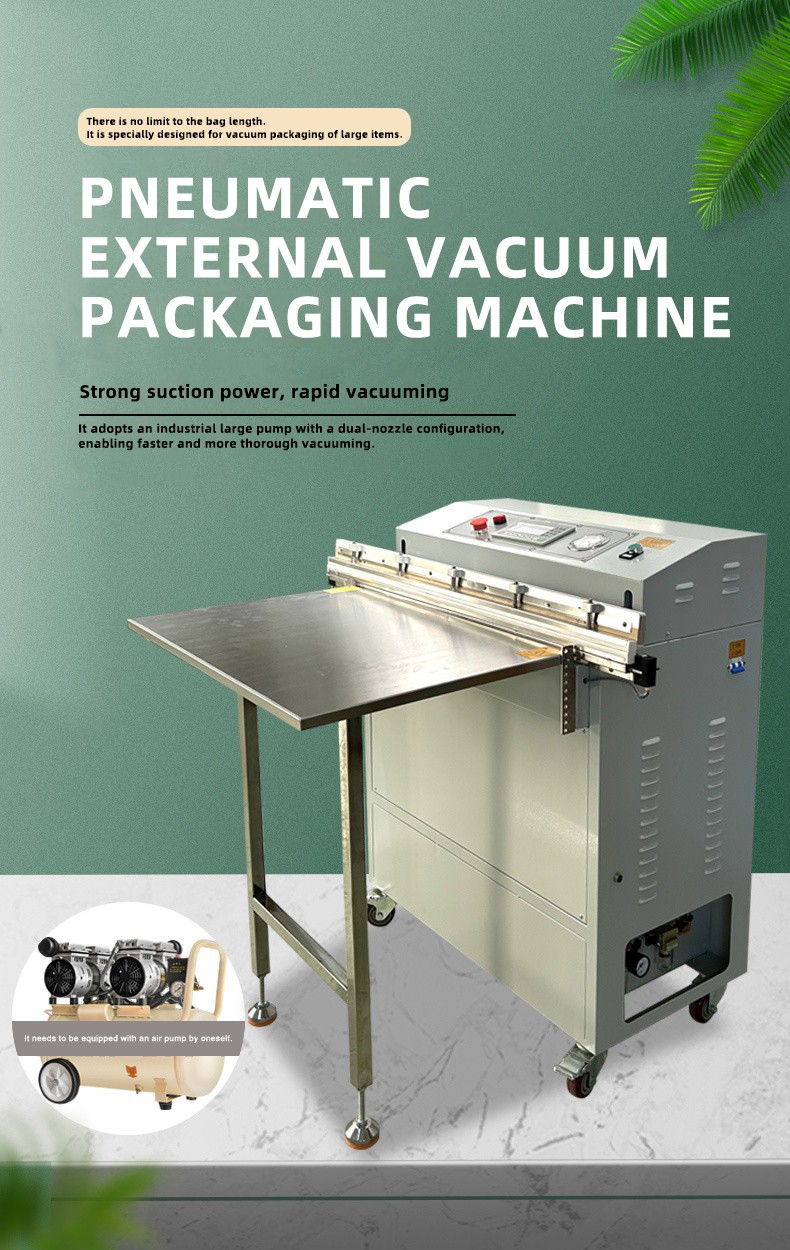

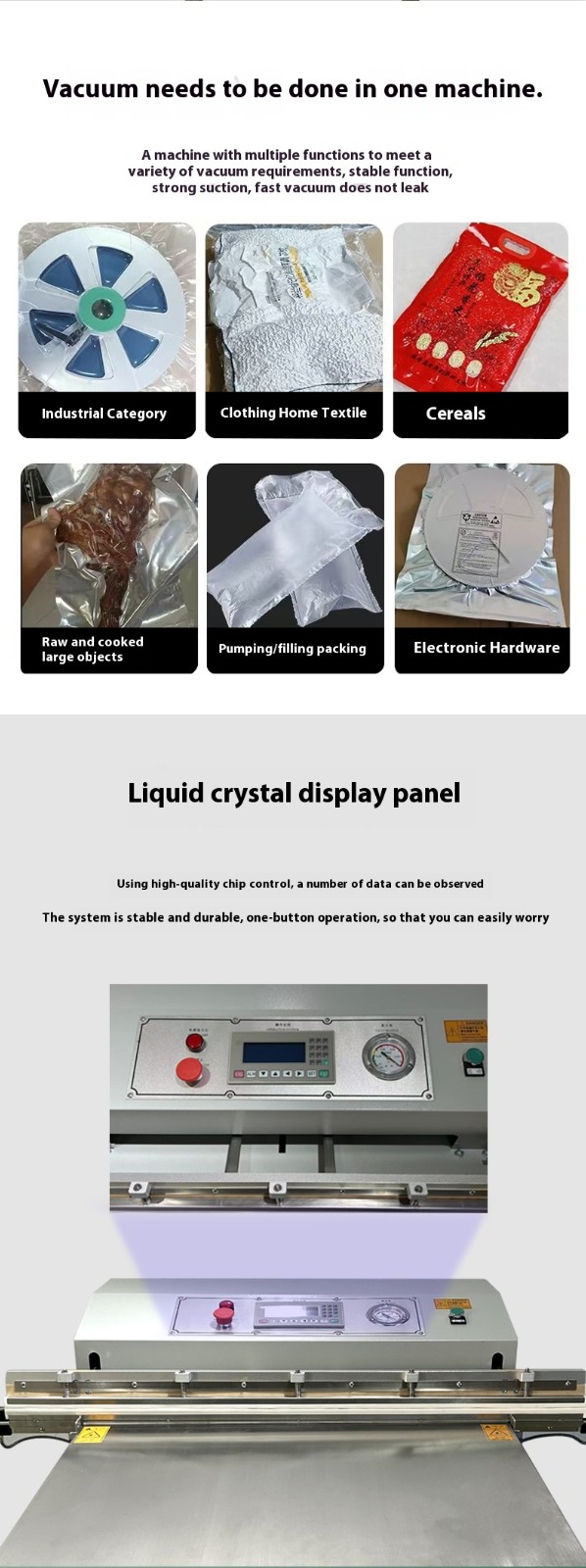

Pneumatic external vacuum packaging machines are suitable for a variety of types of packaging bags. The following are the requirements regarding the materials and shapes:

Material Requirements

Plastic Film Bags:

- Polyethylene (PE) Bags: They have good flexibility, water resistance, and low-temperature resistance. With a relatively low price, they are often used for packaging food items, daily necessities, etc.

- Polypropylene (PP) Bags: They feature high transparency, good mechanical strength, and better heat resistance than PE bags. They can be used for the packaging of products that have high requirements for appearance and need to be sterilized at high temperatures.

- Polyvinyl Chloride (PVC) Bags: They have good transparency and flexibility as well as excellent barrier properties. However, they may release harmful substances when exposed to high temperatures or certain chemical substances. Generally, they are not used for direct food contact packaging but can be used for the packaging of some industrial products.

- Nylon (PA) Bags: They have high strength, abrasion resistance, and puncture resistance. Meanwhile, they also have good gas barrier properties. They are often used for packaging some high-end food products, electronic products, etc., which require high packaging strength and freshness preservation performance.

Composite Material Bags:

- Paper-Plastic Composite Bags: The outer layer is paper, and the inner layer is a plastic film. Combining the printing adaptability of paper and the moisture-proof and barrier properties of plastic, they are often used for packaging powdery and granular products, such as chemical raw materials, agricultural products, etc.

- Aluminum-Plastic Composite Bags: They have excellent barrier properties, which can effectively block light, oxygen, and moisture, and can extend the shelf life of products. They are often used for the packaging of products with high requirements for packaging protection performance, such as pharmaceuticals, health products, electronic components, etc.

Shape Requirements

- Three-Side Sealed Bags: These packaging bags are sealed on three sides and open on one side. They are one of the most common bag types and are suitable for products of various shapes and sizes, especially small block-shaped, granular, or powdery products.

- Four-Side Sealed Bags: They are sealed on all four sides and are usually used for packaging products with regular shapes, small sizes, and high requirements for airtightness, such as small snacks, electronic parts, etc.

- Stand-Up Pouches: They have a flat supporting structure at the bottom, enabling the bags to stand upright, which is convenient for placement and display. Stand-up pouches are often used for packaging liquid, semi-solid, or powdery products, such as beverages, sauces, milk powder, etc.

- Irregular-Shaped Bags: For some products with special shapes, such as toys, handicrafts, etc., irregular-shaped bags can be used for packaging to better fit the shape of the products, reduce the waste of packaging materials, and at the same time play a good role in protection and display.

When choosing packaging bags, factors such as the thickness and heat-sealing performance of the packaging bags also need to be considered to ensure compatibility with the performance of the pneumatic external vacuum packaging machine and achieve a good packaging effect.